Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

273 viewsHydraulic Sheet Bending Machine

Hydraulic Sheet Bending Machine

Uploaded by

NitinThe document describes a hydraulic sheet bending machine. The machine uses hydraulics to bend metal sheets for use in industries like manufacturing. It has a bracket, workbench, and clamping plate to securely hold the metal sheet. The objective is to design a new bending machine with simplified operation by maximizing the hydraulic forces. It has advantages like being energy efficient, accurate bending, and low maintenance costs. However, it requires large presses powered by hydraulics, electricity or other means to shape metal through force and pressure. Pictures show the proposed design and components.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You might also like

- Ecl SodepurDocument27 pagesEcl SodepurSaurish DeNo ratings yet

- IEEE Recommended Practice For Microprocessor-Based Protection Equipment Firmware ControlDocument23 pagesIEEE Recommended Practice For Microprocessor-Based Protection Equipment Firmware ControlJohn Bihag100% (1)

- Cutting ToolsDocument25 pagesCutting ToolsjaiswalsiddharthNo ratings yet

- Domino A Series Classic Spares Catalogue PDFDocument137 pagesDomino A Series Classic Spares Catalogue PDFprusikNo ratings yet

- Accessory Design Guidelines PDFDocument222 pagesAccessory Design Guidelines PDFYu MiNo ratings yet

- Lenovo Y27gDocument108 pagesLenovo Y27gboroda2410No ratings yet

- EDM Die Sinking AKMDocument7 pagesEDM Die Sinking AKMAhmad Sabree Abdul BasitNo ratings yet

- Btech Oe 8 Sem Automation Robotics Koe 091 2023Document2 pagesBtech Oe 8 Sem Automation Robotics Koe 091 2023subham guptaNo ratings yet

- Designing and Fabrication of Double Acting Hacksaw MachineDocument6 pagesDesigning and Fabrication of Double Acting Hacksaw MachineVARSHAN HARIGANTHNo ratings yet

- Explosive Forming An OverviewDocument7 pagesExplosive Forming An OverviewMazurchevici Andrei DănuţNo ratings yet

- Project PPT Spot WeldingDocument19 pagesProject PPT Spot WeldingMehul BariyaNo ratings yet

- Die and Punch Design PresentationDocument24 pagesDie and Punch Design PresentationMebit100% (1)

- Pattern MaterialsDocument16 pagesPattern MaterialsMani Kandan100% (1)

- Machine ShopDocument6 pagesMachine ShopZain MirzaNo ratings yet

- Design and Fabrication of Modern Three Way Dumping Trolley MechanismDocument8 pagesDesign and Fabrication of Modern Three Way Dumping Trolley MechanismvenkataNo ratings yet

- Applications of ECMDocument2 pagesApplications of ECMHassan BashirNo ratings yet

- Design of Spoon Mold Using Flow Analysis and Higher End Design SoftwareDocument6 pagesDesign of Spoon Mold Using Flow Analysis and Higher End Design SoftwareashishNo ratings yet

- Vibration Assisted EDMDocument13 pagesVibration Assisted EDMSanjay KumarNo ratings yet

- Edm Wire Cut LabDocument6 pagesEdm Wire Cut LabJieMan BahRom100% (1)

- Recent Trends in Non-Traditional Machining Processes: Unit - 5Document12 pagesRecent Trends in Non-Traditional Machining Processes: Unit - 5DISHA VNo ratings yet

- ECDMDocument9 pagesECDMRobert NayakNo ratings yet

- MT 1 Lab Manual PDFDocument40 pagesMT 1 Lab Manual PDFrajamanickam sNo ratings yet

- For Wood Cutter MachineDocument19 pagesFor Wood Cutter MachineRahul Rajput100% (1)

- Automatic Copper Wire Cutting MachineDocument79 pagesAutomatic Copper Wire Cutting Machinephoenixsiva100% (2)

- Planer Machine and Types of Planer MachineDocument5 pagesPlaner Machine and Types of Planer MachineVaibhavNo ratings yet

