Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

10 viewsDIMENSIONING

DIMENSIONING

Uploaded by

swap dThis document discusses guidelines and best practices for dimensioning engineering drawings. It covers topics such as:

- The purpose of dimensioning is to specify the size, shape, and tolerances of features on a part.

- Dimensions should be placed clearly with proper spacing and grouping between related dimensions.

- Extension lines are used to associate dimensions with specific features and should be drawn perpendicularly or at an angle if space is limited.

- Dimensioning provides vital size information that cannot be conveyed through drawings alone. Standard practices aim for clarity in communicating design requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You might also like

- Saso Iso 1938-1: 2019Document35 pagesSaso Iso 1938-1: 2019TokoKueAmelaCookis100% (1)

- AutoCAD 2010 Tutorial Series: Drawing a Floor PlanFrom EverandAutoCAD 2010 Tutorial Series: Drawing a Floor PlanRating: 4.5 out of 5 stars4.5/5 (2)

- Engineering DrawingDocument241 pagesEngineering Drawingmantoo vermaNo ratings yet

- Rubber Property-Vulcanization Using Oscillating Disk Cure MeterDocument12 pagesRubber Property-Vulcanization Using Oscillating Disk Cure MeterShaker Qaidi100% (1)

- AutoCAD 2010 Tutorial Series: Drawing Dimensions, Elevations and SectionsFrom EverandAutoCAD 2010 Tutorial Series: Drawing Dimensions, Elevations and SectionsNo ratings yet

- EN - 13262+A1-2009 Railway Applications-Wheelsets and bogies-Wheels-Product RequirementsDocument51 pagesEN - 13262+A1-2009 Railway Applications-Wheelsets and bogies-Wheels-Product RequirementsOrlando117No ratings yet

- AK-LV 02 EnglischDocument23 pagesAK-LV 02 Englischgodmaaty100% (1)

- DIMENSIONINGDocument26 pagesDIMENSIONINGswap dNo ratings yet

- Engineering Graphics (ME-101) - IntroductionDocument68 pagesEngineering Graphics (ME-101) - IntroductionSUSHIL SUSHILNo ratings yet

- Engineering Drawing ME 122LDocument35 pagesEngineering Drawing ME 122LMuhammad Umar SultanNo ratings yet

- Dimensioning: Objectives ImportanceDocument19 pagesDimensioning: Objectives ImportancejfcalaywanNo ratings yet

- Class 3Document12 pagesClass 3amrithakhubaNo ratings yet

- Developments - Cont'D: Mechanical Engineering Graphics MECH 211Document139 pagesDevelopments - Cont'D: Mechanical Engineering Graphics MECH 211psomNo ratings yet

- Dimensioning and Tolerances: Mechanical Engineering Graphics MECH 211Document175 pagesDimensioning and Tolerances: Mechanical Engineering Graphics MECH 211SATHISHKUMAR MNo ratings yet

- 11/26/2013 Engineering Drawing & GraphicsDocument20 pages11/26/2013 Engineering Drawing & GraphicsSam ChaduaryNo ratings yet

- Class 4Document12 pagesClass 4amrithakhubaNo ratings yet

- Chapter B - DimensioningDocument30 pagesChapter B - DimensioningNur Hazirah SadonNo ratings yet

- Dimensioning GuidelinesDocument3 pagesDimensioning GuidelinesSang NguyenNo ratings yet

- Dimensioning and TolerancingDocument94 pagesDimensioning and TolerancingidontlikeebooksNo ratings yet

- ME 104 Engineering Drawing Lec Malik Kamran ShakirDocument22 pagesME 104 Engineering Drawing Lec Malik Kamran ShakirMusaab MahmoodNo ratings yet

- Rules in DimensioningDocument44 pagesRules in DimensioningUg ug ShotiteNo ratings yet

- PRE-LAB # 11: Object: TheoryDocument8 pagesPRE-LAB # 11: Object: TheoryBaloch MuetNo ratings yet

- Standard Practice - DimensioningDocument24 pagesStandard Practice - DimensioningAchinNo ratings yet

- Basics of Dimension IngDocument11 pagesBasics of Dimension IngChandra RaoNo ratings yet

- Chapter 03Document46 pagesChapter 03HARRIS RAZZAQNo ratings yet

- Chapter 2 Lettering and DimensioningDocument37 pagesChapter 2 Lettering and DimensioningKhôi Nguyên Lê100% (1)

- CAD & Engineering DrawingDocument51 pagesCAD & Engineering DrawingTravel & tourism100% (1)

- Lec 3 - SEE-304 Dimensioning (L3)Document41 pagesLec 3 - SEE-304 Dimensioning (L3)chkamranalibandeshaNo ratings yet

