Professional Documents

Culture Documents

Epoxy Flooring

Epoxy Flooring

Uploaded by

Sanup Simon0 ratings0% found this document useful (0 votes)

33 views18 pagesEpoxy flooring is a durable, chemical and abrasion resistant flooring ideal for industrial settings. It has high compressive strength and is easy to apply. There are three main types - an epoxy coating system, a self-leveling system with aggregates, and a screed system primarily made of aggregates. The epoxy is applied by mixing the base, hardener, color pigment and sometimes aggregates. It is applied to the prepared and primed surface, then spike rolled to remove air and level the coating. Epoxy flooring provides low maintenance, seamless floors suited to withstanding chemicals and foot traffic in commercial and industrial facilities.

Original Description:

Epoxy flooring

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentEpoxy flooring is a durable, chemical and abrasion resistant flooring ideal for industrial settings. It has high compressive strength and is easy to apply. There are three main types - an epoxy coating system, a self-leveling system with aggregates, and a screed system primarily made of aggregates. The epoxy is applied by mixing the base, hardener, color pigment and sometimes aggregates. It is applied to the prepared and primed surface, then spike rolled to remove air and level the coating. Epoxy flooring provides low maintenance, seamless floors suited to withstanding chemicals and foot traffic in commercial and industrial facilities.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

33 views18 pagesEpoxy Flooring

Epoxy Flooring

Uploaded by

Sanup SimonEpoxy flooring is a durable, chemical and abrasion resistant flooring ideal for industrial settings. It has high compressive strength and is easy to apply. There are three main types - an epoxy coating system, a self-leveling system with aggregates, and a screed system primarily made of aggregates. The epoxy is applied by mixing the base, hardener, color pigment and sometimes aggregates. It is applied to the prepared and primed surface, then spike rolled to remove air and level the coating. Epoxy flooring provides low maintenance, seamless floors suited to withstanding chemicals and foot traffic in commercial and industrial facilities.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 18

Epoxy flooring

Introduction

This is the state of art, high-tech flooring of the

modern world.

Compressive strength, abrassive resistance and

aesthetics of high standard are blended together

to have this concept of flooring.

It is ideal for industrial or commercial locations

where hard wearing, hygienic, chemical resistant

& dust free environment is essential.

As the floor a movement in different industry

varies, the minimum thickness required for the

epoxy topping are also varied.

ADVANTAGES

Increased compressive strength

Reduced maintenance cost

Increased water resistance

Minimum dusting

Decorative coating

Level floor

Minimized crack formation.

Quick and easy to lay

Seamless

Durable

Proven against a wide range of industrial

chemicals

Solvent free- no odour during application

Slip resistant- different textures available to

suit conditions to avoid slipping

Liquid applied providing complete protection

Available in a wide range of colours to

improve the working environment and

identify slip hazard areas

The three type of system that we are providing

are:

a) Epoxy coating system

b) Epoxy Self levelling system

c) Epoxy Screed system

Epoxy system

Surface Preparation & Priming

The floor should be sound, clean and dry surface.

Grinding is to be done on the surface to remove

any weaker particles, any dents or patches are to

be repaired with epoxy mortar or slurry.

A primer is to be applied on the using felt rollers.

Primers act mechanical key & bonding agent floor

toppings.

Mixing

Resin based epoxy comes in pre-weighed

factory packs in four parts; base, hardener,

colour pigment & aggregates.

These components are mixed thoroughly

using a heavy duty, slow speed paddle mixer

as per the manufacturer’s specification.

Laying

The mixed slurry is then poured on the

primed surface as per the dosage and

covering area & spread it using serrated

trowel to uniform layer of appropriate

thickness.

Spike Roller Application

Standing on spike shoes, nylon spike rollers

are applied on the epoxy toppings to free the

entrapped air and to evenly spread the laid

material.

Finished Floor

After three rounds of spike roller application

the floor topping levels and set to the surface

of the floor.

