Professional Documents

Culture Documents

An Introduction To Drilling

An Introduction To Drilling

Uploaded by

red_hairedsCopyright:

Available Formats

You might also like

- Magical Kitties 2e - River City MapDocument1 pageMagical Kitties 2e - River City Mapecchi.moonlight100% (1)

- Chapter 2 WorkbookDocument31 pagesChapter 2 WorkbookYuni ArtaNo ratings yet

- The Toyota Kata Practice Guide: Practicing Scientific Thinking Skills for Superior Results in 20 Minutes a DayFrom EverandThe Toyota Kata Practice Guide: Practicing Scientific Thinking Skills for Superior Results in 20 Minutes a DayRating: 4.5 out of 5 stars4.5/5 (7)

- Computational Gas-Solids Flows and Reacting Systems - Theory, Methods and Practice (2011)Document500 pagesComputational Gas-Solids Flows and Reacting Systems - Theory, Methods and Practice (2011)Júlio César Spillere RonchiNo ratings yet

- 1 DentascanDocument10 pages1 DentascanSalem Fathi BermawiNo ratings yet

- B257.OL3 - 002 - Safety and Design - Rev01Document70 pagesB257.OL3 - 002 - Safety and Design - Rev01megapoulpeNo ratings yet

- 1 Waja 09 F5 Student's Copy Number BasesDocument12 pages1 Waja 09 F5 Student's Copy Number BasesramjalinaNo ratings yet

- GantchartDocument3 pagesGantchartsubhabirajdarNo ratings yet

- Fig 209 Leak TestDocument1 pageFig 209 Leak TestFRANCISCO JAVIER JARAMILLO MNo ratings yet

- Varec Sistem Masurare LichidTEC012 - 6700Document4 pagesVarec Sistem Masurare LichidTEC012 - 6700stroiebogdanNo ratings yet

- 133 141TP 06 009KecojevicPROOFDocument10 pages133 141TP 06 009KecojevicPROOFDiallo saidouNo ratings yet

- Nirma MPR - JULY 22Document38 pagesNirma MPR - JULY 22Kiran Kumar PatraNo ratings yet

- OLD DOGS, NEW TRICKS-BASS - (5-String)Document3 pagesOLD DOGS, NEW TRICKS-BASS - (5-String)O ThomasNo ratings yet

- AYPChart CriteriaDocument1 pageAYPChart CriteriawheptaNo ratings yet

- OM. K 970 III, K 970 III Rescue, K 970 SmartGuard. 2021-11Document152 pagesOM. K 970 III, K 970 III Rescue, K 970 SmartGuard. 2021-11SamossyzNo ratings yet

- Regleta Indicador de Nivel VAREC PDFDocument2 pagesRegleta Indicador de Nivel VAREC PDFWilson Alberto Poveda OsorioNo ratings yet

- Arc 160 S Inverter Welder sg3525 Ca3140 SCHDocument6 pagesArc 160 S Inverter Welder sg3525 Ca3140 SCHImre Kathi100% (2)

- Effect of Burden and Spacing On FragmentationDocument10 pagesEffect of Burden and Spacing On Fragmentationsaravanan sNo ratings yet

- I'm Still Standing, Melodie (Raphi)Document2 pagesI'm Still Standing, Melodie (Raphi)leunam62No ratings yet

- Mundo - IV of Spades (Bass Guitar)Document5 pagesMundo - IV of Spades (Bass Guitar)VinSongTabs100% (3)

- Drawing STDDocument6 pagesDrawing STDkavooriNo ratings yet

- Suppliers Input Output Customers Process: SipocDocument1 pageSuppliers Input Output Customers Process: SipocAbhishekChowdhuryNo ratings yet

- LagrimaDocument1 pageLagrimaildefonso legidosNo ratings yet

- Vare 6700 - Level Gauge IndicatorDocument4 pagesVare 6700 - Level Gauge IndicatorDylan RamasamyNo ratings yet

- Q2 Item Analysis 12D Q2Document12 pagesQ2 Item Analysis 12D Q2joyce bugayNo ratings yet

- Regleta 6700 Liquid Level IndicatorDocument4 pagesRegleta 6700 Liquid Level IndicatorJulio PCNo ratings yet

- 译文 - 多级离心泵Multistage centrifugal pumpDocument10 pages译文 - 多级离心泵Multistage centrifugal pumpVocal SamirNo ratings yet