- Slush CastingDocument20 pagesSlush Castingamt938100% (1)

- Centrum &magnum C-3000Document12 pagesCentrum &magnum C-3000ศูนย์เครื่องจักรบางบอนโดยวงศ์ธนาวุฒิNo ratings yet

- Resistance WeldingDocument22 pagesResistance WeldingGarden005No ratings yet

- Machine Tools LabDocument85 pagesMachine Tools Labmohammad sammeerNo ratings yet

- B. Tech. Mechanical Engineering PDFDocument138 pagesB. Tech. Mechanical Engineering PDFLarry SmithNo ratings yet

- Laminated Object Manufacturing (LOM)Document19 pagesLaminated Object Manufacturing (LOM)PritamKumarPradhan100% (3)

- Fabrication of Plastic Brick Manufacturing Machine and Brick AnalysisDocument75 pagesFabrication of Plastic Brick Manufacturing Machine and Brick AnalysismmjishnuNo ratings yet

- LegaDrive 2014 13838 En.Document12 pagesLegaDrive 2014 13838 En.Shivam MathurNo ratings yet

- Final PPT For Minor Project 2021-22Document19 pagesFinal PPT For Minor Project 2021-22Dashanand RavanNo ratings yet

- Ae4131 Abaqus Lecture 4Document23 pagesAe4131 Abaqus Lecture 4Shijo AntonyNo ratings yet

- Electrical Discharge MachiningDocument16 pagesElectrical Discharge MachiningRizwan MrnNo ratings yet

- Shaping Machine: Machine Shop Theory and Practice Mechanical EngineeringDocument17 pagesShaping Machine: Machine Shop Theory and Practice Mechanical EngineeringKate BarilNo ratings yet

- Friction Stir Welding FSW Final ReportDocument28 pagesFriction Stir Welding FSW Final ReportShashank Verma100% (1)

- Nontraditional Machining and Thermal Cutting Processes - Chapter 26Document67 pagesNontraditional Machining and Thermal Cutting Processes - Chapter 26xharpreetxNo ratings yet

- Final Automated Welding PresentationDocument26 pagesFinal Automated Welding PresentationAbie RexoMenNo ratings yet

- List of Seminar Topic-MP-2Document2 pagesList of Seminar Topic-MP-2yagnesh50% (2)

- Duw1012 Unit 7 ErgonomicsDocument26 pagesDuw1012 Unit 7 ErgonomicsAzuraNo ratings yet

- Lecture 1 - Introduction To Mechanical Workshop Technology PDFDocument40 pagesLecture 1 - Introduction To Mechanical Workshop Technology PDFLuyando MfwankilaNo ratings yet

- Observations and FindingsDocument2 pagesObservations and FindingsJustin Mark AgtingNo ratings yet

- Welding Table ProjectDocument15 pagesWelding Table ProjectKheri Mohd100% (1)

- Literature Review of Electric Arc Welding MachineDocument4 pagesLiterature Review of Electric Arc Welding MachineafmzxutkxdkdamNo ratings yet

- Shafts, Keys and CouplingsDocument20 pagesShafts, Keys and CouplingssaurabhNo ratings yet

- Rapid Prototyping Seminar ReportDocument35 pagesRapid Prototyping Seminar ReportNaomi Cooke100% (1)

- Micro Project: Title of The ProjectDocument11 pagesMicro Project: Title of The Projectomkar digamabar sononeNo ratings yet

- Industrial Gear Box: Bhalerao Trupti Bhoir Pravin Bhor Sakshi Bodake ShubhamDocument15 pagesIndustrial Gear Box: Bhalerao Trupti Bhoir Pravin Bhor Sakshi Bodake ShubhamMayur Madhukar MankarNo ratings yet

- What Is CastingDocument10 pagesWhat Is CastingMuneeb RehmanNo ratings yet

- Welding Slag CLEANING MachineDocument5 pagesWelding Slag CLEANING MachineSuganthan IasNo ratings yet

- C PROGRAM of Machine DesignDocument12 pagesC PROGRAM of Machine DesignPiyush Baid100% (1)

