Professional Documents

Culture Documents

Movimento Particulas No Inserto

Movimento Particulas No Inserto

Uploaded by

Jose ProenzaCopyright:

Available Formats

You might also like

- Automotive Sensor Testing and Waveform AnalysisFrom EverandAutomotive Sensor Testing and Waveform AnalysisRating: 4.5 out of 5 stars4.5/5 (13)

- SOP (Standard Operating Procedure) "WELDING PROCESS": Shoes Hand Glows GogglesDocument3 pagesSOP (Standard Operating Procedure) "WELDING PROCESS": Shoes Hand Glows GogglesMagesh Waran100% (1)

- Intro ME-GI - Dual FuelDocument37 pagesIntro ME-GI - Dual FuelamasrurNo ratings yet

- Pricing Your Work Corporate and Industrial PhotographyDocument15 pagesPricing Your Work Corporate and Industrial PhotographyManu Mnau MnauNo ratings yet

- Using Mesh Obscuration Technology To Determine The Cleanliness of Internal Combustion LubricantsDocument7 pagesUsing Mesh Obscuration Technology To Determine The Cleanliness of Internal Combustion LubricantsJHON ANGEL VARGAS HUAHUASONCCONo ratings yet

- Maxitrol 325 7AL 1 1 4 BrochureDocument8 pagesMaxitrol 325 7AL 1 1 4 BrochureAlberto GrullonNo ratings yet

- CurvesDocument49 pagesCurvesSAMBHAVNo ratings yet

- 325L 2psi Lever Acting DesignDocument9 pages325L 2psi Lever Acting DesignLexNo ratings yet

- ME1 Cylinder Cutout TestDocument3 pagesME1 Cylinder Cutout TestgoggyNo ratings yet

- Till 11th OctoberDocument14 pagesTill 11th OctoberNM2104TE06 PRATHURI SUMANTHNo ratings yet

- Errata 2016 - RCC CW 2015 - ENDocument113 pagesErrata 2016 - RCC CW 2015 - ENahmedalshawiNo ratings yet

- Vendor DataDocument6 pagesVendor DatasubudhiprasannaNo ratings yet

- Integrated Oil Field Supply & Services LLC: Material Inspection ReportDocument1 pageIntegrated Oil Field Supply & Services LLC: Material Inspection ReportRajkumar ANo ratings yet

- Economics of Gas Gathering CashflowDocument83 pagesEconomics of Gas Gathering CashflowDerrick GloverNo ratings yet

- MicrometricaDocument2 pagesMicrometricaEsteban Vargas RosasNo ratings yet

- Gasometor Ritter mgc10Document15 pagesGasometor Ritter mgc10Edwin Andres Flor MatallanaNo ratings yet

- APEL Aqua Patch Test Data 6e8ded7733Document10 pagesAPEL Aqua Patch Test Data 6e8ded7733Adelina GeorgianaNo ratings yet

- All You Need To Know About Bentonite in Cement Slurries Article Reading HandoutDocument6 pagesAll You Need To Know About Bentonite in Cement Slurries Article Reading HandoutVicente FreitasNo ratings yet

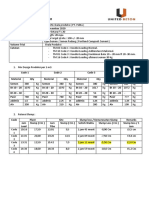

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilNo ratings yet

- Sae J51-2015Document11 pagesSae J51-2015NastyNo ratings yet

- Detailed Studies of The Impact of EEDI On VLCC Design and CO2 EmissionsDocument33 pagesDetailed Studies of The Impact of EEDI On VLCC Design and CO2 EmissionsGeorgios PapakostasNo ratings yet

- Mve SC Series Spec SheetDocument2 pagesMve SC Series Spec SheetБранко ЛуковићNo ratings yet

- Heating, Ventilation & Air ConditioningDocument95 pagesHeating, Ventilation & Air ConditioningmiguelNo ratings yet

- 2.5 Glycol Dehydration SystemDocument55 pages2.5 Glycol Dehydration SystemParesh NayakNo ratings yet

- 19 Manual Chain HoistsDocument1 page19 Manual Chain HoistsJimSpockNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Plumbing & Sanitary Slides PDFDocument27 pagesPlumbing & Sanitary Slides PDFShahril ShahibullahNo ratings yet

