Professional Documents

Culture Documents

Measurement Systems Analysis

Measurement Systems Analysis

Uploaded by

Farrukh JamilCopyright:

Available Formats

You might also like

- MSA Training PPT 14-07-2020 PDFDocument125 pagesMSA Training PPT 14-07-2020 PDFLAKSHYA MITTAL100% (4)

- Practical Risk Theory For ActuariesDocument1 pagePractical Risk Theory For ActuariesCesar JvNo ratings yet

- SPM Addmath 2007 AnswerDocument3 pagesSPM Addmath 2007 Answermaieqa8738% (8)

- Solutions Act. 2-Structural TheoryDocument3 pagesSolutions Act. 2-Structural TheoryChuckie EntocNo ratings yet

- Validation Tool 1Document2 pagesValidation Tool 1Charish Monarca Rosaldes100% (3)

- MSA BriefDocument17 pagesMSA BriefUrdanNo ratings yet

- Assessing Measurement System Variation: Example 1: Fuel Injector Nozzle DiametersDocument20 pagesAssessing Measurement System Variation: Example 1: Fuel Injector Nozzle DiametersnadeemaneezNo ratings yet

- Training Material For: Easurement Ystem NalysisDocument61 pagesTraining Material For: Easurement Ystem NalysisDotecho Jzo EyNo ratings yet

- Training Sample Measurement Systems MTB16 ENDocument19 pagesTraining Sample Measurement Systems MTB16 ENguto_udescNo ratings yet

- 5 MsaDocument81 pages5 MsaVIPIN YADAVNo ratings yet

- TPM Lecture 09Document21 pagesTPM Lecture 09Zeeshan ElahiNo ratings yet

- Lecture 4Document54 pagesLecture 4Eda ÖzkolNo ratings yet

- Chapter 3 - MeasureDocument75 pagesChapter 3 - MeasureNitish NitinNo ratings yet

- MSA Sample PresentationDocument9 pagesMSA Sample PresentationTom@GGCNo ratings yet

- Case Study 2Document5 pagesCase Study 2ramtwinsmeNo ratings yet

- Measurements: Chapter FourDocument14 pagesMeasurements: Chapter FourcuribenNo ratings yet

- CORE TOOLS-MSA 4th EdDocument94 pagesCORE TOOLS-MSA 4th EdcuitlahuacbmoncivaezNo ratings yet

- Lecture 4 - Metrology & MeasurementDocument15 pagesLecture 4 - Metrology & MeasurementharoonNo ratings yet

- Lecture 10Document28 pagesLecture 10anaditaprasadNo ratings yet

- Measurement Systems Analysis: Total Quality ManagementDocument17 pagesMeasurement Systems Analysis: Total Quality Managementkhamaludin100% (1)

- Lecture 3, General Concepts and Definitions in Metrology - DR Janakarajan RamkumarDocument35 pagesLecture 3, General Concepts and Definitions in Metrology - DR Janakarajan RamkumarRUKESHAPSISNo ratings yet

- Measurement Systems Analysis - A Management PerspectiveDocument8 pagesMeasurement Systems Analysis - A Management PerspectiveleovenceNo ratings yet

- Quality Control 1Document59 pagesQuality Control 1Melanie TranNo ratings yet

- EIM PPT 1Document17 pagesEIM PPT 1rahul0% (1)

- Metrology: DefinitionDocument17 pagesMetrology: Definitionmohd zeeshanNo ratings yet

- MSA - Measurement System Analysis - Quality-OneDocument6 pagesMSA - Measurement System Analysis - Quality-OneAmitesh SouravNo ratings yet

- Welcome: Training ProgramDocument66 pagesWelcome: Training ProgramAnkurNo ratings yet

- MSA PPT Latest - 240529 - 141424Document28 pagesMSA PPT Latest - 240529 - 141424Rithesh ShettyNo ratings yet

- Manufacturing Technology (ME 361) - Lecture 20: Engineering MetrologyDocument35 pagesManufacturing Technology (ME 361) - Lecture 20: Engineering MetrologySahil SundaNo ratings yet

