Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

51 viewsTwist

Twist

Uploaded by

Sivakumar KThis document discusses yarn twist, including definitions, measurement, and testing methods. It defines twist as spiral turns that hold fibers together in yarn, giving strength. Twist is measured in turns per unit length and indicated by direction (S or Z). Twist factor normalizes for yarn count. Various testing methods are described, including the twist contraction method used in tension-type testers, where untwisting and re-twisting causes length changes.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You might also like

- Yarn Numbering System - CountDocument45 pagesYarn Numbering System - CountvasineyNo ratings yet

- Design and Analysis of Worm GearDocument26 pagesDesign and Analysis of Worm Gearshahzadali0786100% (2)

- Anjali Jindal - Exp No.1 - Melde's ExperimentDocument9 pagesAnjali Jindal - Exp No.1 - Melde's ExperimentyuhuNo ratings yet

- ST Interview GuideDocument79 pagesST Interview GuideElena Marinaki100% (4)

- Legal Research On Rape in The PhilippinesDocument28 pagesLegal Research On Rape in The PhilippinesRbee C. Ablan100% (8)

- HARP Character Sheet PDFDocument4 pagesHARP Character Sheet PDFBarbarianYNo ratings yet

- Yarn TwistDocument8 pagesYarn Twisthemonto100% (1)

- Unit - IiDocument27 pagesUnit - IiJoseph KuruvilaNo ratings yet

- Flat Belt Drive Lecture Note - Shu PDFDocument64 pagesFlat Belt Drive Lecture Note - Shu PDFraj gangwarNo ratings yet

- Chapter Four Torsion of Circular Shafts & Power TransmissionDocument48 pagesChapter Four Torsion of Circular Shafts & Power TransmissionYalem MesfinNo ratings yet

- Yarn Twist TTQC 1 Lecturer, TE Dept of BUFTDocument9 pagesYarn Twist TTQC 1 Lecturer, TE Dept of BUFTcario galleryNo ratings yet

- Belt, Rope and Chain Drives: Types of Belt Drives: 1.light Drives. Small Powers TransmissionDocument31 pagesBelt, Rope and Chain Drives: Types of Belt Drives: 1.light Drives. Small Powers Transmissionommprakash malikNo ratings yet

- 2018PPE8005 - Design of V Belt (Part 2)Document15 pages2018PPE8005 - Design of V Belt (Part 2)Kartik AggarwalNo ratings yet

- Warp Let Off Motion (Pengluluran Benang Lusi)Document12 pagesWarp Let Off Motion (Pengluluran Benang Lusi)sarah syahidatul fNo ratings yet

- Thread Cutting, Tapping and BroachingDocument95 pagesThread Cutting, Tapping and BroachingKundan PatilNo ratings yet

- Unit 4 Power TransmissionDocument92 pagesUnit 4 Power TransmissionMohit BagurNo ratings yet

- Free VibrationDocument55 pagesFree Vibrationkabilanr100% (1)

- Machine Elements 3-Belt DrivesDocument62 pagesMachine Elements 3-Belt Drivesimam hanafiNo ratings yet

- Flat BeltsDocument44 pagesFlat BeltsArnoah RamirezNo ratings yet

- Study of TwistDocument7 pagesStudy of TwistMoshiur RahmanNo ratings yet

- Chapter 4 Design of Power Transmission ElementsDocument43 pagesChapter 4 Design of Power Transmission ElementsMuhamad Arif100% (2)

- Kinematics of Machinery UNIT-2: Steering Mechanisms & Belt, Rope and Chain DrivesDocument74 pagesKinematics of Machinery UNIT-2: Steering Mechanisms & Belt, Rope and Chain DrivesPuli SatishNo ratings yet

- Chapter 4.1 (Belts) 2016 E.CDocument28 pagesChapter 4.1 (Belts) 2016 E.CmulukenuniNo ratings yet

- Chapter 2 Fabric DimensionsDocument9 pagesChapter 2 Fabric Dimensionskhaledtex98No ratings yet

- Belt & Rope DrivesDocument26 pagesBelt & Rope Drivesarpit089100% (1)

- Lab I Dr. Imran Ali: Mct-211 L Engineering Mechanics (Dynamics)Document8 pagesLab I Dr. Imran Ali: Mct-211 L Engineering Mechanics (Dynamics)Mian Imran AliNo ratings yet

