Professional Documents

Culture Documents

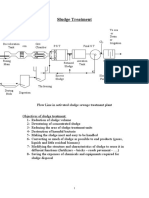

Flow Line in Primary and Secondary Wastewater Treatment

Flow Line in Primary and Secondary Wastewater Treatment

Uploaded by

مصطفى جاسم0 ratings0% found this document useful (0 votes)

24 views13 pagesThis document summarizes information about sludge treatment in wastewater treatment plants. It describes the different types of sludge produced from primary and secondary treatment. It outlines the purposes of sludge treatment, which include reducing organic matter and pathogens, decreasing water content, and producing biogas. The final products of treatment are stabilized solids that can be used as fertilizer, supernatant that needs to be returned to primary treatment, and biogas. Key units in sludge treatment are thickening to reduce volume, anaerobic digestion to reduce volume and organic matter, and drying beds to remove water for reuse of sludge. Design criteria are provided for thickening, digestion, and drying bed operations.

Original Description:

ز

Original Title

Sludge+Treatment

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes information about sludge treatment in wastewater treatment plants. It describes the different types of sludge produced from primary and secondary treatment. It outlines the purposes of sludge treatment, which include reducing organic matter and pathogens, decreasing water content, and producing biogas. The final products of treatment are stabilized solids that can be used as fertilizer, supernatant that needs to be returned to primary treatment, and biogas. Key units in sludge treatment are thickening to reduce volume, anaerobic digestion to reduce volume and organic matter, and drying beds to remove water for reuse of sludge. Design criteria are provided for thickening, digestion, and drying bed operations.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

0 ratings0% found this document useful (0 votes)

24 views13 pagesFlow Line in Primary and Secondary Wastewater Treatment

Flow Line in Primary and Secondary Wastewater Treatment

Uploaded by

مصطفى جاسمThis document summarizes information about sludge treatment in wastewater treatment plants. It describes the different types of sludge produced from primary and secondary treatment. It outlines the purposes of sludge treatment, which include reducing organic matter and pathogens, decreasing water content, and producing biogas. The final products of treatment are stabilized solids that can be used as fertilizer, supernatant that needs to be returned to primary treatment, and biogas. Key units in sludge treatment are thickening to reduce volume, anaerobic digestion to reduce volume and organic matter, and drying beds to remove water for reuse of sludge. Design criteria are provided for thickening, digestion, and drying bed operations.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 13

Sludge treatment

Sources of sludge

Flow line in primary and secondary wastewater treatment

P.S.T F.S.T

Sludge Non oxidized Oxidized

type

Quantity Depends on: Depends on:

Qd, withdrawal time Qd+QR, withdrawal

(min twice a day) time (min twice a day)

in case of H.R.T.F

and a part of it return

before A.T

Description Large particles which Small particles

collected after produced from the

sedimentation under previous biological

its own weight treatment unit

Easy to treat Difficult to treat

Purpose of sludge treatment:

1- Treatment the organic matter in sludge to avoid

undesirable release of gasses.

2- Destroy the pathogenic bacteria to dispose it safely.

3- Decrease the water content to decrease the area needed

for drying beds.

4- To be able to use it as a fertilizer.

5- Decrease the volume of sludge.

6- save the cost of chemicals used to prepare the sludge for

disposal by decreasing the sludge volume and

dewatering facilities.

7- Producing bio gas used as a source of energy.

The final products of sludge treatment:

1- Stable solid matter which can be dried and used as

fertilizer.

2- Supernatant which contain colloidal solids of high

concentration (500 – 1000 P.P.M).

It is very contaminated and should be return before the

P.S.T.

3- Gasses produced from sludge treatment

60 – 70 % methane, 20 – 30 % carbon dioxide, hydrogen

sulphade and ammonia. Which can be used as a source of

energy for the operation of the digester and other unite of

wastewater treatment plant.

