Professional Documents

Culture Documents

Engine Size and Measurements: © 2012 Delmar, Cengage Learning

Engine Size and Measurements: © 2012 Delmar, Cengage Learning

Uploaded by

Keno Domingo0 ratings0% found this document useful (0 votes)

6 views29 pagesOriginal Title

1111128618_276700

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

0 ratings0% found this document useful (0 votes)

6 views29 pagesEngine Size and Measurements: © 2012 Delmar, Cengage Learning

Engine Size and Measurements: © 2012 Delmar, Cengage Learning

Uploaded by

Keno DomingoCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 29

Engine Size and

Measurements

Chapter 17

© 2012 Delmar, Cengage Learning

Objectives

• Describe various ways of measuring engine size

• Understand the effects of engine compression

ratio

• Explain the principles of engine power and

efficiency

• Relate torque to horsepower

• Understand the variations in operation of the

different types of dynamometers

© 2012 Delmar, Cengage Learning

Introduction

• This chapter provides an understanding of:

– Various engine size and performance

measurements

– Methods of understanding and measuring engine

power output

© 2012 Delmar, Cengage Learning

Engine Size Measurements

• Engine’s size

– Determined by volume of air pistons displace in

cylinders

• Cylinder bore size

– Diameter of the cylinder

• Usually three and a half to four inches

– Average engine has a three and a half to four

inch stroke

© 2012 Delmar, Cengage Learning

Engine Size Measurements

(cont’d.)

• Displacement

– Piston or cylinder displacement

• Volume displaced by the piston

• Bore2 x Stroke x 0.7854

– Engine displacement

• Bore2 x Stroke x 0.7854 x number of cylinders

© 2012 Delmar, Cengage Learning

© 2012 Delmar, Cengage Learning

© 2012 Delmar, Cengage Learning

Compression Ratio

• Determines how much air and fuel are

compressed

– Compression ratio is 8:1

• Higher compression ratio increases power and fuel

economy

• Increases exhaust emissions

• Each point of change is said to be worth about four

to six percent change in horsepower

• Compression pressure

– Pressure made by piston moving up in cylinder

• Gasoline engines typically produce 125-175 psi

© 2012 Delmar, Cengage Learning

Compression Ratio (cont’d.)

• Effective compression

ratio

– Determined by point at

which intake valve closes

© 2012 Delmar, Cengage Learning

Physical Principles of Work

• Force: any action that tends to change the

position of something

– Measured in pounds or Newtons

– Push, pull, or lift

• Work: when an object is moved against a

resistant or opposing force

– Lifting or sliding

– English measurements: foot-pounds or watts

– Metric measurements: Newton-meters or joules

– Force x Distance = Work

© 2012 Delmar, Cengage Learning

© 2012 Delmar, Cengage Learning

Physical Principles of Work

(cont’d.)

• One foot-pound: one pound is moved for a

distance of one foot

• Energy: ability to produce motion against

resistance

• Inertia: tendency of a body to keep its state of

rest or motion

– Larger masses are affected more by inertia

• Momentum: product of the body’s mass and

speed

• Power: how fast work is done

© 2012 Delmar, Cengage Learning

Torque

• Torque

– Tendency of a force to rotate a body on which it

acts

• Amount of turning force exerted by crankshaft

– Engine torque varies with rpm

• High at lower speeds

• Heat

– Measured in Btu

– One Btu is the amount of heat required to heat

one pound of water by one degree

© 2012 Delmar, Cengage Learning

© 2012 Delmar, Cengage Learning

Horsepower

• Measurement of an engine’s ability to perform

work in a specified time

– One horsepower equals 33,000 foot-pounds of

work per minute

• Amount of work required to life 550 pounds one

foot in one second

– One horsepower equals 0.746 kilowatts

• Gross horsepower

– Power produced at crankshaft

• Several measurements

© 2012 Delmar, Cengage Learning

© 2012 Delmar, Cengage Learning

Horsepower (cont'd.)