- Mech and Mach CH 2Document48 pagesMech and Mach CH 2SYEDA VANIZA NAVED STUDENTNo ratings yet

- Belt and Chain DriveDocument37 pagesBelt and Chain DriveeldhosekjnitNo ratings yet

- Belt Drive and Power TransmissionDocument31 pagesBelt Drive and Power TransmissionThato TumeloNo ratings yet

- Design & Analysis of Worm & Worm GearDocument32 pagesDesign & Analysis of Worm & Worm Gearshahzadali0786100% (1)

- Warp KnittingDocument93 pagesWarp KnittingSivakumar K100% (1)

- Shaft 2013Document23 pagesShaft 2013Rinardi SoetjiptoNo ratings yet

- Determination of Twist Per Inch of Yarn LengthDocument5 pagesDetermination of Twist Per Inch of Yarn LengthNaimul Hasan67% (3)

- Unit 3Document120 pagesUnit 3ramesh_h2002No ratings yet

- Survey Pratical KnowledgeDocument184 pagesSurvey Pratical KnowledgeSuman JyotiNo ratings yet

- Structural Mechanics Ii (CE 2102) : Dr. Thanuja KulathungaDocument51 pagesStructural Mechanics Ii (CE 2102) : Dr. Thanuja KulathungaJanith amarawickramaNo ratings yet

- Chapter 7 - Torsion - Civil PDFDocument50 pagesChapter 7 - Torsion - Civil PDFcoded coderNo ratings yet

- Yarn TwistDocument36 pagesYarn TwistMd Ahasan HabibNo ratings yet

- Kathmandu University School of Engineering Department of Mechanical EngineeringDocument27 pagesKathmandu University School of Engineering Department of Mechanical EngineeringBikram GCNo ratings yet

- Roving FrameDocument99 pagesRoving Frameirfanfakhar2No ratings yet

- Chapter IV (LoomShedding)Document52 pagesChapter IV (LoomShedding)Prabhakaran J100% (1)

- UNIT VII Angular MeasurementsDocument99 pagesUNIT VII Angular MeasurementsAkash PatilNo ratings yet

- Chapter5 SpringDocument36 pagesChapter5 SpringRajendra RachalwarNo ratings yet

- IndexingDocument44 pagesIndexingKumarGaurav75% (4)

- Micrometer: Chetan Kumar R SPG 16 1537Document11 pagesMicrometer: Chetan Kumar R SPG 16 1537chetanNo ratings yet

- Design of Helical SpringsDocument60 pagesDesign of Helical SpringsKelvin Kindice MapurisaNo ratings yet

- Classification of Shuttle Picking MechanismDocument14 pagesClassification of Shuttle Picking MechanismSANJIT JANANo ratings yet

- Screwthreadmeasurement 170418161010 PDFDocument30 pagesScrewthreadmeasurement 170418161010 PDFejkiranNo ratings yet

- Beat UpDocument10 pagesBeat UpAsifur RahmanNo ratings yet

- Screw Thread MeasurementDocument55 pagesScrew Thread MeasurementMadhuNo ratings yet

- Yarn TwistDocument9 pagesYarn Twistamar9247100% (1)

- Chapter 7 Transverse Shear 111Document55 pagesChapter 7 Transverse Shear 111حاتم الشمرانيNo ratings yet

- Knitting Technology II: Lecture Note 12, 13 &14 Etsehiwot Yisma 2019Document16 pagesKnitting Technology II: Lecture Note 12, 13 &14 Etsehiwot Yisma 2019fekadeNo ratings yet

- Lecture 2Document16 pagesLecture 2Yared FikreNo ratings yet

- File 51Document9 pagesFile 51Tolenuf AbeyaNo ratings yet

- 8/20/2014 1 Hareesha N Gowda, DSCE, Blore-78Document77 pages8/20/2014 1 Hareesha N Gowda, DSCE, Blore-78Santosh DabholeNo ratings yet

- Metrology1 PDFDocument76 pagesMetrology1 PDFDeepankumar AthiyannanNo ratings yet

- Gear Measurement and TestingDocument52 pagesGear Measurement and TestingHemanth Kumar MadhuNo ratings yet

- Weft KnittingDocument177 pagesWeft KnittingV B NagarajanNo ratings yet

- Belt Drives BasicsDocument28 pagesBelt Drives BasicsSUMIT MALUSARENo ratings yet