- Quality Assurance & Lab MathDocument6 pagesQuality Assurance & Lab MathMica BernardoNo ratings yet

- Quality Control For Sampling and Chemical AnalysisDocument63 pagesQuality Control For Sampling and Chemical AnalysisEdgardo Ed Ramirez100% (1)

- Gage R&RDocument25 pagesGage R&RMario Mora GarciaNo ratings yet

- Quality Control in Measurements: Tom Colella CLAS Goldwater Environmental LabDocument20 pagesQuality Control in Measurements: Tom Colella CLAS Goldwater Environmental Labchit catNo ratings yet

- MSA PresentationDocument37 pagesMSA Presentationelifexp100% (1)

- How Often Does The Product Fail ? How Often Does This Car Require Repair ?Document7 pagesHow Often Does The Product Fail ? How Often Does This Car Require Repair ?TahaNo ratings yet

- 05 Metrology (H Karcı) - V2Document63 pages05 Metrology (H Karcı) - V2maloxix105No ratings yet

- CMMDocument90 pagesCMMA S100% (1)

- CalibrationDocument45 pagesCalibrationDeb RoyNo ratings yet

- Measurement: "Whatever Exists, Exists in Some Amount"Document33 pagesMeasurement: "Whatever Exists, Exists in Some Amount"aravinthNo ratings yet

- Single Laboratory ValidationDocument39 pagesSingle Laboratory ValidationMarcos LoredoNo ratings yet

- Quality ManagementDocument80 pagesQuality ManagementMayank GandhiNo ratings yet

- Quality Management ISO 17025:2005Document65 pagesQuality Management ISO 17025:2005Gerrit Van Der WaltNo ratings yet

- Measurement System AnalysisDocument42 pagesMeasurement System Analysisazadsingh1No ratings yet

- QC and QADocument9 pagesQC and QAClarisse De GuzmanNo ratings yet

- Gage Studies For Continuous Data: ObjectivesDocument21 pagesGage Studies For Continuous Data: ObjectivesNigam PatroNo ratings yet

- Measurement Systems Analysis: Total Quality ManagementDocument17 pagesMeasurement Systems Analysis: Total Quality ManagementmanuelNo ratings yet

- Evaluating The Measurement Process (EMP) OverviewDocument12 pagesEvaluating The Measurement Process (EMP) OverviewMorgana MelloNo ratings yet

- Quality Assurance and Quality ControlDocument56 pagesQuality Assurance and Quality ControlprnfbmsdqnNo ratings yet

- 18 Measurement Systems AnalysisDocument118 pages18 Measurement Systems Analysisankit7588No ratings yet

- Metrology: Production Engineering 2 Code: MEC3202Document58 pagesMetrology: Production Engineering 2 Code: MEC3202sakali aliNo ratings yet

- Measurement Systems Analysis: Total Quality ManagementDocument17 pagesMeasurement Systems Analysis: Total Quality Managementtlatuani1000No ratings yet

- CompressedDocument50 pagesCompressedTaimoor HassanNo ratings yet

- Measurement Systems Analysis WebinarDocument37 pagesMeasurement Systems Analysis WebinarOlirvag100% (1)

- MetrologyDocument69 pagesMetrologyU2103097 STUDENTNo ratings yet

- Unit I MQCDocument92 pagesUnit I MQCNACHIKETHA B NNo ratings yet

- MeasurementsDocument14 pagesMeasurementsAmit AdhayeNo ratings yet

- PG&E Advanced Metering Assessment For Residential Electric CustomersDocument12 pagesPG&E Advanced Metering Assessment For Residential Electric CustomersKat DonnellyNo ratings yet

- MSA - Level 1Document8 pagesMSA - Level 1Sachin RamdurgNo ratings yet

- Measurement System Analysis (MSA) : Validating Your Measurement Systems Gy yDocument16 pagesMeasurement System Analysis (MSA) : Validating Your Measurement Systems Gy yHesham MahdyNo ratings yet

