Professional Documents

Culture Documents

Annexure-I - Core Process Mapping - CQI

Annexure-I - Core Process Mapping - CQI

Uploaded by

Raj PrasanthCopyright:

Available Formats

You might also like

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- Quality Control + Quality Assurance + Quality ImprovementDocument34 pagesQuality Control + Quality Assurance + Quality ImprovementMasni-Azian Akiah96% (28)

- c20-540 ClimaticDocument18 pagesc20-540 ClimaticRaj PrasanthNo ratings yet

- RTR#210825-Bail Assembly FO Clamps - 2.80mm WireDocument1 pageRTR#210825-Bail Assembly FO Clamps - 2.80mm WireRaj PrasanthNo ratings yet

- The Six Sigma Project Planner: A Step-by-Step Guide to Leading a Six Sigma Project Through DMAICFrom EverandThe Six Sigma Project Planner: A Step-by-Step Guide to Leading a Six Sigma Project Through DMAICRating: 4.5 out of 5 stars4.5/5 (7)

- ISO 16949 ChecklistDocument9 pagesISO 16949 ChecklistFlorin Popescu100% (1)

- S-1, Quality Assurance & Quality ControlDocument10 pagesS-1, Quality Assurance & Quality ControlAnonymous 0YowLKJI1KNo ratings yet

- Lecture #9 Project Quality Management Quality Processes-Quality Assurance and Quality ControlDocument24 pagesLecture #9 Project Quality Management Quality Processes-Quality Assurance and Quality ControlAtef RagabNo ratings yet

- Module 3 CPM-3Document20 pagesModule 3 CPM-3YogeshNo ratings yet

- Lecture 2 - QMSDocument38 pagesLecture 2 - QMSBaiq Trya Yulian PutriNo ratings yet

- Quality Management in Construction Projects 1: Dr. Nabil El SawalhiDocument77 pagesQuality Management in Construction Projects 1: Dr. Nabil El SawalhiMichael BernardoNo ratings yet

- Chapter - 6 Quality Management and Control: Ataklty Adugna (Ass. Professor)Document49 pagesChapter - 6 Quality Management and Control: Ataklty Adugna (Ass. Professor)yared haftuNo ratings yet

- QualityDocument19 pagesQualityQCL LABNo ratings yet

- BI 10-01429 Kick-Off Meeting Presentation (Quality)Document12 pagesBI 10-01429 Kick-Off Meeting Presentation (Quality)kbldamNo ratings yet

- BS2 Quality Management - TaggedDocument33 pagesBS2 Quality Management - TaggedOreo FestNo ratings yet

- Topic 5: Quality ManagementDocument10 pagesTopic 5: Quality ManagementSimyeen LeongNo ratings yet

- ISO 9001:2015 QMS: Quality Management SystemDocument31 pagesISO 9001:2015 QMS: Quality Management SystemShimul karNo ratings yet

- SLIIT Lecture 10 Quality ManagmentDocument4 pagesSLIIT Lecture 10 Quality ManagmentV. OlukaNo ratings yet

- Iso 9001-2008Document20 pagesIso 9001-2008Mohamed ShabirNo ratings yet

- BI 10-01429 Kick-Off Meeting Presentation (Quality)Document12 pagesBI 10-01429 Kick-Off Meeting Presentation (Quality)kbldamNo ratings yet

- MS 494 TQM Spring 2023 LecturesDocument195 pagesMS 494 TQM Spring 2023 LecturesMuhammad OsamaNo ratings yet

- 5 Q A Dept and Q C ResponsibilitiesDocument64 pages5 Q A Dept and Q C ResponsibilitiesRam Prasad AwasthiNo ratings yet

- FPQM Nike Group 5Document15 pagesFPQM Nike Group 5meghaaadas26No ratings yet

- Handramohan Akshmipathy: ENIOR Quality Professional - Nearly 26 Years of ExperienceDocument5 pagesHandramohan Akshmipathy: ENIOR Quality Professional - Nearly 26 Years of ExperienceANIL PLAMOOTTILNo ratings yet

- 5 Q A - Dept - and - Q C - Responsibilities - necCPSDocument66 pages5 Q A - Dept - and - Q C - Responsibilities - necCPSSuraj PantNo ratings yet

- Qaqc Iso ProcedureDocument135 pagesQaqc Iso ProcedureGomathyselviNo ratings yet

- Quality ManagementDocument36 pagesQuality ManagementGIRITHARANNo ratings yet

- Module-2 Overview of ISO 9001Document16 pagesModule-2 Overview of ISO 9001baluNo ratings yet

