Professional Documents

Culture Documents

Seminar On Multi Staging in Centrifugal Pumps: 26-03-2021 Department of Mechanical Engineering, Vit Pune 1/13

Seminar On Multi Staging in Centrifugal Pumps: 26-03-2021 Department of Mechanical Engineering, Vit Pune 1/13

Uploaded by

VaibhavOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seminar On Multi Staging in Centrifugal Pumps: 26-03-2021 Department of Mechanical Engineering, Vit Pune 1/13

Seminar On Multi Staging in Centrifugal Pumps: 26-03-2021 Department of Mechanical Engineering, Vit Pune 1/13

Uploaded by

VaibhavCopyright:

Available Formats

Seminar On

Multi Staging in Centrifugal Pumps

By

Dnyaneshwari Patil – C54 (11810930)

Kinjalk Patil – C55 (11810086)

Samiksha Patil – C62 (11810948)

Vaibhav Patil – C66 (11810408)

Vivek Pawar – C71 (11810581)

Guide – Prof. S.P.Komble

26-03-2021 DEPARTMENT OF MECHANICAL ENGINEERING, VIT PUNE 1/13

CONTENT

INTRODUCTION TO CENTRIFUGAL PUMPS

MULTI-STAGING: SERIES

MULTI-STAGING: PARALLEL

TYPES OF MULTISTAGE CENTRIFUGAL PUMPS

MANUFACTURERS

CASE STUDY

REFERENCES

26-03-2021 DEPARTMENT OF MECHANICAL ENGINEERING, VIT PUNE 2/13

INTRODUCTION

• What is centrifugal pump?

• Works on principle of forced vortex

flow.

• Components :

a) Impeller

b) Casing

c) Suction Pipe.

d) Delivery Pipe

26-03-2021 DEPARTMENT OF MECHANICAL ENGINEERING, VIT PUNE 3/13

MULTI STAGING

• When two or more impellers are mounted

on the same shaft or on different shaft in a

centrifugal pump is called multistage

centrifugal pumps.

• Need of multistaging

1) To produce a high head

Graphs for Multi Stage Centrifugal Pump

2)To discharge a large quantity of liquid Source – Reference No. 2

26-03-2021 DEPARTMENT OF MECHANICAL ENGINEERING, VIT PUNE 4/13

SERIES COMBINATION

• Impellers are connected in series

• To generate high heads

• Constant discharge

• H = n* Hm

• Qtotal = Q

Schematic of Series Pump Cut Section of Series Combination

Pump

26-03-2021 DEPARTMENT OF MECHANICAL ENGINEERING, VIT PUNE 5/13

SERIES COMBINATION

Advantages:

• Friction losses are reduced.

• Impeller diameter is reduced.

• Higher suction lift is possible.

• Axial thrust can be eliminated.

Combined Characteristics Curve For

Multistage Pumps In Series

26-03-2021 DEPARTMENT OF MECHANICAL ENGINEERING, VIT PUNE 6/13

PARALLEL COMBINATION

• Pumps are connected in Parallel

Schematic of Parallel

• To discharge large quantity of liquid Combination

• Same head

• n = No. of identical pumps arranged in parallel,

Combined Characteristics Curve For

• Q = Discharge from one pump.

Multistage Pump In Parallel

• So, Total discharge, = n × Q

26-03-2021 DEPARTMENT OF MECHANICAL ENGINEERING, VIT PUNE 7/13

PARALLEL COMBINATION

Advantages :

• High flow rate.

• Availability of system.

• Low operating cost.

• Significant energy savings.

Representative Diagram of Centrifugal Centrifugal Pumps in

• Easy Maintenance. Pumps in Parallel Combination Parallel Combination

26-03-2021 DEPARTMENT OF MECHANICAL ENGINEERING, VIT PUNE 8/13

TYPES OF MULTISTAGE CENTRIFUGAL PUMP

1) Horizontal Multistage Pump

• Typically have higher flow rates as compared to vertical type.

