Professional Documents

Culture Documents

Hydro Turbines

Hydro Turbines

Uploaded by

Betty Negusse0 ratings0% found this document useful (0 votes)

30 views12 pagesHydraulic turbines convert the kinetic energy of flowing water into mechanical rotational energy. They consist of a wheel with curved vanes called a runner. Turbines are classified based on the energy of the water (pressure or velocity) and the direction of water flow (axial, radial, or mixed). Common types include Francis, Kaplan, and Pelton turbines. Francis turbines are the most widely used as they can operate over a wide range of heads and flows with high efficiency. They have a spiral casing, stationary stay vanes, adjustable guide vanes, and runner blades that use both impulse and reaction forces. Kaplan turbines have adjustable blades that allow for high efficiency at varying water flows.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHydraulic turbines convert the kinetic energy of flowing water into mechanical rotational energy. They consist of a wheel with curved vanes called a runner. Turbines are classified based on the energy of the water (pressure or velocity) and the direction of water flow (axial, radial, or mixed). Common types include Francis, Kaplan, and Pelton turbines. Francis turbines are the most widely used as they can operate over a wide range of heads and flows with high efficiency. They have a spiral casing, stationary stay vanes, adjustable guide vanes, and runner blades that use both impulse and reaction forces. Kaplan turbines have adjustable blades that allow for high efficiency at varying water flows.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

30 views12 pagesHydro Turbines

Hydro Turbines

Uploaded by

Betty NegusseHydraulic turbines convert the kinetic energy of flowing water into mechanical rotational energy. They consist of a wheel with curved vanes called a runner. Turbines are classified based on the energy of the water (pressure or velocity) and the direction of water flow (axial, radial, or mixed). Common types include Francis, Kaplan, and Pelton turbines. Francis turbines are the most widely used as they can operate over a wide range of heads and flows with high efficiency. They have a spiral casing, stationary stay vanes, adjustable guide vanes, and runner blades that use both impulse and reaction forces. Kaplan turbines have adjustable blades that allow for high efficiency at varying water flows.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 12

Hydro turbines

What are Hydraulic turbines?

Hydraulic Turbines are devices which convert the energy in a stream of falling fluid

into rotational mechanical energy by passing through a system of fixed and moving

blades and causing the wheel to rotate.

A hydraulic turbine consists of

a wheel called the runner provided with a number of curved vanes on its

periphery,

a guiding apparatus to direct the flow of water at inlet in the specified direction.

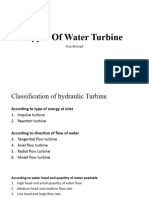

Depending on the operational requirements, Turbines mainly classified in two ways,

A) Based on the nature of energy head of water at inlet

• Reaction or Pressure Turbine: is a turbine in which the water entering the

runner possesses pressure as well as kinetic energy. Examples: Francis turbine,

Kaplan turbine, Thomson turbine

• Impulse or Velocity Turbines: is a turbine in which the water entering the runner

possesses kinetic energy only, i.e., in this case, the water is throughout at

atmospheric pressure. Examples: Pelton wheel, Turgo wheel, Jonval turbine,

Girard turbine

B) Based on the direction of flow along the vanes.

• Axial Flow Hydraulic Turbines: This category of Hydraulic Turbines has the

flow path of the liquid parallel to the axis of rotation. Example: Kaplan

Turbines.

• Radial Flow Hydraulic Turbines: Such Hydraulic Turbines has the liquid

flowing mainly in a plane perpendicular to the axis of rotation. In a radial

flow turbine the water moves along the vanes towards the axis of rotation

of the runner or away from it. When the flow is towards the axis of

rotation, the turbine is called an inward flow turbine. When the flow is

away from the axis of rotation of the turbine is called an outward flow

turbine. Example: Inward flow turbine – Francis (radial), Thomson,

Girard(radial) turbine , Outward flow turbine – Fourneyron turbine.

• Mixed Flow Hydraulic Turbines: For most of the Hydraulic Turbines used

there is a significant component of both axial and radial flows. Such types

of Hydraulic Turbines are called as Mixed Flow Turbines. Example: The

Francis, Kaplan and Pelton wheel turbines

Hydraulic Turbine Working Principle:

So, the working principle of the hydraulic turbine is, according to Newton’s

law, A force is directly proportional to the change in momentum. If there is

any change in momentum of fluid then a force is generated.