Epoxy coating system

Base+hardner+colour

Epoxy Self levelling system

Base+hardner+colour+aggregate

Epoxy Screed system

Base+hardner+aggregate

You might also like

- Din en Iso 19598Document20 pagesDin en Iso 19598rajeskumar100% (1)

- Platinium CCDocument1 pagePlatinium CCGustavo Henrique133% (3)

- Epoxy Epoxy FlooringsDocument47 pagesEpoxy Epoxy Flooringsjeffkarthick1100% (1)

- Specification Package For Epoxy Flooring atDocument6 pagesSpecification Package For Epoxy Flooring atDevinder Sokhi50% (2)

- Pure Epoxies Vs Epoxy Mastics For Maintenance PDFDocument4 pagesPure Epoxies Vs Epoxy Mastics For Maintenance PDF003086100% (1)

- Lab ManualDocument62 pagesLab ManualKhalid M. Hafez100% (1)

- Epoxy Flooring: Nippon PaintsDocument12 pagesEpoxy Flooring: Nippon PaintsK V RajmanikandanNo ratings yet

- Epoxy Methdology 29.10.2023Document7 pagesEpoxy Methdology 29.10.2023Herani DawitNo ratings yet

- Epoxy FlooringDocument34 pagesEpoxy Flooringgowri ajith100% (1)

- Different Systems of Epoxy FlooringDocument11 pagesDifferent Systems of Epoxy FlooringSharon JNo ratings yet

- Ultra Affix PVT LTD PDFDocument10 pagesUltra Affix PVT LTD PDFBijay ThapaNo ratings yet

- Epoxy FlooringDocument12 pagesEpoxy Flooringaisha mahreen patelNo ratings yet

- Epoxy Application GuideDocument24 pagesEpoxy Application GuideAhmed Emad AhmedNo ratings yet

- FloorDocument9 pagesFloorChanda LyNo ratings yet

- Fairtop Fast Floor - Cementitious Self Levelling Flooring SystemsDocument8 pagesFairtop Fast Floor - Cementitious Self Levelling Flooring SystemsfairmatechemicalNo ratings yet

- Ktisis Floor Coatings BrochureDocument8 pagesKtisis Floor Coatings Brochureakis5375No ratings yet

- DR Fixit Epoxy Floor Screed 90 1Document4 pagesDR Fixit Epoxy Floor Screed 90 1amit sharmaNo ratings yet

- Werehouse Epoxy FlooringDocument10 pagesWerehouse Epoxy FlooringTesfaye GirmaNo ratings yet

- Epoxy Grout DAVCODocument2 pagesEpoxy Grout DAVCOcharibackupNo ratings yet

- 5 Flooring Innovation Adopted by The Industry ExpertsDocument6 pages5 Flooring Innovation Adopted by The Industry Expertsks1962No ratings yet

- Cleaning and Restoration Services in Joyner and BrisbaneDocument7 pagesCleaning and Restoration Services in Joyner and Brisbanequalitye ProxyNo ratings yet

- Epofloor: Epoxy-Cement System For FloorsDocument28 pagesEpofloor: Epoxy-Cement System For FloorsClara PolistenaNo ratings yet

- SWOT AnalysisDocument2 pagesSWOT AnalysisAjay HemnaniNo ratings yet

- Repairing ConcreteDocument10 pagesRepairing ConcreteWan HabibNo ratings yet

- Epoxy Painting & Sand Blasting JobDocument11 pagesEpoxy Painting & Sand Blasting JobStrategic ThinkingNo ratings yet

- Construction Methodology For Epoxy FlooringDocument5 pagesConstruction Methodology For Epoxy Flooringaboma mosisaNo ratings yet

- Car Parking System - 17.04.13Document13 pagesCar Parking System - 17.04.13raj06740100% (1)

- Can Fast Installation and Maintenance ManualDocument25 pagesCan Fast Installation and Maintenance ManualTongxiang Shanhe Composite Materials Co., Ltd.No ratings yet

- Rebuild-Vol 9Document20 pagesRebuild-Vol 9ahtin618No ratings yet

- Epoxy ResinDocument7 pagesEpoxy ResinAtiq JamNo ratings yet

- Epoxy PaintDocument1 pageEpoxy PaintDevryl RufinNo ratings yet

- Safe and Hygienic Resin Flooring Systems For The Healthcare MarketDocument4 pagesSafe and Hygienic Resin Flooring Systems For The Healthcare MarketvasantsunerkarNo ratings yet

- Concrete Patio Sealertmzry PDFDocument2 pagesConcrete Patio Sealertmzry PDFblogsonepoxygiareNo ratings yet

