Professional Documents

Culture Documents

Non - Ferrous Alloys: Guided By: Mehra Mam From: Civil Second Shift

Non - Ferrous Alloys: Guided By: Mehra Mam From: Civil Second Shift

Uploaded by

Mohammad AashikSS340 ratings0% found this document useful (0 votes)

8 views6 pagesThis document summarizes various non-ferrous alloys, their compositions, properties, and common uses. It discusses brasses, bronzes, solders, duralumin, and Wood's metal. Key information provided includes that brasses are corrosion resistant and contain copper and zinc; bronzes are tough and contain copper and tin; solders are used for joining and contain lead and tin; duralumin is light and corrosion resistant, containing aluminum, copper, magnesium, and manganese.

Original Description:

Original Title

Non – Ferrous Alloys

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes various non-ferrous alloys, their compositions, properties, and common uses. It discusses brasses, bronzes, solders, duralumin, and Wood's metal. Key information provided includes that brasses are corrosion resistant and contain copper and zinc; bronzes are tough and contain copper and tin; solders are used for joining and contain lead and tin; duralumin is light and corrosion resistant, containing aluminum, copper, magnesium, and manganese.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

8 views6 pagesNon - Ferrous Alloys: Guided By: Mehra Mam From: Civil Second Shift

Non - Ferrous Alloys: Guided By: Mehra Mam From: Civil Second Shift

Uploaded by

Mohammad AashikSS34This document summarizes various non-ferrous alloys, their compositions, properties, and common uses. It discusses brasses, bronzes, solders, duralumin, and Wood's metal. Key information provided includes that brasses are corrosion resistant and contain copper and zinc; bronzes are tough and contain copper and tin; solders are used for joining and contain lead and tin; duralumin is light and corrosion resistant, containing aluminum, copper, magnesium, and manganese.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 6

Non – Ferrous Alloys

Chemistry Micro Project

Guided by : Mehra Mam

From: Civil Second Shift

Students Name Roll no.

1] Mohammad Aashique 23

2] Ubed Khan 22

3] Abhishek Khakre 21

4] Aniket Katare 20

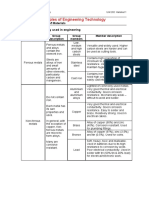

Alloys Composition Properties Uses

A] Brasses Cu = 60-90% These alloys Making sheets,

Zn = 40-10% possess greater utensils,

strength , condenser

durability and tubes etc.

machinabality

than copper

and low m.p.

than copper Cu

and Zn. They

are corrosion

resistant and

water resistant.

Alloys Composition Properties Uses

B] Bronzes Cu = 80-95% They are tough, In making

Sn = 20-53% strong, hard belles, coins,

alloys, resistant status, utensils

to corrosion etc.

and wear can

be easily casted

and machined.

Alloys Composition Properties Uses

C] Solders Pb = 37-67% Solders are low Soldering

Sn = 31-60% melting alloys electrical

Sb = 0.12- 0% of tin and lead. connections,

These can be sealing for tin

soft or hard cans and

depending joining lead

upon the pipes etc.

percentage of

tin and lead.

Alloys Composition Properties Uses

D] Duralumin Al= 95% Duralumin is Extensively

Cu = 4% light, tough, used in making

Mg = 0.5% ductile, easily of aero planes,

castable. It is all kind of

Mn =0.5% structural work,

corrosion

resistant alloy. making of

It is an good rivets, bars,

conductor of body of

heat and vehicles,

electricity. housing cases,

sheets, tubes

etc.

Alloys Composition Properties Uses

E] Wood’s Bi = 50% The most It is used for

Metal Pb = 25% important making of

Sn =12.5% property of safety plugs of

Cd = 12.5% wood’s metal is pressure

that it is easily cookers,

fusible. It has boilers, fire

low melting alarms,

point i.e. m.p. automatic

=71° c. water sprinklers

etc.

You might also like

- Sound Control For Commercial and Residential BuildingsDocument24 pagesSound Control For Commercial and Residential BuildingsEmily OngNo ratings yet

- Design Basis Report 3Document99 pagesDesign Basis Report 3mohdalal8688% (8)

- General Cutting InsertDocument15 pagesGeneral Cutting Insertvipul mishra100% (1)

- 3 Non FerrousDocument18 pages3 Non FerrousYasithbroNo ratings yet

- Malaysia SPM Form 4 ChemistryDocument3 pagesMalaysia SPM Form 4 Chemistryaqua9328No ratings yet

- Ophelia SlidesCarnivalDocument32 pagesOphelia SlidesCarnivalQuel LeNo ratings yet