• Accessories that rob power (absorb about 25%)

– Alternator

– Air conditioning

– Water pump

– Cooling fan

– Power steering

– Smog pump

• Net power is what remains

• Power is also lost through friction

© 2012 Delmar, Cengage Learning

Dynamometer

• Measures engine output

– Engine dynamometer

• Horsepower coming out of the engine

– Chassis dynamometer

• Horsepower available at vehicle’s drive wheels

• Maximizing horsepower and torque

– Valve overlap

• Period when intake and exhaust valves are open

– Scavenging

• Vacuum draws in fresh air and fuel through open intake

valve

© 2012 Delmar, Cengage Learning

© 2012 Delmar, Cengage Learning

© 2012 Delmar, Cengage Learning

Dynamometer (cont’d.)

• Types of dynamometer power absorption units

– Automotive dynamometer power absorption units

• Electromagnetic and water brake

• Measuring torque and horsepower

– Horsepower: (Torque x rpm) / 5250

– Torque readings: made at every 500 rpm

• Horsepower correction factors and comparisons

– Correction factors: compensate for high-altitude

air or hot air

– Comparisons: done with same dynamometer

© 2012 Delmar, Cengage Learning

© 2012 Delmar, Cengage Learning

Dynamometer Safety Concerns

• Engine dynamometer

– Concerns: fire, part failure, and noise

• Chassis dynamometer

– Concerns: carbon monoxide, keeping the vehicle

secured and connected to rollers, part failure,

and noise

• Other dynamometer types

– Towing dynos

– Cycle dyne

© 2012 Delmar, Cengage Learning

Engine Efficiency

• Engine efficiency measurements:

– Mechanical efficiency

• Describes all ways friction is lost in the engine

• Engine output divided by engine input

– Volumetric efficiency

– Thermal efficiency

• Amount of loss

– Difference between efficiency measurement and

100%

© 2012 Delmar, Cengage Learning

© 2012 Delmar, Cengage Learning

Volumetric Efficiency

• Compares volume of airflow entering the engine

with theoretical maximum

– Determines maximum torque output

• Changes with:

– Temperature

– Engine speed

– Load

– Throttle opening

• Increased speed and closing the throttle

– Lowered efficiency

© 2012 Delmar, Cengage Learning

Thermal Efficiency

• Ratio of how effectively an engine converts a

fuel’s heat energy into usable work

– Gasoline’s thermal energy: 19,000 Btu per pound

• Brake thermal efficiency: more useful

– (Brake HP / fuel’s heat input) x 100

• Spark ignition: only one-fourth of the energy

from burning fuel is converted to work

• Diesel fuel: higher heat energy and engines

have a higher compression ratio

– Better fuel economy

© 2012 Delmar, Cengage Learning

© 2012 Delmar, Cengage Learning

Mean Effective Pressure

• Pressure within the cylinder

– Increases during compression stroke

• Highest after ignition

• Peak cylinder pressure

– Should occur between ten and 20 degrees past

TDC

• Combustion pressure moves the piston down

– Pressure drops as cycle continues

© 2012 Delmar, Cengage Learning

You might also like

- Peugeot 4008 2012-2017 Service ManualDocument3,194 pagesPeugeot 4008 2012-2017 Service Manualjosefranciscodinamarca2003No ratings yet

- Cummins N855 BigCam Torque ValueDocument4 pagesCummins N855 BigCam Torque ValueCésar Pérez92% (13)

- M&M - Automobile BasicsDocument133 pagesM&M - Automobile Basicskexadex2No ratings yet

- Diesel Power PlantDocument17 pagesDiesel Power PlantMuhammed ThaslimNo ratings yet

- G3520 SLD PDFDocument43 pagesG3520 SLD PDFdanielh776100% (4)

- Design of Formula SAE Suspension ComponentsDocument13 pagesDesign of Formula SAE Suspension ComponentsYasser Rohom0% (1)

- CBLM DrivingDocument50 pagesCBLM DrivingAbegailnicole Mahilum100% (3)

- Introduction To Automotive TechnologyDocument11 pagesIntroduction To Automotive TechnologyBalaraman100% (1)

- CfmotoDocument155 pagesCfmotoUmar ShamsudinNo ratings yet

- Engine Dimension SelectionDocument29 pagesEngine Dimension SelectionNeeraj YadavNo ratings yet

