Professional Documents

Culture Documents

Cooling Towers

Cooling Towers

Uploaded by

imran Mohammad0 ratings0% found this document useful (0 votes)

54 views5 pagesCooling towers reduce water temperature through evaporation. Standards require automatic controls, variable pumps, drift eliminators, fills, water treatment, and monitoring of water usage, temperatures, and ambient conditions. Maintenance includes inspections and disinfection. New towers should be selected based on load and use efficient designs. Targets include a cycle of concentration of 8-10 and approach of 4-5°C with drift loss under 0.005%. Performance is assessed using temperature ranges and approach.

Original Description:

Original Title

Cooling towers

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCooling towers reduce water temperature through evaporation. Standards require automatic controls, variable pumps, drift eliminators, fills, water treatment, and monitoring of water usage, temperatures, and ambient conditions. Maintenance includes inspections and disinfection. New towers should be selected based on load and use efficient designs. Targets include a cycle of concentration of 8-10 and approach of 4-5°C with drift loss under 0.005%. Performance is assessed using temperature ranges and approach.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

54 views5 pagesCooling Towers

Cooling Towers

Uploaded by

imran MohammadCooling towers reduce water temperature through evaporation. Standards require automatic controls, variable pumps, drift eliminators, fills, water treatment, and monitoring of water usage, temperatures, and ambient conditions. Maintenance includes inspections and disinfection. New towers should be selected based on load and use efficient designs. Targets include a cycle of concentration of 8-10 and approach of 4-5°C with drift loss under 0.005%. Performance is assessed using temperature ranges and approach.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 5

Cooling towers

Cooling tower is used to reduce the temperature of water close to wet

bulb temperature of air through evaporation of water. Different types of

cooling Cooling tower is used to reduce the temperature of water close

to wet bulb temperature of air through evaporation of water. Different

types of cooling.

Standards components

1. Management The industry shall undertake the following:

and control A. Install automatic/ thermostatic controller in cooling tower to switch off cooling tower fans

automatically when the temperatures of return water and supply water are almost same.

B. Install variable frequency drive (VFD) for varying cooling demands in the process.

C. Use cellular PVC (poly vinyl chloride) drift eliminators in place of wooden blade drift

eliminators.

D. Use PVC fills in place of wooden bars.

E. Ensure proper functioning of drift eliminators to control drift losses within limits as provided in

Table.

F. Maintain cycle of concentration (COC) within the limit as provided in Table to minimize make-

up water consumption in cooling water.

G. Use on-line monitoring for centralized large system and periodical measurement for

decentralized smaller cooling tower.

2. Measurement The industry shall measure and record the following:

and recording A. Quantity of make-up water addition used towards compensation of water losses, such as

evaporation loss, drift loss, blowdown loss, etc., on daily basis.

B. Electricity consumption of the cooling tower (includes associated fans and pumps with

dedicated energy meter in place.

C. Inlet and outlet temperatures of water, water flow rate and its pressure on daily basis.

D. Ambient conditions that include dry bulb temperature, wet bulb temperature, and relative

humidity.

Continue

3. Maintenance The industry shall undertake the following:

and inspection A. Undertake visual inspection of fills in the cooling tower once in three months to

ensure proper distribution of water.

B. Carry out chemical disinfection of cooling water sump to avoid micro-organism

growth.

4. Necessary The industry shall consider the following:

measures when A. Undertake load assessment for selection of suitable cooling tower system.

installing new B. Install cooling tower with moulded FRP fans of aerofoil design.

facilities C. Install multiple cooling tower systems in parallel in place of a single large system

to meet higher volume requirements of cooling water.

Target The industry shall:

components A. Maintain cycle of concentration (COC) of 8 to 10 for optimum performance.

B. Maintain an approach of 4 °C – 5 °C.

C. Control the drift loss 0.001% – 0.005% of circulating flow rate.

Common monitorable parameters and performance assessment

The industry shall monitor the following common monitorable parameters as shown in Table to

assess the performance of cooling tower.

The performance of cooling tower can be assessed using following formula.