- Developments - Cont'D: Mechanical Engineering Graphics MECH 211Document139 pagesDevelopments - Cont'D: Mechanical Engineering Graphics MECH 211radule021No ratings yet

- DimensioningDocument51 pagesDimensioningdecastro.oscareNo ratings yet

- Chapter7 Demtol1 - Dimensioning StandardsDocument100 pagesChapter7 Demtol1 - Dimensioning Standardsapi-265554570No ratings yet

- Tle 10 Lot Plan q1w4 1Document25 pagesTle 10 Lot Plan q1w4 1kaii cutieNo ratings yet

- Dimensioning: Restricted Use OnlyDocument101 pagesDimensioning: Restricted Use OnlyWael BazziNo ratings yet

- Lecture 4Document29 pagesLecture 4rishusonkar1526No ratings yet

- Dr. Richard E. Link U.S. Naval Academy Department of Mechanical Engineering 590 Holloway Road Annapolis, MD 21402-5042 All Rights ReservedDocument12 pagesDr. Richard E. Link U.S. Naval Academy Department of Mechanical Engineering 590 Holloway Road Annapolis, MD 21402-5042 All Rights ReservedDaveB2008No ratings yet

- Graphical PresentationsDocument12 pagesGraphical PresentationsJay Bryson RuizNo ratings yet

- 02 - Lettering and DimensioningDocument36 pages02 - Lettering and Dimensioningakshath.rk2002No ratings yet

- Title Block Lettering and DimensioningDocument16 pagesTitle Block Lettering and DimensioningAnubhav YadavNo ratings yet

- Lettering, Lines and DimensioningDocument34 pagesLettering, Lines and DimensioningHarsh KumarNo ratings yet

- Dimension and Projection Lines Are Narrow Continuous Lines 0Document5 pagesDimension and Projection Lines Are Narrow Continuous Lines 0Sulaiman OluwapelumiNo ratings yet

- CAD & Engineering DrawingDocument13 pagesCAD & Engineering DrawingLaiba Khan100% (1)

- Dimensioning: Architectural Visual Communication 1: Graphics 1Document18 pagesDimensioning: Architectural Visual Communication 1: Graphics 1Darryl ReyNo ratings yet

- Drawing 3 - IsometricDocument2 pagesDrawing 3 - IsometricPirene ZunigaNo ratings yet

- CPE414 DimensionDocument27 pagesCPE414 DimensionMuhamad Baihakhi ShamsudinNo ratings yet

- Diametrical & Radial Tolerance Stack-UpDocument19 pagesDiametrical & Radial Tolerance Stack-UpanuragNo ratings yet

- Wk1 D2-3 (Blueprint Reading)Document44 pagesWk1 D2-3 (Blueprint Reading)Mel ParasNo ratings yet

- MIAE 211-Lecture 9Document85 pagesMIAE 211-Lecture 9Thamilkumaran KulanthaiveluNo ratings yet

- EGCD Unit-1Document86 pagesEGCD Unit-1Bhuma Naga PavanNo ratings yet

- Engineering Drawing SlidesDocument20 pagesEngineering Drawing SlidesSheikh M Hassaan AdilNo ratings yet

- 15MEC100 Computer Aided Graphics (CAG)Document34 pages15MEC100 Computer Aided Graphics (CAG)Sumesh SukumaranNo ratings yet

- Inst 12-2aDocument61 pagesInst 12-2asansagithNo ratings yet

- Aircraft Drawing and Blueprint Reading (En)Document54 pagesAircraft Drawing and Blueprint Reading (En)BeaNo ratings yet

- Lettering and DimensionsDocument23 pagesLettering and DimensionsMujtaba AbbasNo ratings yet

- CAD ME 111 - Lecture 4-6 - DimensioningDocument68 pagesCAD ME 111 - Lecture 4-6 - DimensioningZeeshan NazirNo ratings yet

- DimensioningDocument28 pagesDimensioningRochmad EkoNo ratings yet

- DimensioningDocument26 pagesDimensioningLav BajpaiNo ratings yet

- 121 1208 Engineering Drawing I: Carry PrameswariDocument37 pages121 1208 Engineering Drawing I: Carry PrameswariMishal LimbuNo ratings yet

- Lecture 2Document25 pagesLecture 2l227168No ratings yet

- Dimensions and Dimensioning Types PDFDocument8 pagesDimensions and Dimensioning Types PDFKeertanaNo ratings yet

- Dimensions and Dimensioning TypesDocument8 pagesDimensions and Dimensioning TypesKeertanaNo ratings yet

- Dimensioning and Alphabet of Lines PresentationDocument131 pagesDimensioning and Alphabet of Lines PresentationRachel Faith Garcia100% (1)