- Concrete Reinforcement: 23 X 9,150,000 48% 1,315 X 9,864,717 52% RP 19,014,717 ,-/M'Document2 pagesConcrete Reinforcement: 23 X 9,150,000 48% 1,315 X 9,864,717 52% RP 19,014,717 ,-/M'Anonymous Xn5rKyeANo ratings yet

- VT098 - VT099DAM-83RCV2 Remote Control Valves Bosun StoreDocument11 pagesVT098 - VT099DAM-83RCV2 Remote Control Valves Bosun StorelequangNo ratings yet

- Marathon Digital Holdings - Investor Presentation - December 2021Document26 pagesMarathon Digital Holdings - Investor Presentation - December 2021cNo ratings yet

- DNS Normal Suspension Type Tower Detailed Design Report r0!02!08Document51 pagesDNS Normal Suspension Type Tower Detailed Design Report r0!02!08paulltzdaresalaamNo ratings yet

- Recierres 2021Document190 pagesRecierres 2021Wilson Bravo G.No ratings yet

- Fruity 1Document1 pageFruity 1Chim TrờiNo ratings yet

- Miller Remote Control US20120097644Document8 pagesMiller Remote Control US20120097644g4okk8809No ratings yet

- 11vietnam OffhsoreDocument3 pages11vietnam Offhsoremtejada8397No ratings yet

- 5.4 Full Containment Tank System: 5-6 Api S 625Document3 pages5.4 Full Containment Tank System: 5-6 Api S 625ycwangNo ratings yet

- Main Control SwitchDocument1 pageMain Control SwitchPoyaNo ratings yet

- FOREMANDocument1 pageFOREMANriogeskyNo ratings yet

- Kondisi KapalDocument6 pagesKondisi KapalThe AzmodeusNo ratings yet

- Answers To Student Book 2: Check inDocument41 pagesAnswers To Student Book 2: Check inHana MohamedNo ratings yet

- 1707-CEVI NA NIHAJNI ROKI-L15.pDocument2 pages1707-CEVI NA NIHAJNI ROKI-L15.pJanez KoširNo ratings yet

- Plan View Section Thru A-A Section Thru B-B: Scale 1:25 Mts Scale 1:25 Mts Scale 1:25 MtsDocument1 pagePlan View Section Thru A-A Section Thru B-B: Scale 1:25 Mts Scale 1:25 Mts Scale 1:25 MtsCharlene Anne Austria VillarozaNo ratings yet

- SSG Ed 100 Ele SLD 0002 - 2Document2 pagesSSG Ed 100 Ele SLD 0002 - 2Hanugroho AjiNo ratings yet

- SSG Ed 100 Ele SLD 0002 - 2Document2 pagesSSG Ed 100 Ele SLD 0002 - 2Hanugroho AjiNo ratings yet

- SSG Ed 100 Ele SLD 0002 - 2Document2 pagesSSG Ed 100 Ele SLD 0002 - 2Hanugroho AjiNo ratings yet

- SSG Ed 100 Ele SLD 0002 - 2Document2 pagesSSG Ed 100 Ele SLD 0002 - 2Hanugroho AjiNo ratings yet

- SSG Ed 100 Ele SLD 0002 - 2Document2 pagesSSG Ed 100 Ele SLD 0002 - 2Hanugroho AjiNo ratings yet

- SSG Ed 100 Ele SLD 0002 - 2Document2 pagesSSG Ed 100 Ele SLD 0002 - 2Hanugroho AjiNo ratings yet

- Alvarez, Melody Rhyme M.: Milwaukee Paper Manufacturing'S Activities and PredecessorsDocument2 pagesAlvarez, Melody Rhyme M.: Milwaukee Paper Manufacturing'S Activities and PredecessorsfrancisjoviNo ratings yet

- BrightonDocument5 pagesBrightonjosuedelios88No ratings yet

- KIP 3000 Parts Manual: Ver 5.0 Type A and B - Both ModelsDocument121 pagesKIP 3000 Parts Manual: Ver 5.0 Type A and B - Both ModelsjoeNo ratings yet

- Ionian Dorian: Chords and Scales: D Major Modes 1Document1 pageIonian Dorian: Chords and Scales: D Major Modes 1Michael LeFevreNo ratings yet

- TARAPE 3pdfDocument1 pageTARAPE 3pdfKey Mark TarapeNo ratings yet

- ACDC - Hard As A RockDocument2 pagesACDC - Hard As A RockJazz QuevedoNo ratings yet

- Bukid Transient - Floor PlanDocument1 pageBukid Transient - Floor PlanCathrina DuenasNo ratings yet

