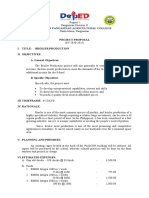

Professional Documents

Culture Documents

Preservation of Foods

Preservation of Foods

Uploaded by

madhuri0 ratings0% found this document useful (0 votes)

26 views33 pagesThe document discusses various methods for preserving foods, including temperature-based methods like chilling, freezing, and heating; controlling oxygen, moisture, and pH levels; and traditional methods like drying, salting, sugaring, pickling. It explains that the goal of preservation is to prevent spoilage by microorganisms and enzymes by manipulating factors that affect microbial growth. Various temperature-based preservation techniques and their effects are described in detail.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses various methods for preserving foods, including temperature-based methods like chilling, freezing, and heating; controlling oxygen, moisture, and pH levels; and traditional methods like drying, salting, sugaring, pickling. It explains that the goal of preservation is to prevent spoilage by microorganisms and enzymes by manipulating factors that affect microbial growth. Various temperature-based preservation techniques and their effects are described in detail.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

26 views33 pagesPreservation of Foods

Preservation of Foods

Uploaded by

madhuriThe document discusses various methods for preserving foods, including temperature-based methods like chilling, freezing, and heating; controlling oxygen, moisture, and pH levels; and traditional methods like drying, salting, sugaring, pickling. It explains that the goal of preservation is to prevent spoilage by microorganisms and enzymes by manipulating factors that affect microbial growth. Various temperature-based preservation techniques and their effects are described in detail.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 33

Preservation of Foods

Aim

• The aim of preservation is to prevent food spoilage as a

result of growth of micro-organisms and breakdown of

food by enzymes.

• Changing raw products into more stable forms that can

be stored for longer periods of time.

• Allows any food to be available any time of the year in

any area of the world.

General Principle

• The principles underlying methods of preservation used in the

past are still the same as today.

• Some of the factors affecting the growth of micro - organisms can

be manipulated in different ways to prolong the life of the food

product.

History

1782—Canning of vinegar was introduced by a Swedish chemist

1843—Sterilization by steam was first attempted by I. Winslow in Maine

1874—The first extensive use of ice in transporting meat at sea was

begun.

1880—The pasteurization of milk was begun in Germany

1955—Sorbic acid was approved for use as a food preservative.

1990—Irradiation of poultry was approved in the United States.

Temperature

Chilling or freezing the food to retard

growth of micro-organisms and inhibit

enzyme activity. Alternatively, heating the

food to destroy micro-organisms and

prevent enzyme activity.

Oxygen

Food kept in an airtight container will

deprive micro-organisms of oxygen and

prevent contamination.

Moisture

Reducing the moisture content of the food to make water, (which is

essential for growth), unavailable to micro-organisms. Alternatively,

placing food in a sugary solution will make water unavailable for the

growth of micro-organisms.

pH level

Placing food in an acidic or alkaline solution will inhibit the growth of

micro-organisms.

Food spoilage

• Ultimately, all natural foods will spoil and even those which have been

preserved in one form or another lose their color, flavor, texture, and

nutritive value.

• Based on their perish ability, foods may be classified as follow:

1. Perishable foods : Those that spoil readily like milk, fish, meat, poultry,

ripe succulent fruits, and leafy vegetables.

2. Semi-perishable foods : Those that can keep for a limited period of time

like onions, garlic, eggs, and roots crops.

3. Relatively nonperishable foods : Those that keep for almost an

unlimited period of time like rice, dried mature beans, mature corns, and

many mature nuts and dry legumes or pulses.

As soon as food is harvested or manufactured into a

product it starts to change. This is caused by two

main processes:

• autolysis – self destruction, caused by enzymes

present in the food;

• microbial spoilage – caused by the growth of

bacteria, yeasts and moulds.

Food Storage

• Primitive and tedious methods

Drying

Salting

Sugaring

Pickling

Cold

storage

• Canning

• Dehydration

Drying

Used to preserve fruit, vegetables, meats, and fish.

Mainly used in the south – warmer climate.

Causes the loss of many natural vitamins.

Salting

Used extensively for pork, beef, and fish.

Bit costly due to required high amount of salt.

Done mainly in cool weather followed by smoking.

Sugaring

Used to preserve fruits for the winter.

Jams and jellies.

Expensive because sugar was scarce commodity in

early America.

Pickling

Fermenting

Used to preserve vegetables.

Use mild salt and vinegar brine.

Increases the salt content and reduces the vitamin

content of the food.

