Professional Documents

Culture Documents

Top 8 Reasons Six Sigma Projects Fail

Top 8 Reasons Six Sigma Projects Fail

Uploaded by

ghafoorian_khoshgovar1488Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Top 8 Reasons Six Sigma Projects Fail

Top 8 Reasons Six Sigma Projects Fail

Uploaded by

ghafoorian_khoshgovar1488Copyright:

Available Formats

The Top Reasons

Six Sigma Projects Fail

Lou Johnson

Technical Training Specialist

Minitab Inc.

ASQ 2008 World Conference

May 2008

© 2008 Minitab, Inc.

Overview

Demographics & Data Collection

Pareto of Common Failure Modes

Top Eight Failure Modes – Detail

What Did Not Make the List

Question and Answer

© 2008 Minitab, Inc.

Demographics: Six Sigma Practitioners

N = 180

Green Belt Black Belt

24% 51%

Master Black Belt Champion

17% 8%

© 2008 Minitab, Inc.

Demographics: Companies

N = 114

Large Mfg. Large Svc.

35% 18%

Small Mfg. Small Svc.

32% 15%

© 2008 Minitab, Inc.

Pareto Chart

Pareto Chart of Failure Modes

1800

70

1500 60

1200 50

Rating

Percent

900 40

660 30

600

20

277

300 231

154 153 150 131 129 126 10

78 74 72 65 64

0 0

t d d ta e at or r rt n n n a er

or se te rg oo po tio ve tio

pp

ba e n da la rm rig p p a i c i gm th

u m d o fo IC as su oc ot

g le s O

tS a ll y le - ba to IC A w d al n t se d

6

e n ci p e A M g a n e is c n

an m a op in rc je ta

em ti at M rD ss ou ct

a g if n n o

o

d

ct

sc

to

D

lf

o

Tr

a in

in

e

re

s

o j e

r p ro

d ers 29 Modes

an n ot ion N je in al ad le pr oo un

M t o e t e t

n o lu Pr ed sm al

r lit th

P n'

c tio S o rc

to o n o o te oes

le tf t ti o T pl

e d

t se j ec j ec i za m e nt

o n o

ec Pr

o

Pr a c em

roj O

rg to ag

P e n

im a

T M

Rating 277 231 154 153 150 131 129 126 78 74 72 65 64 660

P ercent 12 10 7 6 6 6 5 5 3 3 3 3 3 28

C um % 12 21 28 34 41 46 52 57 60 64 67 69 72 100

42 Total Failure Modes

© 2008 Minitab, Inc.

Top 8 Reasons for Failure

Top Eight Failure Modes by Rating

Management Support 277

Project selection not financially based 231

Solution is not implemented 154

No data - bad data 153

Project scope too large 150

Project forced into DMAIC format 131

Project too small for DMAIC rigor 129

Training was poor 126

0 50 100 150 200 250 300 350

Rating

© 2008 Minitab, Inc.

8:Training was Poor

“We did all our training on a TI83 calculator.”

Only Blackbelts are trained - (small company)

• Management doesn’t have the knowledge to support projects

• Process owners don’t feel confident of the outcome

• Project leaders feel overwhelmed

No Project

• “Only 40% of our students complete a project in the 1 st year.”

• “We tell our clients to bring a project to training. They never do.”

• “Trainees never get to practice what they learned.”

No coaching or mentoring from MBB’s or Trainers

© 2008 Minitab, Inc.

The Successful Failure

Project Goal: Reduce wrapping defects to less than .5%

The Defect Slayers’ Percent Wrapping Defects over Time

8

Story Board 7 Implementation

Percent Wrapping Defects

Charter 6

5

4

3

2

1

0

Wrap Tension Part Speed

6 6 6 6 6 6 6 6 6 6 6

2 00 00 00 00 00 20

0 00 20

0 00 00 00

2, ,2 6,

2

4,

2 ,2 , ,2 , ,2 ,2 8,

2

19 r il 2 12 3 0 17 ly

5 23 10 t2

Setting

ch ch ril ay ay ne Ju ly st

Knowledge

ar ar Ap A p M M Ju Ju gu gus

M u Au

Over Production

Operator Setting Gear Shifing M A

Job Change

Defect Slayers Rock!