- Rsag7 820 1950Document1 pageRsag7 820 1950Eduardo BresciaNo ratings yet

- Emergency Lamp ChecklistDocument1 pageEmergency Lamp ChecklistSeprial GifariNo ratings yet

- Burzum - Jesus' TodDocument3 pagesBurzum - Jesus' Toddaky123xdNo ratings yet

- Factor Trees Apple HarvestDocument2 pagesFactor Trees Apple HarvestZeinab ElkholyNo ratings yet

- HighTech Kullanim Klavuzu 2018Document16 pagesHighTech Kullanim Klavuzu 2018ReggieNo ratings yet

- The Power of Scarcity: Leveraging Urgency and Demand to Influence Customer DecisionsFrom EverandThe Power of Scarcity: Leveraging Urgency and Demand to Influence Customer DecisionsNo ratings yet

- Syllabi: The Institution of Engineers, Sri LankaDocument107 pagesSyllabi: The Institution of Engineers, Sri LankaAmal Priyashantha Perera100% (2)

- System FinalDocument6 pagesSystem FinalhdhdhNo ratings yet

- EFI Swap GuideDocument18 pagesEFI Swap Guideasritaip100% (1)

- MBR-C1 Fundamentals of MBRDocument36 pagesMBR-C1 Fundamentals of MBRAlfonso José García Laguna100% (3)

- Awr 2r5srb122mf25sDocument12 pagesAwr 2r5srb122mf25sRubén Alberto Rodríguez PachanoNo ratings yet

- SBC AlternatorDocument4 pagesSBC Alternatormalik budi sNo ratings yet

- 02A Drilling Rig PDFDocument9 pages02A Drilling Rig PDFandrewNo ratings yet

- CFT21V43 Service ManualDocument17 pagesCFT21V43 Service ManualoscarmdNo ratings yet

- Buyer and Supplier Perspectives On Environmental InitiativesDocument33 pagesBuyer and Supplier Perspectives On Environmental InitiativesSifaariNo ratings yet

- Volume 5Document25 pagesVolume 5Gerald See TohNo ratings yet

- Chemistry Unit 1 Revision 1Document23 pagesChemistry Unit 1 Revision 1cuchikapoorNo ratings yet

- Taller 1 ElectrotecniaDocument17 pagesTaller 1 ElectrotecniaAlejoGonzalezNo ratings yet

- Efficiency of SeparationDocument2 pagesEfficiency of SeparationKudzaishe KuonaNo ratings yet

- H2S Safety MetricsDocument4 pagesH2S Safety Metricsbanker415No ratings yet

- Report of Servo MotorDocument3 pagesReport of Servo MotorMUHAMMAD KASHIFNo ratings yet

- 1.2 Applications of The Different Regions of EM Waves: Second Quarter WEEK 3 - Day 1Document18 pages1.2 Applications of The Different Regions of EM Waves: Second Quarter WEEK 3 - Day 1Ellen Rose OlbeNo ratings yet

- Universal X Plus LP (English)Document2 pagesUniversal X Plus LP (English)Srecko StokanovicNo ratings yet

- OJT Overtime Letter 2Document1 pageOJT Overtime Letter 2Audrey GordoNo ratings yet

- Gas Turbine OffshoreDocument214 pagesGas Turbine Offshorepbao_1280% (5)

- PDF ValveDocument13 pagesPDF ValveHyperFlickNo ratings yet

- SOP's TranslatedDocument10 pagesSOP's Translatedhemedi kitilaNo ratings yet

- Reliance Industries LimitedDocument21 pagesReliance Industries Limitedjaikumar608jainNo ratings yet

- I C Engines and Fluid Machinery LabDocument39 pagesI C Engines and Fluid Machinery LabranjithkrajNo ratings yet

- SulfurDocument21 pagesSulfurClaudia MmsNo ratings yet

- 1 s2.0 S0038092X2300107X MainDocument21 pages1 s2.0 S0038092X2300107X MainRachid BendaoudNo ratings yet

- Tank and Vessel Agitator SheetDocument2 pagesTank and Vessel Agitator SheetAnonymous jlLBRMAr3ONo ratings yet

- Csi PSC A0322lcDocument2 pagesCsi PSC A0322lcHeybrajhamNo ratings yet

- ANSI Standards ProtectionDocument6 pagesANSI Standards ProtectionmaungsoekhinNo ratings yet

- G.I. 150.003 Ionizing Radiation Protection PDFDocument12 pagesG.I. 150.003 Ionizing Radiation Protection PDFDurga Jagan Puppala100% (1)

An Introduction To Drilling

An Introduction To Drilling

Uploaded by

red_hairedsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

An Introduction To Drilling

An Introduction To Drilling

Uploaded by

red_hairedsCopyright:

Available Formats

An Introduction To Drilling

Ron Evett

Specialized Tools UK Sales Manager

1 12/08/2021 Confidential Information © 2010 M-I SWACO

Oil – Where it Comes From !

