Professional Documents

Culture Documents

Sandipposter QBD

Sandipposter QBD

Uploaded by

chintiaCopyright:

Available Formats

You might also like

- Lab Photoelectric Effect PhET Simulation KeyDocument5 pagesLab Photoelectric Effect PhET Simulation KeyAnil KrishnanNo ratings yet

- MCAT Prep Organic Equation SheetDocument6 pagesMCAT Prep Organic Equation SheetChris_Barber09No ratings yet

- SQA 0 01 Radical Strategy - Rev1 (Okamoto Version)Document1 pageSQA 0 01 Radical Strategy - Rev1 (Okamoto Version)Reza RahmaputraNo ratings yet

- Accurate Determination of Catalyst Loading On Glassy Carbon Disk and Its Impact On Thin Film Rotating Disk Electrode For Oxygen Reduction Reaction.Document1 pageAccurate Determination of Catalyst Loading On Glassy Carbon Disk and Its Impact On Thin Film Rotating Disk Electrode For Oxygen Reduction Reaction.Muralidhar ChourashiyaNo ratings yet

- QAQC Personnel Qualification Matrix - Fabrication ShopDocument1 pageQAQC Personnel Qualification Matrix - Fabrication ShoparnolhariNo ratings yet

- Job No. 26418: CollahuasiDocument1 pageJob No. 26418: Collahuasicutcnc.concepcionNo ratings yet

- Va2-Yu02-P1bay-145001 - Overall Protection and Metering Single Line Diagram - R1Document1 pageVa2-Yu02-P1bay-145001 - Overall Protection and Metering Single Line Diagram - R1Công TràNo ratings yet

- 3010-0047-01ppr CatFines CPH PressDocument2 pages3010-0047-01ppr CatFines CPH Presskristian.nielsenNo ratings yet

- PicarroDocument1 pagePicarroDidi AdisaputroNo ratings yet

- Anabus PTS GenapDocument2 pagesAnabus PTS GenapRurita HermawatyNo ratings yet

- Section Piping General Arrangment: Hi - Tech Carbon RCC Stack DesignDocument1 pageSection Piping General Arrangment: Hi - Tech Carbon RCC Stack DesignAbhijeet OundhakarNo ratings yet

- 4.LOBBY FLOOR PLAN-Layout1Document1 page4.LOBBY FLOOR PLAN-Layout1farouk 2017No ratings yet

- NGR Sizing 11kVDocument4 pagesNGR Sizing 11kVSantosh100% (2)

- PQR's Material & Planning 27.04.2022 - CopieDocument2 pagesPQR's Material & Planning 27.04.2022 - Copiecsc EXPERTISENo ratings yet

- Hamburg Wheel Tracking Device Update 0412Document2 pagesHamburg Wheel Tracking Device Update 0412Nguyễn Văn MinhNo ratings yet

- KH Bi-10-08643-0007 - MPSRDocument6 pagesKH Bi-10-08643-0007 - MPSRAswin KurupNo ratings yet

- Job No. 26418: CollahuasiDocument1 pageJob No. 26418: Collahuasicutcnc.concepcionNo ratings yet

- Cube Register LogDocument1 pageCube Register LogNickNo ratings yet

- Esquema Coastal LineDocument2 pagesEsquema Coastal LineDaniel NiñoNo ratings yet

- Carrier IdlerDocument22 pagesCarrier Idlerwawan setiawanNo ratings yet

- Quantum Autoencoders With Enhanced Data EncodingDocument7 pagesQuantum Autoencoders With Enhanced Data EncodingfoobarukNo ratings yet

- Jambaran Tiung Biru Project: Electrical Power and Control Cable Schedule - Substation No. 1Document2 pagesJambaran Tiung Biru Project: Electrical Power and Control Cable Schedule - Substation No. 1Alif AnsharNo ratings yet

- PMP - EnglishDocument1 pagePMP - EnglishDalibor MihaljcicNo ratings yet

- SL 6900K01C50 10164 01 - 00Document2 pagesSL 6900K01C50 10164 01 - 00effiezool mohdNo ratings yet

- Location: Hadoron Studio INC As Built PlanDocument1 pageLocation: Hadoron Studio INC As Built PlanRyan RNo ratings yet

- Kaizen Activity Report Selog Medan November 2022Document1 pageKaizen Activity Report Selog Medan November 2022andreas siburianNo ratings yet

- Muranga Milk Etp Drawing-1Document1 pageMuranga Milk Etp Drawing-1NIMRODNo ratings yet

- Siddaganga Institute of Technology, Tumakuru - 572 103. Provisional Results of Even Semester (2020-21) End Examinations August 2021Document3 pagesSiddaganga Institute of Technology, Tumakuru - 572 103. Provisional Results of Even Semester (2020-21) End Examinations August 2021Mr ZekeNo ratings yet

- Current Affairs-166Document3 pagesCurrent Affairs-166Ganji LakshmanaraoNo ratings yet

- Darlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2439)Document1 pageDarlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2439)Elcio BrembattiNo ratings yet

