Professional Documents

Culture Documents

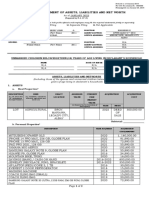

Wal-Mart: Qurat Ul Ain Malik 21536 Sabir Wahab 20603

Wal-Mart: Qurat Ul Ain Malik 21536 Sabir Wahab 20603

Uploaded by

Shantanu Yadav0 ratings0% found this document useful (0 votes)

81 views20 pagesWalmart was founded in 1962 by Sam Walton and is now a large multinational retail corporation. It was one of the first retailers to centralize its distribution system and employ information technology to manage its supply chain processes efficiently. Key IT initiatives included introducing EDI for procurement, establishing a computer network to link stores and headquarters, implementing voice-based ordering in warehouses, using GPS in trucks, forecasting demand in collaboration with suppliers, and asking suppliers to use RFID tags. These IT-driven supply chain innovations helped Walmart reduce costs and inventory levels while improving product availability.

Original Description:

Original Title

Wallmart

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWalmart was founded in 1962 by Sam Walton and is now a large multinational retail corporation. It was one of the first retailers to centralize its distribution system and employ information technology to manage its supply chain processes efficiently. Key IT initiatives included introducing EDI for procurement, establishing a computer network to link stores and headquarters, implementing voice-based ordering in warehouses, using GPS in trucks, forecasting demand in collaboration with suppliers, and asking suppliers to use RFID tags. These IT-driven supply chain innovations helped Walmart reduce costs and inventory levels while improving product availability.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

81 views20 pagesWal-Mart: Qurat Ul Ain Malik 21536 Sabir Wahab 20603

Wal-Mart: Qurat Ul Ain Malik 21536 Sabir Wahab 20603

Uploaded by

Shantanu YadavWalmart was founded in 1962 by Sam Walton and is now a large multinational retail corporation. It was one of the first retailers to centralize its distribution system and employ information technology to manage its supply chain processes efficiently. Key IT initiatives included introducing EDI for procurement, establishing a computer network to link stores and headquarters, implementing voice-based ordering in warehouses, using GPS in trucks, forecasting demand in collaboration with suppliers, and asking suppliers to use RFID tags. These IT-driven supply chain innovations helped Walmart reduce costs and inventory levels while improving product availability.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 20

Wal-Mart

QURAT UL AIN MALIK 21536

SABIR WAHAB 20603

INTRODUCTION

Walmart, an American multinational retail corporation that

runs chains of large department and warehouse stores

Established 1962, Arkansan-USA

Sam Walton- Founder & Mike duke- current CEO

Successful due to its IT usage in SCM

Wal-Mart known for innovative business practices

One of the first retailing companies to centralize distribution

system.

Always among the front runners in employing IT to manage

its supply chain processes.

INTRODUCED EDI FOR

PROCUREMENT

Using EDI for procurement

EDI saved time and made procurement efficient.

Using the bar code scanners, an analysis of daily, weekly,

monthly sales data helped the store manager determine

what products were selling and at what quantity.

Accordingly, the store manager would place orders in the

manufacturing division.

EDI=Electronic Data Interchange

AUTOMATED OPERATIONS

In 1977, Wal-Mart set up a computer terminal network

(CTN) to establish a communication link between its stores

and the company headquarters

Real time business operations

In 1978, Wal-Mart set up its first fully automated

distribution center

Wal-Mart placed orders for huge quantities of goods with its

suppliers

Cost of sales worked out to be 2-3 %(very low from

industry average)