Petroleum, the general name for all carbon

byproducts like oil and natural gas, is formed from

organic material. This material, coming from land or

from dead plankton and other marine organisms,

reaches the floors of bodies of water and becomes

part of the many layers of sedimentary rock that form

there. As these layers form and more layers arrive on

top of them the organic material turns into petroleum

that is contained in the rock, called source rock. This

petroleum becomes oil if the amount of heating and

pressure on the source rock is sufficient but not too

much. To put it simply oil is considered “mature”

petroleum, whereas source rocks that were heated

less or more than is required to reach the mature

level yield less oil and more natural gas. This occurs

in a time frame of 10 to more than 300 million years

2 12/08/2021 Confidential Information © 2010 M-I SWACO

Types Of Rigs

Semi-Submersible

Platform

Jack-Up

Drillship

3 12/08/2021 Confidential Information © 2010 M-I SWACO

Types of Wells

Exploration Wells – Drilling a well into a prospect to test and appraise the levels of oil and gas

that are present.

Development Wells – Drilling a well into a know prospect with the intention to complete and

produce/inject from the reservoir.

Work-Overs – Maintenance work carried out existing wells to improve production or correct a

deficiency.

4 12/08/2021 Confidential Information © 2010 M-I SWACO

Drilling Solutions – Drilling Fluids

Functions of a drilling fluid are:

1. Control Formation Pressure

2. Remove Cuttings

3. Suspend and release cuttings

4. Seal permeable formations

5. Maintain Wellbore Stability

6. Minimize reservoir damage

7. Cool and lubricate the drill bit

8. Transmit hydraulic energy to

tools and the bit

5 12/08/2021 Confidential Information © 2010 M-I SWACO

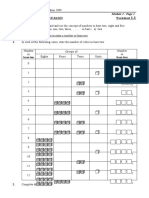

Environmental Solutions – Cuttings Containment/CRI

2

2

2

2 2

2

2

16 2

13 8

7 8

11 9 7

8

10 8

12 7

14 12

12

12

6

12

15

2

Cuttings Transfer 2

2

from Vessel to 2

2

2

Reinjection

1Vessel

2ISO Pump

Platform

Coarse Tank

10

Fines Tank

11 2

2

5

Boat Frame

3

4Tilt Table

Circulating

12 Pump 4

2

Classifying

13 Shaker 2

Floating

5 Hose Batch14 Holding Tank

Reinjection

6 Platform

H.P.

15 Injection Pump

7'R' Valve Injection

16 Wellhead

Weighframe

8 3 3

Slurrification

9 Unit 1

SW 03011

6 12/08/2021 Confidential Information © 2010 M-I SWACO

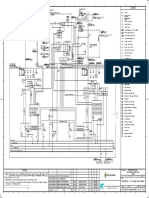

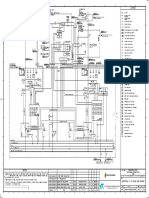

Well Construction – Casing and Liners

Marine Riser – The section of pipe that

connects the rig floor to the sea bed.

BOP –Blow Out Preventers

Casing – The section of pipe that is cemented

from the wellhead/seabed down into the well

Liner – Sections of pipe that are suspended

from casing by means of a hanger system

7 12/08/2021 Confidential Information © 2010 M-I SWACO

Production Casing

Large-diameter pipe lowered into an

open hole and cemented in place. The

well designer must design casing to

withstand a variety of forces, such as

collapse, burst, and tensile failure, as

well as chemically aggressive brines.

Basic Characteristics

•Size – 9.5/8”

•Weight – 53.5#

•Wall Thickness – 0.545”

•I.D. – 8.535”

•Drift – 8.379”

8 12/08/2021 Confidential Information © 2010 M-I SWACO

Production Liners

A casing string that does not extend to the top

of the wellbore, but instead is anchored or

suspended from inside the bottom of the

previous casing string. There is no difference

between the casing joints themselves. The

advantage to the well designer of a liner is a

substantial savings in steel, and therefore

capital costs.