- TNA - Monthly Training Report Kelas Paralel - 2020 - Subcont - PUPDocument1 pageTNA - Monthly Training Report Kelas Paralel - 2020 - Subcont - PUPMuhamad Rizki AzisNo ratings yet

- SLD BudhebhaparDocument1 pageSLD BudhebhaparHarak DhamiNo ratings yet

- GSM F024 Special Pass Through Characteristics FormDocument1 pageGSM F024 Special Pass Through Characteristics FormQMSNo ratings yet

- NSRP LLM WPQTDocument3 pagesNSRP LLM WPQTtranvando1986No ratings yet

- Twitter SLDDocument1 pageTwitter SLDMohamed ShafeyNo ratings yet

- SD-797-QAP_R1-SAEL_C-Sections_dt_14.05.24 (1)Document2 pagesSD-797-QAP_R1-SAEL_C-Sections_dt_14.05.24 (1)Mohammad Furqan ShaikhNo ratings yet

- Mini Assess - : Interim Assess Meet/PlanningDocument1 pageMini Assess - : Interim Assess Meet/Planningapi-588487311No ratings yet

- Bom-Cgs-As Per Isometric DrawingDocument2 pagesBom-Cgs-As Per Isometric DrawingRajnish AnandNo ratings yet

- Msil KH SPCL Press (A+b) Ga Drgs Tce Approved With Comments EdDocument20 pagesMsil KH SPCL Press (A+b) Ga Drgs Tce Approved With Comments Edrohitbhagat005No ratings yet

- Msil KH SPCL Press (A+b) Column Lyt 155 Tce Approved With CommentsDocument1 pageMsil KH SPCL Press (A+b) Column Lyt 155 Tce Approved With Commentsrohitbhagat005No ratings yet

- VFR Corridor Southern Java Airav Aip Amdt 113Document1 pageVFR Corridor Southern Java Airav Aip Amdt 113SAPTONo ratings yet

- Sensors SyllabusDocument2 pagesSensors Syllabusdirector.sportssrmistNo ratings yet

- 99739-6e100selectrical DiagramDocument8 pages99739-6e100selectrical DiagramPETER ADAMNo ratings yet

- CanakkaleDocument9 pagesCanakkalecod modernwarfareNo ratings yet

- 2sc4140 Ds enDocument1 page2sc4140 Ds enAdah BumboneNo ratings yet

- 785C Plano Hidraulico PDFDocument2 pages785C Plano Hidraulico PDFChristian Vásquez BasilioNo ratings yet

- Flow of MaufacturingDocument1 pageFlow of MaufacturingButhetdohNo ratings yet

- TECHNICALPart 6Document1,280 pagesTECHNICALPart 6সীমান্ত ছাড়িয়ে - Shemanto ChariyeNo ratings yet

- DRP001 Ouf Gal 940110 K Ecr 001 002 S1Document1 pageDRP001 Ouf Gal 940110 K Ecr 001 002 S1pathanNo ratings yet

- 076551C 000D Sow 9000 001 - R0Document37 pages076551C 000D Sow 9000 001 - R0ikenn100% (1)

- Method Statement For Installation of Cable Tray: STC Admin Car Park Building ProjectDocument12 pagesMethod Statement For Installation of Cable Tray: STC Admin Car Park Building ProjectSyed AtherNo ratings yet

- PE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1Document1 pagePE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- Module 3 AssessmentDocument3 pagesModule 3 AssessmentSheela AliNo ratings yet

- Leger 11 GenapDocument1 pageLeger 11 GenaptMonz OfficialNo ratings yet

- 1 Overview: STC8A8K64S4A12 Series ManualDocument18 pages1 Overview: STC8A8K64S4A12 Series Manualhossein gholamiNo ratings yet

- 101 - P&id MGF Acf Ro 30M3HR 17012023Document1 page101 - P&id MGF Acf Ro 30M3HR 17012023Sai Kiran PalikaNo ratings yet

- Biochar PosterDocument1 pageBiochar PosterGrafImhoofyNo ratings yet

- Report Akreditasi Batch MBT in Branch Batch 124 2024-04-04 08 48 26Document2 pagesReport Akreditasi Batch MBT in Branch Batch 124 2024-04-04 08 48 26Muhammad Agung PratamaNo ratings yet

- Measure Systems: Basic Engineering Design DataDocument1 pageMeasure Systems: Basic Engineering Design DataTAHIR MAHMOODNo ratings yet

- p3 PDFDocument10 pagesp3 PDFrenilNo ratings yet

- Ucrete RG: Heavy Duty Polyurethane Concrete For Forming Cove Bases and Renovating WallsDocument3 pagesUcrete RG: Heavy Duty Polyurethane Concrete For Forming Cove Bases and Renovating Wallssyifa latifa zahidaNo ratings yet

- Concrete Columns Reinforced by Glass Fiber Reinforced Polymer RodsDocument10 pagesConcrete Columns Reinforced by Glass Fiber Reinforced Polymer RodsShakeel WaseemNo ratings yet