Wrapping Machine

Defects

Lose Lock Down

Pallet Wear Damage

Supplier

Financial Results: saved $30,156 in 2006!

Wrong Pallet

Pallet Movement Bad Plastic

© 2008 Minitab, Inc.

7: Poor use of resources for DMAIC rigor

“My understanding of Six Sigma tells me that improvement realized

through the rigor of Six Sigma methodologies must be

unquestionably significant, must make the process look different,

and generate enough savings to be shared with the team members

and still increase the corporate bottom line”

Praveen Gupta, Quality Digest commentary, 2007

After Completing the Project the Team Members Should Feel it

was Worth the Effort..

Take Home Message: It takes about the same effort to

complete a $300,000 project as a $30,000 project, maybe less.

Selection Execution

$30K

Selection Execution

$300K

© 2008 Minitab, Inc.

Safety Improvement Team

Project Goal: Improve OSHA recordable incidents to < 3 / period.

Scope / Definition of Project *

Weight Evaluation Criteria Answer Risk Score

1 The project has a clearly identified customer Yes 1

1 The project has a clearly definable defect Yes 1

1 The defect can be effectively and accurately measured Yes 1

1 The defect metric can be defined at the opportunity level Yes 1

1 Costs can readily be associated with the defect Yes 1

1 Defects are of an ongoing nature and at a measurable level No 10

1 The process to be improved has reasonably high output volume Yes 1

1 The project can be completed in a timely manner No 10

1 The project has only one defect (one DPMO) Yes 1

1 The project will involve only one product Yes 1

1 Project improvements will not depend on modifying operations outside of organization Yes 1

1 The project is limited to only one geographic location Yes 1

1 The project will have visible management support Yes 1

1 The input variables can be readily modified producing changes in output No 10

Scope/Definition - Project Score 41

* Project Risk Assessment tool available in Quality Companion by Minitab

© 2008 Minitab, Inc.

6: Project forced into DMAIC format

Inappropriate Projects for DMAIC Methodology

• Select a vendor for our SPC software

• Reduce auto part failures one year into life of the car

• Install a new finishing line for our desktop product

– Perhaps DFSS for this project

“ Having BBs and GBs pick their own projects is not a

good strategy in our experience”

Snee & Hoerl , Six Sigma Beyond the Factory Floor, 2005

Six Sigma practice projects

• “You must do a Gage R&R”

© 2008 Minitab, Inc.

5: Project Scope Too Large

Improve the profitability

of the South American

Division

Improve sales Improve sales

by 20% margin by 20%

Improve internet

sales by 25%

Limit Project Scope

Reduce complaints about • One geographical location

internet order to fill time

(include lost orders due • Within organizational influence

to inability to ship as

desired by the customer) • One measurable product / defect

• Clearly defined customer

Decrease internet

order to fill time by • SIPOC

45%

© 2008 Minitab, Inc.

Let’s take a break!

“While only 32% of respondents in organizations with new (< 1 year )

Six Sigma programs frequently or always use a formal prioritization

process, 63% of those in organizations with 5 – 10 years experience

with Six Sigma do.” Jonathan Atwood, iSixSigma Research – Project Selection, 2005

Take Home Message: Selecting the right Six Sigma projects is

key to their success. Utilize a formal project selection process

from the beginning of your Six Sigma implementation.

© 2008 Minitab, Inc.

4: No Data / Bad Data

No Data

• Service Quality projects can be difficult

• Defect occurs in the customer’s process

• Limited access to operations data

– Confidentiality & privacy issues

Bad Data – Check it!