Basic Characteristics

•Size – 7”

•Weight – 29.0#

•Wall Thickness – 0.408”

•I.D. – 6.184”

•Drift – 6.059”

9 12/08/2021 Confidential Information © 2010 M-I SWACO

Well Construction - Completions

Completion Types:

•Tubing Conveyed Perforation

•Open Hole Gravel Pack

•Pre-Packed Screens

•Multi-Lateral

•ESP

10 12/08/2021 Confidential Information © 2010 M-I SWACO

TCP

The use of tubing or drill-pipe convey

perforating guns to the required depth.

Initially, the technique was developed as a

means for conveying the gun string on the

production tubing, with the guns remaining in

the well until they are removed during the

first work-over. The subsequent popularity of

highly deviated and horizontal wells

increased the requirement for tubing-

conveyed perforating as the only means of

gaining access to the perforating depth. The

term is often abbreviated as TCP.

11 12/08/2021 Confidential Information © 2010 M-I SWACO

Gravel Pack

A type of sand-control completion in which

the gravel pack screen is packed off in an

open-hole section with no casing or liner to

support the producing formation.

12 12/08/2021 Confidential Information © 2010 M-I SWACO

Submersible Pumps

An artificial-lift system that utilizes a

downhole pumping system that is electrically

driven. The pump typically comprises

several staged centrifugal pump sections

that can be specifically configured to suit the

production and wellbore characteristics of a

given application. Electrical submersible

pump systems are a common artificial-lift

method, providing flexibility over a range of

sizes and output flow capacities.

13 12/08/2021 Confidential Information © 2010 M-I SWACO

Wellbore Clean-up

Typically between drilling and completion phases the fluid in the well is changed out or

“displaced” in order to prepare for running the completion.

During the displacement the host tubulars (casing and liners etc) are cleaned to prevent

the completion being damaged during running or to prevent debris that may have been

left in the well from causing damage to either the formation or the completion itself

during production. Such damage could shorten the life of the well and or bring on the

need for early work-over.

Typically there are two side to any wellbore clean-up:

1. Fluid/Chemical Clean-up

2. Mechanical Clean-up

14 12/08/2021 Confidential Information © 2010 M-I SWACO

Wellbore Clean-up - Fluids

In order to “displace” the drilling fluid and

prepare the tubulars for the introduction of

brine/completion fluid, a “pill train” is

typically pumped downhole.

This is designed in order to fully displace

the drilling fluid and then typically turn the

tubulars from an “oil wet” to a “water wet”

condition

15 12/08/2021 Confidential Information © 2010 M-I SWACO

Wellbore Clean-up – Mechanical

Mechanical Wellbore Clean-up Systems have been designed to effectively clean all types

of casings and liners and assist with debris extraction from the wellbore during

displacement to completion fluids.

Theses tools can be categorised as: -

Liner Top Test Tools

Casing Cleaning Tools

Circulating Tools

Debris Recovery Tools

Riser Cleaning Tools

BOP Cleaning Tools

Wellhead Cleaning Tools

Ancillary Tools

Customized Tools

16 12/08/2021 Confidential Information © 2010 M-I SWACO

Wellbore Productivity – Completion Fluids

A solids-free liquid used to "complete" an oil or gas well. This fluid is placed in the well to facilitate final

operations prior to initiation of production, such as setting screens production liners, packers, downhole valves

or shooting perforations into the producing zone. The fluid is meant to control a well should downhole hardware

fail, without damaging the producing formation or completion components.

Functions of a completion fluid are:

1. Maintain Hydrostatic in the well

2. Provide a clean environment for the completion

3. Be non-formation damaging

Inhibitors added:

4. Corrosion Inhibitor

5. Oxygen Scavenger

6. Biocide

17 12/08/2021 Confidential Information © 2010 M-I SWACO

Wellbore Productivity – Filtration

Basic Filtration Systems:

1. Bag Filter

2. Cartridge Unit

3. Filter Press and Cartridge Unit

18 12/08/2021 Confidential Information © 2010 M-I SWACO

Wellbore Productivity – Filtration

Filtration is required to provide the

cleanest possible environment for

the completion to exist in and to

protect the formation from invasion

of unwanted particulate.

The removal of debris from

completion fluids is required to

protect the completion components

and avoid the necessity for the well

to be worked over prematurely.

19 12/08/2021 Confidential Information © 2010 M-I SWACO

Wellbore Productivity – Pit Cleaning

Fluid is held within the rig’s “pit system” before being pumped downhole.

Therefore if the pits are not cleaned thoroughly before brine is transferred then

contamination will occur and well clean-up will be extremely time consuming.

