Professional Documents

Culture Documents

Process Engineering Calculations in Cement Industry: Feb 17, 2022 ACC Yanbu Site 1

Process Engineering Calculations in Cement Industry: Feb 17, 2022 ACC Yanbu Site 1

Uploaded by

YhaneCopyright:

Available Formats

You might also like

- Regular Paper 2 - Set A: Section - Ii: Short Descriptive QuestionsDocument23 pagesRegular Paper 2 - Set A: Section - Ii: Short Descriptive QuestionsYogaAnandNo ratings yet

- Coal Mill SafetyDocument17 pagesCoal Mill SafetyJoko Dewoto100% (4)

- The Effects of Oxygen Enrichment On ClinkerDocument9 pagesThe Effects of Oxygen Enrichment On ClinkerNael100% (1)

- Co2 Emission Per Ton ClinkerDocument5 pagesCo2 Emission Per Ton ClinkerJunaid Mazhar50% (2)

- Kiln Preheater Fan CoatingDocument6 pagesKiln Preheater Fan CoatingVijay Bhan100% (1)

- Kiln Cooler Heat Mass BalanceDocument84 pagesKiln Cooler Heat Mass BalancePrabhakar Reddy PeramNo ratings yet

- Calculation of Flame MomentumDocument1 pageCalculation of Flame MomentumAnoop TiwariNo ratings yet

- Kiln Audit Training DetailsDocument20 pagesKiln Audit Training DetailsTamer Fathy100% (5)

- Momentum BURNER CALCULATIONDocument5 pagesMomentum BURNER CALCULATIONTIRIANTONo ratings yet

- 1,2,6a - Flames and Gas FiringDocument29 pages1,2,6a - Flames and Gas FiringMohamed SaadNo ratings yet

- Enhancing Alternate Fuel in Cement Manufacturing Process: A Sustainable Technological ApproachDocument33 pagesEnhancing Alternate Fuel in Cement Manufacturing Process: A Sustainable Technological ApproachManish Kumar100% (1)

- Pillard Burners and FlamesDocument21 pagesPillard Burners and FlamesIrshad HussainNo ratings yet

- How To Control The Hot MealDocument4 pagesHow To Control The Hot MealGiequat100% (2)

- Process Optimization-Pyrosection Hand BookDocument195 pagesProcess Optimization-Pyrosection Hand Bookramsumiran vishwakarma100% (2)

- ROTAFLAM Burner AdjustmentDocument5 pagesROTAFLAM Burner AdjustmentMuhammad Zaghloul100% (2)

- Fine Coal Conveying Velocity in Kiln Firing SystemDocument2 pagesFine Coal Conveying Velocity in Kiln Firing SystemVijay BhanNo ratings yet

- Cement Kiln Pyro BalanceDocument45 pagesCement Kiln Pyro BalanceirfanNo ratings yet

- Ring Formation in KilnDocument12 pagesRing Formation in KilnAbul Qasim100% (2)

- Cement Grinding GuideDocument36 pagesCement Grinding GuideCao Ngoc Anh100% (1)

- K Precalciners1 PDFDocument30 pagesK Precalciners1 PDFKEERTHI INDUSTRIES100% (2)

- Ball Mill Heat Balance ExplanationDocument4 pagesBall Mill Heat Balance ExplanationVisnu Sankar75% (4)

- Roller Press 1Document4 pagesRoller Press 1bipinagarwal100% (1)

- Questionnaire For Pyroprocessing ModificationDocument8 pagesQuestionnaire For Pyroprocessing ModificationVijay BhanNo ratings yet

- Summaries: Summary Mass BalanceDocument51 pagesSummaries: Summary Mass Balanceirfan100% (1)

- 04.04 Kiln Operations Guide Lines - ENGDocument23 pages04.04 Kiln Operations Guide Lines - ENGbrenbra50% (2)

- Kiln Operations Guide Lines - ENGDocument21 pagesKiln Operations Guide Lines - ENGYhane Hermann Back100% (1)

- Odudimu Certification ScenerioDocument50 pagesOdudimu Certification Scenerioabosede2012No ratings yet

- Ask DR. CLARK - OdtDocument50 pagesAsk DR. CLARK - Odtmauryaraj200750% (2)

- VRM C SimulatorDocument19 pagesVRM C SimulatorIrshad HussainNo ratings yet

- Quality and Formulae 2Document2 pagesQuality and Formulae 2zane truesdaleNo ratings yet

- Click Here To Download Holcim, , Lafarge, Most Importnant Manuals, Most Important ExcelDocument26 pagesClick Here To Download Holcim, , Lafarge, Most Importnant Manuals, Most Important ExcelhamedNo ratings yet

- Pyro Process Equipment PDFDocument114 pagesPyro Process Equipment PDFMohamedNo ratings yet

- Cement Grinding OptimizationDocument9 pagesCement Grinding OptimizationFran JimenezNo ratings yet

- Tromp Curve Calculations and ResultsDocument3 pagesTromp Curve Calculations and Resultsrecai100% (3)

- Project:: 2800TPD Burning System CalculationDocument7 pagesProject:: 2800TPD Burning System CalculationOUSSAMA LAKHILINo ratings yet

- Raw MixDocument96 pagesRaw Mixshannu826826No ratings yet

- Calciner Technology in AF FiringDocument22 pagesCalciner Technology in AF Firingkatonbf23100% (3)

- Clinker Vs Kiln Feed FactorDocument3 pagesClinker Vs Kiln Feed FactorSSAC PVT.LTD.100% (2)

- Forms of Alkalies and Their Effect On Clinker FormationDocument11 pagesForms of Alkalies and Their Effect On Clinker Formationkonstantina139No ratings yet

- Measurement DDocument37 pagesMeasurement Dgvrr1954100% (2)

- Pyro ProcessingDocument29 pagesPyro ProcessingMKPashaPasha100% (2)

- Clinker Kiln TheoryDocument37 pagesClinker Kiln TheoryMehmet C100% (1)