- OSHA Training Toolbox Talk - Hazard Communication - Chemical Hazards and Effects PDFDocument2 pagesOSHA Training Toolbox Talk - Hazard Communication - Chemical Hazards and Effects PDFmohd addinNo ratings yet

- Functional Groups ContainingDocument8 pagesFunctional Groups ContainingViku GuptaNo ratings yet

- Determination of Rate of Evaporation of Different Liquids.Document22 pagesDetermination of Rate of Evaporation of Different Liquids.Jinesh Doshi33% (6)

- VizagSteel MgmtTRAINEEDocument28 pagesVizagSteel MgmtTRAINEERaghu88% (16)

- Aw0331f MSDSDocument2 pagesAw0331f MSDSson.nh98bgNo ratings yet

- Structural Steel en 10025-10027Document2 pagesStructural Steel en 10025-10027apply19842371No ratings yet

- Production of Car Seat Cushion Using Palm OilDocument25 pagesProduction of Car Seat Cushion Using Palm OilSeiswaran PandeinNo ratings yet

- Chem-01-Atoms ElectronicStructure Lecture NotesDocument36 pagesChem-01-Atoms ElectronicStructure Lecture NotesSaraNo ratings yet

- 015 Emat Slofec TechniqueDocument9 pages015 Emat Slofec TechniquejasminneeNo ratings yet

- 14.3.3 Non-Premixed Model Input and Solution Procedures in FLUENTDocument11 pages14.3.3 Non-Premixed Model Input and Solution Procedures in FLUENTmohdkamalhafeezNo ratings yet

- Introduction To FRP Pipes Their Properties Specification Codes Joining Supporting and Applications WDocument7 pagesIntroduction To FRP Pipes Their Properties Specification Codes Joining Supporting and Applications WjoecardNo ratings yet

- July Update Paint, Ink, and Coating BookletDocument9 pagesJuly Update Paint, Ink, and Coating BookletMarthinus BoxyNo ratings yet

- Expert System Analysis of TIG Molten Weld Metal Fluidity Using The Bond Dimensionless NumberDocument6 pagesExpert System Analysis of TIG Molten Weld Metal Fluidity Using The Bond Dimensionless NumberInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Paper - 2 (Question Paper) - 6Document16 pagesPaper - 2 (Question Paper) - 6Saumya MundraNo ratings yet

- PSV Sizing CalculationsDocument53 pagesPSV Sizing CalculationsAMITH OK93% (29)

- Week 1a Course DetailsDocument19 pagesWeek 1a Course DetailsAraasu EgambaramNo ratings yet

- Fire Card Running SystemDocument3 pagesFire Card Running SystemAngelica FloresNo ratings yet

- LeakDocument1 pageLeakMohanNo ratings yet

- ECJ Dossier 2020 SustainabilityDocument49 pagesECJ Dossier 2020 SustainabilityJose LopezNo ratings yet

- Fruit and Vegetable Wash TdsDocument1 pageFruit and Vegetable Wash TdsEsheshNo ratings yet

- KITZ ProductDocument44 pagesKITZ Productkingathur26681No ratings yet

- Gelatin YesDocument80 pagesGelatin YesOliver AbordoNo ratings yet

- Chapter 4 Capillary PressureDocument16 pagesChapter 4 Capillary PressureHericane StudioNo ratings yet

- Exp#5 Lab ReportDocument6 pagesExp#5 Lab ReportJake Macneal100% (1)

- Bulletin New Refrigerant R1234yfDocument10 pagesBulletin New Refrigerant R1234yfYudha SetiawanNo ratings yet

Sandipposter QBD

Sandipposter QBD

Uploaded by

chintiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sandipposter QBD

Sandipposter QBD

Uploaded by

chintiaCopyright:

Available Formats

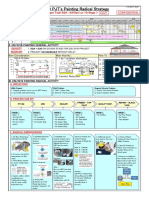

Scale up of Atorvastatin Delayed Release Nanoparticles for Treatment of Hyperlipidemia:

Quality by Design (QbD) Approach

Gite S. M., Mirani A. G., Patravale V.B..

Department of Pharmaceutical Sciences and Technology, Institute of Chemical Technology, Matunga, Mumbai-400019

AIM & OBJECTIVE INTRODUCTION Transformation of nanoformulation from lab scale to pilot scale

Wide absorption window

• Quality by Design development of Atorvastatin calcium delayed

release nanoparticles.

Atorvastatin Calcium

•

• . To evaluate the in vitro & in vivo characteristics of Atorvastatin

calcium delayed-release nanoparticles (NP)

BCS Class II Delayed Release Acid Instability QbD

Nanoparticles (ACDRNPs) Approach X

• Scale up of developed Atorvastatin calcium delayed release

nanoparticles

Low Bioavailability Aqueous phasePeristaltic Organic Evaporation Spray Drying

Pump Phase

EXPERIMENTAL

DOE by QBD DOE by QBD 32 Full Factorial Design (FFD) Preformulation Studies In- Vitro study protocol

Quality Target Product Profile of (ACDRNPs) Independent variables Solubility studies in various stabilizers

More Since this is DR dosage

Cumulative

QTPP Elements Target drug Release

than 80

%

No form, CDR is moderately

critical.