- S Announcement 4431Document25 pagesS Announcement 4431DragonviewerNo ratings yet

- Introduction To The Automobile: © 2012 Delmar, Cengage LearningDocument25 pagesIntroduction To The Automobile: © 2012 Delmar, Cengage LearningpallabNo ratings yet

- Auto Trans ConceptsDocument32 pagesAuto Trans ConceptsnavedNo ratings yet

- Clutch Fundamentals: © 2012 Delmar, Cengage LearningDocument24 pagesClutch Fundamentals: © 2012 Delmar, Cengage Learningshreyas jadhavNo ratings yet

- Clutch Fundamentals: © 2012 Delmar, Cengage LearningDocument24 pagesClutch Fundamentals: © 2012 Delmar, Cengage LearningNarendren KNo ratings yet

- Perform Mensuration and Calculation: LO1. Select Measuring InstrumentsDocument21 pagesPerform Mensuration and Calculation: LO1. Select Measuring InstrumentsGb NYlztEnNo ratings yet

- Emission Control SystemDocument25 pagesEmission Control SystemJC PinoNo ratings yet

- Engine ClasificationDocument13 pagesEngine Clasificationvasanth9046No ratings yet

- Steering Fundamentals: © 2012 Delmar, Cengage LearningDocument25 pagesSteering Fundamentals: © 2012 Delmar, Cengage LearningJ Naveen KumarNo ratings yet

- Front-Wheel-Drive (Transaxle and CV Joint) Fundamentals: © 2012 Delmar, Cengage LearningDocument25 pagesFront-Wheel-Drive (Transaxle and CV Joint) Fundamentals: © 2012 Delmar, Cengage LearningMatthew SmithNo ratings yet

- Clutch Fundamentals: © 2012 Delmar, Cengage LearningDocument24 pagesClutch Fundamentals: © 2012 Delmar, Cengage LearningRahul BhattNo ratings yet

- Clutch FundamentalsDocument24 pagesClutch FundamentalsYerbol KabyshevNo ratings yet

- Diagnosing Engine Mechanical Problems: © 2012 Delmar, Cengage LearningDocument25 pagesDiagnosing Engine Mechanical Problems: © 2012 Delmar, Cengage LearningSinggih DonyNo ratings yet

- Engine Torque, Power and Mean Piston SpeedDocument13 pagesEngine Torque, Power and Mean Piston SpeedJayath Bogahawatte100% (1)

- Starting System Service: © 2012 Delmar, Cengage LearningDocument24 pagesStarting System Service: © 2012 Delmar, Cengage LearningJM Llaban RamosNo ratings yet

- Lesson 3: Reciprocating Engine Theory of OperationDocument20 pagesLesson 3: Reciprocating Engine Theory of OperationTrương DuyNo ratings yet

- Seminar On "Diesel Power Plant": BY Gautam DangiDocument14 pagesSeminar On "Diesel Power Plant": BY Gautam DangiGautam DangiNo ratings yet

- CLSU ABE Review 2022 APE Chap 04 Internal Combustion EngineDocument55 pagesCLSU ABE Review 2022 APE Chap 04 Internal Combustion EngineBilly AgustinNo ratings yet

- Pickerill AEP CH 1 CM RevDocument43 pagesPickerill AEP CH 1 CM RevIvan CalvilloNo ratings yet

- Steering System Service: © 2012 Delmar, Cengage LearningDocument33 pagesSteering System Service: © 2012 Delmar, Cengage LearningRonald Taganas100% (1)

- Theory of Reciprocating EngineDocument20 pagesTheory of Reciprocating EngineMaintenance PSINo ratings yet

- Gasoline Engine: Work Distance X ForceDocument15 pagesGasoline Engine: Work Distance X ForceDepepanshu MahajanNo ratings yet

- EnE 250 Air Quality Management and Pollution Control Lecture 02 - 3 APC Mobile Sources Aug 2015 v2Document117 pagesEnE 250 Air Quality Management and Pollution Control Lecture 02 - 3 APC Mobile Sources Aug 2015 v2Alexis Bryan RiveraNo ratings yet

