Professional Documents

Culture Documents

Our Target 0' Burr

Our Target 0' Burr

Uploaded by

Ankit kumar sah0 ratings0% found this document useful (0 votes)

13 views9 pagesThe document discusses achieving a target of zero burr formation during metal trimming processes. It outlines a systematic approach including checking trim lines after machining, creating a spotting data sheet, developing standard operating procedures, and providing employee training. It then describes various types of burrs that can form and explains a burr correction theory involving understanding the burr type, tool selection, welding, grinding, taking impressions, and removing burrs through stroking and stoning. The goal is to understand burr causes and refine the trimming process until a clean edge with no burrs is achieved.

Original Description:

Original Title

Burr

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses achieving a target of zero burr formation during metal trimming processes. It outlines a systematic approach including checking trim lines after machining, creating a spotting data sheet, developing standard operating procedures, and providing employee training. It then describes various types of burrs that can form and explains a burr correction theory involving understanding the burr type, tool selection, welding, grinding, taking impressions, and removing burrs through stroking and stoning. The goal is to understand burr causes and refine the trimming process until a clean edge with no burrs is achieved.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

13 views9 pagesOur Target 0' Burr

Our Target 0' Burr

Uploaded by

Ankit kumar sahThe document discusses achieving a target of zero burr formation during metal trimming processes. It outlines a systematic approach including checking trim lines after machining, creating a spotting data sheet, developing standard operating procedures, and providing employee training. It then describes various types of burrs that can form and explains a burr correction theory involving understanding the burr type, tool selection, welding, grinding, taking impressions, and removing burrs through stroking and stoning. The goal is to understand burr causes and refine the trimming process until a clean edge with no burrs is achieved.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 9

OUR TARGET ‘0’ BURR

BURR CORRECTION THEORY

• What is the Burr?

Excessive Burr (Small piece of material remained

attached to the edge of panel), More than 10% of Sheet

metal Thickness.

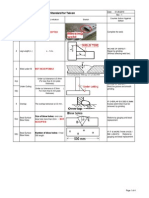

SYSTEMATIC APPROCH FOR ACHIEVE ‘0’BURR

• After machining trim line check sheet.

• Trim line spotting data sheet.

• Made standard operating process.

• Employee training.

Trim line clearance sheet

After machining trim line check sheet.

Spotting data sheet

Types of Burr and Chips

1. Excess clearance burr.

2. Tight clearance burr.

3. Vertical cutting burr.

4. Goose neck air cutting burr.

5. Double cutting burr – zero cutting burr.

6. Trim timing burr.

7. Less hardness burr.

8. Trim edge blunt burr.

9. Upper cutting damages the scrap – burr.

10. Cutting happening with upper cutter but needs to happen with cam cutter – burr.

11. Air cutting burr.

12. Less or no entry burr.

13. Excess trimming by upper cutter – burr.

14. No or insufficient shear angle in profile area – burr.

15. Locating lug double cutting burr.

16. Partial trimming burr.

17. Loose burr with panels.

18. Sharp corners of slot – burr.

19. One side rubbing burr.

20. Punch deflection burr.

21. Excess punch entry burr – say 10mm.

22. Less punch entry burr – say 2mm.

23. Back rubbing burr.

Burr Correction Theory

Understand the type of burr.

Select cutter: Upper or Lower.

Do welding with proper hammering(Pinning).

Start finishing with baby sander, 6mm grinder and 3mm grinder only.

Ensure that welded area is not getting red hot while grinding.

Always keep 3D up by 2mm, in case of Upper tool insert.

Match 3D with reference of adjacent inserts in case of Lower tool.

Keep maximum 0.3mm stock for 2D.

Ensure squareness is maintained at 0.3mm stock and do stoning for 15 minutes.

Load the die on press, clamp it and set relevant shut height.

Apply clay to welded area – clay must be oil less – Dray clay, use general powder in case of wet clay.

Take the shut height down till the clay gets trimmed.

Remove the cut clay with knife or cutter.

Start grinding with 3mm grinder only from bottom so that squareness will be maintained.

Repeat the clay trimming 2-3 times and do grinding accordingly.

Once you understand the clay trimming, remove the clay and apply thick Kometan to master.

Take slider 0.1mm down, you will get impression on welded area, do not grind unless there is overlap.