Factors Low level Middle High level • USP Apparatus 4 (Sotax TM CE7,

(-) Level (+)

Dosage form Nanoparticle

Bioenhancing property of Drug: polymer ratio 1:1 1:2.5 1:5 Switzerland)

Dosage type Delayed release the drug formulations is

• Content Uniformity 200-500

highly responsible for Surfactant concentration (%) 0.25 0.5 1 • Close Loop System

Dosage strength 5/10/20/40/80 mg Particle Size

nm

Yes attaining meaningful

• Assay

Administration Oral

pharmacodynamic effects;

hence was taken up as

32 full factorial Design • 22.6 mm cells (i.d.)

• Particle Size Alu-Alu blister

Packaging

highly critical.

Batch code

Drug: Polymer

ratio

Surfactant concentration

(%)

• Piston pump (Sotax CY7–50)

Stability of nanoparticles is

• PDI

Stability 6 months

Polydispersity

index

0.1-0.3 Yes dependent on PDI so it is ACNP1 1.00 0.25 • Dissolution Medium- 1.2 pH HCL

highly critical

ACNP2 1.00 0.50

• Zeta potential Dosage form is DR, so it is

ACNP3 1.00 1.00

followed by pH 6.8 Phosphate buffer

Encapsulation very important that EE

• DSC

Critical Quality Attributes of ACDRNPs efficiency

(EE)

60-100% Yes should be at higher side. So

it was attributed as highly

ACNP4 2.50 0.25 Polymer drug compatibility studies using FTIR and DSC 900ml at 37±0.5˚C

ACNP5 2.50 0.50

• FTIR

Quality

Attributes

Is this

a

critical parameter

ACNP6 2.50 1.00

• Flow rate- 8 ml/min

of

•

the TEM

Drug

Target

CQA

?

Justification

Risk Assesment analysis ACNP7 5.00 0.25 • Time- 2 hr in 1.2pH HCl and then

• XRD Color

Product

Physical attributes of

ACNP8 5.00 0.50 5,15,30,45,60, 120 min

•

PhysicalIn vitro studies

Odor the formulation were

not considered as

Drug Product

CQA's

Drug:

polymer ratio

Stabilizer

conc.

Stirring

rate

Mixing

time

ACNP9 5.00 1.00

• In vivoAppear

attributes

studies

No

critical, as these are not Experimental procedure for preparation of of Nanoparticle In- Vivo study protocol

ance directly linked to the

Fig. FTIR Spectra of AC Fig. FTIR Spectra of physical mixture

efficacy and safety. Assay and CU Low Low Low Low

Assay and content

• Male Albino rats (6–7 weeks old)

CDR Low Low Low Low

Assay and

uniformity tend to

affect safety and

weighing between 180 and 200 g

90- Particle Size High High Low Low

Content

uniformity

100%

No efficacy of

formulations, variables

• Dose: 9mg/kg

PDI Medium Medium Medium Medium

were regarded

moderately critical.

as • Route of administration: Oral

EE High High Medium Medium

• Time: 0.5, 1, 1.5, 2, 3,4, 6, 8 and 12 h

Medium risk factors are optimized on the basis of Fig.DSC thermogram of AC Fig. FTIR Spectra of physical mixture

preliminary batches

RESULT AND DISCUSSION

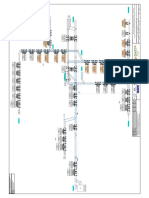

Analysis of Data using Design Expert Validation and scale up of nanoformulation Particle Size and zeta potential

ert® Software

Design-Expert® Software Design-Expert® Software

P Size Predicted

P Size vs . Actual Box-Cox Plot for Power Trans form s

ug:polymer

abilizer

Color points by value of

P Size:

425.3

430.00 Lambda

Current = 1

Best = 0.13

6.36

Particle size and EE of

ACDRNPs

Low C.I. = -1.16

440

262 High C.I. = 1.45

400 62

Recommend transform:

350

Encapsulation efficiency

387.50 None 5.64

395 (Lambda = 1) 61

Particle Size in nm

300

P S iz e

350

250 60

345.00 4.92

305 200 59

260 150 58

302.50 4.19

100

1.00 5.00

50 57

0.81 4.00

260.00 3.47

0 56

0.63 3.00

ACNP1 ACNP2 ACNP3

261.20 302.23 343.25 384.28 425.30 -3 -2 -1 0 1 2 3

0.44 2.00

B: Stabilizer A : Drug:polymer

0.25 1.00

Batch code

X: Actual X: Lam bda

Y : Predic ted Y : Ln(R es idualSS)

Particle Size (nm) Encapsulation efficiency (%)

Fig. 3D-Response and Model diagnostic plots of particle size

The "Pred R-Squared" of 0.9663 is in reasonable agreement with the "Adj R-Squared" of 0.9910. "Adeq Precision"

measures the signal to noise ratio. A ratio greater than is desirable. Here ratio of 41.531 indicates an adequate signal.