- Diamatic Indstries - CONCRETE CUTTING BLADESDocument4 pagesDiamatic Indstries - CONCRETE CUTTING BLADESDiamatic IndustriesNo ratings yet

- Advanced Snake Drill Technique Method For Improving of Oil Extraction PercentageDocument7 pagesAdvanced Snake Drill Technique Method For Improving of Oil Extraction PercentageAkhil GodavarthiNo ratings yet

- Fitting Shop Operations:: 1. Measuring OperationDocument7 pagesFitting Shop Operations:: 1. Measuring OperationAliNo ratings yet

- Design and Analysis of PROTECTED FLANGE COUPLING Solidworks 2016 and ANSYS WorkbenchDocument27 pagesDesign and Analysis of PROTECTED FLANGE COUPLING Solidworks 2016 and ANSYS Workbenchamu100% (1)

- Types of Jigs & Fixtures PDFDocument3 pagesTypes of Jigs & Fixtures PDFABEESH KIRANNo ratings yet

- 156 180Document181 pages156 180Kurnia Adi WibowoNo ratings yet

- Tool Based Micro MachiningDocument8 pagesTool Based Micro MachiningAnmol SatsangiNo ratings yet

- Machining 2 ReportDocument11 pagesMachining 2 ReportTan Jun ZheNo ratings yet

- EDM Lab ReportDocument12 pagesEDM Lab ReportAli Hassan100% (1)

- Advance Welding - Syllabus (KME-055)Document3 pagesAdvance Welding - Syllabus (KME-055)Shashank DwivediNo ratings yet

- Hydraulic Power PressDocument30 pagesHydraulic Power Pressryanmaharana947No ratings yet

- Grinding & FinishingDocument122 pagesGrinding & FinishingNitinNo ratings yet

- Navigus UNPLACED StudentsDocument68 pagesNavigus UNPLACED StudentsNitinNo ratings yet

- Data For Christian Pfeiffer India Pvt. LTDDocument2 pagesData For Christian Pfeiffer India Pvt. LTDNitinNo ratings yet

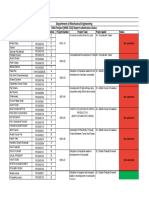

- Mini Project Report Submission StatusDocument6 pagesMini Project Report Submission StatusNitinNo ratings yet

- Ese Vs Gate by Amit SirDocument29 pagesEse Vs Gate by Amit SirNitinNo ratings yet

- Tissue Paper Hot Air Balloon: Andrea Badua Period 2 Physics Ms. BuenconsejoDocument14 pagesTissue Paper Hot Air Balloon: Andrea Badua Period 2 Physics Ms. BuenconsejoAndrea BaduaNo ratings yet

- Inventaris RIG Jacro 200Document2 pagesInventaris RIG Jacro 200edhoNo ratings yet

- Follow Up Spiel SDocument3 pagesFollow Up Spiel SRobert Dakota VillalonNo ratings yet

- 4.1 A Future View of Precision FarmingDocument15 pages4.1 A Future View of Precision FarmingQiu AnNo ratings yet

- Defiinisi ProblemsDocument4 pagesDefiinisi ProblemsDiaz MahardikaNo ratings yet

- STK402 020 PDFDocument4 pagesSTK402 020 PDFGus JoeNo ratings yet

- Shell Bitumen HBDocument12 pagesShell Bitumen HBAbe Kob50% (4)

- C ProgrammingDocument85 pagesC ProgrammingSudhaRatnamNo ratings yet

- Writingfortelevi00unse PDFDocument328 pagesWritingfortelevi00unse PDFBaran AlinaNo ratings yet

- Hogans NN Project2 7472Document16 pagesHogans NN Project2 7472api-374548902No ratings yet

- OSYM PASSAGES 1 (Oklu AçDocument147 pagesOSYM PASSAGES 1 (Oklu AçSinan EkerNo ratings yet