- Arrangement of Atoms in Metals: Malleability and DuctilityDocument3 pagesArrangement of Atoms in Metals: Malleability and DuctilityAlex TanNo ratings yet

- Year 7 MetalsDocument7 pagesYear 7 MetalsMissparish8No ratings yet

- Non Ferrous MaterialsDocument51 pagesNon Ferrous MaterialsDhana LakshmiNo ratings yet

- Construction Materials Ii: 1.1 Ferrous MetalDocument6 pagesConstruction Materials Ii: 1.1 Ferrous MetalQila HusinNo ratings yet

- Year 7 MetalsDocument8 pagesYear 7 MetalsMissparish8No ratings yet

- Ferrous & Non-FerrousDocument1 pageFerrous & Non-Ferrousriain2008100% (3)

- Unit - 1 AluminiumDocument54 pagesUnit - 1 Aluminiumshreshth goswamiNo ratings yet

- Lecture 7Document18 pagesLecture 7Iftekhar ArefinNo ratings yet

- METALS PresentationDocument28 pagesMETALS PresentationTheresa TuliaoNo ratings yet

- Non Ferrous Metals and Alloys and Their Heat TreatmentDocument39 pagesNon Ferrous Metals and Alloys and Their Heat TreatmentMuhammed Adil IqbalNo ratings yet

- ALLOYSDocument3 pagesALLOYSshasha_anuarNo ratings yet

- Unit VDocument48 pagesUnit VRanjit ZendeNo ratings yet

- Material Composition Properties ApplicationsDocument7 pagesMaterial Composition Properties Applicationsvikrant GarudNo ratings yet

- Chem 10 (2nd) PDFDocument32 pagesChem 10 (2nd) PDFRyanNo ratings yet

- Pulse Plating of Sacrificial MN Cu Alloy PDFDocument7 pagesPulse Plating of Sacrificial MN Cu Alloy PDFdanyNo ratings yet

- Alloys - Definition, Purposes of Alloying, Ferrous Alloys and Non-Ferrous With Suitable Examples, Properties and ApplicationsDocument12 pagesAlloys - Definition, Purposes of Alloying, Ferrous Alloys and Non-Ferrous With Suitable Examples, Properties and ApplicationsSk jahidul IslamNo ratings yet

- Chap 4 Metals StudentsDocument35 pagesChap 4 Metals StudentsmaiNo ratings yet

- KSSM Chemistry Form 4 AlloyDocument20 pagesKSSM Chemistry Form 4 AlloyRienellene Joyce FieldadNo ratings yet

- 8.3 Metals: Metals Have Been Extracted and Used For Many Thousands of YearsDocument5 pages8.3 Metals: Metals Have Been Extracted and Used For Many Thousands of YearsClayton FengNo ratings yet

- Unit 5 Non Ferrous Metal and Alloys: Visit For More Learning ResourcesDocument28 pagesUnit 5 Non Ferrous Metal and Alloys: Visit For More Learning ResourcesEXAM CELL AVS TECHNo ratings yet

- Tool Die SteelDocument59 pagesTool Die SteelHussein Turi HtgNo ratings yet

- Reactivity SeriesDocument14 pagesReactivity SeriesDKFBNo ratings yet

- Unit 6 Non Ferrous Metals - IntroductionDocument63 pagesUnit 6 Non Ferrous Metals - IntroductionMruganesh SonarNo ratings yet

- Engineering Alloys (Non Ferrous)Document52 pagesEngineering Alloys (Non Ferrous)Sukhwinder Singh GillNo ratings yet

- Unit6Non FerrousMetalsDocument71 pagesUnit6Non FerrousMetalsHossam ElsayedNo ratings yet

- AlloyDocument2 pagesAlloyJagesh RanjanNo ratings yet

- Unit-2 Part-5Document9 pagesUnit-2 Part-5Tisha MishraNo ratings yet

- Lec 6 MetalsDocument4 pagesLec 6 MetalsAsghar Hussain ShahNo ratings yet

- Edigcse Aap sc15.14wDocument2 pagesEdigcse Aap sc15.14wHassan EL ACHEKNo ratings yet

- Metal PropertiesDocument17 pagesMetal PropertiesParag AlamyanNo ratings yet

- Vi. Ceramics and MetalDocument4 pagesVi. Ceramics and MetalLudwig RamosNo ratings yet

- Advanced Building MaterialDocument9 pagesAdvanced Building MaterialPriyanjita AdhikariNo ratings yet

- Cobre Aleacion PDFDocument6 pagesCobre Aleacion PDFSebastian MorenoNo ratings yet

- Alloys: I) IntroductionDocument12 pagesAlloys: I) IntroductionNikhil ShelarNo ratings yet