Software

This model can be used to navigate the design space.

ANOVA Equation: P Size =+356.60+10.66 * A-36.58 * B-44.20 * A * B-49.45 * A2+24.19 * B2

Design-Expert ® Sof tware

In vivo pharmacokinetics Studies

ymer EE Predicted

EE vs . Actual Box-Cox Plot for Power Transforms

r Color point s by value of

88 EE: 88. 00 6.50

87.5

45.6

76.5

76. 50 6.23

65 Parameters Unit Observed values

EE

65. 00 5.96

53.5

Particle size and EE of ACDRNPs Cmax µg/ml 3.99

53. 50 5.69

42

Tmax h 3.00

T1/2 h 3.85

All the predicted response lie within 95% CI, and gave

42. 00 5.42

1.00 5

42.83 54.00 65.16 76.33 87. 50 -3 -2 -1 0 1 2 3

0.81 4

0.63 3

X: Actual X: Lambda MRT h 8.02

correlation coefficient value near to 0.999.Hence,

0.44 2 Y : Predic ted Y: Ln(ResidualSS)

B: Stabilizer A : Drug:polymer

0.25 1

AUC(0-t) µg/ml h 5.78

Fig. 3D-Response and Model diagnostic plots of Encapsulation efficiency

The "Pred R-Squared" of 0.5463 is in reasonable agreement with the "Adj R-Squared" of 0.7258. "Adeq Precision"

predicted responses are validated AUC(0-∞) µg/ml h 36.91

measures the signal to noise ratio. A ratio greater than is desirable. Here ratio of 9.487 indicates an adequate signal.

AUMC µg/ml h 289.02

This model can be used to navigate the design space.

oftware

ANOVA Equation: EE=+63.03+10.55 * A-9.66*

h 0.17

Scale up of nanoformulation: Optimized batches

Design-Expert® Sof tware

Predicted vs . Actual

Design-Expert® Software Ka

PDI

PDI Box-Cox Plot for Power Trans form s

ymer Color points by value of

h 0.18

0.24 Lambda

PDI: Current = 1 12.90

0.29

0.22 Best = 1.29 Kel

were formulated and subjected to spray drying

Low C.I. = 0.62

0 High C.I. = 2

0.215 0.18

Recommend transform:

None

(Lambda = 1)

7.67

Vd L 1.33

Fig. In vivo absorption

process

k = 0.0022

(used to make

0.14 response values

PD I

0.12 positive) 2.44

0.065

0.05 -2.79

-0.01

1.00 5.00

-0.01 -8.02

Stability Studies as per ICH guidelines

Spray drying parameters:

0.81 4.00 -0.00 0.06 0.12 0.17 0.23 -3 -2 -1 0 1 2 3

0.63 3.00

0.44 2.00 X: Ac tual X: Lam bda

B: Stabilizer

0.25 1.00

A : Drug:polymer Y : Predic ted Y : Ln(R es idualSS)

Batch Size: 2.5 L

Fig. 3D-Response and Model diagnostic plots of polydipsersity index

Drying

The "Pred R-Squared" of 0.9454 is in reasonable agreement with the "Adj R-Squared" of 0.9812. "Adeq Precision" temperature:1000C

measures the signal to noise ratio. A ratio greater than is desirable. Here ratio of 41.531 indicates an adequate signal. Outlet Temperature:50 0C

This model can be used to navigate the design space. 30 °C ± 2 °C/65% RH ± 5% RH 40 °C ± 2 °C/75% RH ± 5% RH

Feed Rate: 4ml/min

ANOVA Equation: PDI =+0.22+0.083 * A-0.026* B+0.0096 * A * B-0.12* A2+0.015 * B2

Aspirator:400

Optimization as a function of Particle In vitro Particle In vitro

Updated risk assessment parameters

desirability Time Size PDI Assay Release Time Size PDI Assay Release

oftware

Overlay Plot Fig. effect of spray drying on particle Size

1.00

0 Month 321.1 0.214 99.23 98.55% 0 Month 321.1 0.214 99.23 97.60%

P Size:

EE:

319.214

60.2261 Drug Product Drug: Stabilizer Stirring Mixing

In vitro release studies

0.81 PDI: 0.220006

ymer X1

X2

3.96

0.93 CQA's polymer ratio conc. rate time 1 Month 329.5 0.245 99.19 97.84% 1 Month 335.1 0.278 100.5 98.60%

PDI: 0.1

0.63

Assay and CU Low Low Low Low

2 month 328.7 0.227 98.56 98.15 2 month 341.2 0.265 99.78 98.4

EE: 70

CDR Low Low Low Low

0.44 3 month 335.7 0.236 98.47 95.69 3 month 319.5 0.284 99.56 99.06

Particle Size Low Low Low Low

0.25

PDI Low Low Low Low 6 Month 339.5 0.265 98.01 96.15 6 Month 374.1 0.301 99.23 97.4