Go down by 0.1 mm, you will reach to entry point.

Now you have to grind from bottom, do not touch the grinder to Kometan impression area.

Go down – max 1mm entry – you will get some hard mark – do not worry.

Go to shut height and then take total stroke of slide for 4 to 5 times.

Do not apply grinder, remove all hard marks by stonning.

SOP

Check clearance through Check clearance through

Apply clay on trim line

masking tap masking tap

Take trim line immpresion Check clearance through kometan

Remove clay & check

You might also like

- Cerec 3d Preparation Guidelines en PDFDocument10 pagesCerec 3d Preparation Guidelines en PDFMarian Si Teofana HasnaNo ratings yet

- How to Build a Global Model Earthship Operation I: Tire WorkFrom EverandHow to Build a Global Model Earthship Operation I: Tire WorkNo ratings yet

- HMT RM65 Radial DrillDocument2 pagesHMT RM65 Radial Drillsomnath213No ratings yet

- Mold Polishing Tips and GuidelinesDocument2 pagesMold Polishing Tips and GuidelinesNazri0% (1)

- Grinding ReportDocument5 pagesGrinding ReportSteady Bunny100% (2)

- Brake SquakeDocument5 pagesBrake SquakeEdy SupriyantoNo ratings yet

- Milling: General Mill InformationDocument11 pagesMilling: General Mill Informationsravan_inboxNo ratings yet

- Mould PolishingDocument4 pagesMould PolishingArun PrasadNo ratings yet

- 12 Gauge Standardization CorianDocument8 pages12 Gauge Standardization Coriananubis2784No ratings yet

- LappingDocument25 pagesLappingSrinivasan Ravi100% (1)

- General DrillingDocument3 pagesGeneral DrillingAndrew GoslingNo ratings yet

- Advantage of Extrusion Blow Molding: Tooling Can Be Produced in AluminumDocument3 pagesAdvantage of Extrusion Blow Molding: Tooling Can Be Produced in AluminumravanNo ratings yet

- OD 141023 Assembly GuideDocument18 pagesOD 141023 Assembly GuideJose Luis CrvNo ratings yet

- TQC Cross Cut Adhesion Test - Cc3000: Product DescriptionDocument4 pagesTQC Cross Cut Adhesion Test - Cc3000: Product DescriptionGeorgianaNo ratings yet

- Platines Et Percage IPE 240Document7 pagesPlatines Et Percage IPE 240ol beNo ratings yet

- Haide EeeeeeDocument32 pagesHaide Eeeeeeusmaniqbal15No ratings yet

- Material:: Simplify3D User GuidelinesDocument2 pagesMaterial:: Simplify3D User GuidelinesRaulNo ratings yet

- 02 The PrintingDocument25 pages02 The PrintingSyedNo ratings yet

- 4 - Technical Newsletter - Trimming MethodsDocument3 pages4 - Technical Newsletter - Trimming MethodsTaha TlijaniNo ratings yet

- SMT Solder Paste Printing Process Quality Improvement Through Six Sigma ApproachDocument30 pagesSMT Solder Paste Printing Process Quality Improvement Through Six Sigma ApproachAnonymous HizOWFNo ratings yet

- DJJ10033-chapter 4.2Document54 pagesDJJ10033-chapter 4.2Abbas SeuNo ratings yet

- Grinding MachineDocument54 pagesGrinding Machineravi upadhyay100% (4)

- Welding Standard Ver1Document4 pagesWelding Standard Ver1Sowmen ChakrobortyNo ratings yet

- Regrind End Mills and VikDocument1 pageRegrind End Mills and VikMawan BentzNo ratings yet

- Glass Edge Work and ProcessingDocument8 pagesGlass Edge Work and ProcessingAndreaski LamboNo ratings yet

- Step 6-10 Tissue ProcessingDocument12 pagesStep 6-10 Tissue ProcessingNisa Claire ParpanNo ratings yet

- Edge WorkDocument16 pagesEdge Worknostromo1979100% (1)

- Setting Doors Into Campervan Furniture: HOW TO GuideDocument8 pagesSetting Doors Into Campervan Furniture: HOW TO GuideHassan SaeedNo ratings yet