- Roving 180515070435Document70 pagesRoving 180515070435Bubuna Palei100% (1)

- Importance of Analysis of Fabric SampleDocument5 pagesImportance of Analysis of Fabric SampleRavi Jain75% (4)

- PickingDocument17 pagesPickingSivakumar KNo ratings yet

- Unit 1 Intelligent Textiles For Medical Applications An OverviewDocument44 pagesUnit 1 Intelligent Textiles For Medical Applications An OverviewSivakumar KNo ratings yet

- Unit 1 Functional GarmentsDocument60 pagesUnit 1 Functional GarmentsSivakumar KNo ratings yet

- Qbank Ietci 2019 2020 OddDocument4 pagesQbank Ietci 2019 2020 OddSivakumar KNo ratings yet

- Qbank FM II 2019-2020 EvenDocument4 pagesQbank FM II 2019-2020 EvenSivakumar KNo ratings yet

- Garment DyeingDocument25 pagesGarment DyeingSivakumar KNo ratings yet

- Advanced SpinningDocument130 pagesAdvanced SpinningSivakumar K100% (5)

- Draw FrameDocument60 pagesDraw FrameSivakumar K100% (1)

- Learner Analysis QuestionsDocument1 pageLearner Analysis Questionsapi-323641842No ratings yet

- Crime: Functionalist, Strain, SubculturalDocument8 pagesCrime: Functionalist, Strain, SubculturalCharlotte BrennanNo ratings yet

- Public Info - FAKE NEWS - 17!10!04 (Reviewed)Document263 pagesPublic Info - FAKE NEWS - 17!10!04 (Reviewed)Calvin Patrick DomingoNo ratings yet

- Virtusa PPDocument6 pagesVirtusa PPGowri Prasanna KusuNo ratings yet

- PBL NMR 1Document5 pagesPBL NMR 1andiNo ratings yet

- Access To Childbirth CareDocument67 pagesAccess To Childbirth CareemeNo ratings yet

- Haddad v. Indiana Pacers Et Al - Document No. 82Document17 pagesHaddad v. Indiana Pacers Et Al - Document No. 82Justia.com100% (1)

- Placement Exam FaqDocument2 pagesPlacement Exam FaqsglovescarsNo ratings yet

- Hall of FameDocument2 pagesHall of FameAhmed AdnanNo ratings yet

- This Study Resource Was: AnswerDocument1 pageThis Study Resource Was: AnswerJoel DufaleNo ratings yet

- Ind AS 115Document36 pagesInd AS 115yashNo ratings yet

- PEOPLE Vs Felipe Demate Et AlDocument13 pagesPEOPLE Vs Felipe Demate Et AlAlexa Neri ValderamaNo ratings yet

- Rabagia - MatenTertiary Tectonic and Sedimentological Evolution of The South Carpathians Foredeep: Tectonic Versus Eustatic Controlco (1999)Document22 pagesRabagia - MatenTertiary Tectonic and Sedimentological Evolution of The South Carpathians Foredeep: Tectonic Versus Eustatic Controlco (1999)Lex AlexaNo ratings yet

- GRE Physics Test: Practice BookDocument91 pagesGRE Physics Test: Practice BookGalo CandelaNo ratings yet

- Kiecolt-Glaser - PNI 2002Document11 pagesKiecolt-Glaser - PNI 2002LaviniaNo ratings yet

- Stalwar DX LiteratureDocument2 pagesStalwar DX LiteratureAnonymous cbXdPkXoNo ratings yet

- 10th Aug - 2022Document39 pages10th Aug - 2022Ranjeet SinghNo ratings yet

- Lesson PlanDocument3 pagesLesson Planapi-530241350No ratings yet

- MTB-Lesson 3Document4 pagesMTB-Lesson 3Clavillas GrachelleNo ratings yet

- Docsity English in Italy Linguistic Educational and Professional ChallengesDocument27 pagesDocsity English in Italy Linguistic Educational and Professional Challengeschiarafoglia74No ratings yet

- Financing Foreign Trade PDFDocument16 pagesFinancing Foreign Trade PDFHemanth Kumar89% (9)

- The Field of Engineering ManagementDocument15 pagesThe Field of Engineering ManagementBelle SolaceNo ratings yet