- Calculation For CO2 Released During CalcinationDocument4 pagesCalculation For CO2 Released During CalcinationD N SHARMANo ratings yet

- Plant Process Audits2 PDFDocument38 pagesPlant Process Audits2 PDFvilas bollabathiniNo ratings yet

- By Pass System in The Dry ProcessDocument34 pagesBy Pass System in The Dry Processfaheemqc100% (1)

- KilnOpBasics - Raw Mix Control - KFUIDocument12 pagesKilnOpBasics - Raw Mix Control - KFUImustaf100% (2)

- 7 Most Common Problem in PyroProcessing For Kiln and CoolerDocument5 pages7 Most Common Problem in PyroProcessing For Kiln and CoolerbudiNo ratings yet

- Guidelines COPROCEM LowDocument136 pagesGuidelines COPROCEM LowDekeukelaere Anne100% (1)

- Pheater Heat BalanceDocument2 pagesPheater Heat BalanceRaji SuriNo ratings yet

- MillOpBasics OperationDocument36 pagesMillOpBasics OperationIrshad HussainNo ratings yet

- Burner Calculation OCLDocument4 pagesBurner Calculation OCLayaskant751001100% (1)

- For Cement and Minerals: Complete SolutionsDocument36 pagesFor Cement and Minerals: Complete SolutionsHamed MostafaNo ratings yet

- High Efficiency Separators 3Document9 pagesHigh Efficiency Separators 3gldiasNo ratings yet

- Feed Gas Pre-Heater Efficiency Calculation and Enhancement of Ammonia PlantDocument10 pagesFeed Gas Pre-Heater Efficiency Calculation and Enhancement of Ammonia PlantShahadat AwanNo ratings yet

- Temperature-Vacuum Swing Adsorption DACDocument19 pagesTemperature-Vacuum Swing Adsorption DACRoy JudeNo ratings yet

- 2023Oct24-Tripod-Water Coil CalculationDocument9 pages2023Oct24-Tripod-Water Coil CalculationTân NguyễnNo ratings yet

- 14 ACC Air Side Performance PDFDocument24 pages14 ACC Air Side Performance PDFDSGNo ratings yet

- Ahu Tonnage Acmv Design - Precooled Ahu CalculationDocument4 pagesAhu Tonnage Acmv Design - Precooled Ahu Calculationjay PrakashNo ratings yet

- Column Diameter and Hetp CheckDocument6 pagesColumn Diameter and Hetp Checkmayur1980100% (1)

- Life-Cycle Assessment of An Industrial Direct Air Capture Process Based On Temperature-Vacuum Swing AdsorptionDocument11 pagesLife-Cycle Assessment of An Industrial Direct Air Capture Process Based On Temperature-Vacuum Swing AdsorptionducanhNo ratings yet

- Contamination Technical ArticleDocument18 pagesContamination Technical ArticleYhaneNo ratings yet

- 03 Maxilift 17 WsDocument25 pages03 Maxilift 17 WsYhaneNo ratings yet

- What Do You Know About The Kiln Coating?: Jin ZhenDocument11 pagesWhat Do You Know About The Kiln Coating?: Jin ZhenYhaneNo ratings yet

- Identifying & Resolving Common Rotary Kiln Processing ChallengesDocument11 pagesIdentifying & Resolving Common Rotary Kiln Processing ChallengesYhaneNo ratings yet

- Cement EnglishonlyDocument12 pagesCement EnglishonlyYhaneNo ratings yet

- 4 Reasons You Have Entrained Air in Your Pumping System: - 2 Min Read PumpsDocument10 pages4 Reasons You Have Entrained Air in Your Pumping System: - 2 Min Read PumpsYhaneNo ratings yet

- 4ReasonsWhyBearingsFail 1693328338320Document11 pages4ReasonsWhyBearingsFail 1693328338320YhaneNo ratings yet

- Infinity For Cement Equipment: Quality & Composition of Cement ClinkerDocument48 pagesInfinity For Cement Equipment: Quality & Composition of Cement ClinkerYhaneNo ratings yet

- Optimization of Air Distribution in A Baghouse Filter Using Computational Fluid DynamicsDocument5 pagesOptimization of Air Distribution in A Baghouse Filter Using Computational Fluid DynamicsYhaneNo ratings yet

- GasConditioningTowers-RedecamGroup 1664087203547Document3 pagesGasConditioningTowers-RedecamGroup 1664087203547YhaneNo ratings yet

- FormulaDocument60 pagesFormulaYhaneNo ratings yet

- Common Problems in Cement Plant: One Issue From Each SectionDocument7 pagesCommon Problems in Cement Plant: One Issue From Each SectionYhaneNo ratings yet

- Bucket Elevator Installation Manual 473793 Revised 2016Document77 pagesBucket Elevator Installation Manual 473793 Revised 2016YhaneNo ratings yet

- Bus Ele Tech Lib Disconnecting MeansDocument5 pagesBus Ele Tech Lib Disconnecting MeansYhaneNo ratings yet

- Common Problems in Cement PlantDocument6 pagesCommon Problems in Cement PlantYhane100% (1)

- Clinkerization-CementPlantOptimization 1670139096737Document12 pagesClinkerization-CementPlantOptimization 1670139096737YhaneNo ratings yet

- CemScanner WEBDocument5 pagesCemScanner WEBYhaneNo ratings yet

- OptimizingRawMillsPerformance theMaterialsWAY 1670142333901Document17 pagesOptimizingRawMillsPerformance theMaterialsWAY 1670142333901YhaneNo ratings yet

- Brochure Cleaning Services E-Mkt3Document4 pagesBrochure Cleaning Services E-Mkt3YhaneNo ratings yet

- OpenCircuit, ShortCircuitandOverloadfault 1670307651977Document28 pagesOpenCircuit, ShortCircuitandOverloadfault 1670307651977YhaneNo ratings yet