- Cn5131 OutlineDocument6 pagesCn5131 OutlineAki EspaldonNo ratings yet

- Setting Co-Ordination Chart & Graph Relay Setting Calculation 0.415 KV Panel - Ecr-2Document90 pagesSetting Co-Ordination Chart & Graph Relay Setting Calculation 0.415 KV Panel - Ecr-2susovan bIswasNo ratings yet

- SAP Solution Manager Service Level Reporting: Best Practice For E2E Solution OperationsDocument18 pagesSAP Solution Manager Service Level Reporting: Best Practice For E2E Solution Operationsamakr2010No ratings yet

- s800 Modbus PDFDocument11 pagess800 Modbus PDFMuhammad NourNo ratings yet

- Shuguang Zhang Et Al - Design of Nanostructured Biological Materials Through Self-Assembly of Peptides and ProteinsDocument8 pagesShuguang Zhang Et Al - Design of Nanostructured Biological Materials Through Self-Assembly of Peptides and ProteinsGmewop30m100% (1)

- BORGER 1500 Rotary Pump MontgomeryDocument28 pagesBORGER 1500 Rotary Pump Montgomeryroyert80No ratings yet

- Updated 20prasanna's 20resumeDocument4 pagesUpdated 20prasanna's 20resumevankudothulucky66No ratings yet

- Virtual SurgeryDocument12 pagesVirtual Surgeryirfanm06100% (1)

- Daaf006099 000Document2 pagesDaaf006099 000apsNo ratings yet

- Lecture 4-Energy Analysis PDFDocument14 pagesLecture 4-Energy Analysis PDFKaity SarsfieldNo ratings yet

- Business Continuity and Contingency Planning Practices For Electronic BankingDocument84 pagesBusiness Continuity and Contingency Planning Practices For Electronic BankingCOT Management Training Insitute100% (1)

- Blacklisted Constructors 28 February 2011Document3 pagesBlacklisted Constructors 28 February 2011Sherry Mae Domingo MaulitNo ratings yet

- 7629Document125 pages7629Mark JohnsonNo ratings yet

- Quality and Cost SavingsDocument2 pagesQuality and Cost Savingsbramirez8098No ratings yet

- Statement - Tue Nov 30 2021 19-18-05 GMT+0200 (South Africa Standard Time)Document2 pagesStatement - Tue Nov 30 2021 19-18-05 GMT+0200 (South Africa Standard Time)Yewena Meli KaveNo ratings yet

Hydraulic Sheet Bending Machine

Hydraulic Sheet Bending Machine

Uploaded by

Nitin0 ratings0% found this document useful (0 votes)

273 views15 pagesThe document describes a hydraulic sheet bending machine. The machine uses hydraulics to bend metal sheets for use in industries like manufacturing. It has a bracket, workbench, and clamping plate to securely hold the metal sheet. The objective is to design a new bending machine with simplified operation by maximizing the hydraulic forces. It has advantages like being energy efficient, accurate bending, and low maintenance costs. However, it requires large presses powered by hydraulics, electricity or other means to shape metal through force and pressure. Pictures show the proposed design and components.

Original Description:

Original Title

HYDRAULIC SHEET BENDING MACHINE

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes a hydraulic sheet bending machine. The machine uses hydraulics to bend metal sheets for use in industries like manufacturing. It has a bracket, workbench, and clamping plate to securely hold the metal sheet. The objective is to design a new bending machine with simplified operation by maximizing the hydraulic forces. It has advantages like being energy efficient, accurate bending, and low maintenance costs. However, it requires large presses powered by hydraulics, electricity or other means to shape metal through force and pressure. Pictures show the proposed design and components.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

273 views15 pagesHydraulic Sheet Bending Machine

Hydraulic Sheet Bending Machine

Uploaded by

NitinThe document describes a hydraulic sheet bending machine. The machine uses hydraulics to bend metal sheets for use in industries like manufacturing. It has a bracket, workbench, and clamping plate to securely hold the metal sheet. The objective is to design a new bending machine with simplified operation by maximizing the hydraulic forces. It has advantages like being energy efficient, accurate bending, and low maintenance costs. However, it requires large presses powered by hydraulics, electricity or other means to shape metal through force and pressure. Pictures show the proposed design and components.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 15