Oldest form of food preservation.

Control of Microorganisms in Foods

1. Control by Low Temperature

Chilling

Freezing

Thawing

2. Control by High Temperature

Heat penetration and Thermal processing

Pasturization

Thermal inactivation

Control by Low Temperature

• Foods are stored at low temperature in different ways to extend

their shelf life. Manyfresh fruits and vegetables are kept at

temperatures between 10 and 20r C or lower, mainly to reduce

their metabolic rate. Microorganisms to which these products are

susceptible, namely yeasts and molds (and some bacteria), can

grow at this temper_x0002_ature. Maintaining a low relative

humidity to prevent moisture build-up on the food surface is very

important to reduce their growth. Highly perishable products are

generally stored at a low temperature, below 7ºC, often in

combination with other preservation methods.

Chilling

• This is used in retail stores where the foods are kept over ice; the

surface in contact with the ice can reach between 0 and 1r C.

Fresh fish, seafood, meats, cut fruits, vegetable salads (in bags),

different types of ready-to-eat salads (prepared at the retail store),

salad dressing (high pH, low caloric), sous vide, and some ethnic

foods (e.g., tofu) are stored by this method. The trend is

increasing. Temperature fluctuation (due to the size of the

container or melting of ice), duration of storage (fresh or several

days), and cross-contamination (raw fish, shrimp, oysters, and

ready-to-eat fish salads in an open container in the same display

case at the retail store) can cause microbiological problems,

especially from foodborne pathogens.

Freezing

• The minimum temperature used in home freezers (in the refrigerator) is –

20rC, a temperature at which most of the free water in a food remains in a

frozen state. Dry ice (–78rC) and liquid nitrogen (–196rC) can also be used

for freezing; they are used for rapid freezing (instant freezing) and not for

only freezing a food to that low temperature. Following freezing, the

temperature of the foods is maintained ca. –20 to –30rC. Depending on the

type, foods can be stored at refrigerated temperature for months or even

more than a year. Raw produce (vegetables, fruits), meat, fish, processed

products, and cooked products (ready-to-eat after thawing and warming) are

preserved by freezing. Microorganisms do not grow at –20rC in frozen foods.

Instead, microbial cells die during frozen storage. However, the survivors can

multiply in the unfrozen foods. Accidental thawing or slow thawing can

facilitate growth of survivors (spoilage and pathogenic microorganisms).

Spores can also germinate and outgrow, depending on the temperature and

time following thawing. Enzymes, released by the dead microbial cells can

reduce the acceptance quality of the food.

Thawing

a) Thaw food thoroughly before cooking. Frozen or partially frozen

food will require longer cooking time. The external surfaces of this

food could be cooked, but the inner portion might remain uncooked

and harmful bacteria within the food may not be killed.

b) Check for ice crystals in the food using your hand or a skewer. If

food is not fully thawed, continue to thaw the food until no ice

crystals are present. Test again before cooking or reheating. For

poultry, check that the joints are flexible.

c) Cook thawed meat right away and do not refreeze thawed food.

Improper handling and refreezing of food may lead to the growth of

bacteria.

d) Thaw only the amount of food you require for cooking.

Three Ways to Thaw Food Safely

a) Thawing in the Refrigerator or Chiller Room

i. Plan ahead for sufficient time and space to defrost small amounts of

food in the refrigerator. If you have limited space in your chiller,

apportion food into smaller quantities before freezing. Place the required

amount in the chiller when you need to thaw the food.

ii. Thaw food in the refrigerator or chiller room at all times until it is used or

consumed. Thawing food in the refrigerator or chiller room will keep it at

a safe temperature.

iii. Thaw raw food at the lowest shelf of the refrigerator or chiller room or

below ready-to-eat food to prevent cross-contamination. Place food on a

tray or in a container to prevent drippings from meat and poultry onto

other food.

b) Thawing in Microwave Oven

i. Place food in the microwave oven on the ‘defrost’ setting.

ii. Stir or turn food over to facilitate thawing.

iii. Cook the food immediately after thawing. Some areas of the food

may

become warm and begin to cook during the thawing process,

bringing

the food to the “Temperature Danger Zone”.

iv. Refrain from thawing large food items in the microwave.

v. Clean the microwave thoroughly after using it for thawing.

c) Thawing under Running Water or in Cold Water

i. Place food to be thawed in a clean leak-proof package or plastic bag.

Put the package in a clean container and thaw the food under running

water, or submerge the package in a container of clean tap water,

changing the water every 30 minutes as the food continues to thaw.