- What Is The Root Cause of High Vibration On Id Fan: MaintenanceforumsDocument8 pagesWhat Is The Root Cause of High Vibration On Id Fan: MaintenanceforumsYhaneNo ratings yet

- 12reasonsforcouplingfailureandhowtoavoidthem Insight AcornIndustrialServicesltd - 1670396292436Document8 pages12reasonsforcouplingfailureandhowtoavoidthem Insight AcornIndustrialServicesltd - 1670396292436YhaneNo ratings yet

- Electric Motor Problems and SolutionsDocument7 pagesElectric Motor Problems and SolutionsYhaneNo ratings yet

- Precalciner Kilns Systems & OperationDocument58 pagesPrecalciner Kilns Systems & OperationYhaneNo ratings yet

- Section Clinker Et Broyage Ciment: Contrat 119 Mecanique ProcessDocument27 pagesSection Clinker Et Broyage Ciment: Contrat 119 Mecanique ProcessYhaneNo ratings yet

- 12reasonsforcouplingfailureandhowtoavoidthem Insight AcornIndustrialServicesltd 1670395912933Document8 pages12reasonsforcouplingfailureandhowtoavoidthem Insight AcornIndustrialServicesltd 1670395912933YhaneNo ratings yet

- A Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BDocument4 pagesA Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BYhaneNo ratings yet

- Uguide 1451Document137 pagesUguide 1451YhaneNo ratings yet

- IncreaseYourMachinesEnergyEfficiency Insight AcornIndustrialServicesltd 1670396101809Document6 pagesIncreaseYourMachinesEnergyEfficiency Insight AcornIndustrialServicesltd 1670396101809YhaneNo ratings yet

- COOLER MANUAL 2 (Process)Document112 pagesCOOLER MANUAL 2 (Process)YhaneNo ratings yet

- Flame Retardant For TextilesDocument23 pagesFlame Retardant For TextilesimranchemiNo ratings yet

- TS002 (WHQ-IMS-PR013) Traceability Supplier SpecificationDocument6 pagesTS002 (WHQ-IMS-PR013) Traceability Supplier SpecificationRafael PerezNo ratings yet

- Tle 9 ReviewerDocument2 pagesTle 9 ReviewerNia De GuzmanNo ratings yet

- Woodcraft Construction Kit Product CatalogueDocument35 pagesWoodcraft Construction Kit Product CatalogueBoban Svemogući ĐokićNo ratings yet

- Review of The Dairy Industry in MauritiusDocument81 pagesReview of The Dairy Industry in MauritiusStephane RacineNo ratings yet

- Fire Alarm Control (IFC 640)Document84 pagesFire Alarm Control (IFC 640)thephuocNo ratings yet

- OB Short and Long Questions Collected by Qazi Umer - 1 NationDocument9 pagesOB Short and Long Questions Collected by Qazi Umer - 1 NationSyed Abrar BukhariNo ratings yet

- Santosh - Sep - 2021Document1 pageSantosh - Sep - 2021santoshkumarNo ratings yet

- Aggregate Impact ValueDocument4 pagesAggregate Impact ValuevinoNo ratings yet

- Between Japan & Germany Related To Dentistry 1Document9 pagesBetween Japan & Germany Related To Dentistry 1Dr Riktesh SrivastavaNo ratings yet

- ANT-ATR4517R10v06-2579 DatasheetDocument2 pagesANT-ATR4517R10v06-2579 DatasheetSilviuSNo ratings yet

- Quality Control TFDocument150 pagesQuality Control TFPrabhat Kumar100% (2)

- Savchencko. Fluid MechanicsDocument19 pagesSavchencko. Fluid Mechanicssameer chaharNo ratings yet

- Bio-Botany Vol-2 - EM PDFDocument216 pagesBio-Botany Vol-2 - EM PDFsudha1987No ratings yet

- W1 Water On EarthDocument28 pagesW1 Water On EarthNetkoNo ratings yet

- Josephine D. Silva Josephine D. SilvaDocument1 pageJosephine D. Silva Josephine D. SilvaclaireNo ratings yet

- Itp Equipment (Static)Document5 pagesItp Equipment (Static)Rajeev KumarNo ratings yet

- Drew Z CVDocument4 pagesDrew Z CVapi-483994460No ratings yet

- ECSS E HB 20 01A (15june2020)Document140 pagesECSS E HB 20 01A (15june2020)Thiago Silva MeloNo ratings yet

- Solar Control Glass PDFDocument16 pagesSolar Control Glass PDFNadiyah MuliaNo ratings yet

- Onkyo TX-SR600 Instruction ManualDocument80 pagesOnkyo TX-SR600 Instruction Manualkuko61No ratings yet

- Module 8 Disciplines and Ideas in The Applied Social SciencesDocument11 pagesModule 8 Disciplines and Ideas in The Applied Social SciencesJonaly Sarita25% (4)

- People vs. Siao, G.R. No. 126021 March 3, 2000Document3 pagesPeople vs. Siao, G.R. No. 126021 March 3, 2000Ria Evita RevitaNo ratings yet

- TFE 5 In. Stroke Operations and Maintenance ManualDocument71 pagesTFE 5 In. Stroke Operations and Maintenance ManualZakNo ratings yet

- Instruction Book: All Models 2019 / 2020Document64 pagesInstruction Book: All Models 2019 / 2020Joshua WelbaumNo ratings yet

- The Bhawanipur Education Society College Department of CommerceDocument3 pagesThe Bhawanipur Education Society College Department of CommerceAyush PathakNo ratings yet

- MANFAAT HABATUSSAUDA (Nigella Sativa L.) Sebagai ASMA Kontroler, Antidiabetik, Antihiperlipidemia, Antimikroba, Dan HepatoprotektorDocument13 pagesMANFAAT HABATUSSAUDA (Nigella Sativa L.) Sebagai ASMA Kontroler, Antidiabetik, Antihiperlipidemia, Antimikroba, Dan HepatoprotektorBaqda A. RahmayantiNo ratings yet