- Tep by TEP Pproach To Valuation and Omparison OF Nalytical EthodsDocument54 pagesTep by TEP Pproach To Valuation and Omparison OF Nalytical EthodsMalliga SundareshanNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Analysis of Variance (Anova) Part 2 Two-Way Anova ReplicationDocument18 pagesAnalysis of Variance (Anova) Part 2 Two-Way Anova ReplicationFarrukh JamilNo ratings yet

- Analysis of Variance (ANOVA)Document12 pagesAnalysis of Variance (ANOVA)Farrukh JamilNo ratings yet

- de 6 Dca 404 CDocument31 pagesde 6 Dca 404 CFarrukh JamilNo ratings yet

- Canada New Order ComforterDocument65 pagesCanada New Order ComforterFarrukh JamilNo ratings yet

- Analysis of Variance (Anova) : Madam Siti Aisyah Zakaria EQT 271 SEM 2 2014/2015Document29 pagesAnalysis of Variance (Anova) : Madam Siti Aisyah Zakaria EQT 271 SEM 2 2014/2015Farrukh JamilNo ratings yet

- Analysis of Variance (Anova) Part 3 Two-Way Anova Replication (Factorial Experiment)Document21 pagesAnalysis of Variance (Anova) Part 3 Two-Way Anova Replication (Factorial Experiment)Farrukh JamilNo ratings yet

- 5 Minute Guide: 4 Press ENTER. 5 Use The MULTI JOG Dial To Choose Your Room SizeDocument1 page5 Minute Guide: 4 Press ENTER. 5 Use The MULTI JOG Dial To Choose Your Room SizeFarrukh JamilNo ratings yet

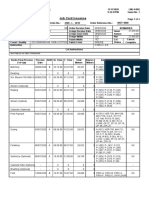

- Liberty Mills Limited: Job Card IssuanceDocument3 pagesLiberty Mills Limited: Job Card IssuanceFarrukh JamilNo ratings yet

- Liberty Mills Limited: Job Card IssuanceDocument4 pagesLiberty Mills Limited: Job Card IssuanceFarrukh JamilNo ratings yet

- Liberty Mills Limited: Job Card IssuanceDocument2 pagesLiberty Mills Limited: Job Card IssuanceFarrukh JamilNo ratings yet

- Liberty Mills Limited: Job Card IssuanceDocument3 pagesLiberty Mills Limited: Job Card IssuanceFarrukh JamilNo ratings yet

- 4) 2006 Georgiou PDFDocument19 pages4) 2006 Georgiou PDFAlejandro Parada LeigueNo ratings yet

- R08791 Modelingandsimulat Objec VE:: L TP C 3 3 ToDocument1 pageR08791 Modelingandsimulat Objec VE:: L TP C 3 3 ToKalai ArasanNo ratings yet

- Three Variable Inequalities PDFDocument18 pagesThree Variable Inequalities PDFLucian Lazar100% (1)

- Thesis Statement For English LiteratureDocument7 pagesThesis Statement For English Literaturekqgcnxejd100% (2)

- Lecture Notes PDE 1Document8 pagesLecture Notes PDE 1vamgaduNo ratings yet

- LECTURE 3A-MEASURES OF CENTRAL TENDENCY Ungrouped DataDocument18 pagesLECTURE 3A-MEASURES OF CENTRAL TENDENCY Ungrouped DataHAFIZAH100% (1)

- 13chap 1.4 Normal DistributionDocument17 pages13chap 1.4 Normal DistributionNyah MargarettNo ratings yet

- Exercise No 1 FDTDocument3 pagesExercise No 1 FDTCollano M. Noel RogieNo ratings yet

- Relations and Functions PDFDocument4 pagesRelations and Functions PDFRabiya FaheemNo ratings yet

- Control of Robot ManipulatorsDocument441 pagesControl of Robot ManipulatorsDomagoj Majstorović100% (1)

- Assignment 2Document4 pagesAssignment 2kalana chamodNo ratings yet

- Semantic Network Analysis in Social SciencesDocument249 pagesSemantic Network Analysis in Social SciencesJUAN FRANCISCO ROZAS DE QUINTANANo ratings yet