HYDRAULIC SHEET

BENDING MACHINE

SUBMITTED BY:

Under the guidence:-

CONTENT:-

• Introduction

• Objective

• Advantage and disadvantages

• Model picture

• Conclusion

• Working

• Project picture

Introduction:-

Hydraulic Bending Machine belongs to forging

machineries. The main role is in the metal processing

industry. Then, its products are widely used in light

industry, aviation, shipbuilding, metallurgy,

instrument, electrical appliances, stainless steel

products, steel structure construction and other

industries

Introduction:-

Structure of Hydraulic Bending Machine: bracket,

workbench and clamping plate

Workbench placed on the bracket

The worktable composed of a base and a pressing plate

The base connected with the clamping plate through a

hinge

Base consists of a base shell, a coil and a cover plate

Coil placed in the recess of the housing

Top of the depression covered with a cover plate

Objective:-

The main objective of this project is to design a new

bending machine with new feature and simplified

operation by handling the hydraulic cylinder reaction

force for the purpose of bending. To maximize the

hydraulic action and reaction force by the help of

right angle lever.

Advantage:-

• Energy saving.

• Environmental protection without pollution.

• Slider is fast and production efficiency is high.

• High accuracy of bending.

• Low maintenance cost

Disadvantages:-

• Metal presses are machine tools that shape pieces

of metal by applying pressure. They work the metal

through a force were works over a distance -- or

stroke -- and forges the metal into shape. Presses

can be powered by hydraulics, electricity,

compressed air (pneumatics) or steam. Hydraulic

presses are built in many different sizes and are

used in all types of manufacturing industry, ranging

from automobile plants to jewelry making

Model picture:-

Model picture:-

Conclusion:-

Hydraulic Bending machine is a procedure which is

utilized to make part for car, aviation, families and

control

plant ventures and so on. Our Hydraulic bending

machine is more affordable, light in weight in

contrast with

different machines along these lines, it can be ideal

for small industry holders, small workshop holders, in

school organizations and so forth.

Working:-

When in use, the coil is energized by a wire. After

electrified, the pressure plate will be gravitated to

realize the clamping of the thin plate between the

pressure plate and the base. Due to the use of

electromagnetic force clamping, SHEARCHY CNC

press brake can press the plate into a variety of work

piece requirements. Moreover, it can process work

pieces with side walls

Project picture:-

Project picture:-

Project picture:-

Thank you

You might also like

- Ecl SodepurDocument27 pagesEcl SodepurSaurish DeNo ratings yet

- IEEE Recommended Practice For Microprocessor-Based Protection Equipment Firmware ControlDocument23 pagesIEEE Recommended Practice For Microprocessor-Based Protection Equipment Firmware ControlJohn Bihag100% (1)

- Cutting ToolsDocument25 pagesCutting ToolsjaiswalsiddharthNo ratings yet

- Domino A Series Classic Spares Catalogue PDFDocument137 pagesDomino A Series Classic Spares Catalogue PDFprusikNo ratings yet

- Accessory Design Guidelines PDFDocument222 pagesAccessory Design Guidelines PDFYu MiNo ratings yet

- Lenovo Y27gDocument108 pagesLenovo Y27gboroda2410No ratings yet

- EDM Die Sinking AKMDocument7 pagesEDM Die Sinking AKMAhmad Sabree Abdul BasitNo ratings yet

- Btech Oe 8 Sem Automation Robotics Koe 091 2023Document2 pagesBtech Oe 8 Sem Automation Robotics Koe 091 2023subham guptaNo ratings yet

- Designing and Fabrication of Double Acting Hacksaw MachineDocument6 pagesDesigning and Fabrication of Double Acting Hacksaw MachineVARSHAN HARIGANTHNo ratings yet

- Explosive Forming An OverviewDocument7 pagesExplosive Forming An OverviewMazurchevici Andrei DănuţNo ratings yet

- Project PPT Spot WeldingDocument19 pagesProject PPT Spot WeldingMehul BariyaNo ratings yet