- Non-Ferrous MetalsDocument24 pagesNon-Ferrous MetalsAbdullah Al Bari TusharNo ratings yet

- Copper and Its AlloysDocument41 pagesCopper and Its AlloysSasaleleNo ratings yet

- Physical Metallurgy BR DR Frank PDFDocument217 pagesPhysical Metallurgy BR DR Frank PDFmichael ananaNo ratings yet

- What Is An Alloy?: Elements. For Example, Combining The Metallic Elements Gold and CopperDocument2 pagesWhat Is An Alloy?: Elements. For Example, Combining The Metallic Elements Gold and CopperFree WomanNo ratings yet

- Section 12 - Welding Consumables - Problem SteelsDocument10 pagesSection 12 - Welding Consumables - Problem SteelsFriedrich SchwimNo ratings yet

- Lesson Plan: Brass PropertiesDocument7 pagesLesson Plan: Brass Propertiessurajit biswasNo ratings yet

- Non FerrousDocument5 pagesNon FerrousMahesh KhadeNo ratings yet

- Effect of Alloying Elements On The Shape Memory Properties ofDocument5 pagesEffect of Alloying Elements On The Shape Memory Properties ofrafael.ramalhoNo ratings yet

- L2 - Uses of MetalsDocument13 pagesL2 - Uses of MetalsKashifNo ratings yet

- The Properties of MaterialsDocument4 pagesThe Properties of MaterialsMuhammad RaihanNo ratings yet

- Unit 202: Principles of Engineering Technology: Handout 1: Range of Materials Materials Commonly Used in EngineeringDocument3 pagesUnit 202: Principles of Engineering Technology: Handout 1: Range of Materials Materials Commonly Used in EngineeringyasirNo ratings yet

- BASIC EE - Module 1Document4 pagesBASIC EE - Module 1Stephanie BesanaNo ratings yet

- Alloys-Module 2-2Document4 pagesAlloys-Module 2-2MUSKAN 22BCE11024No ratings yet

- DJJ30113 CHAPTER 5 - Applications and Types of Meta Alloys Part 2lDocument31 pagesDJJ30113 CHAPTER 5 - Applications and Types of Meta Alloys Part 2lNukris HakimiNo ratings yet

- Surface & Coatings Technology: M. Marín-Sánchez, P. Ocón, A. Conde, I. GarcíaDocument7 pagesSurface & Coatings Technology: M. Marín-Sánchez, P. Ocón, A. Conde, I. GarcíaterNo ratings yet

- Answer Sheet Material Science Final ExamDocument6 pagesAnswer Sheet Material Science Final ExamM Hoqqil FatwaNo ratings yet

- DESIGN 1 NotesDocument7 pagesDESIGN 1 NoteslordyNo ratings yet

- Advances in Dielectric Materials and Electronic Devices: Proceedings of the 107th Annual Meeting of The American Ceramic Society, Baltimore, Maryland, USA 2005From EverandAdvances in Dielectric Materials and Electronic Devices: Proceedings of the 107th Annual Meeting of The American Ceramic Society, Baltimore, Maryland, USA 2005K. M. NairNo ratings yet

- Tushar Kadam GteDocument10 pagesTushar Kadam GteMohammad AashikSS34No ratings yet

- Government Polytechnic, Jalna: CertificateDocument36 pagesGovernment Polytechnic, Jalna: CertificateMohammad AashikSS34No ratings yet

- 22303-Mechanics of StructureDocument132 pages22303-Mechanics of StructureMohammad AashikSS34No ratings yet

- Eac Micro ProjectDocument18 pagesEac Micro ProjectMohammad AashikSS34No ratings yet

- Advance SurveyingFCDocument100 pagesAdvance SurveyingFCMohammad AashikSS34No ratings yet

- Rehan AMP ProjectDocument16 pagesRehan AMP ProjectMohammad AashikSS34No ratings yet

- Ordinary Portland CementDocument5 pagesOrdinary Portland CementMohammad AashikSS34No ratings yet

- Production of X-RaysDocument22 pagesProduction of X-RaysMohammad AashikSS34No ratings yet

- HVAC Welding and Cutting 1202Document14 pagesHVAC Welding and Cutting 1202deangel1701No ratings yet

- Analysis and Design of Reinforced Concrete Bridge Structures IMPORTANTDocument4 pagesAnalysis and Design of Reinforced Concrete Bridge Structures IMPORTANTAndrea Santillan YzazagaNo ratings yet