- Building Material Estimates and Rates Build Up: Second EditionFrom EverandBuilding Material Estimates and Rates Build Up: Second EditionNo ratings yet

- NX 9 for Beginners - Part 2 (Extrude and Revolve Features, Placed Features, and Patterned Geometry)From EverandNX 9 for Beginners - Part 2 (Extrude and Revolve Features, Placed Features, and Patterned Geometry)No ratings yet

- Fundamentals of Hydraulic MotorsDocument8 pagesFundamentals of Hydraulic Motorsswap dNo ratings yet

- Bend Order in SheetmetalDocument29 pagesBend Order in Sheetmetalswap dNo ratings yet

- Rename: Startpart - Sleeve - DRW and Startpart - Sleeve - Flat - DRW FromDocument9 pagesRename: Startpart - Sleeve - DRW and Startpart - Sleeve - Flat - DRW Fromswap dNo ratings yet

- Design GuidelinesDocument21 pagesDesign Guidelinesswap dNo ratings yet

- Snap Fit Design ManualDocument24 pagesSnap Fit Design Manualswap dNo ratings yet

- Weld Symbols On Module Particulate FilterDocument6 pagesWeld Symbols On Module Particulate Filterswap dNo ratings yet

- BY ME-TorsionDocument14 pagesBY ME-Torsionswap dNo ratings yet

- Expanding The Limits of SPCDocument23 pagesExpanding The Limits of SPCswap dNo ratings yet

- Dealing With A Difficult BossDocument16 pagesDealing With A Difficult Bossswap dNo ratings yet

- By Me-WeldingDocument13 pagesBy Me-Weldingswap dNo ratings yet

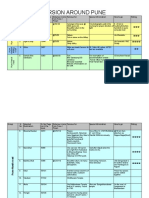

- One Day Excursion Around PuneDocument5 pagesOne Day Excursion Around Puneswap dNo ratings yet

- By Me - Welding1Document21 pagesBy Me - Welding1swap dNo ratings yet

- Missing and Isometric Views PPT V1 by KirankumarDocument93 pagesMissing and Isometric Views PPT V1 by Kirankumarswap dNo ratings yet

- Clutch HandbookDocument199 pagesClutch Handbookswap d100% (1)

- Design Guidelines: Obust and Ptimized Esigns ContinuedDocument3 pagesDesign Guidelines: Obust and Ptimized Esigns Continuedswap dNo ratings yet

- Equalizing Datum TargetsDocument3 pagesEqualizing Datum Targetsswap dNo ratings yet

- Dimensioning: We Value Our RelationshipsDocument41 pagesDimensioning: We Value Our Relationshipsswap dNo ratings yet

- CMM (Co-Ordinate Measuring Machine)Document7 pagesCMM (Co-Ordinate Measuring Machine)swap dNo ratings yet

- Common Terms and Definitions: Basic DimensionDocument9 pagesCommon Terms and Definitions: Basic Dimensionswap dNo ratings yet

- ToleranceDocument26 pagesToleranceswap dNo ratings yet

- Theory of Dimensioning: Vijay SrinivasanDocument34 pagesTheory of Dimensioning: Vijay Srinivasanswap dNo ratings yet

- References: of Assemblies of Rigid Parts. IN: Proceedings of The 1999 IEEE InternationalDocument19 pagesReferences: of Assemblies of Rigid Parts. IN: Proceedings of The 1999 IEEE Internationalswap dNo ratings yet

- DIMENSIONINGDocument26 pagesDIMENSIONINGswap dNo ratings yet

- Cone Tolerance PDFDocument21 pagesCone Tolerance PDFPopoaia MarianNo ratings yet

- Fundamental Mechanical EngineeringDocument150 pagesFundamental Mechanical Engineeringmariza razuri cordovaNo ratings yet

- A618 PDFDocument4 pagesA618 PDFSadashiva sahooNo ratings yet

- 02 Jaulas de Agujas PDFDocument52 pages02 Jaulas de Agujas PDFRodrigo Schaider Dos SantosNo ratings yet

- Fits and TolerancesDocument26 pagesFits and TolerancesMaher ShehabNo ratings yet

- Maintenance and TroubleshootingDocument6 pagesMaintenance and TroubleshootingSilo LibraNo ratings yet

- Absolute ValueDocument19 pagesAbsolute Valueapi-70433300No ratings yet

- Dimensions Tolerance SpecificationDocument12 pagesDimensions Tolerance SpecificationProfessor Dr. Nabeel Al-Bayati-Consultant Engineer0% (1)

- Dfmae Unit 1Document28 pagesDfmae Unit 1Hariprasad100% (1)