Do not place food directly in the sink or into container of water without

packaging it.

ii. Cook thawed food immediately.

iii. Avoid cross-contamination from water dripping off the food or

splashing onto other food, preparation surfaces and utensils.

iv. Thaw food without opening the package to prevent contamination.

v. Ensure that the sink is clean and empty before using it to thaw food

under running water. The sink should be cleaned and sanitised after

being used for thawing.

• During thawing of a frozen food (such as an uncooked

chicken), rapid thawing is desirable in order to control

microbial growth, especially growth of pathogens. If the

food is thawed slowly, the temperature on the food

surface will soon increase, thereby allowing microbial

growth, even when the inside is still frozen. Refrigerated

foods have limited shelf life.

RELATIVE HEAT RESISTANCE OF MICROORGANISMS

• In general, the heat resistance of microorganisms is

related to their optimum growth temperatures.

• Psychrophilic microorganisms are the most heat

sensitive, followed by mesophiles and thermophiles.

• The relative heat resistance of some bacteria and fungi

that cause spoilage of high-acid foods. Of the genus

Alicyclobacillus, A. acidoterrestris is one of the highly

resistant species found in some fruit juice products.

RELATIVE HEAT RESISTANCE OF MICROORGANISMS

More heat resistant Less heat resistant

Sporeforming bacteria Non-sporeformers

Thermophilic sporeformers Mesophilic sporeformers

Gram-positive bacteria Gram negatives

Cocci Non-sporeforming rods

Yeast ascospores Vegetative yeasts

Asexual spores of molds Mold mycelia

Sclerotia are the most heat resistant

and sometimes survive and cause

trouble in canned fruits.

Control by High Temperature

•Heat penetration and Thermal processing

The use of high temperatures to preserve and ensure the safety of

food is based on the effect of microbial destruction. Thermal

processing is one of the most widely used unit operations employed

in the food industry and is frequently determined as a Critical

Control Point (CCP).

The basic purpose for the thermal processing of foods is

To reduce or destroy microbial activity

To reduce or destroy enzyme activity

To produce physical or chemical changes to make the food meet

a certain quality standard.

e.g. gelatenization of starch & denaturation of proteins to produce

edible food. There are a number of types of heat

processing employed by the food industry.

There are two main temperature categories employed in thermal

processing: Pasteurization and Sterilisation.

Mild processes Blanching

Pasteurisation

More severe processes Canning

Baking

Roasting

Frying

Blanchig

• Destroy enzyme activity in fruit and vegetables

• It is not intended as a sole method of preservation, but as a

pre-treatment prior to freezing, drying and canning.

• Blanching is carried out at up to 100°C using hot water or

steam at or near atmospheric pressure.

Functions of blanching

• Reducing surface microbial contamination

• Softening vegetable tissues to facilitate filling into containers

• Removing air from intercellular spaces prior to canning

Pasteurization

• Word pasteurization is derived from the name of an eminent French scientist

Louis Pasteur (1860)

• Pasteurization came into use on a commercial scale in the dairy industry

shortly after 1880 in Germany and Denmark

“A process applied to a product with the object of

minimizing possible health hazards arising from pathogenic

microorganisms associated with milk by heat treatment,

which is consistent with minimal chemical, physical and

sensory changes in the product”

• The term pasteurization as applied Temperature Time

to market milk refers to the

process of heating every particle 63°C For 30 min (low

temperature long time LTLT)

of milk to at least 63°C for 30 min

or 72°C for 15s or to any 72°C For 15 sec (primary high

temperature-time combination temperature short time,HTST

which is equally efficient, in a method)

properly operated equipment. After 89°C For 1.0 sec

pasteurization, the milk is 90°C For 0.5 sec

immediately cooled to 5°C or 94°C For 0.1 sec

below. 100°C For 0.01 sec

The two groups of micro-organisms that survive pasteurisation

temperatures

Thermoduric: organisms that can survive

exposure to relatively high temperatures but do

not necessarily grow at these temperatures e.g.

Streptococcus and Lactobacillus.

Thermophilic: organisms that not only survive

relatively high temperatures but require high

temperatures for their growth.

Method for Pasteurizing

There are number of basic methods of pasteurization

widely used in the industry.

Batch (holding) Method

Importance of Pasteurization

To render milk safe for human consumption by destroying all the pathogenic

microorganisms.

To improve the keeping quality of milk by killing almost all spoilage organisms

(88-99%)

Limitations of Pasteurization

Diminishes the cream line or cream volume.