• It takes high skill to work on these type of pumps.

• Quite costly.

Applications:

Kirloskar RKB Series Horizontal

Reverse Osmosis, Boiler Feed, Pressure Boosting, High Pressure Multistage Centrifugal Pump

Cleaning, Mine Dewatering, Snow Making.

26-03-2021 DEPARTMENT OF MECHANICAL ENGINEERING, VIT PUNE 9/13

TYPES OF MULTISTAGE CENTRIFUGAL PUMP

2) Vertical Multistage Pump

• Great for areas that don’t have much footprint to spare.

• This type of pump does not tolerate debris or significant solids.

• Able to deliver high pressure output with a single pump body and motor.

Applications:

High Pressure Shower Systems

Boiler Feed Pump CNP’s CDL Series Vertical Multistage

Centrifugal Pump

Desuperheater Feed

26-03-2021 DEPARTMENT OF MECHANICAL ENGINEERING, VIT PUNE 10/13

MANUFACTURERS

CNP Pumps India Pvt. Ltd. Shakti Pumps India Ltd. Aqua Group India Ltd.

Thane, Maharashtra Pithampur, Madhya Pradesh Coimbatore, Tamil Nadu

Varuna Pumps Kirloskar Brothers Ltd. Crompton Greaves Consumer Electricals Limited

Ahmedabad, Gujrat Pune, Maharashtra Mumbai, Maharashtra

26-03-2021 DEPARTMENT OF MECHANICAL ENGINEERING, VIT PUNE 11/13

CASE STUDY / RECENT ADAVNCEMENTS

1) Case Study 2) Paper

• A new twisted blade design of

Return Guide Vane is proposed to

achieve a compact pump structure.

• Also, a prototype is developed to

test the performance of proposed

RGV, which was found to be better

and cost effective.

• Efficiency of the designed model

came out be 57.5 % which is

comparable to previous model.

Hindawi Publications, Ref No 3

26-03-2021 DEPARTMENT OF MECHANICAL ENGINEERING, VIT PUNE 12/13

REFERNCES

1. R.K.Rajput, A textbook of Fluid Mechanics and Hydraulic Machines, S.Chand Publications.

2. Rakibuzzaman, Sang-Ho Suh, et.al, ‘ A study on Multistage Centrifugal Pump Performance Characteristics for Variable

Speed Driven System ’ 6th BSME International Conference on Thermal Engineering (ICTE 2014), Elsevier Publications, DOI

: 10.1016/j.proeng.2015.05.109.

3. Qihua Zhang, et.al, ‘ A New Proposed Return Guide Vane for Compact Multistage Centrifugal Pumps ’, Hindawi

Publications, Volume 2013, Article ID 683713, DOI : http://dx.doi.org/10.1155/2013/683713.

4. Crompton Greaves -

https://www.crompton.co.in/product/consumer-pumps/speciality-pumps/multistage-pumps/cvm-series/

5. Kirloskar Pumps - https://www.kirloskarpumps.com/product/RKB--RKBF--RKBK/.

26-03-2021 DEPARTMENT OF MECHANICAL ENGINEERING, VIT PUNE 13/13

You might also like

- Pop Up The Art of Dimensional Moving Paper Designs 4Document20 pagesPop Up The Art of Dimensional Moving Paper Designs 4Rodrigo L. B.100% (1)

- Design and CFD Analysis of Centrifugal Pump IJERTCONV9IS10007Document5 pagesDesign and CFD Analysis of Centrifugal Pump IJERTCONV9IS10007muhammad faisalNo ratings yet

- 8.performance Evaluation of Centrifugal Type Boiler Feed Pump by Varying Blade NumberDocument6 pages8.performance Evaluation of Centrifugal Type Boiler Feed Pump by Varying Blade NumberHazim HazimNo ratings yet