- Thoum MenuDocument12 pagesThoum MenuThoumNo ratings yet

- Special StainsDocument10 pagesSpecial Stainsjgpd2000100% (1)

- Endress Hauser Ftl50h Ate2ad2e6a Liquiphant InstructionsDocument32 pagesEndress Hauser Ftl50h Ate2ad2e6a Liquiphant InstructionsGilberto Prez RomeroNo ratings yet

Process Engineering Calculations in Cement Industry: Feb 17, 2022 ACC Yanbu Site 1

Process Engineering Calculations in Cement Industry: Feb 17, 2022 ACC Yanbu Site 1

Uploaded by

YhaneOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Engineering Calculations in Cement Industry: Feb 17, 2022 ACC Yanbu Site 1

Process Engineering Calculations in Cement Industry: Feb 17, 2022 ACC Yanbu Site 1

Uploaded by

YhaneCopyright:

Available Formats

Process Engineering

Calculations in

Cement Industry

1 Feb 17, 2022 ACC Yanbu Site

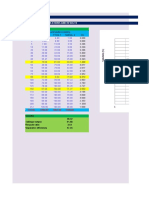

Calculation of Atmospheric Pressure with

Altitude from Sea Level

P (mmwg) = 10133 x e -0.0001255*h

Where h = ht. from sea level in m

2 Feb 17, 2022 ACC Yanbu Site

Conditions at NTP

Pressure = 1 atm = 1.013 x 105 N/m2

Temperature = 273 K

Air Density at NTP

Gas law PxV = nxRxT

V (Volume) = mass/density

n = mass/MW of air

R (Constant) = 8.314

3 Feb 17, 2022 ACC Yanbu Site

Flow

Movement of gas particle in a duct when some

external force is applied on the gas.

4 Feb 17, 2022 ACC Yanbu Site

Pitot Tube, Pressure meter, Thermocouple,

Temperature meter & Anemometer

Pitot Tube Tip Pitot Tube Pipe Connections Digital Pressure Meter

Digital Temperature Meter Anemometer

5 Feb 17, 2022 ACC Yanbu Site

Flow Calculations

Calculation of Velocity in a duct

D.P. = Density x (Velocity)2

2

Velocity = C x (2 x 9.8 x D.P.)0.5

(Density)0.5

Where C = Pitot tube constant

D.P. = Difference in Pressure in mmwg

Density = Kg/m3

Velocity = m/sec

6 Feb 17, 2022 ACC Yanbu Site

Flow Calculations

Calculation of Density

Density ρ = Density at NTP x 273 x (10120-(St.

Pr.))

(Kg/m3) (273+T gas) x 10336

Density at NTP in Kg/Nm3

St. Pr. in mmwg

T gas in degree C

7 Feb 17, 2022 ACC Yanbu Site

Flow Calculations

Calculation of Flow

Flow = Velocity x Area of Duct x 3600

m3/hr

Area of duct (m2) = π x D2

4

Where

D = Diameter of duct (m)

π = 3.14

V = m/sec

8 Feb 17, 2022 ACC Yanbu Site

Flow Calculations

Calculation of Flow at Fan inlet for FD Fans

Flow = Velocity x Area of inlet Duct x 3600

m3/hr

Velocity is measured by Anemometer at Fan inlet

Area of duct = π x D2

4

Where

D = Diameter of duct

π = 3.14

9 Feb 17, 2022 ACC Yanbu Site

Flow Conversion from m3/hr to Nm3/Hr

Volumetric Flow rate = m3/hr

Mass Flow rate (Kg/Hr) = m3/hr x density (kg/m3)

Mass Flow rate (Nm3/Hr) = Mass Flow rate (Kg/hr)

Density at NTP (Kg/Nm3)

10 Feb 17, 2022 ACC Yanbu Site

Flow Conversion from Nm3/hr to m3/Hr

Mass Flow rate = Nm3/hr

Mass Flow rate = Nm3/hr x density at NTP (kg/Nm3)

(Kg/Hr)

Volumetric Flow rate (m3/Hr) = Mass Flow rate (Kg/hr)

Density of gas (Kg/m3)

11 Feb 17, 2022 ACC Yanbu Site

Velocities in ducts

Preheater gas ducts = 16 – 18 m/sec

Tertiary air ducts = 24 – 26 m/sec

Kiln Hood = 6 m/sec

Coal conveying pipes = 35 m/sec

Venting line hood = less than 5 m/sec

12 Feb 17, 2022 ACC Yanbu Site

Composition of Air

By Volume

Oxygen (O2) = 21%

Nitrogen (N2) = 79%

By Weight

Oxygen (O2) = 23.3%

Nitrogen (N2) = 76.7%

13 Feb 17, 2022 ACC Yanbu Site

Calculation of False air in the system

False air (%) = 100 x (O2 (outlet) – O2 (inlet))

(21 - O2 (Outlet))

14 Feb 17, 2022 ACC Yanbu Site

Calculation of Kiln Feed to Clinker Factor

Kiln Feed/Clinker Factor

= (1-Fuel Cons (%) x Fuel Ash (%)) x (1 + Dust Loss)

10000 100____

(1 – LOI)

100

15 Feb 17, 2022 ACC Yanbu Site

Fuels

C + O2 = CO2, Heat Evolved 7829 Kcal/Kg

C + O2 = CO , Heat Evolved 2400 Kcal/Kg

H2 + 0.5 O2 = H2O, Heat Evolved 28641 Kcal/Kg

S + O2 = SO2, Heat Evolved 2213 Kcal/Kg

16 Feb 17, 2022 ACC Yanbu Site

Calculation of Theoretical Air Requirement for

Combustion of Fuel.

HFO Analysis

C 84.5 %

H 11.9 %

N 0.22 %

S 3.28 %

O 0.1 %

C.V. 9407 Kcal/Kg HFO

17 Feb 17, 2022 ACC Yanbu Site

Calculation of Theoretical Air Requirement for

Combustion of Fuel.