- ISO 4406 Cleanliness CodeDocument2 pagesISO 4406 Cleanliness CodeVILLANUEVA_DANIEL2064No ratings yet

- Ringkasan Trial Mix BetonDocument10 pagesRingkasan Trial Mix BetonyohanesfernandoNo ratings yet

- Analysis On The Human Resources EmployedDocument10 pagesAnalysis On The Human Resources EmployedTanmay VivekNo ratings yet

- 1MW Solar PV Templet Surendranagar Rev2 RealisticDocument2 pages1MW Solar PV Templet Surendranagar Rev2 Realisticmysoulfrnd5208100% (1)

- Commissioning Sheet 1Document1 pageCommissioning Sheet 1ABHISHEK SHARMANo ratings yet

- Dosis Obat InotropikDocument6 pagesDosis Obat Inotropikdoni januarindraNo ratings yet

- d601000258 Man 001Document24 pagesd601000258 Man 001Oswaldo VillarroelNo ratings yet

- Economics of Gas Gathering Cashflow of TechsimDocument77 pagesEconomics of Gas Gathering Cashflow of Techsimstructuredes.1No ratings yet

- Consumo RolosDocument3 pagesConsumo RoloselitonamauriNo ratings yet

- Fuel+Table+ +compactorsDocument3 pagesFuel+Table+ +compactorsHopper GrassNo ratings yet

- Fuel+Table+ +compactorsDocument3 pagesFuel+Table+ +compactorsHopper GrassNo ratings yet

- DPM CHECKLISTDocument1 pageDPM CHECKLISTShiftinchargeengineer dadri coalNo ratings yet

- GBK GFK Um en PDFDocument68 pagesGBK GFK Um en PDFYeabsra YonasNo ratings yet

- DVU Selection GuideDocument4 pagesDVU Selection GuideSebastian MartinelliNo ratings yet

- Dgs Report NewDocument678 pagesDgs Report NewVíctor Hugo Morales CurayNo ratings yet

- Design BasisDocument1 pageDesign BasismuhdqasimNo ratings yet

- Diesel Oil Pump 1Document26 pagesDiesel Oil Pump 1Vraja KisoriNo ratings yet

- Target ISO Cleanliness CodesDocument0 pagesTarget ISO Cleanliness CodesRaghavendra DeshpandeNo ratings yet

- Fischer-Tropsch Synthesis For Greener Fuel Oil Production: Pertamina UniversityDocument14 pagesFischer-Tropsch Synthesis For Greener Fuel Oil Production: Pertamina UniversityZakyAlFatonyNo ratings yet

- 325L Series 2PSI Lever Acting DesignDocument4 pages325L Series 2PSI Lever Acting DesignsamNo ratings yet

- COA Shore Tank 17 MFO Import Juni 2022 UpdateDocument3 pagesCOA Shore Tank 17 MFO Import Juni 2022 UpdateFerry Na NheenkNo ratings yet

- IMS APEX Manual Final LOCODocument64 pagesIMS APEX Manual Final LOCOMarjorie Dulay Dumol100% (1)

- CL DG Complex Aeroplanes Iss 02 Rev 01Document61 pagesCL DG Complex Aeroplanes Iss 02 Rev 01sunitaNo ratings yet

- CC IntroDocument86 pagesCC IntroLuis HuirseNo ratings yet

- Interlink TenacityDocument7 pagesInterlink TenacitySameera SampathNo ratings yet

- S1 S2 S3 S4 S5 S6 S7 S8: Tme 0:00 Hours Sphere NoDocument10 pagesS1 S2 S3 S4 S5 S6 S7 S8: Tme 0:00 Hours Sphere NoTHIYAGARAJAN ANo ratings yet

- Cleaner Fluid, Longer Component & Fluid Life, More Uptime!: Roller Contact BearingDocument1 pageCleaner Fluid, Longer Component & Fluid Life, More Uptime!: Roller Contact BearingfrankNo ratings yet