The hydraulic turbine blades (In the case of the Pelton wheel Turbine) are

provided against the flow of water which changes the momentum of it.

As the momentum is changing, a resulting pressure force generated which

rotates the rotor or turbine.As the change in momentum high, the force

generated is high, which increases energy conversion.

So the blade or buckets are designed so that it can change the maximum

momentum of the water. This turbine is used in a hydroelectric power plant.

Advantages of Hydraulic Turbine:

• This is a renewable energy source. The water-energy can be used again and

again.

• This turbine having high efficiency.

• The running cost of the Hydraulic turbine is less as compared to other

turbines.

• Since Dams are used. So it is used for power generation.

• The environmental pollution system is negligible here.

• This is easy to maintain.

• The main advantages of the Hydraulic turbine are that at the turbine place,

the people can visit and come across all the main parts in detail. This is like

an open system.

Disadvantages of Hydraulic Turbine:

• The Installation or Initial cost is very high. This system or plant takes several

decades to produces the profit.

• It can develop at only a few sites where the proper amount of water is

available.

What is a Francis Turbine?

The Francis turbine is a mixed flow turbine, subdivided into impulse and

reaction machines. In the impulse turbines, the total head available is

converted into the kinetic energy.

In the reaction turbines, only some part of the available total head of the

fluid is converted into kinetic energy so that the fluid entering the runner has

pressure energy as well as kinetic energy. The pressure energy is then

converted into kinetic energy in the runner.

Francis turbines are the most common water turbine in use today. They

operate in a water head from 40 to 600 m and are primarily used for electrical

power production. The electric generators which most often use this type of

turbine have a power output which generally ranges just a few kilowatts up to

800 MW.

Design of Francis Turbine

Power Generation using Francis Turbine

Main Components of Francis Turbine

1. Spiral Casing

Spiral casing is the inlet medium of water to the turbine. The water flowing from the reservoir or dam is made to

pass through this pipe with high pressure. The blades of the turbines are circularly placed, which mean the water

striking the turbines blades should flow in the circular axis for efficient striking. So the spiral casing is used, but due to

circular movement of the water, it looses its pressure. To maintain the same pressure the diameter of the casing is

gradually reduced, so as to maintain the pressure uniform, thus uniform momentum or velocity striking the runner

blades.

2. Stay Vanes

Stay vanes and guide vanes guides the water to the runner blades. Stay vanes remain stationary at their position

and reduces the swirling of water due to radial flow, as it enters the runner blades. Thus making turbine more

efficient.

3. Guide Vanes

Guide vanes are not stationary, they change their angle as per the requirement to control the angle of striking of

water to turbine blades to increase the efficiency. They also regulate the flow rate of water into the runner blades

thus controlling the power output of a turbine according to the load on the turbine.

4. Runner Blades

The performance and efficiency of the turbine is dependent on the design of the runner blades. In a Francis

turbine, runner blades are divided into 2 parts. The lower half is made in the shape of small bucket so that it uses the

impulse action of water to rotate the turbine. The upper part of the blades use the reaction force of water flowing

through it. These two forces together makes the runner to rotate.

5. Draft Tube

The pressure at the exit of the runner of Reaction Turbine is generally less than atmospheric pressure. The water at

exit cannot be directly discharged to the tail race. A tube or pipe of gradually increasing area is used for discharging

water from the exit of turbine to the tail race. This tube of increasing area is called Draft Tube. One end of the tube is

connected to the outlet of runner while the other end is sub-merged below the level of water in the tail-race.

Types Of Francis Turbines :

There are mainly two types of Francis turbines

• In open flume type, the turbine is immersed underwater of the headrace

in a concrete chamber and discharges into the tailrace through the draft

tube. The main disadvantage of this type is that runner and the guide-

vane mechanism is under the water and they are not open either for

inspection or repair without draining the chamber.

• In the closed type, the water is led to the turbine through the penstock

whose end is connected to the spiral casing of the turbine. The open

flume type is used for the plants of 10 meters head whereas, closed type

is preferred above 30 meters head. The guide vanes are provided around

the runner to regulate the water flowing through the turbine The guide

vanes provide gradually decreasing area of

flow for all gate openings, so that no eddies are formed, and efficiency

does not suffer much even at part load conditions.