- Specification Submittal For SL Conductive Anti StaticDocument9 pagesSpecification Submittal For SL Conductive Anti StaticPaladi RaviNo ratings yet

- Fairfix UnderlaymentDocument4 pagesFairfix UnderlaymentfairmatechemicalNo ratings yet

- Resin Floorings IsomatDocument36 pagesResin Floorings IsomatBragarin DanNo ratings yet

- Industrial Epoxy Floor Coating - The Ideal Solution For Industrial FacilitiesDocument2 pagesIndustrial Epoxy Floor Coating - The Ideal Solution For Industrial FacilitiesConnor MarshmanNo ratings yet

- FAIRMATE STAMP CONCRETE - BrochureDocument20 pagesFAIRMATE STAMP CONCRETE - Brochurechandan paulNo ratings yet

- Epoxy FlooringDocument7 pagesEpoxy FlooringGrv Srm100% (1)

- Crack Repair TechniquesDocument7 pagesCrack Repair TechniquesMohamad Ben HusseinNo ratings yet

- Isomat Resin Floorings - enDocument36 pagesIsomat Resin Floorings - enMaha MuflehNo ratings yet

- EcoPoxy Resin Build HardenerDocument2 pagesEcoPoxy Resin Build HardenerCarlos AgrizziNo ratings yet

- Euco TopDocument2 pagesEuco Toppravi3434No ratings yet

- Hi-Build Epoxy CoatingDocument5 pagesHi-Build Epoxy CoatingDharmendra DubeyNo ratings yet

- Polymer ConcreteDocument26 pagesPolymer ConcretePrashant Patil50% (2)

- ESD Sight Epoxy Mortar SEP-6505 Method StatmentDocument3 pagesESD Sight Epoxy Mortar SEP-6505 Method StatmentmakdelNo ratings yet

- Preventing Air Bubbles in Epoxy ResinDocument4 pagesPreventing Air Bubbles in Epoxy ResinApitNo ratings yet

- CE CenterDocument19 pagesCE CenterQAQC GCCNo ratings yet

- 3D Epoxy FlooringDocument1 page3D Epoxy FlooringaleeyubjNo ratings yet

- Epoxy ChalkingDocument2 pagesEpoxy Chalkingiran1362100% (1)

- Clay Pattern Styling and Rigid Surface Casting in Today's Composite IndustryDocument3 pagesClay Pattern Styling and Rigid Surface Casting in Today's Composite Industrybugsy77No ratings yet

- Epoxy Coating DetailsDocument2 pagesEpoxy Coating DetailsGoh Seng TakNo ratings yet

- Performance Coatings - Greenheck FansDocument12 pagesPerformance Coatings - Greenheck Fansprsum_572100% (1)

- Chemical Resistant Epoxy PrimerDocument4 pagesChemical Resistant Epoxy PrimerDharmendra DubeyNo ratings yet

- Flat Type+epoxy+floor+coatingDocument3 pagesFlat Type+epoxy+floor+coatingRuano Andreola StumpfNo ratings yet

- The Repair of A Damaged Concrete Floor Doesn't Need To Be A Hard or Tough Repair Job. It May Surprise You How Easily This Can Be Done YourselfDocument2 pagesThe Repair of A Damaged Concrete Floor Doesn't Need To Be A Hard or Tough Repair Job. It May Surprise You How Easily This Can Be Done YourselfScared CreatorNo ratings yet

- Supercast EPT PDFDocument2 pagesSupercast EPT PDFmilanbrasinaNo ratings yet

- Fairmate Floor Finish Brochure - Three FoldDocument2 pagesFairmate Floor Finish Brochure - Three FoldfairmatechemicalNo ratings yet

- Other UsesDocument16 pagesOther UsesKalNo ratings yet

- 72F-Non Metallic Duct HDPE Cable-Technical Offer-18Document6 pages72F-Non Metallic Duct HDPE Cable-Technical Offer-18GUY-FABRE DJILENo ratings yet

- Differences Between ASTM A53 B and ASTM A106 B Steel PipeDocument4 pagesDifferences Between ASTM A53 B and ASTM A106 B Steel PipeAmeer uddinNo ratings yet