- Design and Analysis of Advance Pump Working in Reverse Mode As A Turbine For Hydro Power Plant-A ReviewDocument6 pagesDesign and Analysis of Advance Pump Working in Reverse Mode As A Turbine For Hydro Power Plant-A Reviewشـخـ صـﮱ اسـطورﮱNo ratings yet

- Common Header Line For Pump TestingDocument8 pagesCommon Header Line For Pump TestingNovesa NurgirisiaNo ratings yet

- Simulador Qrod v3 para Bombeo MecanicoDocument3 pagesSimulador Qrod v3 para Bombeo MecanicobeymarNo ratings yet

- Damping HoleDocument11 pagesDamping HoleMurali K oe16d017No ratings yet

- Art 12 Design and Performance Evaluation of A Pump-As-turbineDocument6 pagesArt 12 Design and Performance Evaluation of A Pump-As-turbineEdilson Valderrama0% (1)

- Energies 15 04259Document14 pagesEnergies 15 04259Rigoberto José Martínez CedeñoNo ratings yet

- Design Consideration of Different Volute Casing at Best Efficiency Point PDFDocument5 pagesDesign Consideration of Different Volute Casing at Best Efficiency Point PDFSimon TudorNo ratings yet

- FPMC2014-7856: Efficiency Testing of An Adjustable Linkage Triplex PumpDocument7 pagesFPMC2014-7856: Efficiency Testing of An Adjustable Linkage Triplex PumpFa TiNo ratings yet

- Overview of Artificial Lift SystemsDocument19 pagesOverview of Artificial Lift SystemsyesicaNo ratings yet

- Project ReportDocument26 pagesProject ReportAjay VailoreNo ratings yet

- Cavitation Analysis CFDDocument4 pagesCavitation Analysis CFDshdjjfNo ratings yet

- Centrifugal Pump Piping Design LayoutDocument19 pagesCentrifugal Pump Piping Design LayoutzhangjieNo ratings yet

- 1 s2.0 S111001682200504X MainDocument14 pages1 s2.0 S111001682200504X MainMihaela ConstantinNo ratings yet

- Pumps Turbine Submersible PumpDocument11 pagesPumps Turbine Submersible Pumpahsanul haqueNo ratings yet

- Cheng2021 Article TheTheoreticalPerformanceAnaly1Document16 pagesCheng2021 Article TheTheoreticalPerformanceAnaly1Rishikesh MoreNo ratings yet

- Rod Less Pump OptimizationDocument15 pagesRod Less Pump OptimizationAvanish ChaubeyNo ratings yet

- Artificial Lift (Overview)Document13 pagesArtificial Lift (Overview)adlinaNo ratings yet

- Centrifugal PumpDocument3 pagesCentrifugal PumpJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Ranvir Singh Project B.techDocument15 pagesRanvir Singh Project B.techANUJ MalhotraNo ratings yet

- Study and Analysis of Hydraulic Turbine in Aden City Main Pipiing NetworkDocument19 pagesStudy and Analysis of Hydraulic Turbine in Aden City Main Pipiing NetworkFares NasserNo ratings yet

- 10 A Comparative Study of Two Common Pump-Controlled Hydraulic Circuits For Single Rod Actuator Actuators-12-00193Document13 pages10 A Comparative Study of Two Common Pump-Controlled Hydraulic Circuits For Single Rod Actuator Actuators-12-00193Ahmed ImamNo ratings yet

- Flow Analysis of Kaplan Hydraulic Turbine by Computational Fluid DynamicsDocument5 pagesFlow Analysis of Kaplan Hydraulic Turbine by Computational Fluid DynamicsЖивотаЛазаревићNo ratings yet

- Thesis On Centrifugal Pump DesignDocument6 pagesThesis On Centrifugal Pump Designjessicacannellamanchester100% (2)