1.00 2.00 3.00 4.00 5.00

EE Low Low Low Low

X1: A: D rug:poly mer

X2: B: Stabilizer

Working Space ACDRNPs Showed stability over period of 6 months

as per ICH guideline

Establishment of level A of in vitro in vivo correlation Conclusion References

1. Amidon, G.L., et al. Pharmaceutical

Significant point to point relationship

was observed with regression Research 12, 413–420, 1995

coefficient (R2) of 0.988 and slope 2. C.A. Lipinski, F. Lombardo, B.W. Dominy, P.J.

approaching toward unity, indicating a

Atorvastatin calcium delayed release nanoparticles were successfully prepared and scaled up using QbD Feeney, Advanced Drug Delivery Reviews 46

close correlation between the in vitro approach. (2001) 3–26.

release rates and in vivo absorption of Five fold increase in bioavailability was observed as compared to marketed formulation and Plain AC

the drug.

The prediction error of the Cmax and suspension. Acknowledgement

AUC of the correlation were found to Successful level A correlation was established on the basis of in-vitro and in- vivo release The authors are grateful to University

be 9.62% and 12.02%. The low Nanoformulation showed stability over a period of six months as per ICH guidelines for the parameters Grants Commission and AICTE for the

prediction error indicates the reliability financial assistance provided for the

of model towards carrying out like particle size, PDI, Assay/Drug content, In vitro release. research work.

predictions; hence it can be selected as

a bio relevant tool to screen the best

IVIVC model linear regression plot

You might also like

- Lab Photoelectric Effect PhET Simulation KeyDocument5 pagesLab Photoelectric Effect PhET Simulation KeyAnil KrishnanNo ratings yet

- MCAT Prep Organic Equation SheetDocument6 pagesMCAT Prep Organic Equation SheetChris_Barber09No ratings yet

- SQA 0 01 Radical Strategy - Rev1 (Okamoto Version)Document1 pageSQA 0 01 Radical Strategy - Rev1 (Okamoto Version)Reza RahmaputraNo ratings yet

- Accurate Determination of Catalyst Loading On Glassy Carbon Disk and Its Impact On Thin Film Rotating Disk Electrode For Oxygen Reduction Reaction.Document1 pageAccurate Determination of Catalyst Loading On Glassy Carbon Disk and Its Impact On Thin Film Rotating Disk Electrode For Oxygen Reduction Reaction.Muralidhar ChourashiyaNo ratings yet

- QAQC Personnel Qualification Matrix - Fabrication ShopDocument1 pageQAQC Personnel Qualification Matrix - Fabrication ShoparnolhariNo ratings yet

- Job No. 26418: CollahuasiDocument1 pageJob No. 26418: Collahuasicutcnc.concepcionNo ratings yet

- Va2-Yu02-P1bay-145001 - Overall Protection and Metering Single Line Diagram - R1Document1 pageVa2-Yu02-P1bay-145001 - Overall Protection and Metering Single Line Diagram - R1Công TràNo ratings yet

- 3010-0047-01ppr CatFines CPH PressDocument2 pages3010-0047-01ppr CatFines CPH Presskristian.nielsenNo ratings yet

- PicarroDocument1 pagePicarroDidi AdisaputroNo ratings yet

- Anabus PTS GenapDocument2 pagesAnabus PTS GenapRurita HermawatyNo ratings yet

- Section Piping General Arrangment: Hi - Tech Carbon RCC Stack DesignDocument1 pageSection Piping General Arrangment: Hi - Tech Carbon RCC Stack DesignAbhijeet OundhakarNo ratings yet

- 4.LOBBY FLOOR PLAN-Layout1Document1 page4.LOBBY FLOOR PLAN-Layout1farouk 2017No ratings yet

- NGR Sizing 11kVDocument4 pagesNGR Sizing 11kVSantosh100% (2)

- PQR's Material & Planning 27.04.2022 - CopieDocument2 pagesPQR's Material & Planning 27.04.2022 - Copiecsc EXPERTISENo ratings yet

- Hamburg Wheel Tracking Device Update 0412Document2 pagesHamburg Wheel Tracking Device Update 0412Nguyễn Văn MinhNo ratings yet

- KH Bi-10-08643-0007 - MPSRDocument6 pagesKH Bi-10-08643-0007 - MPSRAswin KurupNo ratings yet

- Job No. 26418: CollahuasiDocument1 pageJob No. 26418: Collahuasicutcnc.concepcionNo ratings yet

- Cube Register LogDocument1 pageCube Register LogNickNo ratings yet

- Esquema Coastal LineDocument2 pagesEsquema Coastal LineDaniel NiñoNo ratings yet

- Carrier IdlerDocument22 pagesCarrier Idlerwawan setiawanNo ratings yet

- Quantum Autoencoders With Enhanced Data EncodingDocument7 pagesQuantum Autoencoders With Enhanced Data EncodingfoobarukNo ratings yet

