Professional Documents

Culture Documents

Metrology and Measurement

Metrology and Measurement

Uploaded by

SATYAJIT BEHERAOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metrology and Measurement

Metrology and Measurement

Uploaded by

SATYAJIT BEHERACopyright:

Available Formats

METROLOGY AND MEASUREMENT

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

METROLOGY

• Metrology is derived from two Greek word, one is metro which means

measurement and other is logy which means science. Metrology is basically

the science of measurement.

• Metrology is field of knowledge concerned with measurement and includes

both theoretical and practical problems with reference to measurement.

• Metrology is the name given to the science of pure measurement.

• Engineering Metrology is restricted to measurements of length & angle.

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

TYPES OF METROLOGY

Metrology is separated into following categories with different levels of

complexity and accuracy:

1.Scientific Metrology

2.Industrial Metrology

3.Legal Metrology

4.Fundamental Metrology

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

TYPES OF METROLOGY

Scientific Metrology deals with the organization and development of

measurement standards and with their maintenance.

Industrial Metrology has to ensure the adequate functioning of measuring

instruments used in industry as well as in production and testing processes.

Legal Metrology is concerned with the accuracy of measurements where these

have influence on the transparency of economical transactions, and health and

safety, e.g., the volume and quality of petrol purchased or the weight and

quality of prepackaged flour. It seeks to protect public against inaccuracy in

trade.

Fundamental Metrology may be described as scientific metrology,

supplemented by those parts of legal and industrial metrology that require

scientific competence. It signifies the highest level of accuracy in the field of

metrology.

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

METROLOGICAL TERMINOLOGIES

Accuracy without Precision

Accuracy & Precision

Precision without Accuracy No Precision &

No Accuracy

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

METHODS OF MEASUREMENTS

Measurement is a set of operations done with the aim of determining the value of a

quantity which can be measured by various methods of measurements depending

upon the accuracy required and the amount of permissible error.

The various methods of measurement are:

Direct Method: This is the simplest method of measurement in which the value of

the quantity to be measured is obtained directly without any calculations, e.g.,

measurements by scales, vernier calipers, micrometers etc. It involves contact or

non-contact type of inspections. Human insensitiveness can affect the accuracy of

measurement.

Indirect Method: The value of the quantity to be measured is obtained by

measuring other quantities, which are frequently related with the required value,

e.g., angle measurement by sine bar, density calculation by measuring mass and

dimensions for calculating volume.

Absolute Method: This is also called fundamental method and is based on the

measurement of the base quantities used to define a particular quantity, e.g.,

measuring a quantity (length) directly in accordance with the definition of that

quantity.

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

MEASURING INSTRUMENT AND THEIR SELECTION

A measuring instrument is any device that may be used to obtain a dimensional

or angular measurement. The important characteristics which govern the

selection of instruments are measuring range, accuracy and precision.

Some instruments, such as a steel rule, may be used to read directly; others like

caliper, are used for transforming or comparing dimensions.

Transformation of a measurable quantity into the required information is a

function of measuring instruments.

Generally, measuring instruments are classified as follows:

i.On the basis of function

a.Length-measuring instruments

b.Angle measuring instruments

c.Surface-roughness measuring instruments

d.Geometrical-form-checking instruments

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

MEASURING INSTRUMENT AND THEIR SELECTION

ii. On the basis of accuracy

a. Most accurate instruments

b. Moderate accurate instruments

c. Below moderate accurate instruments

iii. On the basis of precision

a. Precision measuring instruments

b. Non-precision measuring instruments

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

ERRORS IN MEASUREMENT

• The error in measurement is the difference between the measured value

and the true value of the measuring dimension. (Lecture 2)

• Error may be absolute or relative.

Error in Measurement = Measured Value – True Value

• The actual value or true value is a theoretical size of dimension free from

any error of measurement which helps to examine the errors in a

measurement system that lead to uncertainties.

• The errors in measurements are classified into two testing types – one,

which should not occur and can be eliminated by careful work and

attention; and the other, which is inherent in the measuring process/

system.

• Therefore, the errors are either controllable or random in occurrence.

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

ERRORS IN MEASUREMENT

Absolute Error

It is divided into two types:

True Absolute Error: It is defined as the algebraic difference between the

result of measurement and the conventional true value of the quantity

measured.