Working principles of Francis turbine

Efficiencies Of Francis Turbines :

1. Hydraulic efficiency :

It is defined as the ratio of the power produced by the turbine runner and

the power supplied by the water at the turbine inlet.

2. Volumetric efficiency :

It is possible some water flows out through the clearance between the

runner and casing without passing through the runner.

Volumetric efficiency is defined as the ratio between the volume of water

flowing through the runner and the total volume of water supplied to the

turbine.

3. Mechanical efficiency :

The power produced by the runner is always greater than the power

available at the turbine shaft. This is due to mechanical losses at the bearings,

windage losses and other frictional losses.

4. Overall efficiency :

This is the ratio of power output at the shaft and power input by the water

at the turbine inlet.

Advantage of Francis Turbine :

The difference in the operating head can be extra simply controlled in Francis

turbine than in the Pelton wheel turbine.

The mechanical efficiency of the Pelton wheel decreases faster by wear than Francis

turbine.

Francis turbine variation in operating head can be more simply controlled.

No head failure occurs still at the low discharge of water.

The size of the runner is small.

Small changes in efficiency over time.

• The Francis turbine may be designed for a wide range of heads and flows. This, along

with their high efficiency, has made them the most widely used turbine in the world.

Disadvantage of Francis Turbine :

The water which is not dirt-free can cause extremely rapid wear in high head Francis

turbine.

2. As spiral casing is stranded, the runner is not simply available. Therefore dismantle

is hard.

3. The repair and inspection is much costly and complicated.

4. It faces the hazard of Cavitation.

5. Current losses are certain

• A Kaplan turbine is one kind of a propeller hydro turbine (particularly a reaction turbine) used in hydroelectric plants.

Waterflow both in and out of Kaplan turbines through its rotational axis, which is called axial flow. The point that

makes Kaplan turbines special is that the blades can change their demand to preserve maximum efficiency for

various water flow rates. Kaplan turbine, similar to Francis turbine, is a reaction turbine. Water running through a

Kaplan turbine loses its pressure.

• The area that water can join these turbines is great, equal to the entire space that the blades fill. The large area of

Kaplan turbines makes them most useful where large volumes of water flow can be used even in dams with a

relatively low head. This is especially notable as previous to the Kaplan turbine development, most turbines were

only proper for large heads of water.

• These turbines should be designed to allow large amount of water to flow through them without damage. The way

of designing Kaplan turbines is slightly different from other turbines. The Kaplan turbine is much more modest. There

is a flow passage that injects water in the radial direction, and functional guide vanes – permanent blades that direct

the water abruptly to enter the turbine in the axial orientation.

• The turbine itself is provided with several rotor blades connected directly to the central shaft of the turbine. The

blades are attached with adjustable joints so that the angle can be adjusted, ensuring the maximum efficiency is

achieved for any given flow rate and water head.

• It is necessary to note that this turbine’s blades are not flat. Instead, they rotate slightly because the blade’s exterior

part moves more swiftly than the inside part.

• The way that water moves through a Kaplan turbine is somewhat different from other kinds of turbines. At first, the

water is directed through the turbine radially, advancing from the side. This movement is done since the generator is

typically located somewhere along the turbine’s rotation axis, so if the generator were found here, it would get wet.

Preferably, the guide vanes rapidly carry the water through a ninety-degree turn to hit the blades axially. Rather than

redirecting the water, these vanes are aligned to give the water an appropriate amount of “swirl.”

• The water then moves down over the propeller’s blades, turning it with the “swirl” of the water. Therefore, this type

of turbine is recognized in the class of reaction turbines as the reaction force from pushing the water on the

propeller drives the propeller to move. The water moves out from the turbine axially.