- MELT Air Brakes Single UnitDocument78 pagesMELT Air Brakes Single UnitChristopher LiretteNo ratings yet

- Chap 4 ICE OkDocument36 pagesChap 4 ICE OkMohd AjmainNo ratings yet

- Amta6 6 Using Multiple Cylinder EnginesDocument19 pagesAmta6 6 Using Multiple Cylinder EnginesHridayRanjanHazarikaNo ratings yet

- Performance of Internal Combustion Engine (I.C.E)Document27 pagesPerformance of Internal Combustion Engine (I.C.E)Shem YusoyaNo ratings yet

- Eti 04 PowerFlowAndEfficiencyDocument129 pagesEti 04 PowerFlowAndEfficiencyshivamminapurNo ratings yet

- Thermal Power Plants: 17 Mechanical by Engr. Ans Ahmed Department of Mechanical EngineeringDocument47 pagesThermal Power Plants: 17 Mechanical by Engr. Ans Ahmed Department of Mechanical EngineeringAzhar Ali100% (1)

- Introduction To Performance Evaluation: O-P. Vuorinen January, 2004Document47 pagesIntroduction To Performance Evaluation: O-P. Vuorinen January, 2004mohamedNo ratings yet

- Antilock Brakes, Traction, and Stability Control: © 2012 Delmar, Cengage LearningDocument25 pagesAntilock Brakes, Traction, and Stability Control: © 2012 Delmar, Cengage Learningsengottaiyan100% (1)

- Engr. Alexis T. Belonio, MS Agricultural and Biosystems Engineer ASEAN EngineerDocument28 pagesEngr. Alexis T. Belonio, MS Agricultural and Biosystems Engineer ASEAN EngineerMAPANAO RONALYN B.No ratings yet

- 1 - Introduction To Diesel EngineDocument32 pages1 - Introduction To Diesel EngineAnas DarwishNo ratings yet

- Engine Operating Characteristics 2Document16 pagesEngine Operating Characteristics 2Adnan Abu AwwadNo ratings yet

- 08 Diesel and GT Power Plant - Master Slides-2Document27 pages08 Diesel and GT Power Plant - Master Slides-2madhiNo ratings yet

- Internal Combustion EngineDocument15 pagesInternal Combustion EngineRahul SharmaNo ratings yet

- OEL Power Plant & ICDocument13 pagesOEL Power Plant & ICa68647No ratings yet

- APES Chap04 Intenal Combustion EngineDocument59 pagesAPES Chap04 Intenal Combustion Engineiris ΩNo ratings yet

- Diesel Power PlantDocument22 pagesDiesel Power PlantJerry Andrews100% (1)

- Tire and Wheel Theory: © 2012 Delmar, Cengage LearningDocument25 pagesTire and Wheel Theory: © 2012 Delmar, Cengage LearningRonyNo ratings yet

- Power Output Terms: Engine TerminologyDocument6 pagesPower Output Terms: Engine TerminologyanuradhaNo ratings yet

- Regenerative Braking SystemDocument5 pagesRegenerative Braking Systemm1nitk 19No ratings yet

- Diesel Electric StationDocument42 pagesDiesel Electric StationAhmadNo ratings yet

- Diesel Engines: Engine Systems and PerformanceDocument46 pagesDiesel Engines: Engine Systems and PerformanceGuri DhindsaNo ratings yet

- 03 Engine Operating CharacteristicsDocument34 pages03 Engine Operating CharacteristicsMurhaf KhateebNo ratings yet

- DGsetDocument14 pagesDGsetAntony HegdeNo ratings yet

- Combustion FinDocument29 pagesCombustion FinCarlo SebastianNo ratings yet

- Internal Combustion Engines - The DieselDocument25 pagesInternal Combustion Engines - The DieselTarun PatelNo ratings yet

- 4, Engine Mesurements and PerformanceDocument17 pages4, Engine Mesurements and PerformanceHannah GamierNo ratings yet

- Chapter 2Document74 pagesChapter 2hailemariam markosNo ratings yet

- IC Engine Lec3Document20 pagesIC Engine Lec3mahirNo ratings yet

- DG SetDocument42 pagesDG Setgaurang1111No ratings yet

- Engine FinalDocument144 pagesEngine FinalEr. Narendra Kumar YadavNo ratings yet