• Do the Gage R&R first – 156% of Tolerance!?

• Attribute data has a tremendous potential for variation

• Gage calibration and drift.

© 2008 Minitab, Inc.

3: Solution not implemented

Process owner was not involved in the project

• Six Sigma Department

• Process owner was never interested in the project

• Project hand-off

The DMA.. Methodology

“This is not what we expected!”

© 2008 Minitab, Inc.

2: Project is not linked to finances

Project Goal: Reduce the number of press shutdowns caused

by mold in equipment from 37 to < 14 per month.

Solution

• Preventative planning meetings $$

• Mold designer checks prescription $

• Thicker chrome plating $$$

+ Work!

• Reduce press speed $$$

Is this solution worth implementing?

• One shutdown = $8k

• Potential Project Savings = 12 x 23 x $8k = $2.2kk/yr

• Yes!

© 2008 Minitab, Inc.

2: Project is not linked to finances

Data: A major manufacturer of building materials monitored

project characteristics and project success.

Financial Link?

Yes No

Yes 80 35

Successful?

No 26 41

Failure Rate for linked projects 26 / 106 = 25%

Failure Rate for non-linked projects 41 / 76 = 54%

© 2008 Minitab, Inc.

1: Management support

“You shouldn’t ask your employees to do something you’re not

willing to do yourself. The engagement of senior management is

critical to any significant organizational change”

Alan Kent, CEO of Meadows Regional Medical Center

Commenting on factors that lead to his company’s successful

Lean Six Sigma project, 2007

“After our CEO left the company, our Six Sigma program just faded

away.” Small Service Quality company employee

© 2008 Minitab, Inc.

1: Management Support

Good Management Support - Total = 598

Committed Management Support 277

Appropriate Project Resourses Available 74

Enough Time to Complete the Project 72

Management Understands Six Sigma 64

Consider:

Knowlegable Project Leader 61

• Gantt Charts

Project Scope Changes Only When Necessary 50 • Y Metrics

0 50 100 150 200 250 300

Rating • Cause & Effect Diagrams

• Balloting

• Presentation Mode

© 2008 Minitab, Inc.

Causes that didn’t show up on the list

Project was too complex to solve

No Rewards / Recognition program

“We didn’t understand the statistics behind Six

Sigma”

Politics

© 2008 Minitab, Inc.

Conclusion

Application of DMAIC

Best Practices for Implementation

© 2008 Minitab, Inc.

Thank you for your time and participation!

Questions?

The Top Reasons Six Sigma Projects Fail

Lou Johnson

Technical Training Specialist

Minitab Inc.

ASQ 2008 World Conference

May 2008

© 2008 Minitab, Inc.

You might also like

- The 1 Minute Scalper: Downlaod All Russ Horn ProductsDocument11 pagesThe 1 Minute Scalper: Downlaod All Russ Horn ProductsQio Tensei100% (4)

- UserManual PointwiseDocument378 pagesUserManual PointwiseJoaNo ratings yet

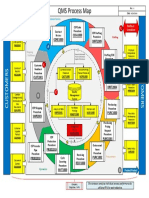

- QM Process Map PDFDocument1 pageQM Process Map PDFghafoorian_khoshgovar148850% (2)

- Principles of Economics Practice Exam 2015 QuestionsDocument6 pagesPrinciples of Economics Practice Exam 2015 Questionsjess100% (1)

- GeneDx HoldingsDocument1 pageGeneDx HoldingsAbdulrahman SharafNo ratings yet

- Powerpact MPRDocument14 pagesPowerpact MPRAntonio Solis MurilloNo ratings yet

- Interland: A-TypeDocument1 pageInterland: A-TypeDuy Giáp NguyễnNo ratings yet

- 610 5Document1 page610 5rt1973No ratings yet

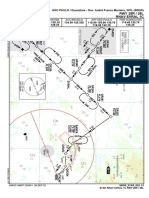

- SBCT - Rnav Matko 1b - Raxit 1b Rwy 33 - Star - 20210909Document1 pageSBCT - Rnav Matko 1b - Raxit 1b Rwy 33 - Star - 20210909junior a,oiNo ratings yet