Information of product, manufacturer, price was recorded

on computer system

That information was passed to centralized data warehouse

Analysis of daily, weekly, monthly sales data helped store

manager to determine which products were sold in which

quantities

So that they can place purchase order

Edi also helped suppliers

Right merchandize at the right time, and have it at right

place at right price

WAREHOUSING

Using voice based technologies: Enhancing warehouse and

logistics management

Wal-Mart could replenish stock at any of its 1525 stores in

US within 24 hours

It enabled the company to receive goods and dispatch them

to stores in less than a day

It installed voice based order filling(VOF) system in all

distribution centers

Is consisted portable Voice Recognition Talkman

Terminals(VRTT) and radio module on company’s wireless

LAN

It eliminated mis-picks and product labeling costs since

VOF didn’t require paper lists labor

GPS

GPS system in communication in trucks

Any truck can be located

Drivers could activate system by voice and interact with

staff

INVENTORY

MANAGEMENT

The Retail Link system- Supporting Inventory Management

Retail link connected EDI network to extranet ,accessible to

all suppliers

Provided suppliers historical sales data of 24 months,

allowed them to track invoice, can make demand forecast

Suppliers could also study competitors products demand

FORECASTING

CPFR (Collaborative Planning Forecasting

Replenishment)

Real time bases to determine product wise demand forecast

Wal-Mart shared past data, customer data, demographic

data, stock positions

Both forecasted demand individually and then co-operated

Reduced inventory cost

Product availability across supply chain

As a result lead time was cut to 11 days from 21 days

On-hand inventory was reduced by two weeks

Sales grew by $8.5 millions in six months

Later on it was implemented to other stores

INITIATIVES

2001- Global Procurement Division[Shenzhen, China

Exchange of sales and inventory data

Best deal procurement from any part of world

Strategy Employed

Identify generic products

Enhance product quality

reduce cost by collaborating

2001- copy paper – increased sales

[ 46% in UK, 94% in Federal Republic of Germany, 38% in Canada,

25% in US]

October 2002- Asked suppliers to replace VAN-EDI to Web based EDI

Direct online communication between trading partners

No transaction costs

Highly secured

Saved millions[ VAN-EDI cost $200 Billion]

No licensing fees

July 2003 – Asked suppliers to place RFID tags on goods, packed in

pallets and crates

VAN-EDI = Value Added Network-EDI

RFID = Radio Frequency Identification

BENEFITS

Drastic decrease in Stock out situations

From $400 million to $1.2 billion for P&G

Lesser labor requirements

Almost $6.34 billion yearly

Decrease in merchandise thefts

Almost $2 billion

Real time tracking of consumption patterns

Would help enhance JIT Inventory management system

Decrease in stock levels by around 25%[IBM]

Total savings expected to be 8.34 billion per year

You might also like

- Wal-Marts Supply Chain Management Practices (B) - Using IT Internet To Manage The Supply ChainDocument8 pagesWal-Marts Supply Chain Management Practices (B) - Using IT Internet To Manage The Supply Chainrakeshb11No ratings yet

- Answers of WalmartDocument4 pagesAnswers of WalmartMuhammad Omer Ateeque83% (6)

- Operations at WhirlpoolDocument5 pagesOperations at WhirlpoolAnonymous kayEII5NNo ratings yet

- Supply Chain 4.0: From Stocking Shelves to Running the World Fuelled by Industry 4.0From EverandSupply Chain 4.0: From Stocking Shelves to Running the World Fuelled by Industry 4.0Rating: 3 out of 5 stars3/5 (1)

- i-VMS 4200 Installation Manual (Linux OS)Document4 pagesi-VMS 4200 Installation Manual (Linux OS)Sureshkumar J0% (3)

- Mis in Walmart: Presented by Archa S & Shifa A RasheedDocument14 pagesMis in Walmart: Presented by Archa S & Shifa A RasheedShifa RasheedNo ratings yet

- 3 Supply Chain of WalmartDocument38 pages3 Supply Chain of WalmartkhyahiaNo ratings yet

- Walmart Case SolutionDocument4 pagesWalmart Case SolutionAnubhav Kumar100% (2)

- Supply Chain of Wal-Mart: Members: Chan Man Ching Chan Mong Tik Chui Wai Ka Lam Fei Fei Man Ka YuDocument38 pagesSupply Chain of Wal-Mart: Members: Chan Man Ching Chan Mong Tik Chui Wai Ka Lam Fei Fei Man Ka YumizbuzieyNo ratings yet