Sludge treatment

Thickening

Digestion

Burying Burning Drying Composting

To reuse Soil conditioner

Thickener:

Purpose:

Increase solid concentration in sludge and decrease the

volume by 20 – 40 %

Design criteria:

1- T = 16 - 36 hr

2- d = 2.5 - 3.5 m

3- Ф ≤ 35 m

4- Total solid = 49 - 59 kg/m²/d

5- S.L.R. = 24 - 30 m³/m²/d

6- V = Qs xT

Gravity thickener

Digester:

Purpose:

1- Decrease the sludge volume to ½ - 1/3 Vs

2- Removal of most of organic matters

3- Removal of harmful bacteria

4- Improve sludge quality for usages

Design criteria:

1- T = 30 ~ 45 days … at temperature = 30 ~ 37 degree

Or T = 10 ~ 20 days … at temperature = 45 ~ 50 degree

2- Ф not > 35 m

3- d = (1/2 ~ 2/3) Ф

4- Out let sludge = 1/3 inlet sludge

5- Volume =( ( Qeff + Qinf ) / 2 ) x time

Anaerobic digester

Drying beds

Purpose:

Removal of all water content in the sludge facilitate its

reuse.

Design criteria:

1- Gravel layer thickness 30 cm.

2- Sand layer thickness 25 cm.

3- Sludge layer thickness 10 cm, and another two layers

are allowed to be added after 5 – 7 days each the last layer

should be covered by sand to avoid breeding flies.

4- drying period 5 – 7 days.

5- Area of bed 5x5m – 20x20m

Drying beds

You might also like

- VCE Task 02 Ankit ChoudharyDocument6 pagesVCE Task 02 Ankit ChoudharyAnkit JaiswalNo ratings yet

- Objectives: Chapter 4 Sludge Treatment and DisposalDocument37 pagesObjectives: Chapter 4 Sludge Treatment and Disposalashe zinabNo ratings yet

- Data Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)Document3 pagesData Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)André HeunisNo ratings yet

- Chapter 6 - 24 Oct 17Document74 pagesChapter 6 - 24 Oct 17Jiana NasirNo ratings yet

- ENV H 440/ENV H 541: Wastewater Treatment Processes (I)Document53 pagesENV H 440/ENV H 541: Wastewater Treatment Processes (I)sacchingupta19No ratings yet

- Tertiary and Sludge TreatmentDocument39 pagesTertiary and Sludge TreatmentmochuzNo ratings yet

- Wastewater Treatment Plant Options and Design CriteriaDocument14 pagesWastewater Treatment Plant Options and Design Criteriaahmed elbazNo ratings yet

- Water TreatmentDocument16 pagesWater TreatmentTamoghna BhattacharjeeNo ratings yet

- Week 9-CHEM4015-CIVE4140-2023-2024Document44 pagesWeek 9-CHEM4015-CIVE4140-2023-2024Nitin RautNo ratings yet

- Sewage Treatment PlantDocument34 pagesSewage Treatment PlantAthi MNo ratings yet

- Trickling Filters PDFDocument16 pagesTrickling Filters PDFJohnclaude ChamandiNo ratings yet

- CHAPTER 2 - Wastewater Treatment 2Document145 pagesCHAPTER 2 - Wastewater Treatment 2PMNo ratings yet

- XXXXXXXXX Cocoa Plant - 200lpdDocument5 pagesXXXXXXXXX Cocoa Plant - 200lpdReneesh KcNo ratings yet

- Waste Water EngineeringDocument12 pagesWaste Water Engineeringsomeshshinde8855No ratings yet

- Wastewater TreatmentDocument27 pagesWastewater Treatmentnayerashoman97No ratings yet

- Sludge Treatment and DisposalDocument4 pagesSludge Treatment and DisposalOla MustafaNo ratings yet