Pasteurized milk---- increase the renneting time.

Fails to destroy bacterial toxins

In India, pasteurization -- not necessary as milk is invariably boiled by the

consumers

You might also like

- Talk To Me in Korean - Level 1Document112 pagesTalk To Me in Korean - Level 1Dina SimamoraNo ratings yet

- Floyd's India - Keith FloydDocument192 pagesFloyd's India - Keith FloydAbhishek Sorampuri67% (3)

- Staffcafetaria Sop-Bbh 1Document7 pagesStaffcafetaria Sop-Bbh 1KumarSv100% (4)

- Meat Inspection - Module 1 & 2.Document17 pagesMeat Inspection - Module 1 & 2.Franz Thelen Lozano CariñoNo ratings yet

- Standard Operating ProcedureDocument4 pagesStandard Operating Procedurejohn carter100% (2)

- Breads & Grains LabDocument17 pagesBreads & Grains Labapi-302915920No ratings yet

- Food Processing (2017)Document49 pagesFood Processing (2017)Ciara Develos100% (1)

- Vegetable ProcessingDocument10 pagesVegetable Processingcinammon bunNo ratings yet

- Structural Design: Reinforced ConcreteDocument11 pagesStructural Design: Reinforced ConcreteSeaver LeeNo ratings yet

- Ansci ReviewerDocument32 pagesAnsci ReviewerPrince Jann Dela CruzNo ratings yet

- Food ProcessingDocument47 pagesFood ProcessingPadmanaaban Prabhu100% (1)

- Module 4 GelecDocument21 pagesModule 4 GelecRandom MusicNo ratings yet

- Guide To Quail Raising - Ag PDFDocument22 pagesGuide To Quail Raising - Ag PDFcurlycarlNo ratings yet

- Animal Production: (Swine)Document43 pagesAnimal Production: (Swine)Faith Garcia100% (1)

- E-Portfolio: Introduction To Agri-Fishery Arts 2Document10 pagesE-Portfolio: Introduction To Agri-Fishery Arts 2Jam Guinto Pitacio JavierNo ratings yet

- Glossary Food Processing TerminologyDocument9 pagesGlossary Food Processing TerminologybeymarNo ratings yet

- Philippine National Standard: Code of Hygienic Practice of MeatDocument27 pagesPhilippine National Standard: Code of Hygienic Practice of MeatOliver TalipNo ratings yet

- Final PPT For Feasib Blue TernateDocument15 pagesFinal PPT For Feasib Blue Ternatechariza alapNo ratings yet

- FTec 150 - Intro To Meat ProcessingDocument51 pagesFTec 150 - Intro To Meat ProcessingJessa Silvano ArgallonNo ratings yet

- CHAPTER 9 RevisedDocument25 pagesCHAPTER 9 RevisedAlliah MendozaNo ratings yet

- Module 2 External Anatomy of Farm AnimalsDocument11 pagesModule 2 External Anatomy of Farm AnimalsJohn Edison BrilloNo ratings yet

- Y3 - Module 6 - Legalize A BusinessDocument10 pagesY3 - Module 6 - Legalize A BusinessMaria Lyn Victoria AbriolNo ratings yet

- Sample Proposal On Biodiversity Conservation To Promote Sustainable LivelihoodsDocument6 pagesSample Proposal On Biodiversity Conservation To Promote Sustainable LivelihoodsDenis Felix DrotiNo ratings yet

- Project Proposal For Broiler ProductionDocument2 pagesProject Proposal For Broiler ProductionAlejandro C. DizoNo ratings yet

- Meat FabricationDocument20 pagesMeat FabricationChrist Almen Lumen TacubanzaNo ratings yet

- Lecture 8. Restraining of Farm AnimalsDocument30 pagesLecture 8. Restraining of Farm AnimalsDr Jay bikram shah100% (1)

- Fish PreservationDocument2 pagesFish PreservationMha RizNo ratings yet

- Feasibility Study On Native ChickenDocument36 pagesFeasibility Study On Native ChickenTunisia DilangalenNo ratings yet

- Pichi Pichi RecDocument4 pagesPichi Pichi RecPaul Michael Andrade Vizcarra100% (1)

- Fish ProcessingDocument21 pagesFish Processingpardeep100% (2)

- Fundamentals Fundamentals Fundamentals of Crop Science of Crop Science of Crop ScienceDocument13 pagesFundamentals Fundamentals Fundamentals of Crop Science of Crop Science of Crop ScienceAlthea Dorado100% (1)