- Jambaran Tiung Biru Project: Electrical Power and Control Cable Schedule - Substation No. 1Document2 pagesJambaran Tiung Biru Project: Electrical Power and Control Cable Schedule - Substation No. 1Alif AnsharNo ratings yet

- PMP - EnglishDocument1 pagePMP - EnglishDalibor MihaljcicNo ratings yet

- SL 6900K01C50 10164 01 - 00Document2 pagesSL 6900K01C50 10164 01 - 00effiezool mohdNo ratings yet

- Location: Hadoron Studio INC As Built PlanDocument1 pageLocation: Hadoron Studio INC As Built PlanRyan RNo ratings yet

- Kaizen Activity Report Selog Medan November 2022Document1 pageKaizen Activity Report Selog Medan November 2022andreas siburianNo ratings yet

- Muranga Milk Etp Drawing-1Document1 pageMuranga Milk Etp Drawing-1NIMRODNo ratings yet

- Siddaganga Institute of Technology, Tumakuru - 572 103. Provisional Results of Even Semester (2020-21) End Examinations August 2021Document3 pagesSiddaganga Institute of Technology, Tumakuru - 572 103. Provisional Results of Even Semester (2020-21) End Examinations August 2021Mr ZekeNo ratings yet

- Current Affairs-166Document3 pagesCurrent Affairs-166Ganji LakshmanaraoNo ratings yet

- Darlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2439)Document1 pageDarlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2439)Elcio BrembattiNo ratings yet

- TNA - Monthly Training Report Kelas Paralel - 2020 - Subcont - PUPDocument1 pageTNA - Monthly Training Report Kelas Paralel - 2020 - Subcont - PUPMuhamad Rizki AzisNo ratings yet

- SLD BudhebhaparDocument1 pageSLD BudhebhaparHarak DhamiNo ratings yet

- GSM F024 Special Pass Through Characteristics FormDocument1 pageGSM F024 Special Pass Through Characteristics FormQMSNo ratings yet

- NSRP LLM WPQTDocument3 pagesNSRP LLM WPQTtranvando1986No ratings yet

- Twitter SLDDocument1 pageTwitter SLDMohamed ShafeyNo ratings yet

- SD-797-QAP_R1-SAEL_C-Sections_dt_14.05.24 (1)Document2 pagesSD-797-QAP_R1-SAEL_C-Sections_dt_14.05.24 (1)Mohammad Furqan ShaikhNo ratings yet

- Mini Assess - : Interim Assess Meet/PlanningDocument1 pageMini Assess - : Interim Assess Meet/Planningapi-588487311No ratings yet

- Bom-Cgs-As Per Isometric DrawingDocument2 pagesBom-Cgs-As Per Isometric DrawingRajnish AnandNo ratings yet

- Msil KH SPCL Press (A+b) Ga Drgs Tce Approved With Comments EdDocument20 pagesMsil KH SPCL Press (A+b) Ga Drgs Tce Approved With Comments Edrohitbhagat005No ratings yet

- Msil KH SPCL Press (A+b) Column Lyt 155 Tce Approved With CommentsDocument1 pageMsil KH SPCL Press (A+b) Column Lyt 155 Tce Approved With Commentsrohitbhagat005No ratings yet

- VFR Corridor Southern Java Airav Aip Amdt 113Document1 pageVFR Corridor Southern Java Airav Aip Amdt 113SAPTONo ratings yet

- Sensors SyllabusDocument2 pagesSensors Syllabusdirector.sportssrmistNo ratings yet

- 99739-6e100selectrical DiagramDocument8 pages99739-6e100selectrical DiagramPETER ADAMNo ratings yet

- CanakkaleDocument9 pagesCanakkalecod modernwarfareNo ratings yet

- 2sc4140 Ds enDocument1 page2sc4140 Ds enAdah BumboneNo ratings yet

- 785C Plano Hidraulico PDFDocument2 pages785C Plano Hidraulico PDFChristian Vásquez BasilioNo ratings yet

- Flow of MaufacturingDocument1 pageFlow of MaufacturingButhetdohNo ratings yet

- TECHNICALPart 6Document1,280 pagesTECHNICALPart 6সীমান্ত ছাড়িয়ে - Shemanto ChariyeNo ratings yet

- DRP001 Ouf Gal 940110 K Ecr 001 002 S1Document1 pageDRP001 Ouf Gal 940110 K Ecr 001 002 S1pathanNo ratings yet

- 076551C 000D Sow 9000 001 - R0Document37 pages076551C 000D Sow 9000 001 - R0ikenn100% (1)

- Method Statement For Installation of Cable Tray: STC Admin Car Park Building ProjectDocument12 pagesMethod Statement For Installation of Cable Tray: STC Admin Car Park Building ProjectSyed AtherNo ratings yet

- PE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1Document1 pagePE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- Module 3 AssessmentDocument3 pagesModule 3 AssessmentSheela AliNo ratings yet