- Grab Janus JS178093WDocument38 pagesGrab Janus JS178093WMakNo ratings yet

- Ext. No. Type Capacity Ext. Mfg. Date HPT Done On HPT Due On Refill Done On Refill Due On Remarks (If Any Life Span Expires)Document1 pageExt. No. Type Capacity Ext. Mfg. Date HPT Done On HPT Due On Refill Done On Refill Due On Remarks (If Any Life Span Expires)srimathiNo ratings yet

- Presentation On Emissions - 11Document76 pagesPresentation On Emissions - 11suranatanuj007No ratings yet

- Cylinder Cutout TestDocument3 pagesCylinder Cutout TestPILAR MARTINEZ100% (1)

- Dispenser Data Gathering - Basic Requirements (260522)Document15 pagesDispenser Data Gathering - Basic Requirements (260522)ags alfNo ratings yet

- Anti Fouling & Trap Corrosion System (M.G.P.S.) Log SheetDocument2 pagesAnti Fouling & Trap Corrosion System (M.G.P.S.) Log Sheetஎன்றும் அன்புடன் கலைNo ratings yet

- Arlon 38NDocument4 pagesArlon 38NRavindrakumar ParvathiniNo ratings yet

- Fundamentals of HydraulicsDocument101 pagesFundamentals of HydraulicswissamhijaziNo ratings yet

- ESSAYDocument7 pagesESSAYKaren OliveraNo ratings yet

- Benefits of Professional Forensics MethodologyDocument57 pagesBenefits of Professional Forensics Methodologysharath_rakkiNo ratings yet

- Manual Tecnico Jblgo PDFDocument2 pagesManual Tecnico Jblgo PDFMarcosDanielSoaresNo ratings yet

- Informe Sobre El Manejo de CostasDocument88 pagesInforme Sobre El Manejo de CostasMetro Puerto RicoNo ratings yet

- 044.QTRE409 - International Human Resource ManagementDocument11 pages044.QTRE409 - International Human Resource ManagementDo Minh Gia AnNo ratings yet

- Jackson - Chimu Sculptures of Huaca TaycanamoDocument27 pagesJackson - Chimu Sculptures of Huaca TaycanamoJose David Nuñez UrviolaNo ratings yet

- SPE 163723 Pressure Transient Analysis of Data From Permanent Downhole GaugesDocument24 pagesSPE 163723 Pressure Transient Analysis of Data From Permanent Downhole GaugesLulut Fitra FalaNo ratings yet

- Whittington 22e Solutions Manual Ch14Document14 pagesWhittington 22e Solutions Manual Ch14潘妍伶No ratings yet

- Forms PensionersDocument15 pagesForms PensionersAnimesh DasNo ratings yet

- Law Enforcement Agency Indentifiers Crosswalk, 2012Document23 pagesLaw Enforcement Agency Indentifiers Crosswalk, 2012Samuel KaminNo ratings yet

- C C P S: Lalit KumarDocument3 pagesC C P S: Lalit KumarAbhishek aby5No ratings yet

- EXAM COG-622: IBM Cognos 10 BI AdministratorDocument16 pagesEXAM COG-622: IBM Cognos 10 BI AdministratorSaptarshi Dey0% (1)

- IRP ReportDocument13 pagesIRP ReportAnkit JajooNo ratings yet

- 15p3 Fourier IntegralDocument7 pages15p3 Fourier IntegralBhargav BhalaraNo ratings yet

- L550 19MY MB XC-EN V1j DX PDFDocument88 pagesL550 19MY MB XC-EN V1j DX PDFAnonymous gMgeQl1SndNo ratings yet

- Predica Billy GrahamDocument4 pagesPredica Billy GrahamJenkis Cam GuerraNo ratings yet

- MalappuramDocument20 pagesMalappuramFayizNo ratings yet

- Basion Horizontal CobenDocument3 pagesBasion Horizontal CobenJegan KumarNo ratings yet

- XXX (Topic) 好处影响1 相反好处 2. 你⾃自⼰己的观点,后⾯面会展开的Document3 pagesXXX (Topic) 好处影响1 相反好处 2. 你⾃自⼰己的观点,后⾯面会展开的Miyou KwanNo ratings yet