Range = Entering cooling water temperature (return from process) – Leaving water temperature (supply to

process)

Approach = Cooling water temperature (supply to process) –Ambient wet bulb temperature

The industry shall refer to the typical performance indicators of cooling towers as provided in the following Table

You might also like

- Water Cooled Chiller - SOPDocument13 pagesWater Cooled Chiller - SOParunceedee100% (4)

- GeoSource Ultra HydronicDocument28 pagesGeoSource Ultra Hydronicdoina slamaNo ratings yet

- Astm G 185 2006Document8 pagesAstm G 185 2006JORGE ARTURO TORIBIO HUERTANo ratings yet

- Adsobtion Chiller SpecDocument6 pagesAdsobtion Chiller Specioan1946No ratings yet

- Adsorption Chiller Guide SpecificationsDocument6 pagesAdsorption Chiller Guide Specificationsmdalt9180No ratings yet

- Module 4 - Cooling TowerDocument15 pagesModule 4 - Cooling Towermadan karkiNo ratings yet

- 3.7 Cooling TowersDocument6 pages3.7 Cooling TowersSaurabh VijNo ratings yet

- Air Cooled FluidDocument23 pagesAir Cooled FluidSmrutiNo ratings yet

- Cooling Tower - Design ConsiderationsDocument6 pagesCooling Tower - Design Considerationsofelherrera77No ratings yet

- SRL Diagnostics: Types of Cooling Tower - Cooling Tower Basic CalculationsDocument13 pagesSRL Diagnostics: Types of Cooling Tower - Cooling Tower Basic CalculationssumitNo ratings yet

- ChE 153Document19 pagesChE 153Joyce EdrozoNo ratings yet

- Cooling Towers Design and Operation ConsiderationsDocument6 pagesCooling Towers Design and Operation ConsiderationsvanmurthyNo ratings yet

- Cooling Tower FundamentalsDocument17 pagesCooling Tower FundamentalsGaurav RathoreNo ratings yet

- Cooling TowersDocument38 pagesCooling TowersMohamed M. Abdul SamieNo ratings yet

- Unit 3 Energy ConservationnDocument77 pagesUnit 3 Energy ConservationnAgent SmithNo ratings yet

- Design Control Document-MVACDocument48 pagesDesign Control Document-MVACRudivic LumainNo ratings yet

- Cooling TowerDocument10 pagesCooling TowerMarsya0% (1)

- RacDocument26 pagesRacgurunakhale123No ratings yet

- Engineering Manual Evaporative CondensersDocument16 pagesEngineering Manual Evaporative Condenserstulamst100% (2)

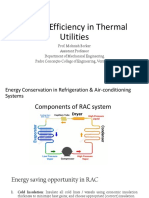

- Energy Efficiency in Thermal UtilitiesDocument14 pagesEnergy Efficiency in Thermal UtilitiesJoeb DsouzaNo ratings yet

- Types of Cooling TowersDocument9 pagesTypes of Cooling TowersPalitha Seneviratne100% (1)

- MV Utility Distribution NetworkDocument3 pagesMV Utility Distribution NetworkeliahudNo ratings yet

- Dartmouth College Design November 15, 2007 & Construction GuidelinesDocument4 pagesDartmouth College Design November 15, 2007 & Construction GuidelinesIndira SharanNo ratings yet

- Cooling Towers Design and Operation ConsiderationsDocument8 pagesCooling Towers Design and Operation ConsiderationsThieuhuyen Ky100% (2)

- Cooling TowerDocument11 pagesCooling TowerAshok PatelNo ratings yet

- Cooling Tower Water CalculationsDocument11 pagesCooling Tower Water CalculationsShesadri ChakrabartyNo ratings yet

- HOT WATER SYSTEML System AssesmentDocument4 pagesHOT WATER SYSTEML System AssesmentF FNo ratings yet

- CoolingDocument32 pagesCoolingTinu Paul JepinNo ratings yet

- Good OnM Practice of Fresh Water Cooling Towers For Air-Conditioning SystemsDocument20 pagesGood OnM Practice of Fresh Water Cooling Towers For Air-Conditioning SystemsAnonymous JFPUiDaNo ratings yet