- Die and Punch Design PresentationDocument24 pagesDie and Punch Design PresentationMebit100% (1)

- Pattern MaterialsDocument16 pagesPattern MaterialsMani Kandan100% (1)

- Machine ShopDocument6 pagesMachine ShopZain MirzaNo ratings yet

- Design and Fabrication of Modern Three Way Dumping Trolley MechanismDocument8 pagesDesign and Fabrication of Modern Three Way Dumping Trolley MechanismvenkataNo ratings yet

- Applications of ECMDocument2 pagesApplications of ECMHassan BashirNo ratings yet

- Design of Spoon Mold Using Flow Analysis and Higher End Design SoftwareDocument6 pagesDesign of Spoon Mold Using Flow Analysis and Higher End Design SoftwareashishNo ratings yet

- Vibration Assisted EDMDocument13 pagesVibration Assisted EDMSanjay KumarNo ratings yet

- Edm Wire Cut LabDocument6 pagesEdm Wire Cut LabJieMan BahRom100% (1)

- Recent Trends in Non-Traditional Machining Processes: Unit - 5Document12 pagesRecent Trends in Non-Traditional Machining Processes: Unit - 5DISHA VNo ratings yet

- ECDMDocument9 pagesECDMRobert NayakNo ratings yet

- MT 1 Lab Manual PDFDocument40 pagesMT 1 Lab Manual PDFrajamanickam sNo ratings yet

- For Wood Cutter MachineDocument19 pagesFor Wood Cutter MachineRahul Rajput100% (1)

- Automatic Copper Wire Cutting MachineDocument79 pagesAutomatic Copper Wire Cutting Machinephoenixsiva100% (2)

- Planer Machine and Types of Planer MachineDocument5 pagesPlaner Machine and Types of Planer MachineVaibhavNo ratings yet

- Slush CastingDocument20 pagesSlush Castingamt938100% (1)

- Centrum &magnum C-3000Document12 pagesCentrum &magnum C-3000ศูนย์เครื่องจักรบางบอนโดยวงศ์ธนาวุฒิNo ratings yet

- Resistance WeldingDocument22 pagesResistance WeldingGarden005No ratings yet

- Machine Tools LabDocument85 pagesMachine Tools Labmohammad sammeerNo ratings yet

- B. Tech. Mechanical Engineering PDFDocument138 pagesB. Tech. Mechanical Engineering PDFLarry SmithNo ratings yet

- Laminated Object Manufacturing (LOM)Document19 pagesLaminated Object Manufacturing (LOM)PritamKumarPradhan100% (3)

- Fabrication of Plastic Brick Manufacturing Machine and Brick AnalysisDocument75 pagesFabrication of Plastic Brick Manufacturing Machine and Brick AnalysismmjishnuNo ratings yet

- LegaDrive 2014 13838 En.Document12 pagesLegaDrive 2014 13838 En.Shivam MathurNo ratings yet

- Final PPT For Minor Project 2021-22Document19 pagesFinal PPT For Minor Project 2021-22Dashanand RavanNo ratings yet

- Ae4131 Abaqus Lecture 4Document23 pagesAe4131 Abaqus Lecture 4Shijo AntonyNo ratings yet

- Electrical Discharge MachiningDocument16 pagesElectrical Discharge MachiningRizwan MrnNo ratings yet

- Shaping Machine: Machine Shop Theory and Practice Mechanical EngineeringDocument17 pagesShaping Machine: Machine Shop Theory and Practice Mechanical EngineeringKate BarilNo ratings yet

- Friction Stir Welding FSW Final ReportDocument28 pagesFriction Stir Welding FSW Final ReportShashank Verma100% (1)

- Nontraditional Machining and Thermal Cutting Processes - Chapter 26Document67 pagesNontraditional Machining and Thermal Cutting Processes - Chapter 26xharpreetxNo ratings yet

- Final Automated Welding PresentationDocument26 pagesFinal Automated Welding PresentationAbie RexoMenNo ratings yet