Apparent Absolute Error: It is defined as the algebraic difference between the

arithmetic mean and one of the results of measurement when a series of

measurements are made.

Absolute Error (EA)

Absolute Error = |Actual Value – Approximate Value|

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

ERRORS IN MEASUREMENT

Relative Error

It is the quotient of the absolute error and the value of comparison used for

calculation of the absolute error.

Percentile Error (EP) Relative error is expressed in percentage form

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

ERRORS IN MEASUREMENT

Static Error

These are the result of physical nature of the various components of a

measuring system, i.e. intrinsic imperfection or limitations of

apparatus/instrument.

Static error may occur due to existence of either characteristic errors or reading

errors or environmental errors, as the environmental effect and other external

factors influence the operating capabilities of an instrument or inspection

procedure.

a.Reading Error: These type of errors apply exclusively to instruments. These

errors may be the result of parallax, optical resolution/readability, and

interpolation.

Parallax error creeps in when the line of sight is not perpendicular to the

measuring scale.

b.Alignment Error: This occurs if the checking of an instrument is not

correctly aligned with the direction of the desired measurement.

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

ERRORS IN MEASUREMENT

c. Characteristic Error: It is the deviation of the output of the measuring

system from the theoretical predicted performance or from the nominal

performance specifications. Linearity, repeatability, and resolution error

are the examples of characteristic error.

d. Environmental Error: These are the errors arising from the effect of the

surrounding temperature, pressure and humidity on the measuring system.

Magnetic and electric fields, nuclear radiations, vibration or shocks may

also lead to errors. Environmental error can be controlled by controlling the

atmospheric factors.

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

ERRORS IN MEASUREMENT

Loading Error If the datum surface on which part to be measured is located is

not flat or if foreign particles like dirt or chips get entrapped between

datum surface and workpiece then an error will be introduced in taking

readings.

Poor contact between the working gauge or the instrument and workpiece

causes an error.

Instrument Loading error is the difference between the value of the measurand

before and after the measuring system is connected or contacted for

measurement.

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

ERRORS IN MEASUREMENT

Dynamic Error It is caused by time variation in the measurand. It is the result

of incapability of the system to respond reliably to time-varying measurement.

Inertia, damping, friction or other physical constraints in sensing or readout or

the display system are the main causes of dynamic errors.

Controllable Error: These are controllable both in magnitude and sense.

These type of errors are regularly repetitive in nature and are of similar form .

It includes following:

a.Calibration Error: These are caused due to the variation in the calibrated

scale from its normal indicated value.

b.Stylus Pressure Error: The too small or too large pressure applied on a

workpiece while measuring, causes stylus pressure.

c.Avoidable Error: These errors occurs due to parallax, non-alignment of

workpiece centres, incorrect location of measuring instrument, and

misalignment of the centre line of a workpiece.

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

ERRORS IN MEASUREMENT

Random Error: Random errors are accidental, non-consistent in nature and as

they occur randomly, they cannot be eliminated since no definite cause can be

located.

Small variations in the position of setting standards and the workpiece, slight

displacement of lever joints in instruments are likely sources of this type of

error.

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

MEASUREMENT STANDARDS

There are three types of measurement standards: (Standards and their

Evolution)

1.Line Standard

2.End Standard

3.Wavelength Standard

1.Line Standard: According to the line standard, the yard or metre is defined as

the distance between inscribed lines on a bar of metal under certain conditions of

temperature and support.

The metre is defined as 1650763.73 wavelengths of the orange radiation in

vaccum of krypton-86 .

The Yard is defined as 0.9144 metre. This is equivalent to 1509458.35

wavelengths of the same radiation.

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

MEASUREMENT STANDARDS

a. The Imperial Standard Yard: It is made of a one-inch square cross section bronze

bar (82% copper, 13% tin, 5% zinc) and is 38 inches long. The bar has a ½ inch

dia* ½ inch deep hole, which are fitted with a 1/10th inch dia gold plug.

The yard is defined as the distance between two central transverse lines on the plugs

when the temperature of the bar is constant at 62°F and the bar is supported on

rollers in a specified manner to prevent flexure, the distance being taken at the point

midway between the two longitudinal lines at 62°F for occasional comparison.