- Megin II M: Lenses LEDDocument2 pagesMegin II M: Lenses LEDnumaionelNo ratings yet

- 10 1007@s41742-018Document9 pages10 1007@s41742-018Radouane El-AmriNo ratings yet

- Drawings - ENYAU BRIDGE 1-8mDocument10 pagesDrawings - ENYAU BRIDGE 1-8mSolomon AhimbisibweNo ratings yet

- BATIMETRI BITUNG B New-1 PDFDocument1 pageBATIMETRI BITUNG B New-1 PDFChristo YakobusNo ratings yet

- Viktec Catalog 2023 v8Document234 pagesViktec Catalog 2023 v8lilymighty8No ratings yet

- Beton IVAN ModelDocument1 pageBeton IVAN ModelIvan MileticNo ratings yet

- ROAD-3: 450mm THKDocument1 pageROAD-3: 450mm THKAhmed MandorNo ratings yet

- scx550-3 Stage5Document8 pagesscx550-3 Stage5Дмитрий БакайNo ratings yet

- Overview of Power Trading & Exchange PerspectiveDocument50 pagesOverview of Power Trading & Exchange PerspectiveamitNo ratings yet

- Micrologic 2.0 A Trip Unit Characteristic Trip Curve No. 613-9Document1 pageMicrologic 2.0 A Trip Unit Characteristic Trip Curve No. 613-9Diki NugrahaNo ratings yet

- Description: Soil Symbols, Samplers and Test Data UscsDocument5 pagesDescription: Soil Symbols, Samplers and Test Data UscsPatrickNo ratings yet

- 2022 Viktec New CatalogueDocument150 pages2022 Viktec New Cataloguelilymighty8No ratings yet

- Stock Market ReactionDocument3 pagesStock Market ReactionDwitiya MukhopadhyayNo ratings yet

- Produced by An Autodesk Educational Product: Sub-Stn - Design Directorate PanchkulaDocument2 pagesProduced by An Autodesk Educational Product: Sub-Stn - Design Directorate Panchkulabalaeee123No ratings yet

- Assembly Bucket Elevator 12M (Print)Document1 pageAssembly Bucket Elevator 12M (Print)mohammadlukmansodiq2185aNo ratings yet

- Jembatan 1b SalmanDocument1 pageJembatan 1b Salmanturnititin8No ratings yet

- CUENCADocument1 pageCUENCAJC ChuquilinNo ratings yet

- 613-11 Curve ET 1.0M Electronic Trip Unit 800 A-1200 A - SchneiderDocument1 page613-11 Curve ET 1.0M Electronic Trip Unit 800 A-1200 A - SchneiderGustavo MarNo ratings yet

- Curvas de Disparo QODocument16 pagesCurvas de Disparo QOIvanNo ratings yet

- SBGR - Rnav Evral 1c Rwy 28r 28l - Star - 20220908Document1 pageSBGR - Rnav Evral 1c Rwy 28r 28l - Star - 20220908JuliaNo ratings yet

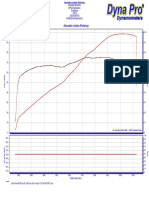

- Adrenaline Junkies Workshop: 3-Dyno Run - DPR, Dyno Run, 17/05/2019, 18:43:26Document1 pageAdrenaline Junkies Workshop: 3-Dyno Run - DPR, Dyno Run, 17/05/2019, 18:43:26Βασίλης ΝαλμπάντηςNo ratings yet

- Hyponic®: Hypoid Right Angle Gearmotor and ReducerDocument120 pagesHyponic®: Hypoid Right Angle Gearmotor and ReducerMauro VergaraNo ratings yet