2

3

20 12/08/2021 Confidential Information © 2010 M-I SWACO

You might also like

- Magical Kitties 2e - River City MapDocument1 pageMagical Kitties 2e - River City Mapecchi.moonlight100% (1)

- Chapter 2 WorkbookDocument31 pagesChapter 2 WorkbookYuni ArtaNo ratings yet

- The Toyota Kata Practice Guide: Practicing Scientific Thinking Skills for Superior Results in 20 Minutes a DayFrom EverandThe Toyota Kata Practice Guide: Practicing Scientific Thinking Skills for Superior Results in 20 Minutes a DayRating: 4.5 out of 5 stars4.5/5 (7)

- Computational Gas-Solids Flows and Reacting Systems - Theory, Methods and Practice (2011)Document500 pagesComputational Gas-Solids Flows and Reacting Systems - Theory, Methods and Practice (2011)Júlio César Spillere RonchiNo ratings yet

- 1 DentascanDocument10 pages1 DentascanSalem Fathi BermawiNo ratings yet

- B257.OL3 - 002 - Safety and Design - Rev01Document70 pagesB257.OL3 - 002 - Safety and Design - Rev01megapoulpeNo ratings yet

- 1 Waja 09 F5 Student's Copy Number BasesDocument12 pages1 Waja 09 F5 Student's Copy Number BasesramjalinaNo ratings yet

- GantchartDocument3 pagesGantchartsubhabirajdarNo ratings yet

- Fig 209 Leak TestDocument1 pageFig 209 Leak TestFRANCISCO JAVIER JARAMILLO MNo ratings yet

- Varec Sistem Masurare LichidTEC012 - 6700Document4 pagesVarec Sistem Masurare LichidTEC012 - 6700stroiebogdanNo ratings yet

- 133 141TP 06 009KecojevicPROOFDocument10 pages133 141TP 06 009KecojevicPROOFDiallo saidouNo ratings yet

- Nirma MPR - JULY 22Document38 pagesNirma MPR - JULY 22Kiran Kumar PatraNo ratings yet

- OLD DOGS, NEW TRICKS-BASS - (5-String)Document3 pagesOLD DOGS, NEW TRICKS-BASS - (5-String)O ThomasNo ratings yet

- AYPChart CriteriaDocument1 pageAYPChart CriteriawheptaNo ratings yet

- OM. K 970 III, K 970 III Rescue, K 970 SmartGuard. 2021-11Document152 pagesOM. K 970 III, K 970 III Rescue, K 970 SmartGuard. 2021-11SamossyzNo ratings yet

- Regleta Indicador de Nivel VAREC PDFDocument2 pagesRegleta Indicador de Nivel VAREC PDFWilson Alberto Poveda OsorioNo ratings yet

- Arc 160 S Inverter Welder sg3525 Ca3140 SCHDocument6 pagesArc 160 S Inverter Welder sg3525 Ca3140 SCHImre Kathi100% (2)

- Effect of Burden and Spacing On FragmentationDocument10 pagesEffect of Burden and Spacing On Fragmentationsaravanan sNo ratings yet

- I'm Still Standing, Melodie (Raphi)Document2 pagesI'm Still Standing, Melodie (Raphi)leunam62No ratings yet

- Mundo - IV of Spades (Bass Guitar)Document5 pagesMundo - IV of Spades (Bass Guitar)VinSongTabs100% (3)

- Drawing STDDocument6 pagesDrawing STDkavooriNo ratings yet

- Suppliers Input Output Customers Process: SipocDocument1 pageSuppliers Input Output Customers Process: SipocAbhishekChowdhuryNo ratings yet

- LagrimaDocument1 pageLagrimaildefonso legidosNo ratings yet

- Vare 6700 - Level Gauge IndicatorDocument4 pagesVare 6700 - Level Gauge IndicatorDylan RamasamyNo ratings yet

- Q2 Item Analysis 12D Q2Document12 pagesQ2 Item Analysis 12D Q2joyce bugayNo ratings yet

- Regleta 6700 Liquid Level IndicatorDocument4 pagesRegleta 6700 Liquid Level IndicatorJulio PCNo ratings yet

- 译文 - 多级离心泵Multistage centrifugal pumpDocument10 pages译文 - 多级离心泵Multistage centrifugal pumpVocal SamirNo ratings yet