- Spe - 9979 Overview of Artificial Lift SystemDocument13 pagesSpe - 9979 Overview of Artificial Lift Systemmartin_montana55_479No ratings yet

- Analytical Investigation of Centrifugal Pump Impeller - Jicr-December-2020Document7 pagesAnalytical Investigation of Centrifugal Pump Impeller - Jicr-December-2020raviNo ratings yet

- Recovery of Hydrocarbons Using The Sucker Rod PumpDocument13 pagesRecovery of Hydrocarbons Using The Sucker Rod PumpKUMAR VATSALNo ratings yet

- CFD Analysis of Centrifugal Pump ImpelleDocument9 pagesCFD Analysis of Centrifugal Pump Impelleبلال بن عميرهNo ratings yet

- Experiment No 07: 7.1.1 Series CombinationDocument10 pagesExperiment No 07: 7.1.1 Series Combinationmursalinme123No ratings yet

- Dave 2017Document13 pagesDave 2017saeedNo ratings yet

- Design and Performance Curve Generation by CFD Analysis of Centrifugal PumpDocument10 pagesDesign and Performance Curve Generation by CFD Analysis of Centrifugal Pumpبلال بن عميرهNo ratings yet

- Optimizing Impeller Geometry For Performance Enhancement of A Centrífugal Pump PDFDocument19 pagesOptimizing Impeller Geometry For Performance Enhancement of A Centrífugal Pump PDFEnrique Javier González HenríquezNo ratings yet

- Multi Phase PumpsDocument6 pagesMulti Phase Pumpsejzuppelli8036No ratings yet

- Seminar Report ON "Solar Pump"Document32 pagesSeminar Report ON "Solar Pump"api-19775783100% (2)

- Suter Curve PDFDocument8 pagesSuter Curve PDF邱瑞河No ratings yet

- Artificial Lift: Focus On Hydraulic Submersible Pumps: Abhishek Bhatia and Scott A.L. Mcallister, Clydeunion PumpsDocument3 pagesArtificial Lift: Focus On Hydraulic Submersible Pumps: Abhishek Bhatia and Scott A.L. Mcallister, Clydeunion PumpsCarlita SuntaxiNo ratings yet

- The Defining Series - Jet Pumps - SLB PDFDocument8 pagesThe Defining Series - Jet Pumps - SLB PDFnoha azamaliNo ratings yet

- 164 Review of Pumps As Turbine (PAT) For Micro-HydropowerDocument8 pages164 Review of Pumps As Turbine (PAT) For Micro-HydropowerSebastián Alexander Flores OroscoNo ratings yet

- Energies 14 05949 v2Document15 pagesEnergies 14 05949 v2msaddamiqbalNo ratings yet

- EleventhASIANConference IDocument11 pagesEleventhASIANConference IIbsaNo ratings yet

- Modelling and Optimization of The Velocity Profiles at The Draft Tube Inlet of A Francis Turbine Within An Operating RangeDocument17 pagesModelling and Optimization of The Velocity Profiles at The Draft Tube Inlet of A Francis Turbine Within An Operating RangeAhmed AhmedNo ratings yet

- Design and Development of Split Case PumpDocument4 pagesDesign and Development of Split Case PumpHasan AdelNo ratings yet

- Boiler Feed Pump Sizing CalculationDocument18 pagesBoiler Feed Pump Sizing CalculationArun Kumar Dey100% (2)

- Performance Evaluation of A Bulb Turbine Designed For Ultra-Low Head ApplicationsDocument8 pagesPerformance Evaluation of A Bulb Turbine Designed For Ultra-Low Head ApplicationsЖивотаЛазаревићNo ratings yet

- 3 CsDocument14 pages3 CsRavindra PawarNo ratings yet

- Fenrg 10 836456Document13 pagesFenrg 10 836456Yazan ArabyNo ratings yet

- Power Consumption Optimization For Multiple Parallel Centrifugal PumpsDocument6 pagesPower Consumption Optimization For Multiple Parallel Centrifugal PumpshachanNo ratings yet