- Evs Unit-2&3Document17 pagesEvs Unit-2&3Jeeva JeevaNo ratings yet

- Domestic Waste and Waste TreatmentDocument42 pagesDomestic Waste and Waste TreatmenterhanzorerNo ratings yet

- Low Cost Pond Water TreatmentDocument16 pagesLow Cost Pond Water TreatmentAlaukik 543No ratings yet

- WaterDocument20 pagesWaterrachita pandeyNo ratings yet

- Wastewater Treatment Processes: (Sep 27 and 28, 2016) by Dr. Arun KumarDocument33 pagesWastewater Treatment Processes: (Sep 27 and 28, 2016) by Dr. Arun Kumarashraf refaatNo ratings yet

- S Announcement 15750Document4 pagesS Announcement 15750Sarah SanchezNo ratings yet

- Sludge Treatment: To Sea or Drain or IrrigationDocument9 pagesSludge Treatment: To Sea or Drain or IrrigationEduard cadavidNo ratings yet

- Sewage Treatment PlantDocument33 pagesSewage Treatment PlantTanish Bhansali100% (1)

- Sludge TreatmentDocument4 pagesSludge TreatmentRicaMyrivilleArellagaNo ratings yet

- Water Treatment Planet.Document6 pagesWater Treatment Planet.badr zakherNo ratings yet

- Case 01Document19 pagesCase 01Rushanth ChandraboseNo ratings yet

- Sewage Treatment Processes: Mohit Pal JoshiDocument44 pagesSewage Treatment Processes: Mohit Pal JoshiArrik KhannaNo ratings yet

- Water Technology Lecture 11 Sludge TreatmentDocument46 pagesWater Technology Lecture 11 Sludge TreatmentDeep SinojiyaNo ratings yet

- Sewage Treatment Technologies Nitish RedicalDocument60 pagesSewage Treatment Technologies Nitish RedicalDhaval GadhiaNo ratings yet

- Management of Food Waste NotesDocument68 pagesManagement of Food Waste NotesAbishek. KNo ratings yet

- 6 - Sludge treatment-NSJDocument71 pages6 - Sludge treatment-NSJZaimastura IbrahimNo ratings yet

- Banglore STP Flow ChartDocument8 pagesBanglore STP Flow Chartrajesh kandimalla100% (1)

- Attached Growth Biological WW Treatment SystemsDocument33 pagesAttached Growth Biological WW Treatment Systemskiran100% (1)

- Rubbish Treatment PlantDocument7 pagesRubbish Treatment PlantZharel AhmadNo ratings yet

- WWTP Mardan 1st PhaseDocument41 pagesWWTP Mardan 1st Phasemohammad armaghan100% (1)

- Astewater Reatment Lant DesignDocument2 pagesAstewater Reatment Lant Designas3ateNo ratings yet

- SEAA2922 Wastewater Engineering: Sludge Treatment and DisposalDocument28 pagesSEAA2922 Wastewater Engineering: Sludge Treatment and DisposalTzipporahNo ratings yet

- Unit III Wastewater Characteristics Primary Treatment 2017 by RBDocument55 pagesUnit III Wastewater Characteristics Primary Treatment 2017 by RBAnisha NotnaniNo ratings yet

- Sewage Treatment PlantDocument9 pagesSewage Treatment Plantabhi vermaNo ratings yet

- WKS R 10Document38 pagesWKS R 10raushanm8434No ratings yet

- A Portion of The Activated Sludge, From The Secondary Clarifier Is Returned To Mix With The Effluents of Primary Clarifier.Document21 pagesA Portion of The Activated Sludge, From The Secondary Clarifier Is Returned To Mix With The Effluents of Primary Clarifier.Náģå Rájú ÇhïmąţäNo ratings yet

- 7 Wastewater Treatment Systems Week 7Document41 pages7 Wastewater Treatment Systems Week 7Divyashini MohanNo ratings yet