- Concrete Reinforcement: 23 X 9,150,000 48% 1,315 X 9,864,717 52% RP 19,014,717 ,-/M'Document2 pagesConcrete Reinforcement: 23 X 9,150,000 48% 1,315 X 9,864,717 52% RP 19,014,717 ,-/M'Anonymous Xn5rKyeANo ratings yet

- VT098 - VT099DAM-83RCV2 Remote Control Valves Bosun StoreDocument11 pagesVT098 - VT099DAM-83RCV2 Remote Control Valves Bosun StorelequangNo ratings yet

- Marathon Digital Holdings - Investor Presentation - December 2021Document26 pagesMarathon Digital Holdings - Investor Presentation - December 2021cNo ratings yet

- DNS Normal Suspension Type Tower Detailed Design Report r0!02!08Document51 pagesDNS Normal Suspension Type Tower Detailed Design Report r0!02!08paulltzdaresalaamNo ratings yet

- Recierres 2021Document190 pagesRecierres 2021Wilson Bravo G.No ratings yet

- Fruity 1Document1 pageFruity 1Chim TrờiNo ratings yet

- Miller Remote Control US20120097644Document8 pagesMiller Remote Control US20120097644g4okk8809No ratings yet

- 11vietnam OffhsoreDocument3 pages11vietnam Offhsoremtejada8397No ratings yet

- 5.4 Full Containment Tank System: 5-6 Api S 625Document3 pages5.4 Full Containment Tank System: 5-6 Api S 625ycwangNo ratings yet

- Main Control SwitchDocument1 pageMain Control SwitchPoyaNo ratings yet

- FOREMANDocument1 pageFOREMANriogeskyNo ratings yet

- Kondisi KapalDocument6 pagesKondisi KapalThe AzmodeusNo ratings yet

- Answers To Student Book 2: Check inDocument41 pagesAnswers To Student Book 2: Check inHana MohamedNo ratings yet

- 1707-CEVI NA NIHAJNI ROKI-L15.pDocument2 pages1707-CEVI NA NIHAJNI ROKI-L15.pJanez KoširNo ratings yet

- Plan View Section Thru A-A Section Thru B-B: Scale 1:25 Mts Scale 1:25 Mts Scale 1:25 MtsDocument1 pagePlan View Section Thru A-A Section Thru B-B: Scale 1:25 Mts Scale 1:25 Mts Scale 1:25 MtsCharlene Anne Austria VillarozaNo ratings yet

- SSG Ed 100 Ele SLD 0002 - 2Document2 pagesSSG Ed 100 Ele SLD 0002 - 2Hanugroho AjiNo ratings yet

- SSG Ed 100 Ele SLD 0002 - 2Document2 pagesSSG Ed 100 Ele SLD 0002 - 2Hanugroho AjiNo ratings yet

- SSG Ed 100 Ele SLD 0002 - 2Document2 pagesSSG Ed 100 Ele SLD 0002 - 2Hanugroho AjiNo ratings yet

- SSG Ed 100 Ele SLD 0002 - 2Document2 pagesSSG Ed 100 Ele SLD 0002 - 2Hanugroho AjiNo ratings yet

- SSG Ed 100 Ele SLD 0002 - 2Document2 pagesSSG Ed 100 Ele SLD 0002 - 2Hanugroho AjiNo ratings yet

- SSG Ed 100 Ele SLD 0002 - 2Document2 pagesSSG Ed 100 Ele SLD 0002 - 2Hanugroho AjiNo ratings yet

- Alvarez, Melody Rhyme M.: Milwaukee Paper Manufacturing'S Activities and PredecessorsDocument2 pagesAlvarez, Melody Rhyme M.: Milwaukee Paper Manufacturing'S Activities and PredecessorsfrancisjoviNo ratings yet

- BrightonDocument5 pagesBrightonjosuedelios88No ratings yet

- KIP 3000 Parts Manual: Ver 5.0 Type A and B - Both ModelsDocument121 pagesKIP 3000 Parts Manual: Ver 5.0 Type A and B - Both ModelsjoeNo ratings yet

- Ionian Dorian: Chords and Scales: D Major Modes 1Document1 pageIonian Dorian: Chords and Scales: D Major Modes 1Michael LeFevreNo ratings yet

- TARAPE 3pdfDocument1 pageTARAPE 3pdfKey Mark TarapeNo ratings yet

- ACDC - Hard As A RockDocument2 pagesACDC - Hard As A RockJazz QuevedoNo ratings yet

- Bukid Transient - Floor PlanDocument1 pageBukid Transient - Floor PlanCathrina DuenasNo ratings yet