- Drawings - ENYAU BRIDGE 2-15mDocument10 pagesDrawings - ENYAU BRIDGE 2-15mSolomon AhimbisibweNo ratings yet

- Resistivity LogsDocument9 pagesResistivity LogsFaisal AzizzNo ratings yet

- Calidad Del CementoDocument2 pagesCalidad Del CementoFranciscoCorreaJaraNo ratings yet

- World Trade Organisation International Trade Statistics 2009Document262 pagesWorld Trade Organisation International Trade Statistics 2009http://besthedgefund.blogspot.com100% (1)

- Gsr-Salt-01-03-Stru-7028-02-R1 - (SH - 02 of 05)Document1 pageGsr-Salt-01-03-Stru-7028-02-R1 - (SH - 02 of 05)Design TeamNo ratings yet

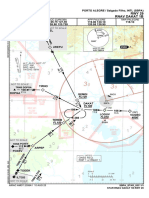

- Sbpa - Rnav Dakat 1b Rwy 29 - Star - 20230810Document1 pageSbpa - Rnav Dakat 1b Rwy 29 - Star - 20230810CMDT MatheusNo ratings yet

- Wabtec Digital Mine Collision Avoidance Brochure 1 Jun'23Document9 pagesWabtec Digital Mine Collision Avoidance Brochure 1 Jun'23sandeepkushwahaNo ratings yet

- Proposed (2) Two Storey With Roof Deck Mrs. Marilyn Chua Marianne S. AbordeDocument3 pagesProposed (2) Two Storey With Roof Deck Mrs. Marilyn Chua Marianne S. AbordeMarianne Solito-Aborde100% (1)

- Rapporte Des Problèmes Conception TESTING For OrderingDocument4 pagesRapporte Des Problèmes Conception TESTING For Orderingabdou.trafficNo ratings yet

- Vỏ Dưới - HGT MQY 3600-1Document1 pageVỏ Dưới - HGT MQY 3600-1Tung Nguyen XuanNo ratings yet

- Multiples of Rated Current: Maximum Single-Pole Trip Times AT 25 C Based On Nema Ab-4, 1991Document1 pageMultiples of Rated Current: Maximum Single-Pole Trip Times AT 25 C Based On Nema Ab-4, 1991Vic AlChNo ratings yet

- J-Frame 250A CircuitBreakers - Trip CurvesDocument3 pagesJ-Frame 250A CircuitBreakers - Trip CurvesFede RodríguezNo ratings yet

- 3G Central Province KPIs December 2016Document145 pages3G Central Province KPIs December 2016Lam HoangNo ratings yet

- Micrologic 5.0/6.0 A/P/H TRIP UNIT Characteristic Trip Curve No. 613-5Document1 pageMicrologic 5.0/6.0 A/P/H TRIP UNIT Characteristic Trip Curve No. 613-5rt1973No ratings yet

- 613-12 Curve ET 1.0I Electronic Trip Unit - Long-Time Pickup and Fixed Delay Instantaneous Pickup 1.5x-12x - SchneiderDocument1 page613-12 Curve ET 1.0I Electronic Trip Unit - Long-Time Pickup and Fixed Delay Instantaneous Pickup 1.5x-12x - SchneiderGustavo MarNo ratings yet

- Ruko RahaDocument2 pagesRuko RahaFidz FaqihNo ratings yet

- Pump GAD For Vertical TurbineDocument9 pagesPump GAD For Vertical TurbineVijay Rama RajuNo ratings yet

- SBFL Rnav-Punod-3a-Rwy14 Sid 20210520Document1 pageSBFL Rnav-Punod-3a-Rwy14 Sid 20210520jose netoNo ratings yet

- Petty Cash Expenses of Chilkalguda For The Month of March 2010Document4 pagesPetty Cash Expenses of Chilkalguda For The Month of March 2010porapandhiNo ratings yet