- Acute Gynaecological Emergencies-1Document14 pagesAcute Gynaecological Emergencies-1Anivasa Kabir100% (1)

- Subdivision of LandDocument6 pagesSubdivision of Land林诗倩No ratings yet

- 3M CorporationDocument3 pages3M CorporationIndoxfeeds GramNo ratings yet

- HUAWEI - SUN2000-20-40KTL-M3-UserManual GCADocument102 pagesHUAWEI - SUN2000-20-40KTL-M3-UserManual GCAReardon MetalsNo ratings yet

- 1.2 FMCC221 - Introduction To International Businesss - Part 1Document19 pages1.2 FMCC221 - Introduction To International Businesss - Part 1Bernie D. TeguenosNo ratings yet

- Andrea Kaneb - Group - 15Document4 pagesAndrea Kaneb - Group - 15Sibi KrishnaNo ratings yet

- DAPA Teams Spider DiagramDocument2 pagesDAPA Teams Spider DiagramEduardoJaimeNo ratings yet

- Beira International School: End of Year ExaminationDocument7 pagesBeira International School: End of Year ExaminationnothandoNo ratings yet

Movimento Particulas No Inserto

Movimento Particulas No Inserto

Uploaded by

Jose ProenzaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Movimento Particulas No Inserto

Movimento Particulas No Inserto

Uploaded by

Jose ProenzaCopyright:

Available Formats

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Illustrating the movement of small particles

inside a CJC Insert

Oct 2015, rev3 1

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Illustrating the movement of small particles

inside a CJC Insert

Oct 2015, rev3 2

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Illustrating the movement of small particles

inside a CJC Insert

Oct 2015, rev3 3

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Illustrating the movement of small particles

inside a CJC Insert

Oct 2015, rev3 4

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Illustrating the movement of small particles

inside a CJC Insert

Oct 2015, rev3 5

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Illustrating the movement of small particles

inside a CJC Insert

Oct 2015, rev3 6

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Illustrating the movement of small particles

inside a CJC Insert

Oct 2015, rev3 7

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Illustrating the movement of small particles

inside a CJC Insert

Oct 2015, rev3 8

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Illustrating the movement of small particles

inside a CJC Insert

Oct 2015, rev3 9

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Saturated CJC Insert

Cut through of used BG15/25

12 months of operation on WTG in Vestas 2 MW wind turbine

Insert is full of real particles. Close to max dirt holding capacity

and pressure (here 2.7 kg drained weight)

Oct 2015, rev3 Source: Test report Anders Damsgaard Serup 10

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

BG 15/25 - ISO 16889. Dirt holding Capacity

This is a ”full” BG 15/25 after

ISO 16889 multipass test.

MTD: 15 mg/l concentration.

=> Dirt Rate : 16 kg/year Test Dust only situated in outer surface of depth filter!

90% Dirt holding capacity still left.

Max DP reached, but is the insert saturated?

Oct 2015, rev3 Source: CJC Project Report 625 11

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Guide for oil cleanliness

Recommendations for oil and fuel

ISO Code NAS 1638 Description Suitable for Dirt/year

ISO 14/12/09 NAS 3 Very clean oil All critical systems 7,5 kg *

ISO 16/14/11 NAS 5 Clean Oil Servo valves, high pressure hydraulics, 17 kg *

Common rail diesel injection

ISO 17/15/12 NAS 6 Light contaminated oil Standard hydraulics, lube oil systems 36 kg *

ISO 19/17/14 NAS 8 New unfiltered oil Low loaded gears, low pressure 144 kg *

systems

ISO 22/20/17 NAS 11 Very contaminated oil Not suitable for oil systems > 570 kg *

*Weight of solid particles passing the system pump yearly at the given ISO code. Based on: 200 l/min, 20 h/day, 300 days/year

ISO 14/12/10 equals approx 0,1 mg/l of solids

ISO 17/15/12 approx 0.5 mg/l

ISO 19/17/14 approx 2 mg/l

ISO 22/20/17 approx 8 mg/l

Oct 2015, rev3 12

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Cleanliness Level

ISO Codes, Complete

Expected Cleanliness level (ISO Code)