- Paint CureDocument8 pagesPaint CurekhurshedlakhoNo ratings yet

- Abrasive Jet MachiningDocument9 pagesAbrasive Jet MachiningArko MazumderNo ratings yet

- Worksheet 11 DANREB PERITDocument3 pagesWorksheet 11 DANREB PERITRika MaeNo ratings yet

- Relief Discoloration/ Staining Pitting: Uddeholm Defect Chart Uddeholm Defect Chart Uddeholm Defect ChartDocument2 pagesRelief Discoloration/ Staining Pitting: Uddeholm Defect Chart Uddeholm Defect Chart Uddeholm Defect Chartodhiles1No ratings yet

- Preventive Maintenance - PFDocument6 pagesPreventive Maintenance - PFAnurag SrivastavaNo ratings yet

- Toolpaths: Ste P Toolpath CommentsDocument11 pagesToolpaths: Ste P Toolpath CommentsuzeyirNo ratings yet

- Sect 29 Preventive MaintenanceDocument6 pagesSect 29 Preventive MaintenancezfiyldvmNo ratings yet

- Study of Thermal Damage During Grinding of RnildDocument3 pagesStudy of Thermal Damage During Grinding of RnildAditya SatopeNo ratings yet

- Credit 6 Mill-2003Document23 pagesCredit 6 Mill-2003Gokul Prasad ChettiNo ratings yet

- How To Make BoomerangsDocument3 pagesHow To Make BoomerangssmagrurakNo ratings yet

- Bit Selection HandbookDocument14 pagesBit Selection HandbookNelson de la RosaNo ratings yet

- Cross Cut Adhesion Test Kit cc2000 m44 1 14Document4 pagesCross Cut Adhesion Test Kit cc2000 m44 1 14OMATNo ratings yet

- Biw Design ConsiderationsDocument35 pagesBiw Design ConsiderationsmurmubickyNo ratings yet

- Drawing A Screw Solidworks PDFDocument11 pagesDrawing A Screw Solidworks PDFGeorge SaadehNo ratings yet

- Adhesion Test cc1000 vf1839 d44Document3 pagesAdhesion Test cc1000 vf1839 d44VanesaNo ratings yet

- Manual Model 180 XTEM Prep Kit 2007Document7 pagesManual Model 180 XTEM Prep Kit 2007iorga_alexandruNo ratings yet

- Cross Cut Adhesion Test cc2000 - d441Document4 pagesCross Cut Adhesion Test cc2000 - d441OMATNo ratings yet

- M-Jet ManualDocument17 pagesM-Jet Manualh2oo2hNo ratings yet

- Drilling OperationsDocument9 pagesDrilling Operationslindobuhledandelion0No ratings yet

- Junk Milling - Description and UsageDocument2 pagesJunk Milling - Description and UsageCarlos Alberto100% (1)

- MT&A - Unit 4Document52 pagesMT&A - Unit 4Yashvanth H LNo ratings yet

- Chapter 14Document32 pagesChapter 14Youssef AkrNo ratings yet

- Milling: SAFETY NOTE! Never Attempt To Operate A Milling Machine While Your Senses Are Impaired by Medication or OtherDocument9 pagesMilling: SAFETY NOTE! Never Attempt To Operate A Milling Machine While Your Senses Are Impaired by Medication or Otherrc94No ratings yet

- Multiple-Ply Conveyor Belt Splicing Manual - EngDocument24 pagesMultiple-Ply Conveyor Belt Splicing Manual - EngShiena CaparrosNo ratings yet

- CR Coils Gradation NormsDocument2 pagesCR Coils Gradation NormsRavi ChauhanNo ratings yet

- MT Lab Manual r21Document49 pagesMT Lab Manual r21vtsks2005No ratings yet

- IBM 4037 Toner SUmmit Web PDFDocument4 pagesIBM 4037 Toner SUmmit Web PDFManuelEzpinozaNo ratings yet

- WorkshopDocument1 pageWorkshopMuhammad AbtaheeNo ratings yet

- Rebuilding YamahaDocument2 pagesRebuilding YamahaTwinFlatfourNo ratings yet

- Worksheet 11 RELATADO VANDocument3 pagesWorksheet 11 RELATADO VANRika MaeNo ratings yet

- How To Sand Your Own Timber Floor: The Ultimate DIY Guide With PicturesFrom EverandHow To Sand Your Own Timber Floor: The Ultimate DIY Guide With PicturesNo ratings yet