- Des67 2017 28Document14 pagesDes67 2017 28mohaned.jedidiNo ratings yet

- Bernard DaCruzDocument20 pagesBernard DaCruzhnalexvnNo ratings yet

- Centrifugal Pump Design1Document48 pagesCentrifugal Pump Design1syuhaimi82No ratings yet

- VauhkonenDocument7 pagesVauhkonenSAINo ratings yet

- Flow Serve VS6 API Pump PDFDocument8 pagesFlow Serve VS6 API Pump PDFBesan LaduNo ratings yet

- Numerical Simulation of Cavitating Flow in A Centrifugal Pump As TurbineDocument21 pagesNumerical Simulation of Cavitating Flow in A Centrifugal Pump As TurbineAung Myat ThuNo ratings yet

- Prediction and Improvement of Steady-State Performance of A Power Controlled Axial Piston PumpDocument10 pagesPrediction and Improvement of Steady-State Performance of A Power Controlled Axial Piston PumpmadmetroidNo ratings yet

- Ede 7Document19 pagesEde 7Shammika JayathungaNo ratings yet

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowRating: 2 out of 5 stars2/5 (1)

- FM CPDocument14 pagesFM CPVaibhavNo ratings yet

- Steps To Fill Exam Form From Student LoginDocument7 pagesSteps To Fill Exam Form From Student LoginVaibhavNo ratings yet

- Heat TransferDocument17 pagesHeat TransferVaibhavNo ratings yet

- CAMDDocument16 pagesCAMDVaibhavNo ratings yet

- Camd GDDocument14 pagesCamd GDVaibhavNo ratings yet

- ProgramDocument5 pagesProgramVaibhavNo ratings yet

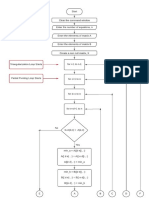

- Flowchart 1Document3 pagesFlowchart 1VaibhavNo ratings yet

- Torque Measuremen T: MQC SeminarDocument17 pagesTorque Measuremen T: MQC SeminarVaibhavNo ratings yet

- ProgramDocument5 pagesProgramVaibhavNo ratings yet

- ProgramDocument2 pagesProgramVaibhavNo ratings yet

- 3 Pro OutDocument1 page3 Pro OutVaibhavNo ratings yet

- Program 6Document2 pagesProgram 6VaibhavNo ratings yet

- Design For EnvironmentDocument18 pagesDesign For EnvironmentVaibhavNo ratings yet

- Batch2 - 31-35 - Cloud Storage and Communication Techniques For IoT SystemsDocument28 pagesBatch2 - 31-35 - Cloud Storage and Communication Techniques For IoT SystemsVaibhavNo ratings yet

- Design For EnvironmentDocument18 pagesDesign For EnvironmentVaibhavNo ratings yet

- Timber Frame Solutions 03Document20 pagesTimber Frame Solutions 03sertackcdgNo ratings yet

- Piping Engineer: Resume CV: Sponsored LinksDocument7 pagesPiping Engineer: Resume CV: Sponsored Linksravi gurungNo ratings yet

- BCCA AB in Febrile Neutropenia GuidelinesDocument2 pagesBCCA AB in Febrile Neutropenia GuidelinesAlvy SyukrieNo ratings yet

- CV Hamza SadrijaDocument3 pagesCV Hamza SadrijaHamza SadrijaNo ratings yet

- English Week 7 Spoken Text Quarter 1 PDFDocument32 pagesEnglish Week 7 Spoken Text Quarter 1 PDFsimaNo ratings yet

- SF - SafeFlame Data Sheet UVIRDocument2 pagesSF - SafeFlame Data Sheet UVIRVincent GabrielNo ratings yet

- 10 1108 - Ijse 11 2017 0507Document14 pages10 1108 - Ijse 11 2017 0507Hanny PurnomoNo ratings yet