- Air Cooled CondensersDocument6 pagesAir Cooled CondensersruchiajmerNo ratings yet

- Thermal Ice Storage Application & Design GuideDocument68 pagesThermal Ice Storage Application & Design GuideJosh Garcia100% (1)

- Guide Spec Summary: Option ListDocument20 pagesGuide Spec Summary: Option ListRamachandra Reddy ChinthamreddyNo ratings yet

- Cooling Tower REPORTDocument25 pagesCooling Tower REPORTSaroj Kumar100% (1)

- 15545-Chilled Water SystemDocument5 pages15545-Chilled Water Systemenlightened1718No ratings yet

- Energy Conservation MeasuresDocument22 pagesEnergy Conservation MeasuresGritty VimalNo ratings yet

- Module 3 - Chiller SystemDocument45 pagesModule 3 - Chiller Systemmadan karkiNo ratings yet

- Sample Mechanical Basis of Design For UW - Chiller SystemsDocument4 pagesSample Mechanical Basis of Design For UW - Chiller SystemsdaveleyconsNo ratings yet

- Absorption Future PDFDocument12 pagesAbsorption Future PDFVaidyanathan KS100% (1)

- 2009-08 EMOs For Cooling SystemsDocument4 pages2009-08 EMOs For Cooling Systemsnikola ilicNo ratings yet

- Mini Project Ns Creation Final-2Document24 pagesMini Project Ns Creation Final-2Nishant SarambaleNo ratings yet

- 09 Heat Rejection SystemsDocument14 pages09 Heat Rejection Systemsscarpredator5No ratings yet

- Weco en - 03-08Document6 pagesWeco en - 03-08Mohd NaserNo ratings yet

- Cooling TowerDocument41 pagesCooling TowerHARSH DHOLAKIYANo ratings yet

- Closed-Loop CompressorDocument2 pagesClosed-Loop CompressorRavikanth AluriNo ratings yet

- Cooling Tower Basics PDFDocument71 pagesCooling Tower Basics PDFMohamed TallyNo ratings yet

- Operational & Maintenance Manual For Cooling TowerDocument12 pagesOperational & Maintenance Manual For Cooling Towergoli bhand100% (1)

- Sample Specification For Cooling TowersDocument3 pagesSample Specification For Cooling TowerscashloverNo ratings yet

- VariableDocument2 pagesVariableThan NaingooNo ratings yet

- Cooling Tower - Question and AnswersDocument6 pagesCooling Tower - Question and AnswersFawaaz Khurwolah75% (4)

- District CoolingDocument17 pagesDistrict CoolingTaha MustahsanNo ratings yet

- Especificaciones Chiler Torre MadridDocument4 pagesEspecificaciones Chiler Torre MadridjalbertNo ratings yet

- ASHRAE Report On Pre Cooling With Indirect Evaporative CoolingDocument8 pagesASHRAE Report On Pre Cooling With Indirect Evaporative CoolingAhmad Mahrous AboulsoudNo ratings yet

- Cooling Towers - Made Easy: Pdhonline Course M320 (7 PDH)Document72 pagesCooling Towers - Made Easy: Pdhonline Course M320 (7 PDH)AbNo ratings yet

- DLT 1027-2006 工业冷却塔测试规程-enDocument30 pagesDLT 1027-2006 工业冷却塔测试规程-en郭允超No ratings yet

- Cooling Tower TNCDocument6 pagesCooling Tower TNCAarol Hatta100% (1)

- Cooling Tower Efficiency Calculations PDFDocument4 pagesCooling Tower Efficiency Calculations PDFhbithoNo ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- 77th Conference on Glass Problems: A Collection of Papers Presented at the 77th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, OH, November 7-9, 2016From Everand77th Conference on Glass Problems: A Collection of Papers Presented at the 77th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, OH, November 7-9, 2016S. K. SundaramNo ratings yet

- Geothermal Energy: Sustainable Heating and Cooling Using the GroundFrom EverandGeothermal Energy: Sustainable Heating and Cooling Using the GroundNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- For All SKUsDocument28 pagesFor All SKUsimran MohammadNo ratings yet