- Piecing Tips & Tricks Tool: Piece Like the Experts, Easy-to-Use Color-Coded Sections, Everything You Need to Know!From EverandPiecing Tips & Tricks Tool: Piece Like the Experts, Easy-to-Use Color-Coded Sections, Everything You Need to Know!Rating: 5 out of 5 stars5/5 (1)

- Sample of A Qualitative Research Proposal PaperDocument6 pagesSample of A Qualitative Research Proposal Paperibhuglbkf100% (1)

- Macroetching Metals and Alloys: Standard Test Method ForDocument11 pagesMacroetching Metals and Alloys: Standard Test Method For陳勉中No ratings yet

- Industrial Training Progress ReportDocument12 pagesIndustrial Training Progress ReportNimesh WijerathneNo ratings yet

- Hight Speep Tool SteelDocument11 pagesHight Speep Tool SteelcadcamtaiNo ratings yet

- MCP101Document9 pagesMCP101Sushant Cr7No ratings yet

- Utilaje PVCDocument6 pagesUtilaje PVCdraser_vNo ratings yet

- Roll Forming TechnologyDocument24 pagesRoll Forming TechnologySaravanan KanniyappanNo ratings yet

- Multiple Streams of Income Khoa BuiDocument167 pagesMultiple Streams of Income Khoa BuiMarie Kris Noga100% (1)

- Experiment No. 5 Centrifugal Casting ProcessDocument6 pagesExperiment No. 5 Centrifugal Casting ProcessDhananjay ShimpiNo ratings yet

- Wear of Coated and Uncoated Carbides in Turning Tool SteelDocument6 pagesWear of Coated and Uncoated Carbides in Turning Tool Steelking9sunNo ratings yet

- FAIDocument14 pagesFAIalejandroruiz020697No ratings yet

- Casting 1Document32 pagesCasting 1Ahmed MahmoudNo ratings yet

- Tle 11Document21 pagesTle 11Joanna AprilNo ratings yet

- Steps For Welding Railroad Tracks - Railroad Thermite WeldingDocument7 pagesSteps For Welding Railroad Tracks - Railroad Thermite WeldingMiroslaw LabudaNo ratings yet

- PWM - Workflow For Structural InspectionDocument1 pagePWM - Workflow For Structural InspectionDruid FamilyNo ratings yet

- MachinesDocument8 pagesMachinesRaheel Neo AhmadNo ratings yet

- MillCarb - SmallDocument2 pagesMillCarb - SmallYoussef KhaliNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/110Document2 pagesInspection Report: IR No.: QETO/IR/SUD/110sudipta dasNo ratings yet

- Steel MillDocument6 pagesSteel MillRenato Gigliotti MPhNo ratings yet

- Material Removal Processes (IM 213) : Arab Academy For Science, Technology, and Maritime TransportDocument36 pagesMaterial Removal Processes (IM 213) : Arab Academy For Science, Technology, and Maritime TransportNicolas EleftheriouNo ratings yet

- Saben Silver Steel 1.2210: C Si MN CR Mo W V CoDocument1 pageSaben Silver Steel 1.2210: C Si MN CR Mo W V CoBernice JohnsonNo ratings yet

- Foundry PracticeDocument58 pagesFoundry PracticetrishNo ratings yet

- Nichita Gabriela Georgeta 1Document5 pagesNichita Gabriela Georgeta 1pill strigNo ratings yet

- BOTEK Single Flute Gundrills Type 110Document32 pagesBOTEK Single Flute Gundrills Type 110radius designNo ratings yet

- ME 328.3 E5 - Welding MetallurgyDocument41 pagesME 328.3 E5 - Welding Metallurgytbmari100% (1)

- S04-Types of DiesDocument13 pagesS04-Types of Diesladyinred90No ratings yet

- Surface Preparation For Coating (Blasting)Document11 pagesSurface Preparation For Coating (Blasting)Prabath MadusankaNo ratings yet

- Quality Plan Fabrication of Bit BreakerDocument3 pagesQuality Plan Fabrication of Bit BreakerAldrin HernandezNo ratings yet

- Switch MakingDocument5 pagesSwitch MakingTejesh MannemNo ratings yet