- Dobor Rezystorow B628xx StepUp Chip - vbc-VB9208-v1.0Document9 pagesDobor Rezystorow B628xx StepUp Chip - vbc-VB9208-v1.0asdfNo ratings yet

- Tentang Takal Melalui Lakaran, TMK, Penulisan Atau Lisan Secara Kreatif)Document2 pagesTentang Takal Melalui Lakaran, TMK, Penulisan Atau Lisan Secara Kreatif)Yayang NasrudinNo ratings yet

- CCR Load Calculator 2014-03-13Document41 pagesCCR Load Calculator 2014-03-13Yahya AlkaffNo ratings yet

- W Hoov TM001 E1 PDFDocument48 pagesW Hoov TM001 E1 PDFDrewNo ratings yet

- SCS Method PDFDocument55 pagesSCS Method PDFWesley BridgemohansinghNo ratings yet

- Chapter 4Document2 pagesChapter 4Lilia GuzunNo ratings yet

- Unit 2 - Basic Instrumentation and Measurement Techniques PPT Notes Material For Sem II Uploaded by Navdeep RaghavDocument72 pagesUnit 2 - Basic Instrumentation and Measurement Techniques PPT Notes Material For Sem II Uploaded by Navdeep Raghavavikool1708No ratings yet

- Multithreaded Airport Simulation SystemsDocument6 pagesMultithreaded Airport Simulation Systemsphanikrishnajagadesh666No ratings yet

- PCK303 Understanding The Lesson 9Document2 pagesPCK303 Understanding The Lesson 9Japhet BagsitNo ratings yet

- MS Fragmentation Functional Groups (Compatibility Mode)Document68 pagesMS Fragmentation Functional Groups (Compatibility Mode)Adriana Estefanía HPNo ratings yet

- Lección 11 - How MuchDocument4 pagesLección 11 - How Muchyo no fuiNo ratings yet

- Foreign Currency TranactionDocument11 pagesForeign Currency TranactionAngelieNo ratings yet

- Journal of Macromolecular Science, Part C: To Cite This Article: John R. Martin, Julian F. Johnson & Anthony R. CooperDocument145 pagesJournal of Macromolecular Science, Part C: To Cite This Article: John R. Martin, Julian F. Johnson & Anthony R. CooperRicky Iqbal SNo ratings yet

- 97 145Document2 pages97 145anon_251242493No ratings yet

- Development On Plot No. Donyo Sabuk/Komarock BLOCK 1/25878 Client: Lilian Lutta MalobaDocument12 pagesDevelopment On Plot No. Donyo Sabuk/Komarock BLOCK 1/25878 Client: Lilian Lutta MalobaAustin AnindoNo ratings yet

- Draft Spec. For Set of Panels For LHB Non AC EOG Coaches PDFDocument27 pagesDraft Spec. For Set of Panels For LHB Non AC EOG Coaches PDFVishal Kinikar0% (1)

- Ministry Planning Made EasyDocument48 pagesMinistry Planning Made Easym28181920No ratings yet

- Submarine Magmatic-Hydrothermal Systems at The Monowai Volcanic Center, Kermadec ArcDocument26 pagesSubmarine Magmatic-Hydrothermal Systems at The Monowai Volcanic Center, Kermadec ArcberthingNo ratings yet

- PPT5-S5 - Problem & Change ManagementDocument29 pagesPPT5-S5 - Problem & Change ManagementDinne RatjNo ratings yet

- Reflective Journal: My Group PresentationDocument4 pagesReflective Journal: My Group PresentationAnh MingNo ratings yet

- Production Planning - 095252Document13 pagesProduction Planning - 095252Jocidelle LubricoNo ratings yet

- Project Eagle QualitativeDocument188 pagesProject Eagle QualitativeCheriel Anne EsnardoNo ratings yet