- EO Annual Requalification ReviewDocument30 pagesEO Annual Requalification ReviewVenkatesh VenkateshNo ratings yet

- Quality Control - IntroductionDocument55 pagesQuality Control - IntroductionHariharan PNo ratings yet

- REKMU (K) 6 - ISO 9000 OverviewDocument23 pagesREKMU (K) 6 - ISO 9000 OverviewItsAndrioNo ratings yet

- Green Modern Financial Management PresentationDocument23 pagesGreen Modern Financial Management PresentationMA D.No ratings yet

- ReportDocument23 pagesReportSalimullahNo ratings yet

- 1 Introduction To QAQC R4Document14 pages1 Introduction To QAQC R4pmpm3457No ratings yet

- Quality AssuranceDocument79 pagesQuality AssuranceAlpha LuscusNo ratings yet

- (Topic 5) Inspection & Quality ControlDocument21 pages(Topic 5) Inspection & Quality ControlMd. Baharul IslamNo ratings yet

- Quality AuditDocument10 pagesQuality Audit1984subbulakshmiNo ratings yet

- CH 1 - Performing The IA EngagementDocument17 pagesCH 1 - Performing The IA EngagementSakhiwo MlumaNo ratings yet

- 1.2 QM Overview - BuildersDocument22 pages1.2 QM Overview - Buildersyhong9317No ratings yet

- EICC VAP AuditOperationsManualv5 01 Ch07 PDFDocument24 pagesEICC VAP AuditOperationsManualv5 01 Ch07 PDFYusuf Bayu AjiNo ratings yet

- Total Quality Management and Just-In-Time Production SystemDocument30 pagesTotal Quality Management and Just-In-Time Production SystemJannibee EstreraNo ratings yet

- Quality in Construction Works: An Introduction To QA/QC Concept and Quality Management System Based On ISO 9001:2008Document38 pagesQuality in Construction Works: An Introduction To QA/QC Concept and Quality Management System Based On ISO 9001:2008sid_calayag100% (2)

- Audi Q Management: Zero-Error StandardDocument13 pagesAudi Q Management: Zero-Error Standardpaulsteaua4968No ratings yet

- Project Quality Management: - Quality Assurance Plan in Road ConstructionDocument30 pagesProject Quality Management: - Quality Assurance Plan in Road Constructionसुजन कार्कीNo ratings yet

- EHQMS Integrated Internal Audit Procedure SampleDocument5 pagesEHQMS Integrated Internal Audit Procedure SampleShengrong Yee100% (1)

- THE MANAGEMENT AND CONTROL OF QUALITY, 5e, © 2002 South-Western/Thomson LearningDocument21 pagesTHE MANAGEMENT AND CONTROL OF QUALITY, 5e, © 2002 South-Western/Thomson Learningcolyneth papaNo ratings yet

- GJF Int Val Update 08 DecDocument14 pagesGJF Int Val Update 08 Decjpmaurya77No ratings yet

- Project WorkDocument1 pageProject WorkYonas BEZUNo ratings yet

- Lecture 6 - Project Quality ManagementDocument29 pagesLecture 6 - Project Quality ManagementZain GhummanNo ratings yet

- Apqp PresentationDocument142 pagesApqp PresentationVijayNo ratings yet

- QFD - Lecture 4Document28 pagesQFD - Lecture 4gahbreezaNo ratings yet

- CertificationDocument20 pagesCertificationxq2y6j5kj5No ratings yet

- Chapter 1 SlidesDocument22 pagesChapter 1 SlidesSheena Doria de VeraNo ratings yet

- Project Quality Management - OverviewDocument20 pagesProject Quality Management - Overviewbobby indaeyoNo ratings yet

- IPC IntroductionDocument41 pagesIPC Introductionram salunkheNo ratings yet

- Quality ControlDocument20 pagesQuality ControlBijoy SalahuddinNo ratings yet

- Quality Control in Projects, Standards ComplianceDocument19 pagesQuality Control in Projects, Standards Compliancegulzamanshakir28No ratings yet

- ISO 9001 Awareness TrainingDocument27 pagesISO 9001 Awareness TrainingA MNo ratings yet

- ISO 9000-2008 AuditingDocument23 pagesISO 9000-2008 AuditingMohamed ShabirNo ratings yet

- Project Quality ManagementDocument32 pagesProject Quality ManagementLemark R.0% (1)

- Clause Based ChecklistDocument9 pagesClause Based ChecklistLim Kim YookNo ratings yet

- Collection of Standards in Electronic Format PDFDocument27 pagesCollection of Standards in Electronic Format PDFRaj PrasanthNo ratings yet