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

MEASUREMENT STANDARDS

b. International Standard Prototype Metre: The metre is the distance

between the centre portions of two lines engraved on the polished surface

of a bar (prototype) made up of platinum (90%) – iridium (10%) alloy

having a unique crossection.

• This bar is kept at 0°C and under normal atmospheric pressure.

• The metric standard, when in use, is supported at two points by two rollers

of at least one-cm diameter, symmetrically situated in the horizontal plane,

and 589 mm apart.

• According to this standard, the length of one meter is defined as the

straight line distance, at 0°C between the centre portion of a pure platinum-

iridium alloy of a total length of 1000-mm and having a web cross section.

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

MEASUREMENT STANDARDS

International Standard Prototype Metre

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

MEASUREMENT STANDARDS

2. End Standard: End standards, in the form of the bars and slip gauges are

used for all practical measurements in workshops and general use in

precision engineering in standard laboratories. In case of vernier calipers

and micrometers, the job is held between the jaws/anvils of the measuring

instrument and the corresponding reading is noted, while a length bar and

slip gauges are used to set the required length to be used as a reference

dimension.

a. End Bar : End bars made of steel having cylindrical cross section of 22.2

mm diameter with the faces lapped and hardened at the ends are available

in sets of various lengths.

End bars are made from high-carbon chromium steel, ensuring that faces

are hardened to 64RC.The bars have a round section of 30mm for greater

stability. Both the ends are threaded, precision lapped to meet requirements

of finish, flatness and gauge length. These are available up to 500 mm in

grades 0,1,2 in an 8-piece set.

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

MEASUREMENT STANDARDS

b. Slip Gauges: Slip gauges are practical end standards and can be used in linear

measurements in many ways. Slip Gauges are rectangular blocks of hardened and

stabilized high-grade cast steel or the ceramic compound zirconium oxide (ZrO 2)

having dimensions of 9mm wide, 30 to 35 mm long cross section.

The length of a slip gauge is strictly the dimension which it measures – in some slip

gauges it is the shortest dimension and in the larger slip gauges it is the longest.

Slip Gauges are made according to the following standards:

IS 2984-1981, Metric BS-4311:1968, Imperial BS.888.1950, DIN: 861-1988, JIS B

7506-1978.

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

MEASUREMENT STANDARDS

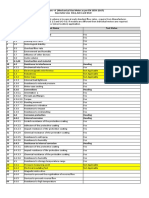

According to accuracy, slip gauges are classified as follows:

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

MEASUREMENT STANDARDS

Measuring faces of slip gauges are forced and wrung against each other so that

the gauges stick together. This is known as wringing of slip gauges.

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

MEASUREMENT STANDARDS

Wavelength Standards: Line and end standards are physical standards and are

made up of materials that can change their size with temperature and other

environmental conditions. The correct lab conditions are required to be maintained

so that the length standard remains unchanged.

High sensitivity length measurements are therefore very important because of high

accuracy.

The CGPM (Conference Generale des Poids et Mesures) adopted a definition of the

metre in terms of the wavelength in vaccum of the radiation corresponding to a

transition between specified energy levels of the krypton-86 atom.

In 1960, orange radiation of the isotope krypton-86 used in a hot-cathode discharge

lamp maintained at a temperature of 63K, was selected to define the metre. The

metre was then defined as equal to 1650763.73 wavelengths of the red-orange

radiation of the krypton isotope-86 gas.

1 metre = 1650763.73 wavelengths and,

I Yard = 0.9144 metre = 0.9144 * 1650763.73 wavelengths

= 1509458.3 wavelengths

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

MEASUREMENT STANDARDS

Wavelength Standards: Material standards are liable to destruction and their

dimensions change slightly with time. But with the monochromatic light we have

the advantage of constant wavelength and since the wavelength is not a physical

one, it need not be preserved. This is reproducible standard of length, and the error

of reproduction can be of the order of 1 part in 100 millions. It is because of this

reason that International Standard measures the metre in terms of wavelength of

krypton 86.

Advantages of wavelength standards

•Not influenced by variation in environment, temperature etc.

•No need to store it under security and thus no fear of destroyed.

•Easily available to all.