Current Machine

Cleanliness (ISO

Code) 21/19/16 20/18/15 19/17/14 18/16/13 17/15/12 16/14/11

16/14/11

16/14/11 15/13/10 14/12/9 13/11/8 12/10/7

2 1.6 3 2 4 2.5 6 3 7 3.5 8 4 >10 5 >10 6 >10 7 >10 >10

24/22/19 1.8 1.3 2.3 1.7 3 2 3.5 2.5 4.5 3 5.5 3.5 7 4 8 5 10 5.5 >10 8.5

1.5 1.5 2 1.7 3 2 4 2.5 5 3 7 3.5 9 4 >10 5 >10 7 >10 10

23/21/18 1.5 1.3 1.8 1.4 2.2 1.6 3 2 3.5 2.5 4.5 3 5 3.5 7 4 9 5.5 10 8

22/20/17

1.3 1.2

1.2 1.05

1.6

1.5

1.5

1.3

2

1.8

1.7

1.4

3

2.3

2

1.7

4

3

2.5

2

5

3.5

3

2.5

7

5

4

3

Example:

9

6

5

4

>10

8 5.5

7 >10

10

9

7

21/19/16

21/19/16

1.3

1.2

1.2

1.1

1.6

1.5

1.5

1.3

2

1.8

1.7

1.5

3

2.2

2

1.7

4

33

2.5

2.5 5 3 By increasing

7 4 oil

9 cleaniness

6 >10 8

21/19/16 22 3.5 2.5 5 3.5 7 4.5 9 6

1.3 1.2

1.2 1.6 1.5 2 1.7 3 2 4 2.5

from 5

ISO3

code:7 4.6 >10 6

20/18/15 1.2 1.1 1.5 1.3 1.8 1.5 2.3 1.7 3 2 3.5 2.5 5.5 3.7 8 5

1.2 1.1

1.3 1.2 1.6 1.5 2 1.7 3 2 4 2.5 6 3 8 5

19/17/14 1.2 1.1 1.5 1.3 1.8 1.5 2.3 1.7 3 2 4 2.5 6 3.5

1.3 1.2 1.6 1.5 2 1.7 3 2 4 3.5 6 4

18/16/13 1.2 1.1 1.5 1.3 1.8 1.5 16/14/11

2.3 1.8 3.7 21/19/16

3 4.5 3.5

Hydraulics

Hydraulics Rolling

Rolling Elements

Element

Elements

and

and Diesel

Diesel Engines

Engines Bearings

Bearings 1.3 1.2 1.6 1.5 2 1.7 3 2 4 2.5

17/15/12 1.2 1.1 1.5 1.4

Hydraulic

1.8 1.5

component

2.3 1.8 3 2.2

Journal

JournalBearings

Journal Bearing Gear

Gear Boxes

Gear Boxes 1.3 1.3 1.6 1.6 2 1.8 3 2

1.2lifetime increase

1.9 41.5times2.3

16/14/11 Bearing Boxes

and

and Turbo

Turbo Machinery

Machinery and

and others

others 1.3 1.6 1.4 1.8

1.4 1.2 1.8 1.5 2.5 1.8

15/13/10

Oct 2015, rev3 1.2 1.1 1.6 1.3 2 1.6 13

You might also like

- Automotive Sensor Testing and Waveform AnalysisFrom EverandAutomotive Sensor Testing and Waveform AnalysisRating: 4.5 out of 5 stars4.5/5 (13)

- SOP (Standard Operating Procedure) "WELDING PROCESS": Shoes Hand Glows GogglesDocument3 pagesSOP (Standard Operating Procedure) "WELDING PROCESS": Shoes Hand Glows GogglesMagesh Waran100% (1)

- Intro ME-GI - Dual FuelDocument37 pagesIntro ME-GI - Dual FuelamasrurNo ratings yet

- Pricing Your Work Corporate and Industrial PhotographyDocument15 pagesPricing Your Work Corporate and Industrial PhotographyManu Mnau MnauNo ratings yet

