Professional Documents

Culture Documents

Standards

Standards

Uploaded by

SATYAJIT BEHERA0 ratings0% found this document useful (0 votes)

23 views20 pagesThere are three types of measurement standards: line standards, end standards, and wavelength standards. Line standards define a unit of measurement as the distance between lines on a reference bar. The international prototype kilogram is an example of a primary line standard. Secondary and working standards are then traceable to the primary standard. End standards like gauge blocks and slip gauges are used for practical measurements and setting reference dimensions. Wavelength standards define units based on the wavelength of specific atomic transitions, like using the wavelength of krypton-86 radiation to define the meter.

Original Description:

Original Title

17861_Standards

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThere are three types of measurement standards: line standards, end standards, and wavelength standards. Line standards define a unit of measurement as the distance between lines on a reference bar. The international prototype kilogram is an example of a primary line standard. Secondary and working standards are then traceable to the primary standard. End standards like gauge blocks and slip gauges are used for practical measurements and setting reference dimensions. Wavelength standards define units based on the wavelength of specific atomic transitions, like using the wavelength of krypton-86 radiation to define the meter.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

0 ratings0% found this document useful (0 votes)

23 views20 pagesStandards

Standards

Uploaded by

SATYAJIT BEHERAThere are three types of measurement standards: line standards, end standards, and wavelength standards. Line standards define a unit of measurement as the distance between lines on a reference bar. The international prototype kilogram is an example of a primary line standard. Secondary and working standards are then traceable to the primary standard. End standards like gauge blocks and slip gauges are used for practical measurements and setting reference dimensions. Wavelength standards define units based on the wavelength of specific atomic transitions, like using the wavelength of krypton-86 radiation to define the meter.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 20

STANDARDS

• In the science of measurement, a standard is an object,

system, or experiment that bears a defined relationship to a

unit of measurement of a physical quantity.

• Standards are the fundamental reference for a system of

weights and measures, against which all other measuring

devices are compared.

The International Prototype Kilogram (IPK) is

an artifact standard or prototype that is

defined to be exactly one kilogram mass.

Hierarchy of standards

Primary reference standards

• Primary standards are made to the highest metrological quality

and are the definitive definition or realization of their unit of

measure.

• An example of a primary standard is the

international prototype kilogram (IPK) which is the master

kilogram and the primary mass standard for the

International System of Units (SI). The IPK is a one kilogram mass

of a platinum-iridium alloy maintained by the

International Bureau of Weights and Measures (BIPM) in Sèvres,

France.

Secondary reference standards

• Secondary reference standards are very close approximations

of primary reference standards.

• For example, major national measuring laboratories such as

the US's National Institute of Standards and Technology (NIST)

will hold several "national standard" kilograms, which are

periodically calibrated against the IPK and each other.

Working standards

• Although the SI definition of the "meter" is based on a

laboratory procedure combining the speed of light and the

duration of a second, a machine shop will have a physical

working standard (gauge blocks for example) that are used

for checking its measuring instruments.

• Working standards and certified reference materials used in

commerce and industry have a traceable relationship to the

secondary and primary standards.

• Working standards are expected to deteriorate, and are no

longer considered traceable to a national standard after a

time period or use count expires.

Laboratory Standards

• National organizations provide calibration and private

industrial laboratories with items, processes and/or

certification so they can provide certified traceability to

national standards.

• These laboratory standards are kept in controlled conditions

to maintain their precision, and used as a reference for

calibration and creating working standards.

• Sometimes they are (incorrectly) called "secondary

standards" because of their high quality and reference

suitability.

Traceability

• Traceability is the ability to verify the history, location, or

application of an item by means of documented recorded

identification.

• The term "measurement traceability" is used to refer to an

unbroken chain of comparisons relating an instrument's

measurements to a known standard.

• In many countries, national standards for weights and

measures are maintained by a National Measurement

Institute (NMI) which provides the highest level of standards

for the calibration / measurement traceability infrastructure

in that country.