- WalmartDocument27 pagesWalmartAkashVermaNo ratings yet

- WalmartDocument53 pagesWalmartkishantejaniNo ratings yet

- Supply Chain Information TechnologyDocument11 pagesSupply Chain Information TechnologyKishore JohnNo ratings yet

- Wall-Mart's Supply Chain Management Practice (B) - Using IT/Internet To Manage The Supply ChainDocument11 pagesWall-Mart's Supply Chain Management Practice (B) - Using IT/Internet To Manage The Supply ChainSurbhi GuptaNo ratings yet

- Role of Infarmation Technology in WalDocument12 pagesRole of Infarmation Technology in WalMukesh KumarNo ratings yet

- Wal-Mart: A Symbol of Success N' InnovationDocument43 pagesWal-Mart: A Symbol of Success N' InnovationKaushal AgarwalNo ratings yet

- Purchasing: Distribution:: MarketsDocument3 pagesPurchasing: Distribution:: MarketsNeeraj GargNo ratings yet

- Wal Mart FinalDocument21 pagesWal Mart FinalFaizan UsmaniNo ratings yet

- Systems and Operations Management: Wal-MartDocument21 pagesSystems and Operations Management: Wal-MartAmitNo ratings yet

- WalMart Supply ChainDocument35 pagesWalMart Supply ChainckapasiNo ratings yet

- Wal - MartDocument37 pagesWal - MartDivyaNo ratings yet

- Project Management ProjectDocument21 pagesProject Management ProjectANAM AFTAB 22GSOB2010404No ratings yet

- Echnologies Used IN Pparel Ndustry: Presented By: ANSHUL Manish Nitin Srikant Poonam RavindraDocument54 pagesEchnologies Used IN Pparel Ndustry: Presented By: ANSHUL Manish Nitin Srikant Poonam RavindraNeo KinNo ratings yet

- Trend in Supply Chain.F.merchandising - RanjanDocument22 pagesTrend in Supply Chain.F.merchandising - RanjanRavi SinghNo ratings yet

- Technology in RetailingDocument47 pagesTechnology in RetailingMahalakshmi MoganNo ratings yet

- It' in Retail Chain: Priyadharshini.R Mohan Kumar.G.VDocument22 pagesIt' in Retail Chain: Priyadharshini.R Mohan Kumar.G.V123mahaqNo ratings yet

- Improvement of Warehouse Operations Through Implementation of Mobile Barcode Systems Aimed at Advancing Sales ProcessDocument7 pagesImprovement of Warehouse Operations Through Implementation of Mobile Barcode Systems Aimed at Advancing Sales ProcessaresatNo ratings yet

- Internet Enabled SCMDocument13 pagesInternet Enabled SCMAyush GoelNo ratings yet

- Supply Chain Management OF: Submitted byDocument11 pagesSupply Chain Management OF: Submitted byprateek gandhiNo ratings yet

- WalmartDocument19 pagesWalmartShweta RawatNo ratings yet

- Emergence of Wireless Technology in RetailDocument7 pagesEmergence of Wireless Technology in RetailMahbubul Islam KoushickNo ratings yet

- Wal Mart EssayDocument4 pagesWal Mart Essayshanaka100No ratings yet

- Wal-Mart and RFIDDocument31 pagesWal-Mart and RFIDTahnee TsenNo ratings yet

- DM NotesDocument22 pagesDM NotesAdarsh RaiNo ratings yet

- Rahul V S ShekhawatDocument25 pagesRahul V S ShekhawatRahul shekhawatNo ratings yet

- As#2, SCM Retail, Tousief AhmedDocument21 pagesAs#2, SCM Retail, Tousief AhmedSyed TousiefNo ratings yet

- The State of RFID Implementation in North AmericaDocument5 pagesThe State of RFID Implementation in North AmericaOtis MelbournNo ratings yet

- Retail Logistics and ITDocument22 pagesRetail Logistics and ITRakeysh CoomarNo ratings yet