- Using Mesh Obscuration Technology To Determine The Cleanliness of Internal Combustion LubricantsDocument7 pagesUsing Mesh Obscuration Technology To Determine The Cleanliness of Internal Combustion LubricantsJHON ANGEL VARGAS HUAHUASONCCONo ratings yet

- Maxitrol 325 7AL 1 1 4 BrochureDocument8 pagesMaxitrol 325 7AL 1 1 4 BrochureAlberto GrullonNo ratings yet

- CurvesDocument49 pagesCurvesSAMBHAVNo ratings yet

- 325L 2psi Lever Acting DesignDocument9 pages325L 2psi Lever Acting DesignLexNo ratings yet

- ME1 Cylinder Cutout TestDocument3 pagesME1 Cylinder Cutout TestgoggyNo ratings yet

- Till 11th OctoberDocument14 pagesTill 11th OctoberNM2104TE06 PRATHURI SUMANTHNo ratings yet

- Errata 2016 - RCC CW 2015 - ENDocument113 pagesErrata 2016 - RCC CW 2015 - ENahmedalshawiNo ratings yet

- Vendor DataDocument6 pagesVendor DatasubudhiprasannaNo ratings yet

- Integrated Oil Field Supply & Services LLC: Material Inspection ReportDocument1 pageIntegrated Oil Field Supply & Services LLC: Material Inspection ReportRajkumar ANo ratings yet

- Economics of Gas Gathering CashflowDocument83 pagesEconomics of Gas Gathering CashflowDerrick GloverNo ratings yet

- MicrometricaDocument2 pagesMicrometricaEsteban Vargas RosasNo ratings yet

- Gasometor Ritter mgc10Document15 pagesGasometor Ritter mgc10Edwin Andres Flor MatallanaNo ratings yet

- APEL Aqua Patch Test Data 6e8ded7733Document10 pagesAPEL Aqua Patch Test Data 6e8ded7733Adelina GeorgianaNo ratings yet

- All You Need To Know About Bentonite in Cement Slurries Article Reading HandoutDocument6 pagesAll You Need To Know About Bentonite in Cement Slurries Article Reading HandoutVicente FreitasNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilNo ratings yet

- Sae J51-2015Document11 pagesSae J51-2015NastyNo ratings yet

- Detailed Studies of The Impact of EEDI On VLCC Design and CO2 EmissionsDocument33 pagesDetailed Studies of The Impact of EEDI On VLCC Design and CO2 EmissionsGeorgios PapakostasNo ratings yet

- Mve SC Series Spec SheetDocument2 pagesMve SC Series Spec SheetБранко ЛуковићNo ratings yet

- Heating, Ventilation & Air ConditioningDocument95 pagesHeating, Ventilation & Air ConditioningmiguelNo ratings yet

- 2.5 Glycol Dehydration SystemDocument55 pages2.5 Glycol Dehydration SystemParesh NayakNo ratings yet

- 19 Manual Chain HoistsDocument1 page19 Manual Chain HoistsJimSpockNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Plumbing & Sanitary Slides PDFDocument27 pagesPlumbing & Sanitary Slides PDFShahril ShahibullahNo ratings yet

- ISO 4406 Cleanliness CodeDocument2 pagesISO 4406 Cleanliness CodeVILLANUEVA_DANIEL2064No ratings yet

- Ringkasan Trial Mix BetonDocument10 pagesRingkasan Trial Mix BetonyohanesfernandoNo ratings yet

- Analysis On The Human Resources EmployedDocument10 pagesAnalysis On The Human Resources EmployedTanmay VivekNo ratings yet

- 1MW Solar PV Templet Surendranagar Rev2 RealisticDocument2 pages1MW Solar PV Templet Surendranagar Rev2 Realisticmysoulfrnd5208100% (1)

- Commissioning Sheet 1Document1 pageCommissioning Sheet 1ABHISHEK SHARMANo ratings yet

- Dosis Obat InotropikDocument6 pagesDosis Obat Inotropikdoni januarindraNo ratings yet

- d601000258 Man 001Document24 pagesd601000258 Man 001Oswaldo VillarroelNo ratings yet