- Lesson 1-07 Measures of Variation STATDocument12 pagesLesson 1-07 Measures of Variation STATallan.manaloto23No ratings yet

- Pol So Cu Grad Reading 1314Document24 pagesPol So Cu Grad Reading 1314rabarber1900No ratings yet

- Collins Further Maths Answers CH 10 To 12Document15 pagesCollins Further Maths Answers CH 10 To 12nathanNo ratings yet

- G Matic 2019 OralsDocument2 pagesG Matic 2019 OralsGonzalo Tan Jr.No ratings yet

- ASTM E691 18 Realización de Un Estudio InterlaboratorioDocument22 pagesASTM E691 18 Realización de Un Estudio InterlaboratorioDoina MarquezNo ratings yet

- 9709 w16 QP 33Document4 pages9709 w16 QP 33AkylamNo ratings yet

- ODS22 - OH PresentationDocument19 pagesODS22 - OH PresentationManojKumarGaliNo ratings yet

- Assignment - 3: Nirma University Institute of Technology B.Tech - (CH) - Semester - III 2MA301, AMCEDocument2 pagesAssignment - 3: Nirma University Institute of Technology B.Tech - (CH) - Semester - III 2MA301, AMCEPunit PatelNo ratings yet

- Research Paper in ItalianoDocument5 pagesResearch Paper in Italianofyr60xv7100% (1)

- Open Methods: by Lale Yurttas, Texas A&M University 1Document24 pagesOpen Methods: by Lale Yurttas, Texas A&M University 1ryinejanNo ratings yet

- An Introduction To Nonlinear WavesDocument163 pagesAn Introduction To Nonlinear WavesSebastian Soto PerdomoNo ratings yet

- I Latin American Workshop On Optimization and ControlDocument55 pagesI Latin American Workshop On Optimization and ControlEduardo TusaNo ratings yet

- Solution of Nonlinear Equations: Root Finding Problems)Document89 pagesSolution of Nonlinear Equations: Root Finding Problems)hadasadidaNo ratings yet

Measurement Systems Analysis

Measurement Systems Analysis

Uploaded by

Farrukh JamilOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Measurement Systems Analysis

Measurement Systems Analysis

Uploaded by

Farrukh JamilCopyright:

Available Formats

Measurement Systems Analysis

• Introduce Measurement Systems

• Assess Measurement Systems Performance

• Understand Measurement System Variation

Measurement Systems Analysis www.qualimations.com

Process Control

A Typical Process

People

Methods

Material Identifying

PROCESS Product

Equipment Product Improvement

Opportunities

Environment

Input Process / System Output

Accurate Measurement

using Measurement System Analysis

Measurement Systems Analysis www.qualimations.com

Assessing Measurement Systems

How good is our

measurement

system?

2 T = 2p + 2m

• Observed Process • Production Gauge

Variation Variation

• Actual Process Variation

Measurement Systems Analysis www.qualimations.com

Assessing Measurement Systems

• Location variation

– Bias

– Stability

• Width variation

– Linearity

– Repeatability, Reproducibility

Measurement Systems Analysis www.qualimations.com

Determining and Assessing Bias

• Bias is the difference between the

Observed

observed average of measurement

Average Value

and the reference value.

• The reference value, also known as Bias

the accepted reference value or

master value, is a value that serves as

an agreed-upon reference for the

measured values. A reference value

can be determined by averaging

several measurements with a higher

level of measuring equipment. Reference

Value

Measurement Systems Analysis www.qualimations.com

Determining and Assessing Stability

Time

• Stability (or drift) is the total variation in

the measurements obtained with a

measurement system

• on the same master or part when

measuring a single characteristic

• over an extended

time period

Reference Value

Measurement Systems Analysis www.qualimations.com

Determining and Assessing Linearity

• Linearity is the difference in the bias values through the expected operating range of the

gauge.