C + O2 = CO2

12 32 44

CO2 Produced = 44/12*0.854

= 3.098 Kg/Kg Fuel

O2 Required = 32/12*0.854

= 2.253 Kg/Kg Fuel

18 Feb 17, 2022 ACC Yanbu Site

Calculation of Theoretical Air Requirement for

Combustion of Fuel.

H2 + 0.5 O2 = H2O

2 16 18

H2O Produced = 18/2*0.119

= 1.071 Kg/Kg Fuel

O2 Required = 16/2*0.119

= 0.952 Kg/Kg Fuel

19 Feb 17, 2022 ACC Yanbu Site

Calculation of Theoretical Air Requirement for

Combustion of Fuel.

S + O2 = SO2

32 32 64

SO2 Produced = 64/32*0.0328

= 0.0656 Kg/Kg Fuel

O2 Required = 32/32*0.0328

= 0.0328 Kg/Kg Fuel

20 Feb 17, 2022 ACC Yanbu Site

Calculation of Theoretical Air Requirement for

Combustion of Fuel.

N2 Produced = 0.0022 Kg/Kg Fuel

O2 Available = 0.001 Kg/Kg Fuel

Total O2 Required for burning of Fuel

O2 for C + O2 for H + O2 for S – O2 Available

2.253 + 0.952 + 0.033 – 0.001 = 3.237 Kg/Kg Fuel

21 Feb 17, 2022 ACC Yanbu Site

Calculation of Theoretical Air Requirement for

Combustion of Fuel.

O2 Required for burning of Fuel = 3.237 Kg/Kg Fuel

Corresponding air = 3.237/ 0.233

= 13.892 Kg/Kg Fuel

= 13.892/1.293

= 10.745 Nm3/Kg Fuel

22 Feb 17, 2022 ACC Yanbu Site

Calculation of Combustion Gases from Fuel

Total Combustion Gases Produced from Combustion of Fuel

CO2 from C + H2O from H + SO2 from S + N2 + Excess O2

= 3.098 + 1.071 + 0.0656 + 0.0022

= 4.2368 Kg Combustion/Kg Fuel.

23 Feb 17, 2022 ACC Yanbu Site

Calculation of Specific Heat Consumption

Clinker Production = 9000 TPD

= 375 TPH

Kiln Fuel Consumption = 11200 Kg/Hr

Pyro-1 Fuel Consumption = 10800 Liter/Hr

= 9720 Kg/Hr

Pyro-2 Fuel Consumption = 10600 Liter/Hr

= 9540 Kg/Hr

Total Fuel Consumption = 30460 Kg/Hr

Specific Fuel Consumption = 0.0812 Kg/Kg Clinker

Calorific Value of Fuel = 9407 Kcal/Kg Fuel

Specific Heat Consumption = 9407* 0.0812

= 763.8 Kcal/Kg Clinker

24 Feb 17, 2022 ACC Yanbu Site

Clinker Cooler Heat & Mass Balance

Tertiary Air

Kiln Cooler Exhaust

Secondary

Air Hot Clinker

Clinker Cooler

Ambient Air Cooled Clinker

25 Feb 17, 2022 ACC Yanbu Site

Fan Laws

Capacity (Fan Speed)

Pressure (Fan Speed)2

Power (Fan Speed)3

Capacity (Impeller Dia.)3

Pressure (Impeller Dia.)2

Power (Impeller Dia.)5

26 Feb 17, 2022 ACC Yanbu Site

Fan Efficiency

Fan Efficiency = Theoretical Power x 100

Shaft Power

Fan Theoretical Power (KW) =

Flow (m3/sec) x Pressure (mmwg)

102

Actual Power =

√3 x Voltage (Volts) x Current (Amps) x Power Factor

Shaft Power = Actual Power x Motor Efficiency

27 Feb 17, 2022 ACC Yanbu Site

Kiln & Cooler Loading

Kiln Volumetric Loading = Kiln Output (TPD)________

Kiln Effective Volume (m3)

Kiln Effective Volume =

π x (Kiln effective Dia.)2 x Kiln Length

4

Norms = 5.5 -6.0 TPD/m3

28 Feb 17, 2022 ACC Yanbu Site

Kiln & Cooler Loading

Kiln Thermal Loading (Million Kcal/hr/m2) =

Kiln O/P (TPD) x Kiln Fuel (%) x Heat Consumption x 10

24 x Kiln effective cross sectional area

Kiln Effective cross sectional area =

π x (Kiln effective Dia.)2

4

Norms = 5.5 -6.0 Million Kcal/hr/m2

29 Feb 17, 2022 ACC Yanbu Site

Kiln & Cooler Loading

Clinker Cooler Loading (TPD/m2)

= Kiln Output (TPD)

Cooler grate area (m2)

Norms = 60 TPD/m2

30 Feb 17, 2022 ACC Yanbu Site

Degree of Material Filling in Kiln

Residence time of material in kiln (min) :-

= 11.4 x Kiln Length (m)________________

Kiln RPM x 60 x (Kiln Effective Dia.) x Kiln Slope (m/m)

Degree of material filling :-

= Clinker (Kg/Hr) x KF/Clk. Factor x R. Time (min) x 100

BD of KF (Kg/m3) x 60 x Kiln Vol. (m3)

Norms :- 12 – 14 %

31 Feb 17, 2022 ACC Yanbu Site

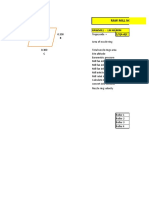

Flame Momentum

Flame momentum is mixing of fuel with primary air & secondary

air for better combustion of fuel.