MEASUREMENT STANDARDS

There are three types of measurement standards: (Standards and their

Evolution)

1.Line Standard

2.End Standard

3.Wavelength Standard

1.Line Standard: According to the line standard, the yard or metre is defined as

the distance between inscribed lines on a bar of metal under certain conditions of

temperature and support.

The metre is defined as 1650763.73 wavelengths of the orange radiation in

vaccum of krypton-86 .

The Yard is defined as 0.9144 metre. This is equivalent to 1509458.35

wavelengths of the same radiation.

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

MEASUREMENT STANDARDS

a. The Imperial Standard Yard: It is made of a one-inch square cross section bronze

bar (82% copper, 13% tin, 5% zinc) and is 38 inches long. The bar has a ½ inch

dia* ½ inch deep hole, which are fitted with a 1/10th inch dia gold plug.

The yard is defined as the distance between two central transverse lines on the plugs

when the temperature of the bar is constant at 62°F and the bar is supported on

rollers in a specified manner to prevent flexure, the distance being taken at the point

midway between the two longitudinal lines at 62°F for occasional comparison.

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

MEASUREMENT STANDARDS

b. International Standard Prototype Metre: The metre is the distance

between the centre portions of two lines engraved on the polished surface

of a bar (prototype) made up of platinum (90%) – iridium (10%) alloy

having a unique crossection.

• This bar is kept at 0°C and under normal atmospheric pressure.

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

MEASUREMENT STANDARDS

International Standard Prototype Metre

• According to this standard, the length of

one meter is defined as the straight line

distance, at 0°C between the centre

portion of a pure platinum-iridium alloy of

a total length of 1000-mm and having a

web cross section.

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

MEASUREMENT STANDARDS

2. End Standard: End standards, in the form of the bars and slip gauges are

used for all practical measurements in workshops and general use in

precision engineering in standard laboratories. In case of vernier calipers

and micrometers, the job is held between the jaws/anvils of the measuring

instrument and the corresponding reading is noted, while a length bar and

slip gauges are used to set the required length to be used as a reference

dimension.

a. End Bar : End bars made of steel having cylindrical cross section of 22.2

mm diameter with the faces lapped and hardened at the ends are available

in sets of various lengths.

End bars are made from high-carbon chromium steel, ensuring that faces

are hardened to 64RC.The bars have a round section of 30mm for greater

stability. Both the ends are threaded, precision lapped to meet requirements

of finish, flatness and gauge length. These are available up to 500 mm in

grades 0,1,2 in an 8-piece set.

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

Gauge block or Slip Gauge

• Gauge blocks (also known as gage blocks, Johansson gauges, slip

gauges, or Jo blocks) are a system for producing precision lengths.

• The individual gauge block is a metal or ceramic block that has been

precision ground and lapped to a specific thickness.

• Gauge blocks come in sets of blocks with a range of standard

lengths. In use, the blocks are stacked to make up a desired length.

• An important feature of gauge blocks is that they can be joined

together with very little dimensional uncertainty. The blocks are

joined by a sliding process called wringing, which causes their

ultraflat surfaces to cling together.

• A small number of gauge blocks can be used to create accurate

lengths within a wide range. By using 3 blocks from a set of 30

blocks, one may create any of the 1000 lengths from 3.000 to

3.999 mm in 0.001 mm steps

• They are used as a reference for the calibration of measuring

equipment used in machine shops, such as micrometers, sine bars,

calipers, and dial indicators (when used in an inspection role).

Gauge blocks are the main means of length standardization used by

industry.

MEASUREMENT STANDARDS

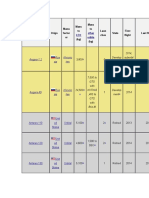

b. Slip Gauges: Slip gauges are practical end standards and can be used in linear

measurements in many ways. Slip Gauges are rectangular blocks of hardened and

stabilized high-grade cast steel or the ceramic compound zirconium oxide (ZrO 2)

having dimensions of 9mm wide, 30 to 35 mm long cross section.