- Wjaec 1 1 2 2012Document7 pagesWjaec 1 1 2 2012Mahmudul HasanNo ratings yet

- Solid Waste Management: BY Adam.SDocument53 pagesSolid Waste Management: BY Adam.SJoelNo ratings yet

- Sludge DigestionDocument13 pagesSludge Digestion1911O27 Prathikshaa KNo ratings yet

- Waste Water TreatmentDocument4 pagesWaste Water TreatmentIbrar ZahidNo ratings yet

- PCT Pollution Control Technology (M REHAN TAHIR) - Waste Water TreatmentDocument71 pagesPCT Pollution Control Technology (M REHAN TAHIR) - Waste Water Treatmentrehan263No ratings yet

- Solid Waste SlideDocument47 pagesSolid Waste SlideikhwanstorageNo ratings yet

- ENCV4WE - June - 2011Document11 pagesENCV4WE - June - 2011Francine NaickerNo ratings yet

- SSDDDocument38 pagesSSDDmseed9092No ratings yet

- Trickling FiltersDocument16 pagesTrickling FiltersGunnar AgarwalNo ratings yet

- Activated Charcoal - MSCDocument17 pagesActivated Charcoal - MSCnayaksanju16No ratings yet

- Waste Water TreatmentDocument44 pagesWaste Water TreatmentSangeethika Madubashini T. Hettige100% (1)

- Wastewater Part2 TreatmentDocument25 pagesWastewater Part2 Treatmentmee chuenNo ratings yet

- ذلجولا 22 دذعلا ، 2 ءضجلا (- 1 سارّا ،) 2015 ISSN 2520-0917Document10 pagesذلجولا 22 دذعلا ، 2 ءضجلا (- 1 سارّا ،) 2015 ISSN 2520-0917Dr.Mohanad M-RidhaNo ratings yet

- Solid Waste ManagementDocument24 pagesSolid Waste ManagementAhmad Al-GhamdiNo ratings yet

- Biogas TechnologyDocument101 pagesBiogas TechnologyRanjan Mano100% (1)

- 15 IJAEMS-APR-2017-22-Natural Adsorbents For Agricultural Waste Water TreatmentDocument3 pages15 IJAEMS-APR-2017-22-Natural Adsorbents For Agricultural Waste Water TreatmentAngelo De La RamaNo ratings yet

- Pollution of Lakes and Rivers: A Paleoenvironmental PerspectiveFrom EverandPollution of Lakes and Rivers: A Paleoenvironmental PerspectiveNo ratings yet

- Concrete Design: Four StagesDocument57 pagesConcrete Design: Four Stagesمصطفى جاسمNo ratings yet

- 607683147Document85 pages607683147مصطفى جاسمNo ratings yet

- 2 5454410575301837119Document121 pages2 5454410575301837119مصطفى جاسمNo ratings yet

- Traffic 4 TrafficFlowFundamentalsDocument58 pagesTraffic 4 TrafficFlowFundamentalsمصطفى جاسمNo ratings yet

- Open Channel Flow: Dr. Tariq Hussein Irrigation and Drainage Engineering 3 YearDocument52 pagesOpen Channel Flow: Dr. Tariq Hussein Irrigation and Drainage Engineering 3 Yearمصطفى جاسمNo ratings yet

- Water Requirement of Crops Study Notes For Civil Engineering PDFDocument15 pagesWater Requirement of Crops Study Notes For Civil Engineering PDFمصطفى جاسمNo ratings yet

- Basics of Indoor GardeningDocument9 pagesBasics of Indoor Gardeningمصطفى جاسمNo ratings yet

- Trickling FilterDocument19 pagesTrickling Filterمصطفى جاسمNo ratings yet

- Shear, Axial Force and Bending Moment Diagrams of BeamsDocument10 pagesShear, Axial Force and Bending Moment Diagrams of Beamsمصطفى جاسمNo ratings yet