- C33-003 Corrosion TestDocument8 pagesC33-003 Corrosion TestRaj PrasanthNo ratings yet

- Thanks For Travelling With Us, Raj Prasanth: Total Bill 174Document1 pageThanks For Travelling With Us, Raj Prasanth: Total Bill 174Raj PrasanthNo ratings yet

- En 50483-1Document18 pagesEn 50483-1Raj Prasanth100% (1)

- LM25 Al - Alloy STDDocument4 pagesLM25 Al - Alloy STDRaj PrasanthNo ratings yet

- Iso 7049 Self Tapping ScrewDocument3 pagesIso 7049 Self Tapping ScrewSNo ratings yet

- Form 9Document272 pagesForm 9Raj PrasanthNo ratings yet

- Uni 6324Document14 pagesUni 6324Raj PrasanthNo ratings yet

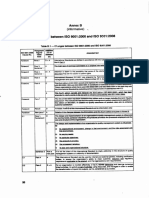

- Differences Between 2000 & 2008Document6 pagesDifferences Between 2000 & 2008Raj PrasanthNo ratings yet

- Hydro Aluminium - AlSi7Mg0 3Document2 pagesHydro Aluminium - AlSi7Mg0 3Raj PrasanthNo ratings yet

- Hydro Aluminium - AlSi7Mg0.6Document2 pagesHydro Aluminium - AlSi7Mg0.6Raj PrasanthNo ratings yet

- Matweb:, The Online Materials Database Aluminum 6201-T6Document2 pagesMatweb:, The Online Materials Database Aluminum 6201-T6Raj PrasanthNo ratings yet

- Iso 286 2Document48 pagesIso 286 2Raj PrasanthNo ratings yet

Annexure-I - Core Process Mapping - CQI

Annexure-I - Core Process Mapping - CQI

Uploaded by

Raj PrasanthOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Annexure-I - Core Process Mapping - CQI

Annexure-I - Core Process Mapping - CQI

Uploaded by

Raj PrasanthCopyright:

Available Formats

AIAG CQI Requirements

To achieve excellent product quality, manufacturing processes of products supplied to our customers

to be robust and consistent at any time. Additional focus and attention are necessary for special

processes like Heat treatment, Casting, Welding and Injection Moulding. Sicame India is required to

perform annual self-assessments, which are specified in the AIAG CQI Checklists - CQI-9 (Heat

treatment), CQI-27 (Casting), CQI-15 (Welding) and CQI-23 (Injection Moulding).

Why do it(Purpose)? When to do it? Key Process Indicators

• Improve the manufacturing • Start annual assessments as per • PPM rate reduction

process as robustness and priority follow 1. CQI-9 (Heat • No. of improvement measures

stability treatment), 2. CQI-27 (Casting), which identified through AIAG

• Reduces waste, variation, and 3. CQI-15 (Welding) and 4. CQI- CQI Self assessments

defects 23 (Injection Moulding)

Input Activity Output

• Heat treatment, Casting, • Self assessment according to • Implementation completed

Welding and Injection Moulding AIAG CQI • Confirmed robust processes

forms part of the value stream • Improvement measures • Fulfilment of customer

identified, defined and requirements

implemented

• Effectiveness verified and

proven

• Annual repetition

1

You might also like

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- Quality Control + Quality Assurance + Quality ImprovementDocument34 pagesQuality Control + Quality Assurance + Quality ImprovementMasni-Azian Akiah96% (28)

- c20-540 ClimaticDocument18 pagesc20-540 ClimaticRaj PrasanthNo ratings yet

- RTR#210825-Bail Assembly FO Clamps - 2.80mm WireDocument1 pageRTR#210825-Bail Assembly FO Clamps - 2.80mm WireRaj PrasanthNo ratings yet

- The Six Sigma Project Planner: A Step-by-Step Guide to Leading a Six Sigma Project Through DMAICFrom EverandThe Six Sigma Project Planner: A Step-by-Step Guide to Leading a Six Sigma Project Through DMAICRating: 4.5 out of 5 stars4.5/5 (7)

- ISO 16949 ChecklistDocument9 pagesISO 16949 ChecklistFlorin Popescu100% (1)

- S-1, Quality Assurance & Quality ControlDocument10 pagesS-1, Quality Assurance & Quality ControlAnonymous 0YowLKJI1KNo ratings yet

- Lecture #9 Project Quality Management Quality Processes-Quality Assurance and Quality ControlDocument24 pagesLecture #9 Project Quality Management Quality Processes-Quality Assurance and Quality ControlAtef RagabNo ratings yet