•Higher accuracy

•It is easily reproducible. (lecture 3 finish)

Saturday 28 August 2021 LOVELY PROFESSIONAL UNIVERSITY

You might also like

- EXPERIMENT 1. Measurements and ErrorsDocument18 pagesEXPERIMENT 1. Measurements and ErrorsBrylle Acosta100% (1)

- Engineering Metrology and Measurements NotesDocument131 pagesEngineering Metrology and Measurements NotesBALAMUGUNDAN91% (32)

- 1773 DIN EN - EnglischDocument8 pages1773 DIN EN - EnglischZmeulZmeilorNo ratings yet

- Theory of errorsAADocument5 pagesTheory of errorsAAmrunmayeeNo ratings yet

- Unit 1Document23 pagesUnit 1Udayakumar MohanNo ratings yet

- SMEA1301Document137 pagesSMEA1301Nandha Gopal SenthilnathanNo ratings yet

- SPR 1202 Engineering Metrology: Technical TermsDocument23 pagesSPR 1202 Engineering Metrology: Technical TermsBHOOMINo ratings yet

- MI UNIT-I Lec5-Types of ErrorsDocument17 pagesMI UNIT-I Lec5-Types of ErrorsPratik ANo ratings yet

- Venky Unit-IVDocument5 pagesVenky Unit-IVVenkateshYadavCivarlaNo ratings yet

- Me TrologyDocument341 pagesMe TrologyArpit Kumar JainNo ratings yet

- Outcomes: UnderstandDocument18 pagesOutcomes: UnderstandHundaol FekaduNo ratings yet

- Unit-I Concepts of MeasurementDocument33 pagesUnit-I Concepts of Measurementmuru0105No ratings yet

- Instrument NotesDocument40 pagesInstrument Notesummehr2017No ratings yet

- Errors in Measurement Mathematics in PhysicsDocument21 pagesErrors in Measurement Mathematics in PhysicsMark RamosNo ratings yet

- Introduction To Errors and CorrectionsDocument5 pagesIntroduction To Errors and CorrectionsHoward GhanaNo ratings yet

- Basic Principles of Engineering MetrologyDocument25 pagesBasic Principles of Engineering MetrologyRay DebashishNo ratings yet

- FME UNIT-5 Notes Part-1Document44 pagesFME UNIT-5 Notes Part-1Neel's Official100% (1)

- Accuracy and ErrorDocument5 pagesAccuracy and Errormahesh bhattaraiNo ratings yet

- Electrical and Electronincs MeasurementsDocument51 pagesElectrical and Electronincs Measurementsrao asadNo ratings yet

- Modul Lengkap EE101 MeasurementDocument104 pagesModul Lengkap EE101 MeasurementAtha AillahNo ratings yet

- Lecture-6-Uncertainity and Errorin MeasurementDocument35 pagesLecture-6-Uncertainity and Errorin MeasurementDANIEL WELDAYNo ratings yet

- Unit 1: Generalized Measurement SystemDocument51 pagesUnit 1: Generalized Measurement Systemanadinath sharmaNo ratings yet

- 15EC34TDocument131 pages15EC34Tmadhurya86No ratings yet

- MMT Notes1Document34 pagesMMT Notes1sajinirajithNo ratings yet

- Module 1 Introduction To Metrology PDFDocument10 pagesModule 1 Introduction To Metrology PDFhegdemachaNo ratings yet

- Engineering Metrology and Measurements NotesDocument127 pagesEngineering Metrology and Measurements NotesNagendar SelvakumarNo ratings yet

- The Importance of MetrologyDocument7 pagesThe Importance of MetrologyElmahdi OumiaNo ratings yet

- Introduction To Linear MetrologyDocument71 pagesIntroduction To Linear MetrologyDivakaran MullathNo ratings yet

- Instrumentation ManualDocument114 pagesInstrumentation Manualqasim awaisNo ratings yet

- Solution For Individual Assignment1 of MthedologyDocument19 pagesSolution For Individual Assignment1 of MthedologyTame PcAddictNo ratings yet

- Metrology-and-Measurements-Notes MCQDocument10 pagesMetrology-and-Measurements-Notes MCQUjjwal kecNo ratings yet

- Chapter One of Adjustment ComputationDocument4 pagesChapter One of Adjustment ComputationGemechu KotolaNo ratings yet