- VEKP Deadlock IssueDocument5 pagesVEKP Deadlock IssueDuy ThanhNo ratings yet

- Republic Vs Drugmake R'S LAB (GR NO. 190837 MARCH 5, 2014)Document10 pagesRepublic Vs Drugmake R'S LAB (GR NO. 190837 MARCH 5, 2014)Harrison sajorNo ratings yet

- How To Speak English FluentlyDocument129 pagesHow To Speak English FluentlyMARIA ANGELES100% (3)

- RS 1803 HFS BP Enterprise Artificial Intelligence (AI) Services 2018Document70 pagesRS 1803 HFS BP Enterprise Artificial Intelligence (AI) Services 2018pantmukulNo ratings yet

- Tan Sri Ali Hashim (JCORP)Document7 pagesTan Sri Ali Hashim (JCORP)syafiqahanidaNo ratings yet

Twist

Twist

Uploaded by

Sivakumar K0 ratings0% found this document useful (0 votes)

51 views27 pagesThis document discusses yarn twist, including definitions, measurement, and testing methods. It defines twist as spiral turns that hold fibers together in yarn, giving strength. Twist is measured in turns per unit length and indicated by direction (S or Z). Twist factor normalizes for yarn count. Various testing methods are described, including the twist contraction method used in tension-type testers, where untwisting and re-twisting causes length changes.

Original Description:

yarn twist - tpes

Original Title

twist

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses yarn twist, including definitions, measurement, and testing methods. It defines twist as spiral turns that hold fibers together in yarn, giving strength. Twist is measured in turns per unit length and indicated by direction (S or Z). Twist factor normalizes for yarn count. Various testing methods are described, including the twist contraction method used in tension-type testers, where untwisting and re-twisting causes length changes.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

51 views27 pagesTwist

Twist

Uploaded by

Sivakumar KThis document discusses yarn twist, including definitions, measurement, and testing methods. It defines twist as spiral turns that hold fibers together in yarn, giving strength. Twist is measured in turns per unit length and indicated by direction (S or Z). Twist factor normalizes for yarn count. Various testing methods are described, including the twist contraction method used in tension-type testers, where untwisting and re-twisting causes length changes.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 27

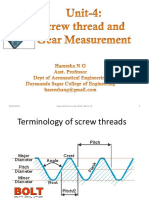

Yarn Twist

Yarn Twist: Definitions of twist, determination

of twist of single and ply yarn.

Learning outcomes

1. Describe the working principle of single yarn

and ply yarn twister

2. Illustrate the concepts of yarn twist, twist

factor and their relationship to yarn count

Twist :

• It is the measure of the spiral turns given to

yarn in order to hold the fibres or threads

together.

• Twist is necessary to give coherence and

strength to the yarn.

• Twist is primarily inserted into a staple yarn to

hold the constituent fibres together, thus giving

strength to the yarn.

The effects of the twist are twofold:

As the twist increases,

• The lateral force holding the fibres together is

increased so that more fibres could be contributed

to the overall strength of the yarn.

• The angle that the fibres make with the yarn axis

increases, which prevents them from developing

their maximum strength, which occurs when they

are oriented in the direction of the applied force.

• As a result, at certain point the yarn strength

reaches a maximum value after which the strength

is reduced as the twist is increased still further

Quantity of Twist

• In a given length l of yarn, let there be n turns.

• Turns per unit length = n/l

• The amount of twist is usually expressed in

Turns per Centimetre (TPC)

Turns per Inch (TPI)

Turns per Meter (TPM)

Direction of twist

• The direction twist is expressed as either

S – Twist or

Z - Twist

S-twist:

• The twist in yam due to which its spirals are in line

with the central portion of the letter S, when the

yarn is held in a vertical position.

Z-twist:

• The twist in yarn due to which its spirals are in line

with the central portion of the letter Z, when the

yarn is held in a vertical position.

Twist Factor or Twist Multiplier

• The amount of twist in terms of TPI or TPM

does not take into account the count (thickness

or diameter) of the yarn.

• A 20s yarn with 20 tpi and a 80s yarn the same

20 tpi will have vastly different properties.

• By using an expression known as ‘twist factor’

or ‘twist multiplier’ it is possible to appreciate

the twist character of a yarn even without the

knowledge of the count of the yarn.