- Module 3 CPM-3Document20 pagesModule 3 CPM-3YogeshNo ratings yet

- Lecture 2 - QMSDocument38 pagesLecture 2 - QMSBaiq Trya Yulian PutriNo ratings yet

- Quality Management in Construction Projects 1: Dr. Nabil El SawalhiDocument77 pagesQuality Management in Construction Projects 1: Dr. Nabil El SawalhiMichael BernardoNo ratings yet

- Chapter - 6 Quality Management and Control: Ataklty Adugna (Ass. Professor)Document49 pagesChapter - 6 Quality Management and Control: Ataklty Adugna (Ass. Professor)yared haftuNo ratings yet

- QualityDocument19 pagesQualityQCL LABNo ratings yet

- BI 10-01429 Kick-Off Meeting Presentation (Quality)Document12 pagesBI 10-01429 Kick-Off Meeting Presentation (Quality)kbldamNo ratings yet

- BS2 Quality Management - TaggedDocument33 pagesBS2 Quality Management - TaggedOreo FestNo ratings yet

- Topic 5: Quality ManagementDocument10 pagesTopic 5: Quality ManagementSimyeen LeongNo ratings yet

- ISO 9001:2015 QMS: Quality Management SystemDocument31 pagesISO 9001:2015 QMS: Quality Management SystemShimul karNo ratings yet

- SLIIT Lecture 10 Quality ManagmentDocument4 pagesSLIIT Lecture 10 Quality ManagmentV. OlukaNo ratings yet

- Iso 9001-2008Document20 pagesIso 9001-2008Mohamed ShabirNo ratings yet

- BI 10-01429 Kick-Off Meeting Presentation (Quality)Document12 pagesBI 10-01429 Kick-Off Meeting Presentation (Quality)kbldamNo ratings yet

- MS 494 TQM Spring 2023 LecturesDocument195 pagesMS 494 TQM Spring 2023 LecturesMuhammad OsamaNo ratings yet

- 5 Q A Dept and Q C ResponsibilitiesDocument64 pages5 Q A Dept and Q C ResponsibilitiesRam Prasad AwasthiNo ratings yet

- FPQM Nike Group 5Document15 pagesFPQM Nike Group 5meghaaadas26No ratings yet

- Handramohan Akshmipathy: ENIOR Quality Professional - Nearly 26 Years of ExperienceDocument5 pagesHandramohan Akshmipathy: ENIOR Quality Professional - Nearly 26 Years of ExperienceANIL PLAMOOTTILNo ratings yet

- 5 Q A - Dept - and - Q C - Responsibilities - necCPSDocument66 pages5 Q A - Dept - and - Q C - Responsibilities - necCPSSuraj PantNo ratings yet

- Qaqc Iso ProcedureDocument135 pagesQaqc Iso ProcedureGomathyselviNo ratings yet

- Quality ManagementDocument36 pagesQuality ManagementGIRITHARANNo ratings yet

- Module-2 Overview of ISO 9001Document16 pagesModule-2 Overview of ISO 9001baluNo ratings yet

- EO Annual Requalification ReviewDocument30 pagesEO Annual Requalification ReviewVenkatesh VenkateshNo ratings yet

- Quality Control - IntroductionDocument55 pagesQuality Control - IntroductionHariharan PNo ratings yet

- REKMU (K) 6 - ISO 9000 OverviewDocument23 pagesREKMU (K) 6 - ISO 9000 OverviewItsAndrioNo ratings yet

- Green Modern Financial Management PresentationDocument23 pagesGreen Modern Financial Management PresentationMA D.No ratings yet

- ReportDocument23 pagesReportSalimullahNo ratings yet

- 1 Introduction To QAQC R4Document14 pages1 Introduction To QAQC R4pmpm3457No ratings yet

- Quality AssuranceDocument79 pagesQuality AssuranceAlpha LuscusNo ratings yet

- (Topic 5) Inspection & Quality ControlDocument21 pages(Topic 5) Inspection & Quality ControlMd. Baharul IslamNo ratings yet

- Quality AuditDocument10 pagesQuality Audit1984subbulakshmiNo ratings yet

- CH 1 - Performing The IA EngagementDocument17 pagesCH 1 - Performing The IA EngagementSakhiwo MlumaNo ratings yet

- 1.2 QM Overview - BuildersDocument22 pages1.2 QM Overview - Buildersyhong9317No ratings yet

- EICC VAP AuditOperationsManualv5 01 Ch07 PDFDocument24 pagesEICC VAP AuditOperationsManualv5 01 Ch07 PDFYusuf Bayu AjiNo ratings yet