Reference

Observed Reference

Value Observed

Average Value Value

Average Value

Smaller Larger

Bias Bias

50mm 200mm

Measurement Systems Analysis www.qualimations.com

Determining Repeatability

• Repeatability is the variation in

measurements obtained

• By one appraiser

• with one measurement

instrument

• when used several times

• while measuring the

identical characteristic

• on the same part Repeatability

Measurement Systems Analysis www.qualimations.com

Determining Reproducibility

• Reproducibility is the variation in

the average of the measurements

made

• by different appraisers

• using the same measuring

instrument

• when measuring the

identical characteristic

Reproducibility

• on the same part

Measurement Systems Analysis www.qualimations.com

Preparing For A Measurement System Study

• Variable Gauge Study (Average and Range Method)

The average and range method of gauge study breaks the gauge error into

repeatability and reproducibility.

Optimum conditions:

• 3 operators;

• 3 trials;

• 10 parts.

Study of the results can provide information concerning the causes of the

measurement error.

• If reproducibility is large compared to repeatability then;

• The operator is not properly trained in how to use and read the gauge;

• Graduations on the gauge are not clear.

Measurement Systems Analysis www.qualimations.com

Determining and Assessing

Repeatability and Reproducibility

• If repeatability is large compared to reproducibility, the reasons may be:

– The instrument needs maintenance;

– The gauge should be redesigned to be more rigid;

– The clamping or location for gauging needs to be improved;

– There is excessive part variation.

• If reproducibility is large compared to repeatability, then possible causes could be:

– The appraiser needs to be better trained in how to use and read the gauge instrument;

– Calibrations on the gauge dial are not clear;

– A fixture of some sort may be needed to help the appraiser use the gauge more

consistently.

Measurement Systems Analysis www.qualimations.com

Acceptability Criteria

• R&R Indices

10% Acceptable Measurement System

– 10% - 30% May be acceptable based upon application,

cost of measurement device, cost of repair,

30% Not acceptable. Measurement system

needs improvement.

• Number of Distinct Categories Index

– 1 Unacceptable. One part cannot be

distinguished form another.

– 2 -4 Generally unacceptable

5 Recommended

Measurement Systems Analysis www.qualimations.com

You might also like

- MSA Training PPT 14-07-2020 PDFDocument125 pagesMSA Training PPT 14-07-2020 PDFLAKSHYA MITTAL100% (4)

- Practical Risk Theory For ActuariesDocument1 pagePractical Risk Theory For ActuariesCesar JvNo ratings yet

- SPM Addmath 2007 AnswerDocument3 pagesSPM Addmath 2007 Answermaieqa8738% (8)

- Solutions Act. 2-Structural TheoryDocument3 pagesSolutions Act. 2-Structural TheoryChuckie EntocNo ratings yet

- Validation Tool 1Document2 pagesValidation Tool 1Charish Monarca Rosaldes100% (3)

- MSA BriefDocument17 pagesMSA BriefUrdanNo ratings yet

- Assessing Measurement System Variation: Example 1: Fuel Injector Nozzle DiametersDocument20 pagesAssessing Measurement System Variation: Example 1: Fuel Injector Nozzle DiametersnadeemaneezNo ratings yet

- Training Material For: Easurement Ystem NalysisDocument61 pagesTraining Material For: Easurement Ystem NalysisDotecho Jzo EyNo ratings yet

- Training Sample Measurement Systems MTB16 ENDocument19 pagesTraining Sample Measurement Systems MTB16 ENguto_udescNo ratings yet

- 5 MsaDocument81 pages5 MsaVIPIN YADAVNo ratings yet

- TPM Lecture 09Document21 pagesTPM Lecture 09Zeeshan ElahiNo ratings yet

- Lecture 4Document54 pagesLecture 4Eda ÖzkolNo ratings yet

- Chapter 3 - MeasureDocument75 pagesChapter 3 - MeasureNitish NitinNo ratings yet

- MSA Sample PresentationDocument9 pagesMSA Sample PresentationTom@GGCNo ratings yet