- List of Seminar Topic-MP-2Document2 pagesList of Seminar Topic-MP-2yagnesh50% (2)

- Duw1012 Unit 7 ErgonomicsDocument26 pagesDuw1012 Unit 7 ErgonomicsAzuraNo ratings yet

- Lecture 1 - Introduction To Mechanical Workshop Technology PDFDocument40 pagesLecture 1 - Introduction To Mechanical Workshop Technology PDFLuyando MfwankilaNo ratings yet

- Observations and FindingsDocument2 pagesObservations and FindingsJustin Mark AgtingNo ratings yet

- Welding Table ProjectDocument15 pagesWelding Table ProjectKheri Mohd100% (1)

- Literature Review of Electric Arc Welding MachineDocument4 pagesLiterature Review of Electric Arc Welding MachineafmzxutkxdkdamNo ratings yet

- Shafts, Keys and CouplingsDocument20 pagesShafts, Keys and CouplingssaurabhNo ratings yet

- Rapid Prototyping Seminar ReportDocument35 pagesRapid Prototyping Seminar ReportNaomi Cooke100% (1)

- Micro Project: Title of The ProjectDocument11 pagesMicro Project: Title of The Projectomkar digamabar sononeNo ratings yet

- Industrial Gear Box: Bhalerao Trupti Bhoir Pravin Bhor Sakshi Bodake ShubhamDocument15 pagesIndustrial Gear Box: Bhalerao Trupti Bhoir Pravin Bhor Sakshi Bodake ShubhamMayur Madhukar MankarNo ratings yet

- What Is CastingDocument10 pagesWhat Is CastingMuneeb RehmanNo ratings yet

- Welding Slag CLEANING MachineDocument5 pagesWelding Slag CLEANING MachineSuganthan IasNo ratings yet

- C PROGRAM of Machine DesignDocument12 pagesC PROGRAM of Machine DesignPiyush Baid100% (1)

- Diamatic Indstries - CONCRETE CUTTING BLADESDocument4 pagesDiamatic Indstries - CONCRETE CUTTING BLADESDiamatic IndustriesNo ratings yet

- Advanced Snake Drill Technique Method For Improving of Oil Extraction PercentageDocument7 pagesAdvanced Snake Drill Technique Method For Improving of Oil Extraction PercentageAkhil GodavarthiNo ratings yet

- Fitting Shop Operations:: 1. Measuring OperationDocument7 pagesFitting Shop Operations:: 1. Measuring OperationAliNo ratings yet

- Design and Analysis of PROTECTED FLANGE COUPLING Solidworks 2016 and ANSYS WorkbenchDocument27 pagesDesign and Analysis of PROTECTED FLANGE COUPLING Solidworks 2016 and ANSYS Workbenchamu100% (1)

- Types of Jigs & Fixtures PDFDocument3 pagesTypes of Jigs & Fixtures PDFABEESH KIRANNo ratings yet

- 156 180Document181 pages156 180Kurnia Adi WibowoNo ratings yet

- Tool Based Micro MachiningDocument8 pagesTool Based Micro MachiningAnmol SatsangiNo ratings yet

- Machining 2 ReportDocument11 pagesMachining 2 ReportTan Jun ZheNo ratings yet

- EDM Lab ReportDocument12 pagesEDM Lab ReportAli Hassan100% (1)

- Advance Welding - Syllabus (KME-055)Document3 pagesAdvance Welding - Syllabus (KME-055)Shashank DwivediNo ratings yet

- Hydraulic Power PressDocument30 pagesHydraulic Power Pressryanmaharana947No ratings yet

- Grinding & FinishingDocument122 pagesGrinding & FinishingNitinNo ratings yet

- Navigus UNPLACED StudentsDocument68 pagesNavigus UNPLACED StudentsNitinNo ratings yet

- Data For Christian Pfeiffer India Pvt. LTDDocument2 pagesData For Christian Pfeiffer India Pvt. LTDNitinNo ratings yet

- Mini Project Report Submission StatusDocument6 pagesMini Project Report Submission StatusNitinNo ratings yet