- IS 3589-2001 MS PipesDocument21 pagesIS 3589-2001 MS Pipesiampatanjali100% (5)

- Fos AsmeDocument41 pagesFos AsmeMahender Kumar100% (1)

- JFE StandardsDocument38 pagesJFE Standardsispat_jagadeeshNo ratings yet

- Standard Specification For: Designation: B167 11Document9 pagesStandard Specification For: Designation: B167 11Allan DiasNo ratings yet

- XXXX BN CLT Tolerance GuideDocument5 pagesXXXX BN CLT Tolerance GuideMNo ratings yet

- Asme B5.31-1953Document21 pagesAsme B5.31-1953vijay pawarNo ratings yet

- A511 96 PDFDocument7 pagesA511 96 PDFJohano AraújoNo ratings yet

- En 485-3 - 2003 (NF)Document14 pagesEn 485-3 - 2003 (NF)Shrikant BhirudNo ratings yet

- Japanese Quality InnovatorsDocument3 pagesJapanese Quality InnovatorsJennifer SamaniegoNo ratings yet

- Is 7452Document15 pagesIs 7452RishabhNo ratings yet

- 002005ea 2Document34 pages002005ea 2AliArababadiNo ratings yet

- AS10169Document11 pagesAS10169JOECOOL67No ratings yet

- A 370 03aDocument173 pagesA 370 03aJose ColmenaresNo ratings yet

- Irc Gov in 083-1 1999 PDFDocument40 pagesIrc Gov in 083-1 1999 PDFsaithejaNo ratings yet

- RESM Angle EncoderDocument8 pagesRESM Angle EncoderJaswinder SinghNo ratings yet

- FAG-V Spherical Roller Bearings VibratingDocument4 pagesFAG-V Spherical Roller Bearings VibratingVishnu Sathya100% (1)

- Iron-Nickel-Chromium-Molybdenum Alloy (UNS N08028) Plate, Sheet, and StripDocument4 pagesIron-Nickel-Chromium-Molybdenum Alloy (UNS N08028) Plate, Sheet, and StripROHITNo ratings yet

DIMENSIONING

DIMENSIONING

Uploaded by

swap d0 ratings0% found this document useful (0 votes)

10 views26 pagesThis document discusses guidelines and best practices for dimensioning engineering drawings. It covers topics such as:

- The purpose of dimensioning is to specify the size, shape, and tolerances of features on a part.

- Dimensions should be placed clearly with proper spacing and grouping between related dimensions.

- Extension lines are used to associate dimensions with specific features and should be drawn perpendicularly or at an angle if space is limited.

- Dimensioning provides vital size information that cannot be conveyed through drawings alone. Standard practices aim for clarity in communicating design requirements.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses guidelines and best practices for dimensioning engineering drawings. It covers topics such as:

- The purpose of dimensioning is to specify the size, shape, and tolerances of features on a part.

- Dimensions should be placed clearly with proper spacing and grouping between related dimensions.

- Extension lines are used to associate dimensions with specific features and should be drawn perpendicularly or at an angle if space is limited.

- Dimensioning provides vital size information that cannot be conveyed through drawings alone. Standard practices aim for clarity in communicating design requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

0 ratings0% found this document useful (0 votes)

10 views26 pagesDIMENSIONING

DIMENSIONING

Uploaded by

swap dThis document discusses guidelines and best practices for dimensioning engineering drawings. It covers topics such as:

- The purpose of dimensioning is to specify the size, shape, and tolerances of features on a part.

- Dimensions should be placed clearly with proper spacing and grouping between related dimensions.

- Extension lines are used to associate dimensions with specific features and should be drawn perpendicularly or at an angle if space is limited.

- Dimensioning provides vital size information that cannot be conveyed through drawings alone. Standard practices aim for clarity in communicating design requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 26

DIMENSIONING

• Geometrics is the science of

specifying and tolerancing the shapes

and locations of features on objects.

•Once the shape of the part is defined

with an orthographic drawing, the size

information is added in the form of

dimensions.

•Dimensioning a drawing identifies the

tolerance required for each dimension.

• All drawings should be understood by all

users of the drawings, regardless of the

user's role in the design process.

• For a drafter or designer, communication of

the design needs of a part to the others on

the team is done by dimensioning.

• A fully defined part has three elements :

Graphics, dimensions and words (notes).

• Dimensioning provides the vital details that

cannot be conveyed by drawing details

alone.

Terminology in GD & T

• Dimension : the numerical value that

defines the size or geometric

characteristic of a feature.

• Dimension text height = 3 mm (0.125”)

• Space between lines of text = 1.5 mm

(0.0625”)

• In metric dimensioning, when the value is

less than one, a zero precedes the decimal

point.