- Case Study 2Document5 pagesCase Study 2ramtwinsmeNo ratings yet

- Measurements: Chapter FourDocument14 pagesMeasurements: Chapter FourcuribenNo ratings yet

- CORE TOOLS-MSA 4th EdDocument94 pagesCORE TOOLS-MSA 4th EdcuitlahuacbmoncivaezNo ratings yet

- Lecture 4 - Metrology & MeasurementDocument15 pagesLecture 4 - Metrology & MeasurementharoonNo ratings yet

- Lecture 10Document28 pagesLecture 10anaditaprasadNo ratings yet

- Measurement Systems Analysis: Total Quality ManagementDocument17 pagesMeasurement Systems Analysis: Total Quality Managementkhamaludin100% (1)

- Lecture 3, General Concepts and Definitions in Metrology - DR Janakarajan RamkumarDocument35 pagesLecture 3, General Concepts and Definitions in Metrology - DR Janakarajan RamkumarRUKESHAPSISNo ratings yet

- Measurement Systems Analysis - A Management PerspectiveDocument8 pagesMeasurement Systems Analysis - A Management PerspectiveleovenceNo ratings yet

- Quality Control 1Document59 pagesQuality Control 1Melanie TranNo ratings yet

- EIM PPT 1Document17 pagesEIM PPT 1rahul0% (1)

- Metrology: DefinitionDocument17 pagesMetrology: Definitionmohd zeeshanNo ratings yet

- MSA - Measurement System Analysis - Quality-OneDocument6 pagesMSA - Measurement System Analysis - Quality-OneAmitesh SouravNo ratings yet

- Welcome: Training ProgramDocument66 pagesWelcome: Training ProgramAnkurNo ratings yet

- MSA PPT Latest - 240529 - 141424Document28 pagesMSA PPT Latest - 240529 - 141424Rithesh ShettyNo ratings yet

- Manufacturing Technology (ME 361) - Lecture 20: Engineering MetrologyDocument35 pagesManufacturing Technology (ME 361) - Lecture 20: Engineering MetrologySahil SundaNo ratings yet

- Quality Assurance & Lab MathDocument6 pagesQuality Assurance & Lab MathMica BernardoNo ratings yet

- Quality Control For Sampling and Chemical AnalysisDocument63 pagesQuality Control For Sampling and Chemical AnalysisEdgardo Ed Ramirez100% (1)

- Gage R&RDocument25 pagesGage R&RMario Mora GarciaNo ratings yet

- Quality Control in Measurements: Tom Colella CLAS Goldwater Environmental LabDocument20 pagesQuality Control in Measurements: Tom Colella CLAS Goldwater Environmental Labchit catNo ratings yet

- MSA PresentationDocument37 pagesMSA Presentationelifexp100% (1)

- How Often Does The Product Fail ? How Often Does This Car Require Repair ?Document7 pagesHow Often Does The Product Fail ? How Often Does This Car Require Repair ?TahaNo ratings yet

- 05 Metrology (H Karcı) - V2Document63 pages05 Metrology (H Karcı) - V2maloxix105No ratings yet

- CMMDocument90 pagesCMMA S100% (1)

- CalibrationDocument45 pagesCalibrationDeb RoyNo ratings yet

- Measurement: "Whatever Exists, Exists in Some Amount"Document33 pagesMeasurement: "Whatever Exists, Exists in Some Amount"aravinthNo ratings yet

- Single Laboratory ValidationDocument39 pagesSingle Laboratory ValidationMarcos LoredoNo ratings yet

- Quality ManagementDocument80 pagesQuality ManagementMayank GandhiNo ratings yet

- Quality Management ISO 17025:2005Document65 pagesQuality Management ISO 17025:2005Gerrit Van Der WaltNo ratings yet

- Measurement System AnalysisDocument42 pagesMeasurement System Analysisazadsingh1No ratings yet

- QC and QADocument9 pagesQC and QAClarisse De GuzmanNo ratings yet

- Gage Studies For Continuous Data: ObjectivesDocument21 pagesGage Studies For Continuous Data: ObjectivesNigam PatroNo ratings yet