- Epsilon Echos 2 BDocument40 pagesEpsilon Echos 2 BDaniel JoseNo ratings yet

- ReporthuehuehueheuhuhuheeDocument14 pagesReporthuehuehueheuhuhuheeAnonymous GV18teQO8ONo ratings yet

- EAE E-Line - GeneralDocument12 pagesEAE E-Line - GeneralFarkas TamásNo ratings yet

- Autocatalytic (Electroless) Nickel-Phosphorus Coatings On MetalDocument13 pagesAutocatalytic (Electroless) Nickel-Phosphorus Coatings On MetalSathish KumarNo ratings yet

- Electrical Control For Machines 7th Edition Lobsiger Solutions ManualDocument3 pagesElectrical Control For Machines 7th Edition Lobsiger Solutions Manualhanhanselmuv0smNo ratings yet

- Assignment 5: Me 607: Introduction To Composite Materials: =230 Gpa; Α =-1.3 Μm/M/ C;E =3.4 Gpa; Α = 63 Μm/M/ CDocument2 pagesAssignment 5: Me 607: Introduction To Composite Materials: =230 Gpa; Α =-1.3 Μm/M/ C;E =3.4 Gpa; Α = 63 Μm/M/ CNishant PatilNo ratings yet

- Structural Glazing AND Curtain Wall: Presentation by - Pradnya Ranjit Inamdar. T.Y.B.Arch Div-B Roll No.-3Document21 pagesStructural Glazing AND Curtain Wall: Presentation by - Pradnya Ranjit Inamdar. T.Y.B.Arch Div-B Roll No.-3Pradnya InamdarNo ratings yet

- Section 15 Section 21 Handling of Bulk Solids &Document2 pagesSection 15 Section 21 Handling of Bulk Solids &kimikal eMediaNo ratings yet

- Microsoft Word - Roofing & Re-RoofingDocument7 pagesMicrosoft Word - Roofing & Re-RoofingkokueiNo ratings yet

- CPE-CRANE-FKX 9000 DIN-TD-EN-A4-2019 - 03 - 29-WebDocument70 pagesCPE-CRANE-FKX 9000 DIN-TD-EN-A4-2019 - 03 - 29-WebSajad FilabiNo ratings yet

- Notching On BeamsDocument28 pagesNotching On BeamsElvie Rodado GubalaneNo ratings yet

- Specification of KIRBY KLM 2100 PanelDocument2 pagesSpecification of KIRBY KLM 2100 PanelKishore Kumar0% (1)

- Anchorage To Concrete - Means and MethodsDocument28 pagesAnchorage To Concrete - Means and MethodsMustafaNo ratings yet

- G5 High Profile Unit Cooler G5HP 205 V3 0Document9 pagesG5 High Profile Unit Cooler G5HP 205 V3 0Nguyễn Hữu HiệpNo ratings yet

- Civn 2009: Materials and Structures Ii Tutorial No. IiDocument2 pagesCivn 2009: Materials and Structures Ii Tutorial No. Iimotsepe thompsonNo ratings yet

- Epbu-14-04-Ga-Kt-057a (6M Octagonal Pole) R4-Approval PDFDocument1 pageEpbu-14-04-Ga-Kt-057a (6M Octagonal Pole) R4-Approval PDFP.MannaNo ratings yet

- PD 1096 - Basic LawDocument1 pagePD 1096 - Basic Lawhannah marvillaNo ratings yet

- .2.14 Stress-Strain Relations For Linear Elastic Transversely Isotropic MaterialDocument6 pages.2.14 Stress-Strain Relations For Linear Elastic Transversely Isotropic MaterialHanmant PhadatareNo ratings yet

- Building Code b1 StructuresDocument94 pagesBuilding Code b1 StructuresMehedi ChowdhuryNo ratings yet

- Data Collection Sheet 20181023Document79 pagesData Collection Sheet 20181023Bisho AtefNo ratings yet

- Ammunition & Explosive Storage Magazines: Defense and SecurityDocument2 pagesAmmunition & Explosive Storage Magazines: Defense and SecurityMaria RodriguesNo ratings yet

- DLP AbbreviationDocument8 pagesDLP AbbreviationTrecita BacoNo ratings yet

- A 1 1 E1557 05 Uniformat II PDFDocument54 pagesA 1 1 E1557 05 Uniformat II PDFPercy SuarezNo ratings yet

- 1.9.5 Surface Test Station PDFDocument2 pages1.9.5 Surface Test Station PDFSoltani AliNo ratings yet

- How To Reinforce Concrete Slab On Ground To Control Cracking - For Construction ProsDocument16 pagesHow To Reinforce Concrete Slab On Ground To Control Cracking - For Construction ProsCyril Jean-BaptisteNo ratings yet