- 5072E Package Type STP 25 KLD Mr. Vikas (Navsari)Document20 pages5072E Package Type STP 25 KLD Mr. Vikas (Navsari)Nakclean Water SolutionsNo ratings yet

- Power Plant - DRAUGHT SYSTEMDocument25 pagesPower Plant - DRAUGHT SYSTEMscorpion60% (1)

- Small Scale Water TreatmentDocument1 pageSmall Scale Water TreatmentDayliffNo ratings yet

- Is 01Document4 pagesIs 01Hany HanfyNo ratings yet

- Cessna®: Service/Parts ManualDocument7 pagesCessna®: Service/Parts ManualFranco PugaNo ratings yet

- HMTDocument2 pagesHMTBragadish BragsNo ratings yet

- Fluid DynamicsDocument14 pagesFluid DynamicsBabylyn AustriaNo ratings yet

- Parametric Studies of An Automotive Air Conditioning SystemDocument4 pagesParametric Studies of An Automotive Air Conditioning SystemIDESNo ratings yet

- Technical Specification HP200Document1 pageTechnical Specification HP200MSEGLLCNo ratings yet

- VENTILATIONDocument51 pagesVENTILATIONhudhaNo ratings yet

- EPA Water Treatment Manual PreliminaryDocument111 pagesEPA Water Treatment Manual Preliminarybob_rocksNo ratings yet

- Reynolds Stress ModelDocument8 pagesReynolds Stress ModelEddieqNo ratings yet

- Iwwwfb34 29Document4 pagesIwwwfb34 29Fahmy ArdhiansyahNo ratings yet

- P39 Standard Gas Regulators: Applications SpecificationsDocument4 pagesP39 Standard Gas Regulators: Applications SpecificationsAlexander Charry GiraldoNo ratings yet

- Yenen By-Pass Valve BrochureDocument2 pagesYenen By-Pass Valve Brochureruhul01No ratings yet

- Experimental Analysis of LPG Refrigeration SystemDocument4 pagesExperimental Analysis of LPG Refrigeration SystemBharath HariNo ratings yet

- Factors Affecting EquilibriumDocument23 pagesFactors Affecting EquilibriumDavid AntonitoNo ratings yet

- CGB 75 CGB 100 Montage Und BedienungsanleitungDocument56 pagesCGB 75 CGB 100 Montage Und BedienungsanleitungAna-Maria DamianNo ratings yet

- Hydrology New Ocr FormatDocument33 pagesHydrology New Ocr FormatIES-GATEWizNo ratings yet

- C-Series Vertical (CSV) Water-Cooled Self-Contained Units, B Generation Engineering GuideDocument54 pagesC-Series Vertical (CSV) Water-Cooled Self-Contained Units, B Generation Engineering Guidenalin singhalNo ratings yet

- Safety Relief Valves For Thermal, Hydraulic and Domestic Water SystemsDocument8 pagesSafety Relief Valves For Thermal, Hydraulic and Domestic Water SystemsNenad VlajkovicNo ratings yet

- Ashrae ChartDocument2 pagesAshrae Chartsophia arellanoNo ratings yet

- Serie HPRDocument4 pagesSerie HPREstebanRojasKrustofskyNo ratings yet

- Green WaterTreatment Solution - PresentationDocument17 pagesGreen WaterTreatment Solution - Presentationsrekumar kumarNo ratings yet

- 1st Sem Timetable CPE 21-22Document5 pages1st Sem Timetable CPE 21-22EmmanuelNo ratings yet

- Drill - Pipe - GradesDocument1 pageDrill - Pipe - GradesQuality controllerNo ratings yet

- Expansion Valve Series T Alco ControlDocument9 pagesExpansion Valve Series T Alco ControlisaiasvaNo ratings yet

- Raghavendra R. Hegde, M. G. Kamath, Atul DahiyaDocument7 pagesRaghavendra R. Hegde, M. G. Kamath, Atul DahiyaarunkumardoraiNo ratings yet