- Ese Vs Gate by Amit SirDocument29 pagesEse Vs Gate by Amit SirNitinNo ratings yet

- Tissue Paper Hot Air Balloon: Andrea Badua Period 2 Physics Ms. BuenconsejoDocument14 pagesTissue Paper Hot Air Balloon: Andrea Badua Period 2 Physics Ms. BuenconsejoAndrea BaduaNo ratings yet

- Inventaris RIG Jacro 200Document2 pagesInventaris RIG Jacro 200edhoNo ratings yet

- Follow Up Spiel SDocument3 pagesFollow Up Spiel SRobert Dakota VillalonNo ratings yet

- 4.1 A Future View of Precision FarmingDocument15 pages4.1 A Future View of Precision FarmingQiu AnNo ratings yet

- Defiinisi ProblemsDocument4 pagesDefiinisi ProblemsDiaz MahardikaNo ratings yet

- STK402 020 PDFDocument4 pagesSTK402 020 PDFGus JoeNo ratings yet

- Shell Bitumen HBDocument12 pagesShell Bitumen HBAbe Kob50% (4)

- C ProgrammingDocument85 pagesC ProgrammingSudhaRatnamNo ratings yet

- Writingfortelevi00unse PDFDocument328 pagesWritingfortelevi00unse PDFBaran AlinaNo ratings yet

- Hogans NN Project2 7472Document16 pagesHogans NN Project2 7472api-374548902No ratings yet

- OSYM PASSAGES 1 (Oklu AçDocument147 pagesOSYM PASSAGES 1 (Oklu AçSinan EkerNo ratings yet

- Cn5131 OutlineDocument6 pagesCn5131 OutlineAki EspaldonNo ratings yet

- Setting Co-Ordination Chart & Graph Relay Setting Calculation 0.415 KV Panel - Ecr-2Document90 pagesSetting Co-Ordination Chart & Graph Relay Setting Calculation 0.415 KV Panel - Ecr-2susovan bIswasNo ratings yet

- SAP Solution Manager Service Level Reporting: Best Practice For E2E Solution OperationsDocument18 pagesSAP Solution Manager Service Level Reporting: Best Practice For E2E Solution Operationsamakr2010No ratings yet

- s800 Modbus PDFDocument11 pagess800 Modbus PDFMuhammad NourNo ratings yet

- Shuguang Zhang Et Al - Design of Nanostructured Biological Materials Through Self-Assembly of Peptides and ProteinsDocument8 pagesShuguang Zhang Et Al - Design of Nanostructured Biological Materials Through Self-Assembly of Peptides and ProteinsGmewop30m100% (1)

- BORGER 1500 Rotary Pump MontgomeryDocument28 pagesBORGER 1500 Rotary Pump Montgomeryroyert80No ratings yet

- Updated 20prasanna's 20resumeDocument4 pagesUpdated 20prasanna's 20resumevankudothulucky66No ratings yet

- Virtual SurgeryDocument12 pagesVirtual Surgeryirfanm06100% (1)

- Daaf006099 000Document2 pagesDaaf006099 000apsNo ratings yet

- Lecture 4-Energy Analysis PDFDocument14 pagesLecture 4-Energy Analysis PDFKaity SarsfieldNo ratings yet

- Business Continuity and Contingency Planning Practices For Electronic BankingDocument84 pagesBusiness Continuity and Contingency Planning Practices For Electronic BankingCOT Management Training Insitute100% (1)

- Blacklisted Constructors 28 February 2011Document3 pagesBlacklisted Constructors 28 February 2011Sherry Mae Domingo MaulitNo ratings yet

- 7629Document125 pages7629Mark JohnsonNo ratings yet

- Quality and Cost SavingsDocument2 pagesQuality and Cost Savingsbramirez8098No ratings yet

- Statement - Tue Nov 30 2021 19-18-05 GMT+0200 (South Africa Standard Time)Document2 pagesStatement - Tue Nov 30 2021 19-18-05 GMT+0200 (South Africa Standard Time)Yewena Meli KaveNo ratings yet