- Walmart Value ChainDocument4 pagesWalmart Value ChainManvinder Bali100% (1)

- IT Enabled Supply Chain Management: Definition of SCMDocument4 pagesIT Enabled Supply Chain Management: Definition of SCMjehana_bethNo ratings yet

- Solutions For Week 6 Case Study 2Document3 pagesSolutions For Week 6 Case Study 2ThiyyaguraSudheerKumarReddyNo ratings yet

- Wal-Mart Stores, Inc. Is An American: Public CorporationDocument4 pagesWal-Mart Stores, Inc. Is An American: Public CorporationMayank Sharan GargNo ratings yet

- MIS ProjectDocument7 pagesMIS ProjectAbeer Sultan AwanNo ratings yet

- Supply Chain Management (Wal-Mart)Document34 pagesSupply Chain Management (Wal-Mart)bombasticbratNo ratings yet

- SynopsisDocument4 pagesSynopsisSameer MalhotraNo ratings yet

- Procter & Gamble: Using Agent Based Modeling and RFID: Supply Chain ManagementDocument18 pagesProcter & Gamble: Using Agent Based Modeling and RFID: Supply Chain ManagementJames KudrowNo ratings yet

- Rfid Cloud ComputingDocument8 pagesRfid Cloud ComputingLejithNo ratings yet

- Assignment 1: Submitted To: Prof Manpreet Kaur Submitted By: Sagar AroraDocument7 pagesAssignment 1: Submitted To: Prof Manpreet Kaur Submitted By: Sagar AroraSharry AroraNo ratings yet

- 3 Supply Chain ManagementDocument9 pages3 Supply Chain ManagementkarimakkiNo ratings yet

- Case Study Presentation On Walmart: Service Operations ManagementDocument24 pagesCase Study Presentation On Walmart: Service Operations ManagementmsulgadleNo ratings yet

- Pivotal To A Truly Intelligent Supply ChainDocument11 pagesPivotal To A Truly Intelligent Supply ChainRithin PrakashNo ratings yet

- Chapter 12 QADocument6 pagesChapter 12 QAShamara ZamanNo ratings yet

- IS - MBA - Session 12Document25 pagesIS - MBA - Session 12Rohit KumarNo ratings yet

- Synnex Case AnalysisDocument25 pagesSynnex Case AnalysisRajarshi Dey100% (1)

- Supply Chian History ArticleDocument2 pagesSupply Chian History ArticlenileshNo ratings yet

- Mobile Store ManagmentDocument72 pagesMobile Store ManagmentSandeep KumarNo ratings yet

- Walmart's Supply ChainDocument18 pagesWalmart's Supply ChainNeha SinghNo ratings yet

- SCM WalmartDocument5 pagesSCM Walmartmuditmathur24100% (1)

- Emergence of Wireless Technology in RetailDocument7 pagesEmergence of Wireless Technology in RetailChandan PahelwaniNo ratings yet

- Development and Implementation of RadiofrequencyDocument18 pagesDevelopment and Implementation of RadiofrequencyisttNo ratings yet

- Presentation ON: Wal-Mart'S Supply Chain Management PracticesDocument19 pagesPresentation ON: Wal-Mart'S Supply Chain Management Practicesswati_vigNo ratings yet

- Group 3 - TQM - Narayana Vs JayadevaDocument12 pagesGroup 3 - TQM - Narayana Vs JayadevaShantanu YadavNo ratings yet

- Pitch Deck - Theme2Document27 pagesPitch Deck - Theme2Shantanu YadavNo ratings yet

- US Trade Wars: A Bri Ef Hi Story ofDocument1 pageUS Trade Wars: A Bri Ef Hi Story ofShantanu YadavNo ratings yet

- Slide in Oil Demand: Said in A Statement Last MonthDocument2 pagesSlide in Oil Demand: Said in A Statement Last MonthShantanu YadavNo ratings yet

- Compendium-IIFT MBADocument3 pagesCompendium-IIFT MBAShantanu YadavNo ratings yet