Twist factor (K) is defined as:

K= (turns/unit length)/√count

Value of K differs with each count system.

• (a) In Tex (direct system): K= TPM x √Tex

• (b) Indirect system: K= TPI /√Cotton count

TWIST = TM × √count

Twist Per Inch (TPI) = Twist Multiplier X √count

Twist Per Inch

Twist Multiplier (TM) = ----------------------

√count

Twist Angle

• The twist angle θ is the angle between a tangent to

the helix formed by the fiber and the yarn axis.

• By “unrolling” the surface layer we see that the

fibers becomes the hypotenuse of a right-angled

triangle.

• Let the yarn diameter be D unit and let be the

length of yarn occupied by one complete turn of

twist. Then, tanѲ = ∏D /L

• The greater the diameter of the yarn, the larger is

the angle produced by on turn of twist. As 1/L is

equivalent to turns per unit length then:

Classification twist tester

• The Straightened Fibre Method

- Single yarn twist tester

- Continuous Twist Tester

• Twist Contraction Method

Tension types twist tester

• Twist to break method

• Optical method

• Take-up Twist tester

• Electronic twist tester

Twist Contraction Method

• This method is called as Untwist and Retwist.

• The tension type twist tester is working on the principle of

twist contraction.

• Suppose a yarn is twisted in Z direction and has a length L.

• Let the twist be completely removed to produce an untwisted

strand of length L + C where C is the contraction due to

twist.

• If the strand is now twisted in S way with a number of turns

equal to those removed, it can be expected that the strand will

again contract to the original length L.

• This method is suitable for single yams.

• Tension scale reading

= 156 / English count

• The tension-type twist tester as shown above

has two jaws (fixed and rotating) for fixing the

yarn.

• The position of the non-rotating jaw is variable

according to the gauge length.

• The pointer connected to the rotating jaw

moves over a scale having two graduations.

• The rotating jaw shaft has a worm at the middle to give drive

to the mechanical counter.

• A pinion is provided at the other end of the shaft and is rotated

by the hand wheel through the gear.

• As the handle rotates, the rotating jaw rotates and the rotations

are transferred to the mechanical counter which consists of

two discs, one at the bottom and one at the top.

• The top disc is graduated into 100 divisions and has 100 teeth.

• Placed over the top disc is a pointer which is connected to the

bottom disc that has 99 teeth.

• Therefore, for one revolution of the top disc, the pointer

moves only 99 teeth and always lags one tooth.

• This helps in determining the dial reading more than 100.

• The rotating jaw assembly has a spring-loaded

knob.

• By pushing this, the two discs of the counter can

be disengaged from the worm for zero setting.

• There is an index mark on the frame of the

rotating jaw.

• For zero setting, the pointer and the zero mark

of the counter should coincide with the mark on

the frame.

Procedure

• The two discs are disengaged from the worm and

are rotated such that the pointer and zero mark

coincide with the index mark.

• The yarn is first gripped in the fixed clamp. After

being led through the rotating jaw, the yarn is

pulled through until the pointer lies opposite a

zero line on a small quadrant scale.

• The jaw is then closed.

• At this stage, the specimen is under a small

tension and has a nominal length (gauge length).

• As the twist is removed the yarn gets extended and

the pointer reaches a vertical position.

• Eventually all the twist is taken out, but the jaw is

kept rotating in the same direction until sufficient

twist has been inserted to bring the pointer back to

the zero mark.

• When the pointer coincides with the mark, the dial

reading is noted and the twists per inch can be

calculated using the following formula:

• Twist per inch = dial reading / (gauge length × 2)

Take-up Twist tester

• Take-up twist tester consists of two jaws for

fixing the yarn rotating and non – rotating.

• The position of the non-rotating jaw can be

varied to test the material at different gauge

length.

• To base of the instrument, a scale is fixed.