The length of a slip gauge is strictly the dimension which it measures – in some slip

gauges it is the shortest dimension and in the larger slip gauges it is the longest.

Slip Gauges are made according to the following standards:

Metric gauge block set

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

MEASUREMENT STANDARDS

Measuring faces of slip gauges are forced and wrung against each other so that

the gauges stick together. This is known as wringing of slip gauges.

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

Wringing

• Wringing is the process of sliding two blocks together so that

their faces lightly bond.

• Because of their ultraflat surfaces, when wrung, gauge blocks

adhere to each other tightly. Properly wrung blocks may

withstand a 75 lbf (330 N) pull.

MEASUREMENT STANDARDS

Wavelength Standards: Line and end standards are physical standards and are

made up of materials that can change their size with temperature and other

environmental conditions. The correct lab conditions are required to be maintained

so that the length standard remains unchanged.

High sensitivity length measurements are therefore very important because of high

accuracy.

The CGPM (Conference Generale des Poids et Mesures) adopted a definition of the

metre in terms of the wavelength in vaccum of the radiation corresponding to a

transition between specified energy levels of the krypton-86 atom.

In 1960, orange radiation of the isotope krypton-86 used in a hot-cathode discharge

lamp maintained at a temperature of 63K, was selected to define the metre. The

metre was then defined as equal to 1650763.73 wavelengths of the red-orange

radiation of the krypton isotope-86 gas.

1 metre = 1650763.73 wavelengths and,

I Yard = 0.9144 metre = 0.9144 * 1650763.73 wavelengths

= 1509458.3 wavelengths

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

MEASUREMENT STANDARDS

Wavelength Standards: Material standards are liable to destruction and their

dimensions change slightly with time. But with the monochromatic light we have

the advantage of constant wavelength and since the wavelength is not a physical

one, it need not be preserved. This is reproducible standard of length, and the error

of reproduction can be of the order of 1 part in 100 millions. It is because of this

reason that International Standard measures the metre in terms of wavelength of

krypton 86.

Advantages of wavelength standards

•Not influenced by variation in environment, temperature etc.

•No need to store it under security and thus no fear of destroyed.

•Easily available to all.

•Higher accuracy

•It is easily reproducible. (lecture 3 finish)

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

Speed of light standard

• The shortcomings of the krypton standard were

demonstrated by the measurement of the wavelength of the

light from a methane-stabilized helium–neon laser (λ ≈

3.39 µm).

• The krypton line was found to be asymmetrical, so different

wavelengths could be found for the laser light depending on

which point on the krypton line was taken for reference.

• The asymmetry also affected the precision to which the

wavelengths could be measured.

• Hence it was superseded by laser and finally following is the

definition

The metre is the length of the path travelled by light in vacuum during a time

interval of 1 ⁄ 299,792,458 of a second.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Risk AssessmentDocument6 pagesRisk AssessmentEhab Yahia Khalel100% (2)

- Conveyor - Service - Parts Stero SCT 94sDocument32 pagesConveyor - Service - Parts Stero SCT 94sJose MarcanoNo ratings yet

- Tool Nomenclature and GeometryDocument42 pagesTool Nomenclature and GeometrySATYAJIT BEHERANo ratings yet

- Machine ToolsDocument143 pagesMachine ToolsSATYAJIT BEHERANo ratings yet

- Types of ErrorsDocument11 pagesTypes of ErrorsSATYAJIT BEHERANo ratings yet

- Metrology and MeasurementDocument28 pagesMetrology and MeasurementSATYAJIT BEHERANo ratings yet

- Comparison of Orbital Launch SystemsDocument173 pagesComparison of Orbital Launch SystemsgihadNo ratings yet