Main Parts of a Kaplan Turbine

A Kaplan Turbine is comprised of:

• Scroll casing,

• Guide vane mechanism,

• Draft tube, and

• Runner blades

You might also like

- Isscc 2021 Tutorial: Silicon Photonics: From Basics To AsicsDocument88 pagesIsscc 2021 Tutorial: Silicon Photonics: From Basics To AsicsdxzhangNo ratings yet

- Owners Handbook - BUKH DV 24 RMEDocument24 pagesOwners Handbook - BUKH DV 24 RMELeonid Kolesnikov50% (2)

- Project Report On Water TurbineDocument20 pagesProject Report On Water TurbineNAVEEN ROY75% (4)

- Fluid Machinery Assignment.Document15 pagesFluid Machinery Assignment.Kamna KumarNo ratings yet

- Francis Turbine: Abbas Bilal Sami Hussein Name: Subject: Third Power Plant Class /branch: D.Laith Ayad SupervisorDocument6 pagesFrancis Turbine: Abbas Bilal Sami Hussein Name: Subject: Third Power Plant Class /branch: D.Laith Ayad Supervisorabbas bilalNo ratings yet

- UNIT-I & II Hydraulic Machine. Up Dated. PPT - By. Dr. Subhash KamalDocument80 pagesUNIT-I & II Hydraulic Machine. Up Dated. PPT - By. Dr. Subhash KamalNagendra Manral100% (3)

- Presentation On Module 6Document31 pagesPresentation On Module 6Rushikesh MantriNo ratings yet

- Lecture 2 - Francis TurbineDocument15 pagesLecture 2 - Francis TurbineNatty tobieNo ratings yet

- 2Document73 pages2Sachin MeenaNo ratings yet

- Water Turbines: Our SubtopicDocument28 pagesWater Turbines: Our SubtopicVaish NaoNo ratings yet

- Hydraulic TurbinesDocument14 pagesHydraulic Turbineshussen belewNo ratings yet

- Turbine Type 1Document35 pagesTurbine Type 1Fiza AhmadNo ratings yet

- Group Member Name Id Card NoDocument12 pagesGroup Member Name Id Card NolataNo ratings yet

- Unit V: - TurbinesDocument56 pagesUnit V: - TurbinesparthibankNo ratings yet

- Types of Turbines, Generators and AdvDocument5 pagesTypes of Turbines, Generators and AdvMackdonald ShiwaniNo ratings yet

- Main AssignmentDocument18 pagesMain AssignmentAmanuelNo ratings yet

- 3 WatertirbineDocument31 pages3 WatertirbineRaj GunalNo ratings yet

- Unit 4Document55 pagesUnit 4Ashish KhariNo ratings yet

- How Does Francis Turbine Work ?: Runner - at The Heart of The SystemDocument3 pagesHow Does Francis Turbine Work ?: Runner - at The Heart of The SystemKamrul HasanNo ratings yet

- TurbineDocument19 pagesTurbineTawsiful AlamNo ratings yet

- Typer of TurbineDocument24 pagesTyper of TurbineRatul HasanNo ratings yet

- Aat Concept Video: Fluid Mechanics and Hydraulic Machines TopicDocument7 pagesAat Concept Video: Fluid Mechanics and Hydraulic Machines TopicAayush AthavaleNo ratings yet

- ME-Laboratory Report: Submitted By: Felisilda, Amelia MDocument30 pagesME-Laboratory Report: Submitted By: Felisilda, Amelia MAllen EspeletaNo ratings yet

- Reaction Turbine: BY Engineer Ghulam MurtazaDocument25 pagesReaction Turbine: BY Engineer Ghulam MurtazaDawood MasihNo ratings yet

- Module-3 (HM)Document14 pagesModule-3 (HM)Nikhil SekharanNo ratings yet

- 1 b1 Hydro Power Plant TurbinesDocument27 pages1 b1 Hydro Power Plant TurbinesWinston LibangaNo ratings yet

- Pelton TurbineDocument5 pagesPelton Turbinegauravarora93No ratings yet

- Module IV BmeDocument108 pagesModule IV BmeAnonymous VDnLHNG7QQNo ratings yet

- Module 4 - TurbinesDocument70 pagesModule 4 - TurbinesASHITA K BNo ratings yet

- I Year (Ii Sem) SESSION-2020-2021: UNIT-1Document26 pagesI Year (Ii Sem) SESSION-2020-2021: UNIT-1Kushagra SrivastavaNo ratings yet

- Unit 5Document7 pagesUnit 5eyobNo ratings yet

- Main Components of Francis Turbine: 1. Spiral CasingDocument3 pagesMain Components of Francis Turbine: 1. Spiral CasingaliriazNo ratings yet