- Lecture 1 - Reciprocating Engine TheoryDocument36 pagesLecture 1 - Reciprocating Engine TheoryIan WhitingNo ratings yet

- Seminar Report by UDIT NARAYAN SUTHARDocument16 pagesSeminar Report by UDIT NARAYAN SUTHARanirudh singh solankiNo ratings yet

- 5 BrakeDocument69 pages5 BrakeAtalelew ZeruNo ratings yet

- Naval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyFrom EverandNaval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyNo ratings yet

- G37 Factory Service Manual Section ADPDocument207 pagesG37 Factory Service Manual Section ADPTannerNo ratings yet

- 948te Zf9hp48 Zip inDocument12 pages948te Zf9hp48 Zip inRonald100% (1)

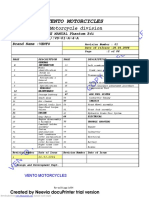

- Vento Phantom R4i Service Maintenance ManualDocument88 pagesVento Phantom R4i Service Maintenance ManualBlackheart GoonNo ratings yet

- ElectricvehiclesDocument41 pagesElectricvehiclesMIHIR KASHYAPNo ratings yet

- PREMIERTRAK 600 Illustrated Parts Catalog - Revision 0.4Document633 pagesPREMIERTRAK 600 Illustrated Parts Catalog - Revision 0.4andrew stables100% (1)

- Agrotron M 600 - 610 - 620Document347 pagesAgrotron M 600 - 610 - 620Bence PassNo ratings yet

- How A Jet Engine Creates ThrustDocument4 pagesHow A Jet Engine Creates ThrustRossNo ratings yet

- BMW E23Document281 pagesBMW E23mnbvqwert100% (1)

- Volvo Gear Actuator: Design - Function - RepairDocument76 pagesVolvo Gear Actuator: Design - Function - RepairNadeem Mohd100% (2)

- V2.1 English Technical Data SH100 AgriDocument3 pagesV2.1 English Technical Data SH100 Agrijunyang liNo ratings yet

- Gas Turbine: Principle of OperationDocument20 pagesGas Turbine: Principle of Operationwaleed paliNo ratings yet

- AIM Lotus Cluster Installation Guide 100Document2 pagesAIM Lotus Cluster Installation Guide 100vincent.loNo ratings yet

- SB 10105587 9340Document4 pagesSB 10105587 9340Andre RahmanNo ratings yet

- Litehawk Bullet Exploded ViewDocument1 pageLitehawk Bullet Exploded ViewTNNo ratings yet

- UG 40 Governor: Lever or Dial Type Speed Setting With Adjustable DroopDocument4 pagesUG 40 Governor: Lever or Dial Type Speed Setting With Adjustable DroopPhilippe DAVIDNo ratings yet

- Hitachi Zaxis 145WDocument28 pagesHitachi Zaxis 145WAndrea797No ratings yet

- MG ZT 2 5 160 2001 05 Timing BeltDocument6 pagesMG ZT 2 5 160 2001 05 Timing BeltIan RobertsNo ratings yet

- Transaxle Part No'sDocument9 pagesTransaxle Part No'sRon BonnevilleNo ratings yet

- Classic Ford - Issue 287 - March 2020 PDFDocument118 pagesClassic Ford - Issue 287 - March 2020 PDFSAEL SOLARNo ratings yet

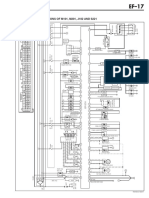

- 3.3 Wiring Diagram: 3.3.1 FOR EU SPECIFICATIONS OF M101, M201, J102 AND S221Document1 page3.3 Wiring Diagram: 3.3.1 FOR EU SPECIFICATIONS OF M101, M201, J102 AND S221David MendezNo ratings yet

- L150E Operators ManualDocument202 pagesL150E Operators ManualBosna Ekspres100% (1)

- Bentley BrochureDocument9 pagesBentley Brochureelliot pickardNo ratings yet

- 3rd q94r-n PDFDocument7 pages3rd q94r-n PDFbelchior alvaro100% (1)