- Total Quality Management and Just-In-Time Production SystemDocument30 pagesTotal Quality Management and Just-In-Time Production SystemJannibee EstreraNo ratings yet

- Quality in Construction Works: An Introduction To QA/QC Concept and Quality Management System Based On ISO 9001:2008Document38 pagesQuality in Construction Works: An Introduction To QA/QC Concept and Quality Management System Based On ISO 9001:2008sid_calayag100% (2)

- Audi Q Management: Zero-Error StandardDocument13 pagesAudi Q Management: Zero-Error Standardpaulsteaua4968No ratings yet

- Project Quality Management: - Quality Assurance Plan in Road ConstructionDocument30 pagesProject Quality Management: - Quality Assurance Plan in Road Constructionसुजन कार्कीNo ratings yet

- EHQMS Integrated Internal Audit Procedure SampleDocument5 pagesEHQMS Integrated Internal Audit Procedure SampleShengrong Yee100% (1)

- THE MANAGEMENT AND CONTROL OF QUALITY, 5e, © 2002 South-Western/Thomson LearningDocument21 pagesTHE MANAGEMENT AND CONTROL OF QUALITY, 5e, © 2002 South-Western/Thomson Learningcolyneth papaNo ratings yet

- GJF Int Val Update 08 DecDocument14 pagesGJF Int Val Update 08 Decjpmaurya77No ratings yet

- Project WorkDocument1 pageProject WorkYonas BEZUNo ratings yet

- Lecture 6 - Project Quality ManagementDocument29 pagesLecture 6 - Project Quality ManagementZain GhummanNo ratings yet

- Apqp PresentationDocument142 pagesApqp PresentationVijayNo ratings yet

- QFD - Lecture 4Document28 pagesQFD - Lecture 4gahbreezaNo ratings yet

- CertificationDocument20 pagesCertificationxq2y6j5kj5No ratings yet

- Chapter 1 SlidesDocument22 pagesChapter 1 SlidesSheena Doria de VeraNo ratings yet

- Project Quality Management - OverviewDocument20 pagesProject Quality Management - Overviewbobby indaeyoNo ratings yet

- IPC IntroductionDocument41 pagesIPC Introductionram salunkheNo ratings yet

- Quality ControlDocument20 pagesQuality ControlBijoy SalahuddinNo ratings yet

- Quality Control in Projects, Standards ComplianceDocument19 pagesQuality Control in Projects, Standards Compliancegulzamanshakir28No ratings yet

- ISO 9001 Awareness TrainingDocument27 pagesISO 9001 Awareness TrainingA MNo ratings yet

- ISO 9000-2008 AuditingDocument23 pagesISO 9000-2008 AuditingMohamed ShabirNo ratings yet

- Project Quality ManagementDocument32 pagesProject Quality ManagementLemark R.0% (1)

- Clause Based ChecklistDocument9 pagesClause Based ChecklistLim Kim YookNo ratings yet

- Collection of Standards in Electronic Format PDFDocument27 pagesCollection of Standards in Electronic Format PDFRaj PrasanthNo ratings yet

- C33-003 Corrosion TestDocument8 pagesC33-003 Corrosion TestRaj PrasanthNo ratings yet

- Thanks For Travelling With Us, Raj Prasanth: Total Bill 174Document1 pageThanks For Travelling With Us, Raj Prasanth: Total Bill 174Raj PrasanthNo ratings yet

- En 50483-1Document18 pagesEn 50483-1Raj Prasanth100% (1)

- LM25 Al - Alloy STDDocument4 pagesLM25 Al - Alloy STDRaj PrasanthNo ratings yet

- Iso 7049 Self Tapping ScrewDocument3 pagesIso 7049 Self Tapping ScrewSNo ratings yet

- Form 9Document272 pagesForm 9Raj PrasanthNo ratings yet

- Uni 6324Document14 pagesUni 6324Raj PrasanthNo ratings yet

- Differences Between 2000 & 2008Document6 pagesDifferences Between 2000 & 2008Raj PrasanthNo ratings yet

- Hydro Aluminium - AlSi7Mg0 3Document2 pagesHydro Aluminium - AlSi7Mg0 3Raj PrasanthNo ratings yet

- Hydro Aluminium - AlSi7Mg0.6Document2 pagesHydro Aluminium - AlSi7Mg0.6Raj PrasanthNo ratings yet

- Matweb:, The Online Materials Database Aluminum 6201-T6Document2 pagesMatweb:, The Online Materials Database Aluminum 6201-T6Raj PrasanthNo ratings yet

- Iso 286 2Document48 pagesIso 286 2Raj PrasanthNo ratings yet