- What Are Errors in Measurement? Types of Errors With CalculationDocument8 pagesWhat Are Errors in Measurement? Types of Errors With CalculationMahlatse BaloyiNo ratings yet

- Metrology and MeasurementsDocument69 pagesMetrology and MeasurementsVishal PatilNo ratings yet

- Uncertainty AnalysisDocument29 pagesUncertainty AnalysisAmna RashidNo ratings yet

- Class 3,4 - FinalDocument32 pagesClass 3,4 - FinalDINESH DHANABALANNo ratings yet

- EEGI 3131-Adjustment Computations-Lesson 2Document20 pagesEEGI 3131-Adjustment Computations-Lesson 2Jecinta wNo ratings yet

- Physics Project by DurvaDocument10 pagesPhysics Project by DurvaDurva YerunkarNo ratings yet

- Errors of Measurement, and ROLE of ERROR in Physics: Group 1Document41 pagesErrors of Measurement, and ROLE of ERROR in Physics: Group 1Kaysean MielNo ratings yet

- Engineering Metrology and MeasurementsDocument128 pagesEngineering Metrology and MeasurementsArvind Bhosale100% (7)

- Introduction To Phy113Document38 pagesIntroduction To Phy113okparaobogheneNo ratings yet

- TOPIC 1 Measurement DevicesDocument32 pagesTOPIC 1 Measurement DevicesBryan MatthiasNo ratings yet

- Physics Project FileDocument24 pagesPhysics Project FileManoj Kumar100% (1)

- What Are Errors in Measurement? Types of Errors With CalculationDocument4 pagesWhat Are Errors in Measurement? Types of Errors With Calculationprerna raiNo ratings yet

- Engineering Metrology and Measurements Unit 1 2Document82 pagesEngineering Metrology and Measurements Unit 1 2scorpionarnold100% (1)

- 00-Basic Concepts of Measurement-1Document8 pages00-Basic Concepts of Measurement-1Jaya BayuNo ratings yet

- MeasurmentDocument29 pagesMeasurmentسيمو بشيريNo ratings yet

- Instrumention Group Assignmnt1Document6 pagesInstrumention Group Assignmnt1Craig JamuNo ratings yet

- Emi Discriptive Typeall Units Material.Document123 pagesEmi Discriptive Typeall Units Material.Vamsi KrishnaNo ratings yet

- Topic 1Document32 pagesTopic 1AzWia MkhtrNo ratings yet

- WWW - Mechanical.in: Unit-I Concepts of MeasurementDocument33 pagesWWW - Mechanical.in: Unit-I Concepts of Measurementharim_meNo ratings yet

- Chapter 2 - General Characterstics of MeasurmentDocument46 pagesChapter 2 - General Characterstics of Measurmentgideykibrom80No ratings yet

- FMEM - UNIT-4 NotesDocument54 pagesFMEM - UNIT-4 NotesBodhi SealNo ratings yet

- Measurements and Sources of Errors1Document32 pagesMeasurements and Sources of Errors1Umer MushirNo ratings yet

- Chapter 1Document16 pagesChapter 1MulugetaNo ratings yet

- Theory of Physical and Technical MeasurementFrom EverandTheory of Physical and Technical MeasurementRating: 5 out of 5 stars5/5 (1)

- Overview Of Bayesian Approach To Statistical Methods: SoftwareFrom EverandOverview Of Bayesian Approach To Statistical Methods: SoftwareNo ratings yet

- Embedded Mechatronic Systems: Analysis of Failures, Predictive ReliabilityFrom EverandEmbedded Mechatronic Systems: Analysis of Failures, Predictive ReliabilityNo ratings yet

- Measuring Quality Improvement in Healthcare: A Guide to Statistical Process Control ApplicationsFrom EverandMeasuring Quality Improvement in Healthcare: A Guide to Statistical Process Control ApplicationsNo ratings yet

- Calibration of Asphalt DistributorDocument4 pagesCalibration of Asphalt DistributorvnilNo ratings yet

- Activity 1 Pacing Tekiner, Aldrien CE1Document3 pagesActivity 1 Pacing Tekiner, Aldrien CE1Aldrien TekinerNo ratings yet