- Provil CV ME 2018Document12 pagesProvil CV ME 2018Anov HerdiyantoNo ratings yet

- 8 Classroom Block ARCHDocument21 pages8 Classroom Block ARCHbluishimageNo ratings yet

- MELTING - I Kearney. Type 0 OJ. ............ KP:'.) .RNEY. ANS I. C3 7 - 4 2 .. 1981 ............................ J - 1100Document2 pagesMELTING - I Kearney. Type 0 OJ. ............ KP:'.) .RNEY. ANS I. C3 7 - 4 2 .. 1981 ............................ J - 1100JUAN DAVID MINA CASARANNo ratings yet

- Six Sigma How To Use 1 105Document30 pagesSix Sigma How To Use 1 105cpkakopeNo ratings yet

- Oil Tank Settlement AnalysisDocument1 pageOil Tank Settlement AnalysisChowdhury PriodeepNo ratings yet

- PLANODocument1 pagePLANOe8ud.2003No ratings yet

- Edgemaps: Visualizing Explicit and Implicit RelationsDocument12 pagesEdgemaps: Visualizing Explicit and Implicit RelationsMatiasBarriosNo ratings yet

- Mapa de Comunidades NativasDocument1 pageMapa de Comunidades NativasLizeth Licas camposNo ratings yet

- Sdre14-17 TFW 1-9-Rev17Document10 pagesSdre14-17 TFW 1-9-Rev17lwin_oo2435No ratings yet

- Kpi Information: TCH Traffic (Erl)Document25 pagesKpi Information: TCH Traffic (Erl)taji arselanNo ratings yet

- Internal Audit Standard 2023Document108 pagesInternal Audit Standard 2023ghafoorian_khoshgovar1488100% (1)

- Fish Bone DiagramDocument10 pagesFish Bone Diagramghafoorian_khoshgovar1488No ratings yet

- Problem Solving A3Document55 pagesProblem Solving A3ghafoorian_khoshgovar1488100% (1)

- Basic Improvement ToolsDocument141 pagesBasic Improvement Toolsghafoorian_khoshgovar1488No ratings yet

- 8-D Problem Solving Guide Rev G3Document246 pages8-D Problem Solving Guide Rev G3ghafoorian_khoshgovar1488No ratings yet

- Six Sigma at EricssonDocument49 pagesSix Sigma at Ericssonghafoorian_khoshgovar1488No ratings yet

- BS en 12255-16-2021 PDFDocument25 pagesBS en 12255-16-2021 PDFghafoorian_khoshgovar1488No ratings yet

- What Is The Difference Between P-And Np-Charts?Document31 pagesWhat Is The Difference Between P-And Np-Charts?ghafoorian_khoshgovar1488No ratings yet

- CP CPK Six SigmaDocument53 pagesCP CPK Six Sigmaghafoorian_khoshgovar1488No ratings yet

- ISO TC 176 - N544 Guidance On Process ApproachDocument11 pagesISO TC 176 - N544 Guidance On Process Approachghafoorian_khoshgovar1488100% (1)

- Dmaic Standard Work Template: Control ControlDocument17 pagesDmaic Standard Work Template: Control Controlghafoorian_khoshgovar1488No ratings yet

- 2012 08 PDFDocument294 pages2012 08 PDFMahardhyka PrakashaNo ratings yet

- ASCO CO2 Production Plants GoodDocument4 pagesASCO CO2 Production Plants Goodghafoorian_khoshgovar1488No ratings yet

- IMS ManualDocument66 pagesIMS Manualghafoorian_khoshgovar1488No ratings yet

- Soft Drink Manufacturing Paper PDFDocument7 pagesSoft Drink Manufacturing Paper PDFghafoorian_khoshgovar1488No ratings yet

- SixSigmaChart PDFDocument1 pageSixSigmaChart PDFghafoorian_khoshgovar1488No ratings yet