- Economics of Gas Gathering Cashflow of TechsimDocument77 pagesEconomics of Gas Gathering Cashflow of Techsimstructuredes.1No ratings yet

- Consumo RolosDocument3 pagesConsumo RoloselitonamauriNo ratings yet

- Fuel+Table+ +compactorsDocument3 pagesFuel+Table+ +compactorsHopper GrassNo ratings yet

- Fuel+Table+ +compactorsDocument3 pagesFuel+Table+ +compactorsHopper GrassNo ratings yet

- DPM CHECKLISTDocument1 pageDPM CHECKLISTShiftinchargeengineer dadri coalNo ratings yet

- GBK GFK Um en PDFDocument68 pagesGBK GFK Um en PDFYeabsra YonasNo ratings yet

- DVU Selection GuideDocument4 pagesDVU Selection GuideSebastian MartinelliNo ratings yet

- Dgs Report NewDocument678 pagesDgs Report NewVíctor Hugo Morales CurayNo ratings yet

- Design BasisDocument1 pageDesign BasismuhdqasimNo ratings yet

- Diesel Oil Pump 1Document26 pagesDiesel Oil Pump 1Vraja KisoriNo ratings yet

- Target ISO Cleanliness CodesDocument0 pagesTarget ISO Cleanliness CodesRaghavendra DeshpandeNo ratings yet

- Fischer-Tropsch Synthesis For Greener Fuel Oil Production: Pertamina UniversityDocument14 pagesFischer-Tropsch Synthesis For Greener Fuel Oil Production: Pertamina UniversityZakyAlFatonyNo ratings yet

- 325L Series 2PSI Lever Acting DesignDocument4 pages325L Series 2PSI Lever Acting DesignsamNo ratings yet

- COA Shore Tank 17 MFO Import Juni 2022 UpdateDocument3 pagesCOA Shore Tank 17 MFO Import Juni 2022 UpdateFerry Na NheenkNo ratings yet

- IMS APEX Manual Final LOCODocument64 pagesIMS APEX Manual Final LOCOMarjorie Dulay Dumol100% (1)

- CL DG Complex Aeroplanes Iss 02 Rev 01Document61 pagesCL DG Complex Aeroplanes Iss 02 Rev 01sunitaNo ratings yet

- CC IntroDocument86 pagesCC IntroLuis HuirseNo ratings yet

- Interlink TenacityDocument7 pagesInterlink TenacitySameera SampathNo ratings yet

- S1 S2 S3 S4 S5 S6 S7 S8: Tme 0:00 Hours Sphere NoDocument10 pagesS1 S2 S3 S4 S5 S6 S7 S8: Tme 0:00 Hours Sphere NoTHIYAGARAJAN ANo ratings yet

- Cleaner Fluid, Longer Component & Fluid Life, More Uptime!: Roller Contact BearingDocument1 pageCleaner Fluid, Longer Component & Fluid Life, More Uptime!: Roller Contact BearingfrankNo ratings yet

- Grab Janus JS178093WDocument38 pagesGrab Janus JS178093WMakNo ratings yet

- Ext. No. Type Capacity Ext. Mfg. Date HPT Done On HPT Due On Refill Done On Refill Due On Remarks (If Any Life Span Expires)Document1 pageExt. No. Type Capacity Ext. Mfg. Date HPT Done On HPT Due On Refill Done On Refill Due On Remarks (If Any Life Span Expires)srimathiNo ratings yet

- Presentation On Emissions - 11Document76 pagesPresentation On Emissions - 11suranatanuj007No ratings yet

- Cylinder Cutout TestDocument3 pagesCylinder Cutout TestPILAR MARTINEZ100% (1)

- Dispenser Data Gathering - Basic Requirements (260522)Document15 pagesDispenser Data Gathering - Basic Requirements (260522)ags alfNo ratings yet

- Anti Fouling & Trap Corrosion System (M.G.P.S.) Log SheetDocument2 pagesAnti Fouling & Trap Corrosion System (M.G.P.S.) Log Sheetஎன்றும் அன்புடன் கலைNo ratings yet