- Paper - Estimating Carrying Capacity in A Natural Protected Area As A Conservation StrategyDocument7 pagesPaper - Estimating Carrying Capacity in A Natural Protected Area As A Conservation StrategysendalmasjidNo ratings yet

- Installation Instructions For Line Mounted ROMET Meters: RM600 - RM56000 RM16 - RM1600 G10 - G1000Document2 pagesInstallation Instructions For Line Mounted ROMET Meters: RM600 - RM56000 RM16 - RM1600 G10 - G1000Eies Líderes En CapacitaciónNo ratings yet

- Non Standard UnitDocument4 pagesNon Standard UnitGreg ManNo ratings yet

- Bankgyan Practice Set 2Document277 pagesBankgyan Practice Set 2vivek tiwariNo ratings yet

- Handbook of Ship Calculations, Construction and OperationDocument776 pagesHandbook of Ship Calculations, Construction and OperationYuriyAK91% (11)

- Mathematics April Paper 2 2019 Solved PaperDocument16 pagesMathematics April Paper 2 2019 Solved PaperArman BajajNo ratings yet

- Converting Metric Distances: Answer KeyDocument2 pagesConverting Metric Distances: Answer KeyDong Phan Thi AnhNo ratings yet

- CN111322209A - Gravity Engine - Google PatentsDocument7 pagesCN111322209A - Gravity Engine - Google PatentsShyz ByzNo ratings yet

- CH 01Document11 pagesCH 01msy83635No ratings yet

- Ga251 Fieldwork For Physical Geography - Hydrological Studies - Sept 2001 Series 13 Autumn Issue Unit 251Document4 pagesGa251 Fieldwork For Physical Geography - Hydrological Studies - Sept 2001 Series 13 Autumn Issue Unit 251eeeeeksNo ratings yet

- Mechanical Meter Testing - (Gas Metro EN1359)Document3 pagesMechanical Meter Testing - (Gas Metro EN1359)Aladdin AdelNo ratings yet

- Part 12 Calibration ReportsDocument14 pagesPart 12 Calibration ReportsPaul KIMNo ratings yet

- High Pressure Calibration: Fluxi 2000/TZDocument5 pagesHigh Pressure Calibration: Fluxi 2000/TZBELCY LIZARAZONo ratings yet

- RFI BBS For Drain - Cast In-Situ (950 MM)Document4 pagesRFI BBS For Drain - Cast In-Situ (950 MM)HegdeVenugopalNo ratings yet

- ME4105 NUS Offshore Oil and Gas Technology Exercise 1 ADocument5 pagesME4105 NUS Offshore Oil and Gas Technology Exercise 1 Afardin77100% (1)

- 4th English Maths 2Document136 pages4th English Maths 2madhumster1240No ratings yet

- GSM CalculationDocument2 pagesGSM Calculationtarek113100% (1)

- "IAP-in-a-Box" Testing Hood Specifications SheetDocument3 pages"IAP-in-a-Box" Testing Hood Specifications Sheetprozoam21No ratings yet

- Water Test BenchDocument3 pagesWater Test Benchswizar pradhanNo ratings yet

- Spayed Wing Wall BBS 162+911 RHS FinalDocument2 pagesSpayed Wing Wall BBS 162+911 RHS FinalHegdeVenugopalNo ratings yet

- APCircular Motion LabDocument4 pagesAPCircular Motion LabLidya Nia KurniawanNo ratings yet

- Review Mathematics 2 - V3Document6 pagesReview Mathematics 2 - V3L'arc WillNo ratings yet

- Build A Cubic Meter LessonDocument3 pagesBuild A Cubic Meter Lessonapi-253637444No ratings yet

- Vibration Meter Model VB450: User GuideDocument7 pagesVibration Meter Model VB450: User GuideManuel Morales EncinasNo ratings yet

- Dasar PengukuranDocument18 pagesDasar Pengukuranrnurwahid.workNo ratings yet

- Chapter Brief Physics IX Unit 1 Physical Quantities and Measurement (2022-23)Document7 pagesChapter Brief Physics IX Unit 1 Physical Quantities and Measurement (2022-23)shahaniali051No ratings yet

- Class XI Final Physics Manual-1Document27 pagesClass XI Final Physics Manual-1Ahmed haatimNo ratings yet