- Activity Based Costing & Activity Based Management: Dosen: Drs. Eddy Budiono, MM., QIADocument45 pagesActivity Based Costing & Activity Based Management: Dosen: Drs. Eddy Budiono, MM., QIAresty widyaaNo ratings yet

- External Factors Analysis Summary Opportunities Weight Rating Weighted Score CommentsDocument3 pagesExternal Factors Analysis Summary Opportunities Weight Rating Weighted Score CommentsShankraKrishnaNo ratings yet

- PV8b IMH Carmarthen MBA Programmes of Study Handbook 2019-20Document27 pagesPV8b IMH Carmarthen MBA Programmes of Study Handbook 2019-20Vernon WhiteNo ratings yet

- The Future of Bank Risk Management Full ReportDocument32 pagesThe Future of Bank Risk Management Full ReportChristian John RojoNo ratings yet

- Securitization Is IllegalDocument34 pagesSecuritization Is IllegalCharlton ButlerNo ratings yet

- Global Marketing ManagementDocument3 pagesGlobal Marketing ManagementsiyazkNo ratings yet

- Working Capital Management inDocument10 pagesWorking Capital Management inVauntedNo ratings yet

- Eurovent 6-2 - 2015 Machinery For AHUDocument10 pagesEurovent 6-2 - 2015 Machinery For AHUHamzaNo ratings yet

- Administrative Assistant Resume SampleDocument2 pagesAdministrative Assistant Resume Sampleresume7.com100% (7)

- AFITDocument409 pagesAFITBenNo ratings yet

- IKEA Group Policy On Anti CorruptionDocument2 pagesIKEA Group Policy On Anti Corruptiondanalin_ursu_8976885100% (1)

- Sap TableDocument82 pagesSap TableGooyong Byeon0% (1)

- Consolidated Technique Procedure4Document45 pagesConsolidated Technique Procedure4imamNo ratings yet

- Perfast Corporation - NotesDocument9 pagesPerfast Corporation - NotesMCDABCNo ratings yet

- Curriculum PDFDocument1 pageCurriculum PDFRina RaymundoNo ratings yet

- What Is LeasingDocument9 pagesWhat Is LeasingHassan KianiNo ratings yet

- Law Enumeration:: Books and Records of CorporationDocument2 pagesLaw Enumeration:: Books and Records of Corporationkookiefied 090197No ratings yet

- Introduction To Information Security Power Point PresentationDocument45 pagesIntroduction To Information Security Power Point PresentationkumarbiconsultantNo ratings yet

- Assets Management Policy and Strategies. ICPAK PDFDocument39 pagesAssets Management Policy and Strategies. ICPAK PDFNassir CeellaabeNo ratings yet

- I.T.C. Limited RM ProjectsDocument29 pagesI.T.C. Limited RM ProjectsViraj Pisal0% (1)

- Fostering InnovationDocument15 pagesFostering InnovationDDNo ratings yet

- Employee Welfare - Its Benefits and PrinciplesDocument3 pagesEmployee Welfare - Its Benefits and PrinciplesBrajnandan AryaNo ratings yet

- Amity School of Business: Public Relations and Corporate ImageDocument21 pagesAmity School of Business: Public Relations and Corporate ImageVarun LalwaniNo ratings yet

- Prospectus, Allotment of Securities and Private Placement Co Act 2013 BGDocument5 pagesProspectus, Allotment of Securities and Private Placement Co Act 2013 BGachuthan100% (1)

- An Exploration of Accounting Conservatism Practise: Empirical Evidence From Developing CountryDocument8 pagesAn Exploration of Accounting Conservatism Practise: Empirical Evidence From Developing CountryYohana Eka Pratiwi IINo ratings yet

- Business Value Analysis FloQastDocument9 pagesBusiness Value Analysis FloQastGoogleNo ratings yet

- MDocument11 pagesMRizqiNo ratings yet