- Rsag7 820 1950Document1 pageRsag7 820 1950Eduardo BresciaNo ratings yet

- Emergency Lamp ChecklistDocument1 pageEmergency Lamp ChecklistSeprial GifariNo ratings yet

- Burzum - Jesus' TodDocument3 pagesBurzum - Jesus' Toddaky123xdNo ratings yet

- Factor Trees Apple HarvestDocument2 pagesFactor Trees Apple HarvestZeinab ElkholyNo ratings yet

- HighTech Kullanim Klavuzu 2018Document16 pagesHighTech Kullanim Klavuzu 2018ReggieNo ratings yet

- The Power of Scarcity: Leveraging Urgency and Demand to Influence Customer DecisionsFrom EverandThe Power of Scarcity: Leveraging Urgency and Demand to Influence Customer DecisionsNo ratings yet

- Syllabi: The Institution of Engineers, Sri LankaDocument107 pagesSyllabi: The Institution of Engineers, Sri LankaAmal Priyashantha Perera100% (2)

- System FinalDocument6 pagesSystem FinalhdhdhNo ratings yet

- EFI Swap GuideDocument18 pagesEFI Swap Guideasritaip100% (1)

- MBR-C1 Fundamentals of MBRDocument36 pagesMBR-C1 Fundamentals of MBRAlfonso José García Laguna100% (3)

- Awr 2r5srb122mf25sDocument12 pagesAwr 2r5srb122mf25sRubén Alberto Rodríguez PachanoNo ratings yet

- SBC AlternatorDocument4 pagesSBC Alternatormalik budi sNo ratings yet

- 02A Drilling Rig PDFDocument9 pages02A Drilling Rig PDFandrewNo ratings yet

- CFT21V43 Service ManualDocument17 pagesCFT21V43 Service ManualoscarmdNo ratings yet

- Buyer and Supplier Perspectives On Environmental InitiativesDocument33 pagesBuyer and Supplier Perspectives On Environmental InitiativesSifaariNo ratings yet

- Volume 5Document25 pagesVolume 5Gerald See TohNo ratings yet

- Chemistry Unit 1 Revision 1Document23 pagesChemistry Unit 1 Revision 1cuchikapoorNo ratings yet

- Taller 1 ElectrotecniaDocument17 pagesTaller 1 ElectrotecniaAlejoGonzalezNo ratings yet

- Efficiency of SeparationDocument2 pagesEfficiency of SeparationKudzaishe KuonaNo ratings yet

- H2S Safety MetricsDocument4 pagesH2S Safety Metricsbanker415No ratings yet

- Report of Servo MotorDocument3 pagesReport of Servo MotorMUHAMMAD KASHIFNo ratings yet

- 1.2 Applications of The Different Regions of EM Waves: Second Quarter WEEK 3 - Day 1Document18 pages1.2 Applications of The Different Regions of EM Waves: Second Quarter WEEK 3 - Day 1Ellen Rose OlbeNo ratings yet

- Universal X Plus LP (English)Document2 pagesUniversal X Plus LP (English)Srecko StokanovicNo ratings yet

- OJT Overtime Letter 2Document1 pageOJT Overtime Letter 2Audrey GordoNo ratings yet

- Gas Turbine OffshoreDocument214 pagesGas Turbine Offshorepbao_1280% (5)

- PDF ValveDocument13 pagesPDF ValveHyperFlickNo ratings yet

- SOP's TranslatedDocument10 pagesSOP's Translatedhemedi kitilaNo ratings yet

- Reliance Industries LimitedDocument21 pagesReliance Industries Limitedjaikumar608jainNo ratings yet

- I C Engines and Fluid Machinery LabDocument39 pagesI C Engines and Fluid Machinery LabranjithkrajNo ratings yet

- SulfurDocument21 pagesSulfurClaudia MmsNo ratings yet

- 1 s2.0 S0038092X2300107X MainDocument21 pages1 s2.0 S0038092X2300107X MainRachid BendaoudNo ratings yet

- Tank and Vessel Agitator SheetDocument2 pagesTank and Vessel Agitator SheetAnonymous jlLBRMAr3ONo ratings yet

- Csi PSC A0322lcDocument2 pagesCsi PSC A0322lcHeybrajhamNo ratings yet

- ANSI Standards ProtectionDocument6 pagesANSI Standards ProtectionmaungsoekhinNo ratings yet

- G.I. 150.003 Ionizing Radiation Protection PDFDocument12 pagesG.I. 150.003 Ionizing Radiation Protection PDFDurga Jagan Puppala100% (1)