• Basic Dimension : a numerical value

defining the theoretically exact size of a

feature.

• Reference dimension : a nemurical value

enclosed in parenthesis, providing for

information only and not used in the

fabrication of the part.

• Arrows : Symbols placed at the ends of

dimension lines to shoe the limits of

dimension. Arrows are uniform in size and

style, regardless of the size of drawing.

• Arrows are usually about

• 3 mm (1/8”) long and

• should be one third as

• wide as they are long.

• Extension Line : a thin, solid line

perpendicular to a dimension line,

indicating which feature is associated

with the dimension.

• There should be a visible gap between

the feature’s corners and the end of the

extension line.

• Visible Gap : a visible space of 1.5 mm

(1/16”) between the feature’s corner4s

and the end of the extension line.

• Limit dimensioning : the largest

acceptable size and minimum acceptable

size of a feature. The value for the

largest acceptable size, expressed as the

maximum material condition (MMC), is

placed over the value for the minimum

acceptable size, expressed as the least

material condition (LMC), to denote the

limit-dimension based tolerance for the

feature.

• Plus and minus dimensioning : the largest

allowable positive and negative variance

from the dimension specified. The plus and

minus values may or may not be equal.

• Tolerance : the amount of a particular

dimension is allowed to vary. All

dimensions (except reference dimensions)

have an associated tolerance. A tolerance

may be expressed either through limit

dimensioning, plus and minus

dimensioning, or a general note.

• Dimensions should not be excessive,

either through duplication or

dimensioning a feature more than one

way.

CO-ORDINATE DIMENSIONS

• The advent of computer controlled

manufacturing has encouraged

dimensioning in terms of rectangular

coordinates. In rectangular dimensioning, a

baseline is established for each Cartesian

coordinate direction, and all dimensions are

specified with respect to these baselines.

This is also known as datum dimensioning,

or baseline dimensioning. Dimensions may

be given with dimension lines and

arrowheads (fig.) or without dimension lines

and arrowheads

Co ordinate dimensioned part with the

origin at the center of hole A4 instead of the

lower left corner of the part

• Tabular coordinate dimensioning

involves labeling each feature with a

letter, and then providing information

on size and location in a table as

shown.

• Standard practices : the guiding

principle for dimensioning the drawing

is clarity.

• Placement : dimension placement

depends on the space available

between the extension lines. When

space permits, dimensions and arrows

are placed between the extension lines,

as shown next.

• Spacing : the minimum distance from

the object to the first dimension is 10

mm (3/8”).

• The minimum spacing between the

dimensions is 6 mm (1/4”). These

values may be increased where

appropriate.

• Grouping and Staggering : dimensions

should be grouped, for uniform

appearance, as shown .

• As general rule do not use object lines

as part for your dimension.

• Where there are several parallel

dimensions, the values should be

staggered, as shown next.

EXTENSION LINES

• Extension lines are used to relate a

dimension to one or more features and

are usually drawn perpendicular to the

associated dimension line. Where the

space is limited, the extension line can

be drawn at an angle, as shown. Where

angled extension lines are used, they

must be parallel, and the associated

dimension lines must be drawn in the

direction to which they apply.

• Extension lines should not cross

dimension lines, and should avoid

crossing other lines whenever

possible.

• When the center of a feature is being

dimensioned, the centerline of the

feature is used as an extension line.

• When a point is being located by

extension lines only, the

extension line must pass through

the point.

You might also like

- Saso Iso 1938-1: 2019Document35 pagesSaso Iso 1938-1: 2019TokoKueAmelaCookis100% (1)

- AutoCAD 2010 Tutorial Series: Drawing a Floor PlanFrom EverandAutoCAD 2010 Tutorial Series: Drawing a Floor PlanRating: 4.5 out of 5 stars4.5/5 (2)

- Engineering DrawingDocument241 pagesEngineering Drawingmantoo vermaNo ratings yet

- Rubber Property-Vulcanization Using Oscillating Disk Cure MeterDocument12 pagesRubber Property-Vulcanization Using Oscillating Disk Cure MeterShaker Qaidi100% (1)

- AutoCAD 2010 Tutorial Series: Drawing Dimensions, Elevations and SectionsFrom EverandAutoCAD 2010 Tutorial Series: Drawing Dimensions, Elevations and SectionsNo ratings yet

- EN - 13262+A1-2009 Railway Applications-Wheelsets and bogies-Wheels-Product RequirementsDocument51 pagesEN - 13262+A1-2009 Railway Applications-Wheelsets and bogies-Wheels-Product RequirementsOrlando117No ratings yet

- AK-LV 02 EnglischDocument23 pagesAK-LV 02 Englischgodmaaty100% (1)