- Measurement Systems Analysis: Total Quality ManagementDocument17 pagesMeasurement Systems Analysis: Total Quality ManagementmanuelNo ratings yet

- Evaluating The Measurement Process (EMP) OverviewDocument12 pagesEvaluating The Measurement Process (EMP) OverviewMorgana MelloNo ratings yet

- Quality Assurance and Quality ControlDocument56 pagesQuality Assurance and Quality ControlprnfbmsdqnNo ratings yet

- 18 Measurement Systems AnalysisDocument118 pages18 Measurement Systems Analysisankit7588No ratings yet

- Metrology: Production Engineering 2 Code: MEC3202Document58 pagesMetrology: Production Engineering 2 Code: MEC3202sakali aliNo ratings yet

- Measurement Systems Analysis: Total Quality ManagementDocument17 pagesMeasurement Systems Analysis: Total Quality Managementtlatuani1000No ratings yet

- CompressedDocument50 pagesCompressedTaimoor HassanNo ratings yet

- Measurement Systems Analysis WebinarDocument37 pagesMeasurement Systems Analysis WebinarOlirvag100% (1)

- MetrologyDocument69 pagesMetrologyU2103097 STUDENTNo ratings yet

- Unit I MQCDocument92 pagesUnit I MQCNACHIKETHA B NNo ratings yet

- MeasurementsDocument14 pagesMeasurementsAmit AdhayeNo ratings yet

- PG&E Advanced Metering Assessment For Residential Electric CustomersDocument12 pagesPG&E Advanced Metering Assessment For Residential Electric CustomersKat DonnellyNo ratings yet

- MSA - Level 1Document8 pagesMSA - Level 1Sachin RamdurgNo ratings yet

- Measurement System Analysis (MSA) : Validating Your Measurement Systems Gy yDocument16 pagesMeasurement System Analysis (MSA) : Validating Your Measurement Systems Gy yHesham MahdyNo ratings yet

- Tep by TEP Pproach To Valuation and Omparison OF Nalytical EthodsDocument54 pagesTep by TEP Pproach To Valuation and Omparison OF Nalytical EthodsMalliga SundareshanNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Analysis of Variance (Anova) Part 2 Two-Way Anova ReplicationDocument18 pagesAnalysis of Variance (Anova) Part 2 Two-Way Anova ReplicationFarrukh JamilNo ratings yet

- Analysis of Variance (ANOVA)Document12 pagesAnalysis of Variance (ANOVA)Farrukh JamilNo ratings yet

- de 6 Dca 404 CDocument31 pagesde 6 Dca 404 CFarrukh JamilNo ratings yet

- Canada New Order ComforterDocument65 pagesCanada New Order ComforterFarrukh JamilNo ratings yet

- Analysis of Variance (Anova) : Madam Siti Aisyah Zakaria EQT 271 SEM 2 2014/2015Document29 pagesAnalysis of Variance (Anova) : Madam Siti Aisyah Zakaria EQT 271 SEM 2 2014/2015Farrukh JamilNo ratings yet

- Analysis of Variance (Anova) Part 3 Two-Way Anova Replication (Factorial Experiment)Document21 pagesAnalysis of Variance (Anova) Part 3 Two-Way Anova Replication (Factorial Experiment)Farrukh JamilNo ratings yet

- 5 Minute Guide: 4 Press ENTER. 5 Use The MULTI JOG Dial To Choose Your Room SizeDocument1 page5 Minute Guide: 4 Press ENTER. 5 Use The MULTI JOG Dial To Choose Your Room SizeFarrukh JamilNo ratings yet

- Liberty Mills Limited: Job Card IssuanceDocument3 pagesLiberty Mills Limited: Job Card IssuanceFarrukh JamilNo ratings yet

- Liberty Mills Limited: Job Card IssuanceDocument4 pagesLiberty Mills Limited: Job Card IssuanceFarrukh JamilNo ratings yet