• Load = tex / 2 g

You might also like

- Yarn Numbering System - CountDocument45 pagesYarn Numbering System - CountvasineyNo ratings yet

- Design and Analysis of Worm GearDocument26 pagesDesign and Analysis of Worm Gearshahzadali0786100% (2)

- Anjali Jindal - Exp No.1 - Melde's ExperimentDocument9 pagesAnjali Jindal - Exp No.1 - Melde's ExperimentyuhuNo ratings yet

- ST Interview GuideDocument79 pagesST Interview GuideElena Marinaki100% (4)

- Legal Research On Rape in The PhilippinesDocument28 pagesLegal Research On Rape in The PhilippinesRbee C. Ablan100% (8)

- HARP Character Sheet PDFDocument4 pagesHARP Character Sheet PDFBarbarianYNo ratings yet

- Yarn TwistDocument8 pagesYarn Twisthemonto100% (1)

- Unit - IiDocument27 pagesUnit - IiJoseph KuruvilaNo ratings yet

- Flat Belt Drive Lecture Note - Shu PDFDocument64 pagesFlat Belt Drive Lecture Note - Shu PDFraj gangwarNo ratings yet

- Chapter Four Torsion of Circular Shafts & Power TransmissionDocument48 pagesChapter Four Torsion of Circular Shafts & Power TransmissionYalem MesfinNo ratings yet

- Yarn Twist TTQC 1 Lecturer, TE Dept of BUFTDocument9 pagesYarn Twist TTQC 1 Lecturer, TE Dept of BUFTcario galleryNo ratings yet

- Belt, Rope and Chain Drives: Types of Belt Drives: 1.light Drives. Small Powers TransmissionDocument31 pagesBelt, Rope and Chain Drives: Types of Belt Drives: 1.light Drives. Small Powers Transmissionommprakash malikNo ratings yet

- 2018PPE8005 - Design of V Belt (Part 2)Document15 pages2018PPE8005 - Design of V Belt (Part 2)Kartik AggarwalNo ratings yet

- Warp Let Off Motion (Pengluluran Benang Lusi)Document12 pagesWarp Let Off Motion (Pengluluran Benang Lusi)sarah syahidatul fNo ratings yet

- Thread Cutting, Tapping and BroachingDocument95 pagesThread Cutting, Tapping and BroachingKundan PatilNo ratings yet

- Unit 4 Power TransmissionDocument92 pagesUnit 4 Power TransmissionMohit BagurNo ratings yet

- Free VibrationDocument55 pagesFree Vibrationkabilanr100% (1)

- Machine Elements 3-Belt DrivesDocument62 pagesMachine Elements 3-Belt Drivesimam hanafiNo ratings yet

- Flat BeltsDocument44 pagesFlat BeltsArnoah RamirezNo ratings yet

- Study of TwistDocument7 pagesStudy of TwistMoshiur RahmanNo ratings yet

- Chapter 4 Design of Power Transmission ElementsDocument43 pagesChapter 4 Design of Power Transmission ElementsMuhamad Arif100% (2)

- Kinematics of Machinery UNIT-2: Steering Mechanisms & Belt, Rope and Chain DrivesDocument74 pagesKinematics of Machinery UNIT-2: Steering Mechanisms & Belt, Rope and Chain DrivesPuli SatishNo ratings yet

- Chapter 4.1 (Belts) 2016 E.CDocument28 pagesChapter 4.1 (Belts) 2016 E.CmulukenuniNo ratings yet

- Chapter 2 Fabric DimensionsDocument9 pagesChapter 2 Fabric Dimensionskhaledtex98No ratings yet

- Belt & Rope DrivesDocument26 pagesBelt & Rope Drivesarpit089100% (1)

- Lab I Dr. Imran Ali: Mct-211 L Engineering Mechanics (Dynamics)Document8 pagesLab I Dr. Imran Ali: Mct-211 L Engineering Mechanics (Dynamics)Mian Imran AliNo ratings yet

- Mech and Mach CH 2Document48 pagesMech and Mach CH 2SYEDA VANIZA NAVED STUDENTNo ratings yet

- Belt and Chain DriveDocument37 pagesBelt and Chain DriveeldhosekjnitNo ratings yet

- Belt Drive and Power TransmissionDocument31 pagesBelt Drive and Power TransmissionThato TumeloNo ratings yet

- Design & Analysis of Worm & Worm GearDocument32 pagesDesign & Analysis of Worm & Worm Gearshahzadali0786100% (1)

- Warp KnittingDocument93 pagesWarp KnittingSivakumar K100% (1)

- Shaft 2013Document23 pagesShaft 2013Rinardi SoetjiptoNo ratings yet

- Determination of Twist Per Inch of Yarn LengthDocument5 pagesDetermination of Twist Per Inch of Yarn LengthNaimul Hasan67% (3)