- Hydro Power Engineering: Types of TurbineDocument15 pagesHydro Power Engineering: Types of TurbineartiNo ratings yet

- Francis TurbineDocument45 pagesFrancis TurbineAshish AgarwalNo ratings yet

- Hydro WorkingDocument45 pagesHydro Workingabdulmuqutadir1No ratings yet

- Hydraulic MachineDocument11 pagesHydraulic MachineMD.TAUKIR AHMEDNo ratings yet

- Applied Hyd TrbnsDocument92 pagesApplied Hyd TrbnsKadaikodi PaamaranNo ratings yet

- Francis and Kaplan Reaction TurbinesDocument5 pagesFrancis and Kaplan Reaction TurbinesfahadNo ratings yet

- TurbineDocument14 pagesTurbineArjit GoswamiNo ratings yet

- CE212-Part II - Hydraulic Machinery-TurbinesDocument18 pagesCE212-Part II - Hydraulic Machinery-TurbinesAbdulwahab khanNo ratings yet

- Hydroelectric Turbines: Submitted To: - Sir Kashif Habib Submitted By: - Nehal Aslam (M13-418)Document2 pagesHydroelectric Turbines: Submitted To: - Sir Kashif Habib Submitted By: - Nehal Aslam (M13-418)ErAbdulRehmanNo ratings yet

- Turbines: M Usama Zia Bilal Hassan Syed M Raza NaqviDocument45 pagesTurbines: M Usama Zia Bilal Hassan Syed M Raza NaqviUsama ZiaNo ratings yet

- Operation and Maintenance of Hydro TurbineDocument133 pagesOperation and Maintenance of Hydro TurbineDSTPS ANDALNo ratings yet

- Francis TurbineDocument11 pagesFrancis TurbineYaswanth sai100% (1)

- Hydraulic MachinesDocument64 pagesHydraulic MachinesInnocent RevocatusNo ratings yet

- Hydraulic Machines and Fluid Power LabDocument24 pagesHydraulic Machines and Fluid Power LabDilshad CMNo ratings yet

- Hydraulic Turbines: Working PrincipleDocument5 pagesHydraulic Turbines: Working Principle962943415xNo ratings yet

- 5 6294316585658090348Document54 pages5 6294316585658090348ADARSH MEHERNo ratings yet

- Hydropower Equipment and Generation StatiDocument54 pagesHydropower Equipment and Generation StatiAytac GuvenNo ratings yet

- FluidhailhydranumericalDocument46 pagesFluidhailhydranumericalDanishNo ratings yet

- Hydro-Electric Power Plant: Their Classification With Advantages and DisadvantagesDocument37 pagesHydro-Electric Power Plant: Their Classification With Advantages and DisadvantagesHarsh BhavsarNo ratings yet

- Types of Turbines: Turbine ClassificationsDocument6 pagesTypes of Turbines: Turbine ClassificationsalbertNo ratings yet

- Turbine Student Copy - 072238Document8 pagesTurbine Student Copy - 072238Redwan ShaikatNo ratings yet

- Francis Turbine and Kaplan TurbineDocument9 pagesFrancis Turbine and Kaplan Turbineadityatna369No ratings yet

- Francis TurbineDocument12 pagesFrancis TurbineMeenakshi ChauhanNo ratings yet

- Lec 8 - 9 HydropowerDocument41 pagesLec 8 - 9 HydropowerRazaNo ratings yet

- Infrastructure Operations Management - Session VIDocument37 pagesInfrastructure Operations Management - Session VISai Ujjwala VemuriNo ratings yet

- Types of Turbines and Its UtilizationDocument5 pagesTypes of Turbines and Its UtilizationRao SamiNo ratings yet

- Module - 4 Hydraulic MachinesDocument93 pagesModule - 4 Hydraulic MachinesHerradlinNo ratings yet

- Francis TurbineDocument7 pagesFrancis TurbineLucy TyasNo ratings yet

- Hydraulic Turbines WordDocument4 pagesHydraulic Turbines WordsubNo ratings yet

- Finite Difference Methods For HJB PDEsDocument12 pagesFinite Difference Methods For HJB PDEsbobmezzNo ratings yet