- Liberty Mills Limited: Job Card IssuanceDocument2 pagesLiberty Mills Limited: Job Card IssuanceFarrukh JamilNo ratings yet

- Liberty Mills Limited: Job Card IssuanceDocument3 pagesLiberty Mills Limited: Job Card IssuanceFarrukh JamilNo ratings yet

- 4) 2006 Georgiou PDFDocument19 pages4) 2006 Georgiou PDFAlejandro Parada LeigueNo ratings yet

- R08791 Modelingandsimulat Objec VE:: L TP C 3 3 ToDocument1 pageR08791 Modelingandsimulat Objec VE:: L TP C 3 3 ToKalai ArasanNo ratings yet

- Three Variable Inequalities PDFDocument18 pagesThree Variable Inequalities PDFLucian Lazar100% (1)

- Thesis Statement For English LiteratureDocument7 pagesThesis Statement For English Literaturekqgcnxejd100% (2)

- Lecture Notes PDE 1Document8 pagesLecture Notes PDE 1vamgaduNo ratings yet

- LECTURE 3A-MEASURES OF CENTRAL TENDENCY Ungrouped DataDocument18 pagesLECTURE 3A-MEASURES OF CENTRAL TENDENCY Ungrouped DataHAFIZAH100% (1)

- 13chap 1.4 Normal DistributionDocument17 pages13chap 1.4 Normal DistributionNyah MargarettNo ratings yet

- Exercise No 1 FDTDocument3 pagesExercise No 1 FDTCollano M. Noel RogieNo ratings yet

- Relations and Functions PDFDocument4 pagesRelations and Functions PDFRabiya FaheemNo ratings yet

- Control of Robot ManipulatorsDocument441 pagesControl of Robot ManipulatorsDomagoj Majstorović100% (1)

- Assignment 2Document4 pagesAssignment 2kalana chamodNo ratings yet

- Semantic Network Analysis in Social SciencesDocument249 pagesSemantic Network Analysis in Social SciencesJUAN FRANCISCO ROZAS DE QUINTANANo ratings yet

- Lesson 1-07 Measures of Variation STATDocument12 pagesLesson 1-07 Measures of Variation STATallan.manaloto23No ratings yet

- Pol So Cu Grad Reading 1314Document24 pagesPol So Cu Grad Reading 1314rabarber1900No ratings yet

- Collins Further Maths Answers CH 10 To 12Document15 pagesCollins Further Maths Answers CH 10 To 12nathanNo ratings yet

- G Matic 2019 OralsDocument2 pagesG Matic 2019 OralsGonzalo Tan Jr.No ratings yet

- ASTM E691 18 Realización de Un Estudio InterlaboratorioDocument22 pagesASTM E691 18 Realización de Un Estudio InterlaboratorioDoina MarquezNo ratings yet

- 9709 w16 QP 33Document4 pages9709 w16 QP 33AkylamNo ratings yet

- ODS22 - OH PresentationDocument19 pagesODS22 - OH PresentationManojKumarGaliNo ratings yet

- Assignment - 3: Nirma University Institute of Technology B.Tech - (CH) - Semester - III 2MA301, AMCEDocument2 pagesAssignment - 3: Nirma University Institute of Technology B.Tech - (CH) - Semester - III 2MA301, AMCEPunit PatelNo ratings yet

- Research Paper in ItalianoDocument5 pagesResearch Paper in Italianofyr60xv7100% (1)

- Open Methods: by Lale Yurttas, Texas A&M University 1Document24 pagesOpen Methods: by Lale Yurttas, Texas A&M University 1ryinejanNo ratings yet

- An Introduction To Nonlinear WavesDocument163 pagesAn Introduction To Nonlinear WavesSebastian Soto PerdomoNo ratings yet

- I Latin American Workshop On Optimization and ControlDocument55 pagesI Latin American Workshop On Optimization and ControlEduardo TusaNo ratings yet

- Solution of Nonlinear Equations: Root Finding Problems)Document89 pagesSolution of Nonlinear Equations: Root Finding Problems)hadasadidaNo ratings yet