- Leger 11 GenapDocument1 pageLeger 11 GenaptMonz OfficialNo ratings yet

- 1 Overview: STC8A8K64S4A12 Series ManualDocument18 pages1 Overview: STC8A8K64S4A12 Series Manualhossein gholamiNo ratings yet

- 101 - P&id MGF Acf Ro 30M3HR 17012023Document1 page101 - P&id MGF Acf Ro 30M3HR 17012023Sai Kiran PalikaNo ratings yet

- Biochar PosterDocument1 pageBiochar PosterGrafImhoofyNo ratings yet

- Report Akreditasi Batch MBT in Branch Batch 124 2024-04-04 08 48 26Document2 pagesReport Akreditasi Batch MBT in Branch Batch 124 2024-04-04 08 48 26Muhammad Agung PratamaNo ratings yet

- Measure Systems: Basic Engineering Design DataDocument1 pageMeasure Systems: Basic Engineering Design DataTAHIR MAHMOODNo ratings yet

- p3 PDFDocument10 pagesp3 PDFrenilNo ratings yet

- Ucrete RG: Heavy Duty Polyurethane Concrete For Forming Cove Bases and Renovating WallsDocument3 pagesUcrete RG: Heavy Duty Polyurethane Concrete For Forming Cove Bases and Renovating Wallssyifa latifa zahidaNo ratings yet

- Concrete Columns Reinforced by Glass Fiber Reinforced Polymer RodsDocument10 pagesConcrete Columns Reinforced by Glass Fiber Reinforced Polymer RodsShakeel WaseemNo ratings yet

- OSHA Training Toolbox Talk - Hazard Communication - Chemical Hazards and Effects PDFDocument2 pagesOSHA Training Toolbox Talk - Hazard Communication - Chemical Hazards and Effects PDFmohd addinNo ratings yet

- Functional Groups ContainingDocument8 pagesFunctional Groups ContainingViku GuptaNo ratings yet

- Determination of Rate of Evaporation of Different Liquids.Document22 pagesDetermination of Rate of Evaporation of Different Liquids.Jinesh Doshi33% (6)

- VizagSteel MgmtTRAINEEDocument28 pagesVizagSteel MgmtTRAINEERaghu88% (16)

- Aw0331f MSDSDocument2 pagesAw0331f MSDSson.nh98bgNo ratings yet

- Structural Steel en 10025-10027Document2 pagesStructural Steel en 10025-10027apply19842371No ratings yet

- Production of Car Seat Cushion Using Palm OilDocument25 pagesProduction of Car Seat Cushion Using Palm OilSeiswaran PandeinNo ratings yet

- Chem-01-Atoms ElectronicStructure Lecture NotesDocument36 pagesChem-01-Atoms ElectronicStructure Lecture NotesSaraNo ratings yet

- 015 Emat Slofec TechniqueDocument9 pages015 Emat Slofec TechniquejasminneeNo ratings yet

- 14.3.3 Non-Premixed Model Input and Solution Procedures in FLUENTDocument11 pages14.3.3 Non-Premixed Model Input and Solution Procedures in FLUENTmohdkamalhafeezNo ratings yet

- Introduction To FRP Pipes Their Properties Specification Codes Joining Supporting and Applications WDocument7 pagesIntroduction To FRP Pipes Their Properties Specification Codes Joining Supporting and Applications WjoecardNo ratings yet

- July Update Paint, Ink, and Coating BookletDocument9 pagesJuly Update Paint, Ink, and Coating BookletMarthinus BoxyNo ratings yet

- Expert System Analysis of TIG Molten Weld Metal Fluidity Using The Bond Dimensionless NumberDocument6 pagesExpert System Analysis of TIG Molten Weld Metal Fluidity Using The Bond Dimensionless NumberInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Paper - 2 (Question Paper) - 6Document16 pagesPaper - 2 (Question Paper) - 6Saumya MundraNo ratings yet

- PSV Sizing CalculationsDocument53 pagesPSV Sizing CalculationsAMITH OK93% (29)

- Week 1a Course DetailsDocument19 pagesWeek 1a Course DetailsAraasu EgambaramNo ratings yet

- Fire Card Running SystemDocument3 pagesFire Card Running SystemAngelica FloresNo ratings yet

- LeakDocument1 pageLeakMohanNo ratings yet

- ECJ Dossier 2020 SustainabilityDocument49 pagesECJ Dossier 2020 SustainabilityJose LopezNo ratings yet

- Fruit and Vegetable Wash TdsDocument1 pageFruit and Vegetable Wash TdsEsheshNo ratings yet

- KITZ ProductDocument44 pagesKITZ Productkingathur26681No ratings yet

- Gelatin YesDocument80 pagesGelatin YesOliver AbordoNo ratings yet

- Chapter 4 Capillary PressureDocument16 pagesChapter 4 Capillary PressureHericane StudioNo ratings yet

- Exp#5 Lab ReportDocument6 pagesExp#5 Lab ReportJake Macneal100% (1)

- Bulletin New Refrigerant R1234yfDocument10 pagesBulletin New Refrigerant R1234yfYudha SetiawanNo ratings yet