- Hazra Chowdhury - CompressedDocument31 pagesHazra Chowdhury - CompressedSamrat BandyopadhyayNo ratings yet

- Introduction Application WiseDocument7 pagesIntroduction Application Wiserajveer raj singh100% (1)

- Current Transformers, Voltage Transformers, Distribution TransformersDocument7 pagesCurrent Transformers, Voltage Transformers, Distribution TransformersSharafat Ali100% (1)

- Natural Rubber HybridDocument9 pagesNatural Rubber HybridsabrinaasyifaNo ratings yet

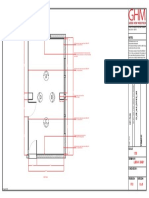

- GI - ID5 - Va.0 - OFFICE - LKB-KEY PLANDocument1 pageGI - ID5 - Va.0 - OFFICE - LKB-KEY PLANAr. Libin K BabyNo ratings yet

- Caulking - Silco SIL-BOND RTV 4500Document1 pageCaulking - Silco SIL-BOND RTV 4500Estevan huertasNo ratings yet

- USG Boral FireStop - FA - 041217 - PH PDFDocument4 pagesUSG Boral FireStop - FA - 041217 - PH PDFridwanmdNo ratings yet

- Coveral eDocument4 pagesCoveral eJonathan Cortes RangelNo ratings yet

- Bauder Protection Fleece WB300 69001310 TDS 0420 ENDocument1 pageBauder Protection Fleece WB300 69001310 TDS 0420 ENPetra KapsaliNo ratings yet

- ONPOW SWITCH LAS2F Without LEDDocument1 pageONPOW SWITCH LAS2F Without LEDcosNo ratings yet

- Aluminium Welding Pocket Guide PDF FreeDocument31 pagesAluminium Welding Pocket Guide PDF FreeMihaela NastaseNo ratings yet

- Panel Supported On Three Sides ExampleDocument4 pagesPanel Supported On Three Sides Examplesaman2580No ratings yet

- Bamboo, Timber & CaneDocument21 pagesBamboo, Timber & CaneJafar Gorikhan100% (1)

- Defects in Plaster & RemediesDocument3 pagesDefects in Plaster & RemediesGaurav DhumneNo ratings yet

- Australian Standard: Methods of Testing Concrete Method 2: Preparation of Concrete Mixes in The LaboratoryDocument3 pagesAustralian Standard: Methods of Testing Concrete Method 2: Preparation of Concrete Mixes in The LaboratoryM. Gunawan BudisusilaNo ratings yet

- Concrete Mix DesignDocument53 pagesConcrete Mix DesignAjayNo ratings yet

- Durakrit: Waterproof Breathable Cementitious Composite/Acrylic PolymerDocument1 pageDurakrit: Waterproof Breathable Cementitious Composite/Acrylic PolymerrudrabirNo ratings yet

- Nextdent Crown and Bridge MFH Microfilled Composite 3-D Printing Resin PDFDocument2 pagesNextdent Crown and Bridge MFH Microfilled Composite 3-D Printing Resin PDFDavid CNo ratings yet

- WD 01 Indicator Detector For Hidden Wiring ManualDocument9 pagesWD 01 Indicator Detector For Hidden Wiring ManualTuan NguyenNo ratings yet

- Product Data Sheet: USG Boral SHEETROCK® Standard PlasterboardDocument2 pagesProduct Data Sheet: USG Boral SHEETROCK® Standard Plasterboardkaval chhabraNo ratings yet

- Lift Core at BaddaDocument2 pagesLift Core at BaddaMasud AbidNo ratings yet

- Sikadur 752 Pds enDocument3 pagesSikadur 752 Pds entitieNo ratings yet

- Tejavathbhavsingh EEN208 Lab5Document29 pagesTejavathbhavsingh EEN208 Lab5suriya rsNo ratings yet

- Installation Guidelines For ITW Insulation Systems Metal Jacketing Used On Insulated PipeDocument22 pagesInstallation Guidelines For ITW Insulation Systems Metal Jacketing Used On Insulated Pipeabdelkader benabdallahNo ratings yet

- SINOXX 4435 Steel: Designation by StandardsDocument2 pagesSINOXX 4435 Steel: Designation by StandardsMohammad MaroufkhaniNo ratings yet