- Dough Mixers Instruction Manual: Models MX-CN-0037, 0043, 0053 Items 19194, 19195, 19196Document12 pagesDough Mixers Instruction Manual: Models MX-CN-0037, 0043, 0053 Items 19194, 19195, 19196imran MohammadNo ratings yet

- Savings and Application Guide For Power Factor Correction and Harmonic SolutionsDocument19 pagesSavings and Application Guide For Power Factor Correction and Harmonic Solutionsimran MohammadNo ratings yet

- Cold Room SavingsDocument2 pagesCold Room Savingsimran MohammadNo ratings yet

- Recycling of Precious Metal CatalystsDocument3 pagesRecycling of Precious Metal CatalystsSarangNo ratings yet

- IFAF CIFT Abstracts PDFDocument640 pagesIFAF CIFT Abstracts PDFDr RUSHINADHA RAO KAKARA0% (2)

- FungiDocument8 pagesFungiNeha UpadhyayNo ratings yet

- Catalogo ASCODocument4 pagesCatalogo ASCOIkaro MatosNo ratings yet

- Durability of ConcreteDocument24 pagesDurability of Concreteyash khandol0% (1)

- ICEEIS 2018 Proceedings BookDocument261 pagesICEEIS 2018 Proceedings BookRaj KumarNo ratings yet

- Research Paper On Hvac System PDFDocument8 pagesResearch Paper On Hvac System PDFafnhinzugpbcgw100% (1)

- P2 Sample Working DrawingDocument1 pageP2 Sample Working DrawingjasonNo ratings yet

- Warranty Quick-Step VinylDocument7 pagesWarranty Quick-Step VinylRicardo BalauNo ratings yet

- All About PuneDocument79 pagesAll About PuneMichelle McdonaldNo ratings yet

- Xing 2011Document8 pagesXing 2011Mohamed KamalNo ratings yet

- 2014 FALL FrostByte FinalLowResDocument8 pages2014 FALL FrostByte FinalLowResJOHNNo ratings yet

- Gruvlok Water-Wastewater ProductsDocument16 pagesGruvlok Water-Wastewater Productsmax_powerNo ratings yet

- Process EngineerDocument3 pagesProcess EngineerJowy DeaunaNo ratings yet

- Water Demineralization BasicsDocument16 pagesWater Demineralization BasicsvenkeekuNo ratings yet

- Terengganu Travel Guide BookDocument54 pagesTerengganu Travel Guide BookNur NezannaNo ratings yet

- Chapter 7 PowerpointDocument73 pagesChapter 7 PowerpointhdaveyNo ratings yet

- Appendix - Propgress Report IDocument406 pagesAppendix - Propgress Report IFebri Ramdani NugrahaNo ratings yet

- Fire Flow CalculationDocument2 pagesFire Flow Calculationcoolsummer1112143No ratings yet

- ASTR191 Cheat Sheet 10Document6 pagesASTR191 Cheat Sheet 10AHMER ALINo ratings yet

- Ecological SuccessionDocument4 pagesEcological SuccessionChristine ShellyNo ratings yet

- Pubb 5.48 102.1-r-166 Udine2 2004Document21 pagesPubb 5.48 102.1-r-166 Udine2 2004abdsittNo ratings yet

- E13 AtqDocument9 pagesE13 AtqfemalejayNo ratings yet

- RecoPurSystem Water TreatmentDocument2 pagesRecoPurSystem Water TreatmentsalcedopozasNo ratings yet

- Everdure Waterstop - Page1Document1 pageEverdure Waterstop - Page1Jefferd AlicanNo ratings yet

- Air Conditioner With Refrigerant R134aDocument178 pagesAir Conditioner With Refrigerant R134aArierep OdariesmeNo ratings yet

- SECTION 33 05 13 Manholes: Revised 03/2012Document52 pagesSECTION 33 05 13 Manholes: Revised 03/2012FAISAL NAZEERNo ratings yet

- Dam Design Manual PDFDocument106 pagesDam Design Manual PDFSileshie Mesfin100% (2)

- De Thi Vao 10 HN Nam 2022-2023Document4 pagesDe Thi Vao 10 HN Nam 2022-2023kieudiem76653No ratings yet