Flame momentum :- % of primary air x Tip velocity (m/sec)

Unit of flame momentum :- %. m/sec

or

:- N/MW (European standard)

Norms :- 1400 – 1450 %.m/sec

5.0 – 5.5 N/MW

32 Feb 17, 2022 ACC Yanbu Site

Thank You

33 Feb 17, 2022 ACC Yanbu Site

You might also like

- Regular Paper 2 - Set A: Section - Ii: Short Descriptive QuestionsDocument23 pagesRegular Paper 2 - Set A: Section - Ii: Short Descriptive QuestionsYogaAnandNo ratings yet

- Coal Mill SafetyDocument17 pagesCoal Mill SafetyJoko Dewoto100% (4)

- The Effects of Oxygen Enrichment On ClinkerDocument9 pagesThe Effects of Oxygen Enrichment On ClinkerNael100% (1)

- Co2 Emission Per Ton ClinkerDocument5 pagesCo2 Emission Per Ton ClinkerJunaid Mazhar50% (2)

- Kiln Preheater Fan CoatingDocument6 pagesKiln Preheater Fan CoatingVijay Bhan100% (1)

- Kiln Cooler Heat Mass BalanceDocument84 pagesKiln Cooler Heat Mass BalancePrabhakar Reddy PeramNo ratings yet

- Calculation of Flame MomentumDocument1 pageCalculation of Flame MomentumAnoop TiwariNo ratings yet

- Kiln Audit Training DetailsDocument20 pagesKiln Audit Training DetailsTamer Fathy100% (5)

- Momentum BURNER CALCULATIONDocument5 pagesMomentum BURNER CALCULATIONTIRIANTONo ratings yet

- 1,2,6a - Flames and Gas FiringDocument29 pages1,2,6a - Flames and Gas FiringMohamed SaadNo ratings yet

- Enhancing Alternate Fuel in Cement Manufacturing Process: A Sustainable Technological ApproachDocument33 pagesEnhancing Alternate Fuel in Cement Manufacturing Process: A Sustainable Technological ApproachManish Kumar100% (1)

- Pillard Burners and FlamesDocument21 pagesPillard Burners and FlamesIrshad HussainNo ratings yet

- How To Control The Hot MealDocument4 pagesHow To Control The Hot MealGiequat100% (2)

- Process Optimization-Pyrosection Hand BookDocument195 pagesProcess Optimization-Pyrosection Hand Bookramsumiran vishwakarma100% (2)

- ROTAFLAM Burner AdjustmentDocument5 pagesROTAFLAM Burner AdjustmentMuhammad Zaghloul100% (2)

- Fine Coal Conveying Velocity in Kiln Firing SystemDocument2 pagesFine Coal Conveying Velocity in Kiln Firing SystemVijay BhanNo ratings yet

- Cement Kiln Pyro BalanceDocument45 pagesCement Kiln Pyro BalanceirfanNo ratings yet

- Ring Formation in KilnDocument12 pagesRing Formation in KilnAbul Qasim100% (2)

- Cement Grinding GuideDocument36 pagesCement Grinding GuideCao Ngoc Anh100% (1)

- K Precalciners1 PDFDocument30 pagesK Precalciners1 PDFKEERTHI INDUSTRIES100% (2)

- Ball Mill Heat Balance ExplanationDocument4 pagesBall Mill Heat Balance ExplanationVisnu Sankar75% (4)

- Roller Press 1Document4 pagesRoller Press 1bipinagarwal100% (1)

- Questionnaire For Pyroprocessing ModificationDocument8 pagesQuestionnaire For Pyroprocessing ModificationVijay BhanNo ratings yet

- Summaries: Summary Mass BalanceDocument51 pagesSummaries: Summary Mass Balanceirfan100% (1)

- 04.04 Kiln Operations Guide Lines - ENGDocument23 pages04.04 Kiln Operations Guide Lines - ENGbrenbra50% (2)

- Kiln Operations Guide Lines - ENGDocument21 pagesKiln Operations Guide Lines - ENGYhane Hermann Back100% (1)

- Odudimu Certification ScenerioDocument50 pagesOdudimu Certification Scenerioabosede2012No ratings yet

- Ask DR. CLARK - OdtDocument50 pagesAsk DR. CLARK - Odtmauryaraj200750% (2)

- VRM C SimulatorDocument19 pagesVRM C SimulatorIrshad HussainNo ratings yet

- Quality and Formulae 2Document2 pagesQuality and Formulae 2zane truesdaleNo ratings yet

- Click Here To Download Holcim, , Lafarge, Most Importnant Manuals, Most Important ExcelDocument26 pagesClick Here To Download Holcim, , Lafarge, Most Importnant Manuals, Most Important ExcelhamedNo ratings yet

- Pyro Process Equipment PDFDocument114 pagesPyro Process Equipment PDFMohamedNo ratings yet

- Cement Grinding OptimizationDocument9 pagesCement Grinding OptimizationFran JimenezNo ratings yet

- Tromp Curve Calculations and ResultsDocument3 pagesTromp Curve Calculations and Resultsrecai100% (3)

- Project:: 2800TPD Burning System CalculationDocument7 pagesProject:: 2800TPD Burning System CalculationOUSSAMA LAKHILINo ratings yet

- Raw MixDocument96 pagesRaw Mixshannu826826No ratings yet

- Calciner Technology in AF FiringDocument22 pagesCalciner Technology in AF Firingkatonbf23100% (3)

- Clinker Vs Kiln Feed FactorDocument3 pagesClinker Vs Kiln Feed FactorSSAC PVT.LTD.100% (2)

- Forms of Alkalies and Their Effect On Clinker FormationDocument11 pagesForms of Alkalies and Their Effect On Clinker Formationkonstantina139No ratings yet

- Measurement DDocument37 pagesMeasurement Dgvrr1954100% (2)

- Pyro ProcessingDocument29 pagesPyro ProcessingMKPashaPasha100% (2)

- Clinker Kiln TheoryDocument37 pagesClinker Kiln TheoryMehmet C100% (1)

- Calculation For CO2 Released During CalcinationDocument4 pagesCalculation For CO2 Released During CalcinationD N SHARMANo ratings yet

- Plant Process Audits2 PDFDocument38 pagesPlant Process Audits2 PDFvilas bollabathiniNo ratings yet

- By Pass System in The Dry ProcessDocument34 pagesBy Pass System in The Dry Processfaheemqc100% (1)