- LogDocument17 pagesLogNeneng KomalasariNo ratings yet

- The Digital in Architecture - Then, Now and in The Future - SPACE10Document45 pagesThe Digital in Architecture - Then, Now and in The Future - SPACE10André VianaNo ratings yet

- Icc3 PDFDocument1,336 pagesIcc3 PDF783520101No ratings yet

- Daily Time Record Keeping SystemDocument6 pagesDaily Time Record Keeping SystemVickram JainNo ratings yet

- Virtual Simulation For Radiatiotherapy Treatment Using CT Medical DataDocument7 pagesVirtual Simulation For Radiatiotherapy Treatment Using CT Medical Datasangeetha maniNo ratings yet

- Densification of GNSS Control Points For CadastralDocument13 pagesDensification of GNSS Control Points For Cadastralshio shioNo ratings yet

- BS The Legend of Zelda (Map 2)Document33 pagesBS The Legend of Zelda (Map 2)Edgardo SicatNo ratings yet

- 2015 SALN Form PDFDocument2 pages2015 SALN Form PDFHenry JohnNo ratings yet

- US4834701Document6 pagesUS4834701laureanojeremiasgimenezNo ratings yet

- Real-Time Automation Controller (RTAC)Document12 pagesReal-Time Automation Controller (RTAC)RodrigoNo ratings yet

- Mikkonen TiiaDocument49 pagesMikkonen Tiia11mustafa.mNo ratings yet

- Roll No 316 Zohaib Shaikh Practical Assignment 1Document70 pagesRoll No 316 Zohaib Shaikh Practical Assignment 1Zohaib ShaikhNo ratings yet

- SPM NotesDocument15 pagesSPM NotesFaiz 7011No ratings yet

- AQM Test Report 21 08 2013Document3 pagesAQM Test Report 21 08 2013Mohamed YehiaNo ratings yet

- 1769CRR1 13544 DatasheetDocument1 page1769CRR1 13544 DatasheetAlvin Azhar IrfaniNo ratings yet

- TSS RX 22 HL PDFDocument1 pageTSS RX 22 HL PDFtsdcnNo ratings yet

- DVR Models of Different Platforms 240130Document36 pagesDVR Models of Different Platforms 240130kevin RamirezNo ratings yet

- DocuWide 3035 BrochureDocument8 pagesDocuWide 3035 BrochureRumen Stoychev0% (1)

- Abdelrahman Elsharbaty ResumeDocument2 pagesAbdelrahman Elsharbaty Resumeabdelrhman aymanNo ratings yet

- Database Management Systems-1Document10 pagesDatabase Management Systems-1Arun SasidharanNo ratings yet

- Gamification - A Path To Growth Mindset: A Guide For ParentsDocument12 pagesGamification - A Path To Growth Mindset: A Guide For ParentsPhạm Bích HồngNo ratings yet

- PunyaweePosri WEB PHISHINGDocument16 pagesPunyaweePosri WEB PHISHINGALGO INDUSTRYNo ratings yet

- NessusDocument29 pagesNessusAlan LimNo ratings yet

- Untitled fr11Document69 pagesUntitled fr11Nathan FMNo ratings yet

- MS Access Database Creating Process DetailsDocument4 pagesMS Access Database Creating Process DetailsAli MurtazaNo ratings yet

- ITECH - 1103 - Mid - Sem - TestDocument3 pagesITECH - 1103 - Mid - Sem - TestharryNo ratings yet

- Ubuntu BIOS & UEFI Requirements: Canonical LTDDocument42 pagesUbuntu BIOS & UEFI Requirements: Canonical LTDTazkiya ArofahNo ratings yet

- 202003251324427324himanshu Linked ListDocument60 pages202003251324427324himanshu Linked Listaparna gurramNo ratings yet

- How To Add A Password To The XAMPP Root UserDocument3 pagesHow To Add A Password To The XAMPP Root UserMilan BaratovicNo ratings yet