- Unit 3Document120 pagesUnit 3ramesh_h2002No ratings yet

- Survey Pratical KnowledgeDocument184 pagesSurvey Pratical KnowledgeSuman JyotiNo ratings yet

- Structural Mechanics Ii (CE 2102) : Dr. Thanuja KulathungaDocument51 pagesStructural Mechanics Ii (CE 2102) : Dr. Thanuja KulathungaJanith amarawickramaNo ratings yet

- Chapter 7 - Torsion - Civil PDFDocument50 pagesChapter 7 - Torsion - Civil PDFcoded coderNo ratings yet

- Yarn TwistDocument36 pagesYarn TwistMd Ahasan HabibNo ratings yet

- Kathmandu University School of Engineering Department of Mechanical EngineeringDocument27 pagesKathmandu University School of Engineering Department of Mechanical EngineeringBikram GCNo ratings yet

- Roving FrameDocument99 pagesRoving Frameirfanfakhar2No ratings yet

- Chapter IV (LoomShedding)Document52 pagesChapter IV (LoomShedding)Prabhakaran J100% (1)

- UNIT VII Angular MeasurementsDocument99 pagesUNIT VII Angular MeasurementsAkash PatilNo ratings yet

- Chapter5 SpringDocument36 pagesChapter5 SpringRajendra RachalwarNo ratings yet

- IndexingDocument44 pagesIndexingKumarGaurav75% (4)

- Micrometer: Chetan Kumar R SPG 16 1537Document11 pagesMicrometer: Chetan Kumar R SPG 16 1537chetanNo ratings yet

- Design of Helical SpringsDocument60 pagesDesign of Helical SpringsKelvin Kindice MapurisaNo ratings yet

- Classification of Shuttle Picking MechanismDocument14 pagesClassification of Shuttle Picking MechanismSANJIT JANANo ratings yet

- Screwthreadmeasurement 170418161010 PDFDocument30 pagesScrewthreadmeasurement 170418161010 PDFejkiranNo ratings yet

- Beat UpDocument10 pagesBeat UpAsifur RahmanNo ratings yet

- Screw Thread MeasurementDocument55 pagesScrew Thread MeasurementMadhuNo ratings yet

- Yarn TwistDocument9 pagesYarn Twistamar9247100% (1)

- Chapter 7 Transverse Shear 111Document55 pagesChapter 7 Transverse Shear 111حاتم الشمرانيNo ratings yet

- Knitting Technology II: Lecture Note 12, 13 &14 Etsehiwot Yisma 2019Document16 pagesKnitting Technology II: Lecture Note 12, 13 &14 Etsehiwot Yisma 2019fekadeNo ratings yet

- Lecture 2Document16 pagesLecture 2Yared FikreNo ratings yet

- File 51Document9 pagesFile 51Tolenuf AbeyaNo ratings yet

- 8/20/2014 1 Hareesha N Gowda, DSCE, Blore-78Document77 pages8/20/2014 1 Hareesha N Gowda, DSCE, Blore-78Santosh DabholeNo ratings yet

- Metrology1 PDFDocument76 pagesMetrology1 PDFDeepankumar AthiyannanNo ratings yet

- Gear Measurement and TestingDocument52 pagesGear Measurement and TestingHemanth Kumar MadhuNo ratings yet

- Weft KnittingDocument177 pagesWeft KnittingV B NagarajanNo ratings yet

- Belt Drives BasicsDocument28 pagesBelt Drives BasicsSUMIT MALUSARENo ratings yet

- Roving 180515070435Document70 pagesRoving 180515070435Bubuna Palei100% (1)

- Importance of Analysis of Fabric SampleDocument5 pagesImportance of Analysis of Fabric SampleRavi Jain75% (4)

- PickingDocument17 pagesPickingSivakumar KNo ratings yet

- Unit 1 Intelligent Textiles For Medical Applications An OverviewDocument44 pagesUnit 1 Intelligent Textiles For Medical Applications An OverviewSivakumar KNo ratings yet

- Unit 1 Functional GarmentsDocument60 pagesUnit 1 Functional GarmentsSivakumar KNo ratings yet

- Qbank Ietci 2019 2020 OddDocument4 pagesQbank Ietci 2019 2020 OddSivakumar KNo ratings yet