- Arlon 38NDocument4 pagesArlon 38NRavindrakumar ParvathiniNo ratings yet

- Fundamentals of HydraulicsDocument101 pagesFundamentals of HydraulicswissamhijaziNo ratings yet

- ESSAYDocument7 pagesESSAYKaren OliveraNo ratings yet

- Benefits of Professional Forensics MethodologyDocument57 pagesBenefits of Professional Forensics Methodologysharath_rakkiNo ratings yet

- Manual Tecnico Jblgo PDFDocument2 pagesManual Tecnico Jblgo PDFMarcosDanielSoaresNo ratings yet

- Informe Sobre El Manejo de CostasDocument88 pagesInforme Sobre El Manejo de CostasMetro Puerto RicoNo ratings yet

- 044.QTRE409 - International Human Resource ManagementDocument11 pages044.QTRE409 - International Human Resource ManagementDo Minh Gia AnNo ratings yet

- Jackson - Chimu Sculptures of Huaca TaycanamoDocument27 pagesJackson - Chimu Sculptures of Huaca TaycanamoJose David Nuñez UrviolaNo ratings yet

- SPE 163723 Pressure Transient Analysis of Data From Permanent Downhole GaugesDocument24 pagesSPE 163723 Pressure Transient Analysis of Data From Permanent Downhole GaugesLulut Fitra FalaNo ratings yet

- Whittington 22e Solutions Manual Ch14Document14 pagesWhittington 22e Solutions Manual Ch14潘妍伶No ratings yet

- Forms PensionersDocument15 pagesForms PensionersAnimesh DasNo ratings yet

- Law Enforcement Agency Indentifiers Crosswalk, 2012Document23 pagesLaw Enforcement Agency Indentifiers Crosswalk, 2012Samuel KaminNo ratings yet

- C C P S: Lalit KumarDocument3 pagesC C P S: Lalit KumarAbhishek aby5No ratings yet

- EXAM COG-622: IBM Cognos 10 BI AdministratorDocument16 pagesEXAM COG-622: IBM Cognos 10 BI AdministratorSaptarshi Dey0% (1)

- IRP ReportDocument13 pagesIRP ReportAnkit JajooNo ratings yet

- 15p3 Fourier IntegralDocument7 pages15p3 Fourier IntegralBhargav BhalaraNo ratings yet

- L550 19MY MB XC-EN V1j DX PDFDocument88 pagesL550 19MY MB XC-EN V1j DX PDFAnonymous gMgeQl1SndNo ratings yet

- Predica Billy GrahamDocument4 pagesPredica Billy GrahamJenkis Cam GuerraNo ratings yet

- MalappuramDocument20 pagesMalappuramFayizNo ratings yet

- Basion Horizontal CobenDocument3 pagesBasion Horizontal CobenJegan KumarNo ratings yet

- XXX (Topic) 好处影响1 相反好处 2. 你⾃自⼰己的观点,后⾯面会展开的Document3 pagesXXX (Topic) 好处影响1 相反好处 2. 你⾃自⼰己的观点,后⾯面会展开的Miyou KwanNo ratings yet

- Acute Gynaecological Emergencies-1Document14 pagesAcute Gynaecological Emergencies-1Anivasa Kabir100% (1)

- Subdivision of LandDocument6 pagesSubdivision of Land林诗倩No ratings yet

- 3M CorporationDocument3 pages3M CorporationIndoxfeeds GramNo ratings yet

- HUAWEI - SUN2000-20-40KTL-M3-UserManual GCADocument102 pagesHUAWEI - SUN2000-20-40KTL-M3-UserManual GCAReardon MetalsNo ratings yet

- 1.2 FMCC221 - Introduction To International Businesss - Part 1Document19 pages1.2 FMCC221 - Introduction To International Businesss - Part 1Bernie D. TeguenosNo ratings yet

- Andrea Kaneb - Group - 15Document4 pagesAndrea Kaneb - Group - 15Sibi KrishnaNo ratings yet

- DAPA Teams Spider DiagramDocument2 pagesDAPA Teams Spider DiagramEduardoJaimeNo ratings yet

- Beira International School: End of Year ExaminationDocument7 pagesBeira International School: End of Year ExaminationnothandoNo ratings yet