- API 541ti Q&ADocument5 pagesAPI 541ti Q&ATasawwur TahirNo ratings yet

- Crackers (FCCS), Cokers and Hydrocrackers. in Addition To Breaking Chains, There AreDocument2 pagesCrackers (FCCS), Cokers and Hydrocrackers. in Addition To Breaking Chains, There AreMina AdelNo ratings yet

- Spell CurrencyDocument22 pagesSpell CurrencysivavilmaNo ratings yet

- Traducido DespuésDocument19 pagesTraducido DespuésSandra GarcíaNo ratings yet

- CHE3161 Semester1 2010 Solutions PDFDocument14 pagesCHE3161 Semester1 2010 Solutions PDFkumiristineNo ratings yet

- 6.hydrogen Its CompoundDocument17 pages6.hydrogen Its CompoundpjaindakNo ratings yet

- NJM4558Document4 pagesNJM4558Capuñay Diaz ChristianNo ratings yet

- National Institute of Technology, Calicut: Department of Architecture and PlanningDocument20 pagesNational Institute of Technology, Calicut: Department of Architecture and PlanningDriya HariNo ratings yet

- Flowchart ArduinoDocument4 pagesFlowchart ArduinoSeptian Citra KusumaNo ratings yet

- 18GA002-C.Arvind KrishnanDocument40 pages18GA002-C.Arvind KrishnanArvindNo ratings yet

- Bending Strength and Nondestructive Evaluation of Structural BambooDocument5 pagesBending Strength and Nondestructive Evaluation of Structural BambooLuanna Silva de Pires Campos AlvesNo ratings yet

- Palm Pixi Plus - How To Install Homebrew Apps - WebOS NationDocument28 pagesPalm Pixi Plus - How To Install Homebrew Apps - WebOS NationCA_KenNo ratings yet

- A.sateesh 17-202Document17 pagesA.sateesh 17-202Naresh GadidasulaNo ratings yet

- Ni Based Superalloy: Casting Technology, Metallurgy, Development, Properties and ApplicationsDocument46 pagesNi Based Superalloy: Casting Technology, Metallurgy, Development, Properties and ApplicationsffazlaliNo ratings yet

- Unit-4 Blood Pressure Measurement: M F Pimentel August 26, 2019 Blood Pressure - Biomedical Signal ProcessingDocument59 pagesUnit-4 Blood Pressure Measurement: M F Pimentel August 26, 2019 Blood Pressure - Biomedical Signal Processingpriya dharshiniNo ratings yet

- 12class - Docx 100 MCQDocument7 pages12class - Docx 100 MCQMithun PadoleNo ratings yet

- 100 X4FS140 HU B ProductData en DEDocument2 pages100 X4FS140 HU B ProductData en DEcontato.tiagogatodesouzaNo ratings yet

- Analysis and Design of Down-Aisle Pallet Rack StructuresDocument11 pagesAnalysis and Design of Down-Aisle Pallet Rack StructuresAbdalla Sharf EldienNo ratings yet

- Sedemac gc1200 002 Manual For gc1200 ControllersDocument75 pagesSedemac gc1200 002 Manual For gc1200 ControllersKrishnakumar GanesanNo ratings yet

- EC IES 2017 Objective Paper 2Document32 pagesEC IES 2017 Objective Paper 2wemazefomiNo ratings yet

- CLEF 2023 Paper 6291Document19 pagesCLEF 2023 Paper 6291Rabindra Nath NandiNo ratings yet

- Homework English Course: Univeristatea Titu Maiorescu Bucuresti Facultatea de InformaticaDocument9 pagesHomework English Course: Univeristatea Titu Maiorescu Bucuresti Facultatea de InformaticaMihai Alexandru TuțuNo ratings yet

- Sin & Cos - The Programmer's PalsDocument24 pagesSin & Cos - The Programmer's PalsRicardo De Oliveira AlvesNo ratings yet

- AuxiliariesDocument14 pagesAuxiliariesKeadilan Harus Ditegakkan100% (3)

- 5 - Spiral SpringDocument2 pages5 - Spiral SpringKavindu MunasingheNo ratings yet

- 1.) AutonomyDocument1 page1.) Autonomymanoj22490No ratings yet

- MSDS 6. 33kv, 33 KV, PTDocument2 pagesMSDS 6. 33kv, 33 KV, PTRamu RamuNo ratings yet