- Qbank FM II 2019-2020 EvenDocument4 pagesQbank FM II 2019-2020 EvenSivakumar KNo ratings yet

- Garment DyeingDocument25 pagesGarment DyeingSivakumar KNo ratings yet

- Advanced SpinningDocument130 pagesAdvanced SpinningSivakumar K100% (5)

- Draw FrameDocument60 pagesDraw FrameSivakumar K100% (1)

- Learner Analysis QuestionsDocument1 pageLearner Analysis Questionsapi-323641842No ratings yet

- Crime: Functionalist, Strain, SubculturalDocument8 pagesCrime: Functionalist, Strain, SubculturalCharlotte BrennanNo ratings yet

- Public Info - FAKE NEWS - 17!10!04 (Reviewed)Document263 pagesPublic Info - FAKE NEWS - 17!10!04 (Reviewed)Calvin Patrick DomingoNo ratings yet

- Virtusa PPDocument6 pagesVirtusa PPGowri Prasanna KusuNo ratings yet

- PBL NMR 1Document5 pagesPBL NMR 1andiNo ratings yet

- Access To Childbirth CareDocument67 pagesAccess To Childbirth CareemeNo ratings yet

- Haddad v. Indiana Pacers Et Al - Document No. 82Document17 pagesHaddad v. Indiana Pacers Et Al - Document No. 82Justia.com100% (1)

- Placement Exam FaqDocument2 pagesPlacement Exam FaqsglovescarsNo ratings yet

- Hall of FameDocument2 pagesHall of FameAhmed AdnanNo ratings yet

- This Study Resource Was: AnswerDocument1 pageThis Study Resource Was: AnswerJoel DufaleNo ratings yet

- Ind AS 115Document36 pagesInd AS 115yashNo ratings yet

- PEOPLE Vs Felipe Demate Et AlDocument13 pagesPEOPLE Vs Felipe Demate Et AlAlexa Neri ValderamaNo ratings yet

- Rabagia - MatenTertiary Tectonic and Sedimentological Evolution of The South Carpathians Foredeep: Tectonic Versus Eustatic Controlco (1999)Document22 pagesRabagia - MatenTertiary Tectonic and Sedimentological Evolution of The South Carpathians Foredeep: Tectonic Versus Eustatic Controlco (1999)Lex AlexaNo ratings yet

- GRE Physics Test: Practice BookDocument91 pagesGRE Physics Test: Practice BookGalo CandelaNo ratings yet

- Kiecolt-Glaser - PNI 2002Document11 pagesKiecolt-Glaser - PNI 2002LaviniaNo ratings yet

- Stalwar DX LiteratureDocument2 pagesStalwar DX LiteratureAnonymous cbXdPkXoNo ratings yet

- 10th Aug - 2022Document39 pages10th Aug - 2022Ranjeet SinghNo ratings yet

- Lesson PlanDocument3 pagesLesson Planapi-530241350No ratings yet

- MTB-Lesson 3Document4 pagesMTB-Lesson 3Clavillas GrachelleNo ratings yet

- Docsity English in Italy Linguistic Educational and Professional ChallengesDocument27 pagesDocsity English in Italy Linguistic Educational and Professional Challengeschiarafoglia74No ratings yet

- Financing Foreign Trade PDFDocument16 pagesFinancing Foreign Trade PDFHemanth Kumar89% (9)

- The Field of Engineering ManagementDocument15 pagesThe Field of Engineering ManagementBelle SolaceNo ratings yet

- VEKP Deadlock IssueDocument5 pagesVEKP Deadlock IssueDuy ThanhNo ratings yet

- Republic Vs Drugmake R'S LAB (GR NO. 190837 MARCH 5, 2014)Document10 pagesRepublic Vs Drugmake R'S LAB (GR NO. 190837 MARCH 5, 2014)Harrison sajorNo ratings yet

- How To Speak English FluentlyDocument129 pagesHow To Speak English FluentlyMARIA ANGELES100% (3)

- RS 1803 HFS BP Enterprise Artificial Intelligence (AI) Services 2018Document70 pagesRS 1803 HFS BP Enterprise Artificial Intelligence (AI) Services 2018pantmukulNo ratings yet

- Tan Sri Ali Hashim (JCORP)Document7 pagesTan Sri Ali Hashim (JCORP)syafiqahanidaNo ratings yet