- Code 16 swhihatPAD KIT ARDUINODocument5 pagesCode 16 swhihatPAD KIT ARDUINOBayu PriguntoroNo ratings yet

- The Hong Kong Polytechnic University Department of Electronic and Information EngineeringDocument4 pagesThe Hong Kong Polytechnic University Department of Electronic and Information EngineeringNiaz ManikNo ratings yet

- Assignment 1 Part 1Document6 pagesAssignment 1 Part 1Aditi AgrawalNo ratings yet

- Smart Universal Signal ConditionerDocument4 pagesSmart Universal Signal ConditionerYudi RambutanNo ratings yet

- Bab 06 - Seq Mining - Part 2Document26 pagesBab 06 - Seq Mining - Part 2Mochammad Adji FirmansyahNo ratings yet

- RadDocument35 pagesRadabdellaNo ratings yet

- Ecpins D-Mop: Digital Maritime Operations PlotDocument2 pagesEcpins D-Mop: Digital Maritime Operations PlotPramestika WinahyuNo ratings yet

- FESTO Eguide Final2Document26 pagesFESTO Eguide Final2CasHeerNo ratings yet

- Kupdf WeldingDocument44 pagesKupdf WeldingSamayapuramNo ratings yet

- BI Authentication PDFDocument22 pagesBI Authentication PDFrajibzzamanibcsNo ratings yet

- Gusset Plate Connection To Round HSS Tension MembersDocument7 pagesGusset Plate Connection To Round HSS Tension MembersSergioAlcantaraNo ratings yet

- Global Local Analysis WhitepaperDocument3 pagesGlobal Local Analysis WhitepaperagniflameNo ratings yet

- DM Fadg 2017Document51 pagesDM Fadg 2017wal1547No ratings yet

- Emergency Procedure in Flight SafetyDocument21 pagesEmergency Procedure in Flight Safetylidya ardiyanNo ratings yet

- 3RH - Contactor RelaysDocument13 pages3RH - Contactor Relaysreza_powerNo ratings yet

- Plumbing Arithmetic SeriesDocument130 pagesPlumbing Arithmetic SeriesAnonymous J1Plmv8No ratings yet

- Corsa Lite Corsa Astra 5 Door Meriva Zafi Ra Tigra Astra GTC Astra Twin TopDocument24 pagesCorsa Lite Corsa Astra 5 Door Meriva Zafi Ra Tigra Astra GTC Astra Twin Topgqnwuqlkwnvh100% (1)

- Rathaur 2020 Mater. Res. Express 7 015305Document9 pagesRathaur 2020 Mater. Res. Express 7 015305Steven Rojas CuellarNo ratings yet

- The Dynatest Model 8000 Truck Mounted Deflectometer Test System SpecificationsDocument11 pagesThe Dynatest Model 8000 Truck Mounted Deflectometer Test System SpecificationsTimu OvidiuNo ratings yet

- Haide EeeeeeDocument32 pagesHaide Eeeeeeusmaniqbal15No ratings yet

- 300 PR DofollowDocument4 pages300 PR DofollowRalph Vincent FerrarenNo ratings yet

- 1 Lindapter Maggio 2023Document84 pages1 Lindapter Maggio 2023CALGERINo ratings yet

- International Conference, GrdsDocument36 pagesInternational Conference, GrdsGlobal Research and Development ServicesNo ratings yet

- A Review Paper On Replacement of Fine AggregateDocument5 pagesA Review Paper On Replacement of Fine AggregateIJRASETPublicationsNo ratings yet

- French Level 2 - Student Workbook PDFDocument100 pagesFrench Level 2 - Student Workbook PDFmetztli100% (2)

- AJM MODULE1 Admixtures BMCDocument31 pagesAJM MODULE1 Admixtures BMCfaheem momdNo ratings yet

- BS 4206 PDFDocument11 pagesBS 4206 PDFbich100% (1)