- DIMENSIONINGDocument26 pagesDIMENSIONINGswap dNo ratings yet

- Engineering Graphics (ME-101) - IntroductionDocument68 pagesEngineering Graphics (ME-101) - IntroductionSUSHIL SUSHILNo ratings yet

- Engineering Drawing ME 122LDocument35 pagesEngineering Drawing ME 122LMuhammad Umar SultanNo ratings yet

- Dimensioning: Objectives ImportanceDocument19 pagesDimensioning: Objectives ImportancejfcalaywanNo ratings yet

- Class 3Document12 pagesClass 3amrithakhubaNo ratings yet

- Developments - Cont'D: Mechanical Engineering Graphics MECH 211Document139 pagesDevelopments - Cont'D: Mechanical Engineering Graphics MECH 211psomNo ratings yet

- Dimensioning and Tolerances: Mechanical Engineering Graphics MECH 211Document175 pagesDimensioning and Tolerances: Mechanical Engineering Graphics MECH 211SATHISHKUMAR MNo ratings yet

- 11/26/2013 Engineering Drawing & GraphicsDocument20 pages11/26/2013 Engineering Drawing & GraphicsSam ChaduaryNo ratings yet

- Class 4Document12 pagesClass 4amrithakhubaNo ratings yet

- Chapter B - DimensioningDocument30 pagesChapter B - DimensioningNur Hazirah SadonNo ratings yet

- Dimensioning GuidelinesDocument3 pagesDimensioning GuidelinesSang NguyenNo ratings yet

- Dimensioning and TolerancingDocument94 pagesDimensioning and TolerancingidontlikeebooksNo ratings yet

- ME 104 Engineering Drawing Lec Malik Kamran ShakirDocument22 pagesME 104 Engineering Drawing Lec Malik Kamran ShakirMusaab MahmoodNo ratings yet

- Rules in DimensioningDocument44 pagesRules in DimensioningUg ug ShotiteNo ratings yet

- PRE-LAB # 11: Object: TheoryDocument8 pagesPRE-LAB # 11: Object: TheoryBaloch MuetNo ratings yet

- Standard Practice - DimensioningDocument24 pagesStandard Practice - DimensioningAchinNo ratings yet

- Basics of Dimension IngDocument11 pagesBasics of Dimension IngChandra RaoNo ratings yet

- Chapter 03Document46 pagesChapter 03HARRIS RAZZAQNo ratings yet

- Chapter 2 Lettering and DimensioningDocument37 pagesChapter 2 Lettering and DimensioningKhôi Nguyên Lê100% (1)

- CAD & Engineering DrawingDocument51 pagesCAD & Engineering DrawingTravel & tourism100% (1)

- Lec 3 - SEE-304 Dimensioning (L3)Document41 pagesLec 3 - SEE-304 Dimensioning (L3)chkamranalibandeshaNo ratings yet

- Developments - Cont'D: Mechanical Engineering Graphics MECH 211Document139 pagesDevelopments - Cont'D: Mechanical Engineering Graphics MECH 211radule021No ratings yet

- DimensioningDocument51 pagesDimensioningdecastro.oscareNo ratings yet

- Chapter7 Demtol1 - Dimensioning StandardsDocument100 pagesChapter7 Demtol1 - Dimensioning Standardsapi-265554570No ratings yet

- Tle 10 Lot Plan q1w4 1Document25 pagesTle 10 Lot Plan q1w4 1kaii cutieNo ratings yet

- Dimensioning: Restricted Use OnlyDocument101 pagesDimensioning: Restricted Use OnlyWael BazziNo ratings yet

- Lecture 4Document29 pagesLecture 4rishusonkar1526No ratings yet

- Dr. Richard E. Link U.S. Naval Academy Department of Mechanical Engineering 590 Holloway Road Annapolis, MD 21402-5042 All Rights ReservedDocument12 pagesDr. Richard E. Link U.S. Naval Academy Department of Mechanical Engineering 590 Holloway Road Annapolis, MD 21402-5042 All Rights ReservedDaveB2008No ratings yet

- Graphical PresentationsDocument12 pagesGraphical PresentationsJay Bryson RuizNo ratings yet

- 02 - Lettering and DimensioningDocument36 pages02 - Lettering and Dimensioningakshath.rk2002No ratings yet

- Title Block Lettering and DimensioningDocument16 pagesTitle Block Lettering and DimensioningAnubhav YadavNo ratings yet

- Lettering, Lines and DimensioningDocument34 pagesLettering, Lines and DimensioningHarsh KumarNo ratings yet

- Dimension and Projection Lines Are Narrow Continuous Lines 0Document5 pagesDimension and Projection Lines Are Narrow Continuous Lines 0Sulaiman OluwapelumiNo ratings yet