- KilnOpBasics - Raw Mix Control - KFUIDocument12 pagesKilnOpBasics - Raw Mix Control - KFUImustaf100% (2)

- 7 Most Common Problem in PyroProcessing For Kiln and CoolerDocument5 pages7 Most Common Problem in PyroProcessing For Kiln and CoolerbudiNo ratings yet

- Guidelines COPROCEM LowDocument136 pagesGuidelines COPROCEM LowDekeukelaere Anne100% (1)

- Pheater Heat BalanceDocument2 pagesPheater Heat BalanceRaji SuriNo ratings yet

- MillOpBasics OperationDocument36 pagesMillOpBasics OperationIrshad HussainNo ratings yet

- Burner Calculation OCLDocument4 pagesBurner Calculation OCLayaskant751001100% (1)

- For Cement and Minerals: Complete SolutionsDocument36 pagesFor Cement and Minerals: Complete SolutionsHamed MostafaNo ratings yet

- High Efficiency Separators 3Document9 pagesHigh Efficiency Separators 3gldiasNo ratings yet

- Feed Gas Pre-Heater Efficiency Calculation and Enhancement of Ammonia PlantDocument10 pagesFeed Gas Pre-Heater Efficiency Calculation and Enhancement of Ammonia PlantShahadat AwanNo ratings yet

- Temperature-Vacuum Swing Adsorption DACDocument19 pagesTemperature-Vacuum Swing Adsorption DACRoy JudeNo ratings yet

- 2023Oct24-Tripod-Water Coil CalculationDocument9 pages2023Oct24-Tripod-Water Coil CalculationTân NguyễnNo ratings yet

- 14 ACC Air Side Performance PDFDocument24 pages14 ACC Air Side Performance PDFDSGNo ratings yet

- Ahu Tonnage Acmv Design - Precooled Ahu CalculationDocument4 pagesAhu Tonnage Acmv Design - Precooled Ahu Calculationjay PrakashNo ratings yet

- Column Diameter and Hetp CheckDocument6 pagesColumn Diameter and Hetp Checkmayur1980100% (1)

- Life-Cycle Assessment of An Industrial Direct Air Capture Process Based On Temperature-Vacuum Swing AdsorptionDocument11 pagesLife-Cycle Assessment of An Industrial Direct Air Capture Process Based On Temperature-Vacuum Swing AdsorptionducanhNo ratings yet

- Contamination Technical ArticleDocument18 pagesContamination Technical ArticleYhaneNo ratings yet

- 03 Maxilift 17 WsDocument25 pages03 Maxilift 17 WsYhaneNo ratings yet

- What Do You Know About The Kiln Coating?: Jin ZhenDocument11 pagesWhat Do You Know About The Kiln Coating?: Jin ZhenYhaneNo ratings yet

- Identifying & Resolving Common Rotary Kiln Processing ChallengesDocument11 pagesIdentifying & Resolving Common Rotary Kiln Processing ChallengesYhaneNo ratings yet

- Cement EnglishonlyDocument12 pagesCement EnglishonlyYhaneNo ratings yet

- 4 Reasons You Have Entrained Air in Your Pumping System: - 2 Min Read PumpsDocument10 pages4 Reasons You Have Entrained Air in Your Pumping System: - 2 Min Read PumpsYhaneNo ratings yet

- 4ReasonsWhyBearingsFail 1693328338320Document11 pages4ReasonsWhyBearingsFail 1693328338320YhaneNo ratings yet

- Infinity For Cement Equipment: Quality & Composition of Cement ClinkerDocument48 pagesInfinity For Cement Equipment: Quality & Composition of Cement ClinkerYhaneNo ratings yet

- Optimization of Air Distribution in A Baghouse Filter Using Computational Fluid DynamicsDocument5 pagesOptimization of Air Distribution in A Baghouse Filter Using Computational Fluid DynamicsYhaneNo ratings yet

- GasConditioningTowers-RedecamGroup 1664087203547Document3 pagesGasConditioningTowers-RedecamGroup 1664087203547YhaneNo ratings yet

- FormulaDocument60 pagesFormulaYhaneNo ratings yet

- Common Problems in Cement Plant: One Issue From Each SectionDocument7 pagesCommon Problems in Cement Plant: One Issue From Each SectionYhaneNo ratings yet

- Bucket Elevator Installation Manual 473793 Revised 2016Document77 pagesBucket Elevator Installation Manual 473793 Revised 2016YhaneNo ratings yet

- Bus Ele Tech Lib Disconnecting MeansDocument5 pagesBus Ele Tech Lib Disconnecting MeansYhaneNo ratings yet

- Common Problems in Cement PlantDocument6 pagesCommon Problems in Cement PlantYhane100% (1)

- Clinkerization-CementPlantOptimization 1670139096737Document12 pagesClinkerization-CementPlantOptimization 1670139096737YhaneNo ratings yet

- CemScanner WEBDocument5 pagesCemScanner WEBYhaneNo ratings yet

- OptimizingRawMillsPerformance theMaterialsWAY 1670142333901Document17 pagesOptimizingRawMillsPerformance theMaterialsWAY 1670142333901YhaneNo ratings yet

- Brochure Cleaning Services E-Mkt3Document4 pagesBrochure Cleaning Services E-Mkt3YhaneNo ratings yet

- OpenCircuit, ShortCircuitandOverloadfault 1670307651977Document28 pagesOpenCircuit, ShortCircuitandOverloadfault 1670307651977YhaneNo ratings yet

- What Is The Root Cause of High Vibration On Id Fan: MaintenanceforumsDocument8 pagesWhat Is The Root Cause of High Vibration On Id Fan: MaintenanceforumsYhaneNo ratings yet

- 12reasonsforcouplingfailureandhowtoavoidthem Insight AcornIndustrialServicesltd - 1670396292436Document8 pages12reasonsforcouplingfailureandhowtoavoidthem Insight AcornIndustrialServicesltd - 1670396292436YhaneNo ratings yet