- CAD & Engineering DrawingDocument13 pagesCAD & Engineering DrawingLaiba Khan100% (1)

- Dimensioning: Architectural Visual Communication 1: Graphics 1Document18 pagesDimensioning: Architectural Visual Communication 1: Graphics 1Darryl ReyNo ratings yet

- Drawing 3 - IsometricDocument2 pagesDrawing 3 - IsometricPirene ZunigaNo ratings yet

- CPE414 DimensionDocument27 pagesCPE414 DimensionMuhamad Baihakhi ShamsudinNo ratings yet

- Diametrical & Radial Tolerance Stack-UpDocument19 pagesDiametrical & Radial Tolerance Stack-UpanuragNo ratings yet

- Wk1 D2-3 (Blueprint Reading)Document44 pagesWk1 D2-3 (Blueprint Reading)Mel ParasNo ratings yet

- MIAE 211-Lecture 9Document85 pagesMIAE 211-Lecture 9Thamilkumaran KulanthaiveluNo ratings yet

- EGCD Unit-1Document86 pagesEGCD Unit-1Bhuma Naga PavanNo ratings yet

- Engineering Drawing SlidesDocument20 pagesEngineering Drawing SlidesSheikh M Hassaan AdilNo ratings yet

- 15MEC100 Computer Aided Graphics (CAG)Document34 pages15MEC100 Computer Aided Graphics (CAG)Sumesh SukumaranNo ratings yet

- Inst 12-2aDocument61 pagesInst 12-2asansagithNo ratings yet

- Aircraft Drawing and Blueprint Reading (En)Document54 pagesAircraft Drawing and Blueprint Reading (En)BeaNo ratings yet

- Lettering and DimensionsDocument23 pagesLettering and DimensionsMujtaba AbbasNo ratings yet

- CAD ME 111 - Lecture 4-6 - DimensioningDocument68 pagesCAD ME 111 - Lecture 4-6 - DimensioningZeeshan NazirNo ratings yet

- DimensioningDocument28 pagesDimensioningRochmad EkoNo ratings yet

- DimensioningDocument26 pagesDimensioningLav BajpaiNo ratings yet

- 121 1208 Engineering Drawing I: Carry PrameswariDocument37 pages121 1208 Engineering Drawing I: Carry PrameswariMishal LimbuNo ratings yet

- Lecture 2Document25 pagesLecture 2l227168No ratings yet

- Dimensions and Dimensioning Types PDFDocument8 pagesDimensions and Dimensioning Types PDFKeertanaNo ratings yet

- Dimensions and Dimensioning TypesDocument8 pagesDimensions and Dimensioning TypesKeertanaNo ratings yet

- Dimensioning and Alphabet of Lines PresentationDocument131 pagesDimensioning and Alphabet of Lines PresentationRachel Faith Garcia100% (1)

- Building Material Estimates and Rates Build Up: Second EditionFrom EverandBuilding Material Estimates and Rates Build Up: Second EditionNo ratings yet

- NX 9 for Beginners - Part 2 (Extrude and Revolve Features, Placed Features, and Patterned Geometry)From EverandNX 9 for Beginners - Part 2 (Extrude and Revolve Features, Placed Features, and Patterned Geometry)No ratings yet

- Fundamentals of Hydraulic MotorsDocument8 pagesFundamentals of Hydraulic Motorsswap dNo ratings yet

- Bend Order in SheetmetalDocument29 pagesBend Order in Sheetmetalswap dNo ratings yet

- Rename: Startpart - Sleeve - DRW and Startpart - Sleeve - Flat - DRW FromDocument9 pagesRename: Startpart - Sleeve - DRW and Startpart - Sleeve - Flat - DRW Fromswap dNo ratings yet

- Design GuidelinesDocument21 pagesDesign Guidelinesswap dNo ratings yet

- Snap Fit Design ManualDocument24 pagesSnap Fit Design Manualswap dNo ratings yet

- Weld Symbols On Module Particulate FilterDocument6 pagesWeld Symbols On Module Particulate Filterswap dNo ratings yet

- BY ME-TorsionDocument14 pagesBY ME-Torsionswap dNo ratings yet

- Expanding The Limits of SPCDocument23 pagesExpanding The Limits of SPCswap dNo ratings yet

- Dealing With A Difficult BossDocument16 pagesDealing With A Difficult Bossswap dNo ratings yet

- By Me-WeldingDocument13 pagesBy Me-Weldingswap dNo ratings yet

- One Day Excursion Around PuneDocument5 pagesOne Day Excursion Around Puneswap dNo ratings yet

- By Me - Welding1Document21 pagesBy Me - Welding1swap dNo ratings yet

- Missing and Isometric Views PPT V1 by KirankumarDocument93 pagesMissing and Isometric Views PPT V1 by Kirankumarswap dNo ratings yet

- Clutch HandbookDocument199 pagesClutch Handbookswap d100% (1)

- Design Guidelines: Obust and Ptimized Esigns ContinuedDocument3 pagesDesign Guidelines: Obust and Ptimized Esigns Continuedswap dNo ratings yet

- Equalizing Datum TargetsDocument3 pagesEqualizing Datum Targetsswap dNo ratings yet

- Dimensioning: We Value Our RelationshipsDocument41 pagesDimensioning: We Value Our Relationshipsswap dNo ratings yet

- CMM (Co-Ordinate Measuring Machine)Document7 pagesCMM (Co-Ordinate Measuring Machine)swap dNo ratings yet

- Common Terms and Definitions: Basic DimensionDocument9 pagesCommon Terms and Definitions: Basic Dimensionswap dNo ratings yet

- ToleranceDocument26 pagesToleranceswap dNo ratings yet

- Theory of Dimensioning: Vijay SrinivasanDocument34 pagesTheory of Dimensioning: Vijay Srinivasanswap dNo ratings yet

- References: of Assemblies of Rigid Parts. IN: Proceedings of The 1999 IEEE InternationalDocument19 pagesReferences: of Assemblies of Rigid Parts. IN: Proceedings of The 1999 IEEE Internationalswap dNo ratings yet

- DIMENSIONINGDocument26 pagesDIMENSIONINGswap dNo ratings yet

- Cone Tolerance PDFDocument21 pagesCone Tolerance PDFPopoaia MarianNo ratings yet

- Fundamental Mechanical EngineeringDocument150 pagesFundamental Mechanical Engineeringmariza razuri cordovaNo ratings yet

- A618 PDFDocument4 pagesA618 PDFSadashiva sahooNo ratings yet

- 02 Jaulas de Agujas PDFDocument52 pages02 Jaulas de Agujas PDFRodrigo Schaider Dos SantosNo ratings yet

- Fits and TolerancesDocument26 pagesFits and TolerancesMaher ShehabNo ratings yet

- Maintenance and TroubleshootingDocument6 pagesMaintenance and TroubleshootingSilo LibraNo ratings yet

- Absolute ValueDocument19 pagesAbsolute Valueapi-70433300No ratings yet

- Dimensions Tolerance SpecificationDocument12 pagesDimensions Tolerance SpecificationProfessor Dr. Nabeel Al-Bayati-Consultant Engineer0% (1)

- Dfmae Unit 1Document28 pagesDfmae Unit 1Hariprasad100% (1)

- IS 3589-2001 MS PipesDocument21 pagesIS 3589-2001 MS Pipesiampatanjali100% (5)

- Fos AsmeDocument41 pagesFos AsmeMahender Kumar100% (1)

- JFE StandardsDocument38 pagesJFE Standardsispat_jagadeeshNo ratings yet

- Standard Specification For: Designation: B167 11Document9 pagesStandard Specification For: Designation: B167 11Allan DiasNo ratings yet

- XXXX BN CLT Tolerance GuideDocument5 pagesXXXX BN CLT Tolerance GuideMNo ratings yet

- Asme B5.31-1953Document21 pagesAsme B5.31-1953vijay pawarNo ratings yet

- A511 96 PDFDocument7 pagesA511 96 PDFJohano AraújoNo ratings yet

- En 485-3 - 2003 (NF)Document14 pagesEn 485-3 - 2003 (NF)Shrikant BhirudNo ratings yet

- Japanese Quality InnovatorsDocument3 pagesJapanese Quality InnovatorsJennifer SamaniegoNo ratings yet

- Is 7452Document15 pagesIs 7452RishabhNo ratings yet

- 002005ea 2Document34 pages002005ea 2AliArababadiNo ratings yet

- AS10169Document11 pagesAS10169JOECOOL67No ratings yet

- A 370 03aDocument173 pagesA 370 03aJose ColmenaresNo ratings yet

- Irc Gov in 083-1 1999 PDFDocument40 pagesIrc Gov in 083-1 1999 PDFsaithejaNo ratings yet

- RESM Angle EncoderDocument8 pagesRESM Angle EncoderJaswinder SinghNo ratings yet

- FAG-V Spherical Roller Bearings VibratingDocument4 pagesFAG-V Spherical Roller Bearings VibratingVishnu Sathya100% (1)

- Iron-Nickel-Chromium-Molybdenum Alloy (UNS N08028) Plate, Sheet, and StripDocument4 pagesIron-Nickel-Chromium-Molybdenum Alloy (UNS N08028) Plate, Sheet, and StripROHITNo ratings yet