- Electric Motor Problems and SolutionsDocument7 pagesElectric Motor Problems and SolutionsYhaneNo ratings yet

- Precalciner Kilns Systems & OperationDocument58 pagesPrecalciner Kilns Systems & OperationYhaneNo ratings yet

- Section Clinker Et Broyage Ciment: Contrat 119 Mecanique ProcessDocument27 pagesSection Clinker Et Broyage Ciment: Contrat 119 Mecanique ProcessYhaneNo ratings yet

- 12reasonsforcouplingfailureandhowtoavoidthem Insight AcornIndustrialServicesltd 1670395912933Document8 pages12reasonsforcouplingfailureandhowtoavoidthem Insight AcornIndustrialServicesltd 1670395912933YhaneNo ratings yet

- A Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BDocument4 pagesA Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BYhaneNo ratings yet

- Uguide 1451Document137 pagesUguide 1451YhaneNo ratings yet

- IncreaseYourMachinesEnergyEfficiency Insight AcornIndustrialServicesltd 1670396101809Document6 pagesIncreaseYourMachinesEnergyEfficiency Insight AcornIndustrialServicesltd 1670396101809YhaneNo ratings yet

- COOLER MANUAL 2 (Process)Document112 pagesCOOLER MANUAL 2 (Process)YhaneNo ratings yet

- Flame Retardant For TextilesDocument23 pagesFlame Retardant For TextilesimranchemiNo ratings yet

- TS002 (WHQ-IMS-PR013) Traceability Supplier SpecificationDocument6 pagesTS002 (WHQ-IMS-PR013) Traceability Supplier SpecificationRafael PerezNo ratings yet

- Tle 9 ReviewerDocument2 pagesTle 9 ReviewerNia De GuzmanNo ratings yet

- Woodcraft Construction Kit Product CatalogueDocument35 pagesWoodcraft Construction Kit Product CatalogueBoban Svemogući ĐokićNo ratings yet

- Review of The Dairy Industry in MauritiusDocument81 pagesReview of The Dairy Industry in MauritiusStephane RacineNo ratings yet

- Fire Alarm Control (IFC 640)Document84 pagesFire Alarm Control (IFC 640)thephuocNo ratings yet

- OB Short and Long Questions Collected by Qazi Umer - 1 NationDocument9 pagesOB Short and Long Questions Collected by Qazi Umer - 1 NationSyed Abrar BukhariNo ratings yet

- Santosh - Sep - 2021Document1 pageSantosh - Sep - 2021santoshkumarNo ratings yet

- Aggregate Impact ValueDocument4 pagesAggregate Impact ValuevinoNo ratings yet

- Between Japan & Germany Related To Dentistry 1Document9 pagesBetween Japan & Germany Related To Dentistry 1Dr Riktesh SrivastavaNo ratings yet

- ANT-ATR4517R10v06-2579 DatasheetDocument2 pagesANT-ATR4517R10v06-2579 DatasheetSilviuSNo ratings yet

- Quality Control TFDocument150 pagesQuality Control TFPrabhat Kumar100% (2)

- Savchencko. Fluid MechanicsDocument19 pagesSavchencko. Fluid Mechanicssameer chaharNo ratings yet

- Bio-Botany Vol-2 - EM PDFDocument216 pagesBio-Botany Vol-2 - EM PDFsudha1987No ratings yet

- W1 Water On EarthDocument28 pagesW1 Water On EarthNetkoNo ratings yet

- Josephine D. Silva Josephine D. SilvaDocument1 pageJosephine D. Silva Josephine D. SilvaclaireNo ratings yet

- Itp Equipment (Static)Document5 pagesItp Equipment (Static)Rajeev KumarNo ratings yet

- Drew Z CVDocument4 pagesDrew Z CVapi-483994460No ratings yet

- ECSS E HB 20 01A (15june2020)Document140 pagesECSS E HB 20 01A (15june2020)Thiago Silva MeloNo ratings yet

- Solar Control Glass PDFDocument16 pagesSolar Control Glass PDFNadiyah MuliaNo ratings yet

- Onkyo TX-SR600 Instruction ManualDocument80 pagesOnkyo TX-SR600 Instruction Manualkuko61No ratings yet

- Module 8 Disciplines and Ideas in The Applied Social SciencesDocument11 pagesModule 8 Disciplines and Ideas in The Applied Social SciencesJonaly Sarita25% (4)

- People vs. Siao, G.R. No. 126021 March 3, 2000Document3 pagesPeople vs. Siao, G.R. No. 126021 March 3, 2000Ria Evita RevitaNo ratings yet

- TFE 5 In. Stroke Operations and Maintenance ManualDocument71 pagesTFE 5 In. Stroke Operations and Maintenance ManualZakNo ratings yet

- Instruction Book: All Models 2019 / 2020Document64 pagesInstruction Book: All Models 2019 / 2020Joshua WelbaumNo ratings yet

- The Bhawanipur Education Society College Department of CommerceDocument3 pagesThe Bhawanipur Education Society College Department of CommerceAyush PathakNo ratings yet

- MANFAAT HABATUSSAUDA (Nigella Sativa L.) Sebagai ASMA Kontroler, Antidiabetik, Antihiperlipidemia, Antimikroba, Dan HepatoprotektorDocument13 pagesMANFAAT HABATUSSAUDA (Nigella Sativa L.) Sebagai ASMA Kontroler, Antidiabetik, Antihiperlipidemia, Antimikroba, Dan HepatoprotektorBaqda A. RahmayantiNo ratings yet

- Thoum MenuDocument12 pagesThoum MenuThoumNo ratings yet

- Special StainsDocument10 pagesSpecial Stainsjgpd2000100% (1)

- Endress Hauser Ftl50h Ate2ad2e6a Liquiphant InstructionsDocument32 pagesEndress Hauser Ftl50h Ate2ad2e6a Liquiphant InstructionsGilberto Prez RomeroNo ratings yet