- Chapter 6: The Network DiagramDocument6 pagesChapter 6: The Network DiagramMichael Adrian MagbanuaNo ratings yet

- Thesis About Piggery LayoutDocument3 pagesThesis About Piggery LayoutMar Lorenz Robles LingaoNo ratings yet

- Module 6-Slaughtering ProcedureDocument7 pagesModule 6-Slaughtering ProcedureVincent Felix A. HernandezNo ratings yet

- Ansci Lab 3Document4 pagesAnsci Lab 3Aleah TyNo ratings yet

- Fish Processing: By: Laureno, Divina Villaver Dela Cruz, Cedrick P. Estor, Vanessa RDocument24 pagesFish Processing: By: Laureno, Divina Villaver Dela Cruz, Cedrick P. Estor, Vanessa REstor, Vanessa R.No ratings yet

- MSQ-06 - Master BudgetDocument12 pagesMSQ-06 - Master BudgetfrancklineNo ratings yet

- Fisheries NarrativeDocument7 pagesFisheries NarrativeKenny KenNo ratings yet

- Advantages of Duck FarmingDocument10 pagesAdvantages of Duck FarmingMartin S. NoblezadaNo ratings yet

- Sun-Dried Sweet Potato Leaf As Health-Giving Cookie FINAL JOURNALDocument5 pagesSun-Dried Sweet Potato Leaf As Health-Giving Cookie FINAL JOURNALHana Tricia PiamonteNo ratings yet

- Food PreservationDocument5 pagesFood PreservationUmarani Mohanasundaram0% (1)

- Topic 2-FUNDAMENTALS OF FOOD TECHNOLOGYDocument31 pagesTopic 2-FUNDAMENTALS OF FOOD TECHNOLOGYRosalinda LaranNo ratings yet

- Gr. 10 - Cereals and Pasta CookeryDocument39 pagesGr. 10 - Cereals and Pasta CookeryJulie Ann Cortez100% (2)

- Module 4 - Rules and Regulations Governing Meat Inspection in The PhilippinesDocument11 pagesModule 4 - Rules and Regulations Governing Meat Inspection in The PhilippinesVincent Felix A. HernandezNo ratings yet

- Food PackagingDocument18 pagesFood Packagingrhea agulay50% (2)

- Agricultural MechanizationDocument3 pagesAgricultural MechanizationSAMIA AKHTARNo ratings yet

- Philippine National Standard: Code of Hygienic Practice For MeatDocument26 pagesPhilippine National Standard: Code of Hygienic Practice For MeatSofia Kamille TagleNo ratings yet

- Horticulture 22Document19 pagesHorticulture 22Jodelyn JumadasNo ratings yet

- Food AdditivesDocument5 pagesFood AdditivesChu Wai Seng100% (1)

- Management Practices On PoultryDocument31 pagesManagement Practices On PoultrySeraphinaNo ratings yet

- FS IntroductionDocument5 pagesFS IntroductionrustyNo ratings yet

- Market Forms of Fish TLE 8Document4 pagesMarket Forms of Fish TLE 8Jessie EballaNo ratings yet

- Minimum Requirements For Conversion To Organic Agriculture: What Will You LearnDocument9 pagesMinimum Requirements For Conversion To Organic Agriculture: What Will You LearnRoma QuiochoNo ratings yet

- Agriculture and The SocietyDocument11 pagesAgriculture and The SocietyMark Iandy LumamigNo ratings yet

- Cropprot1 - Botanical Control Approach of Golden Apple SnailDocument13 pagesCropprot1 - Botanical Control Approach of Golden Apple SnailSeph PensotesNo ratings yet

- Use Tools, Equipment, and Paraphernalia: Lesson 1Document11 pagesUse Tools, Equipment, and Paraphernalia: Lesson 1norshidaNo ratings yet

- 2nd Quarter Exam TLE 10Document4 pages2nd Quarter Exam TLE 10Fely MaryNo ratings yet

- Research Rambutan SeedDocument18 pagesResearch Rambutan SeedJoyce Ivy TalaocNo ratings yet

- Spoilage of Fish ProductsDocument12 pagesSpoilage of Fish ProductsAgrobacterium TumefaciensNo ratings yet

- Yama ASDocument10 pagesYama ASJosh SchultzNo ratings yet

- Post Harvest Handling CropsDocument58 pagesPost Harvest Handling CropsRollyDumaliBito-onNo ratings yet

- Agric-114-Chapter Ii: Rules and Regulations Governing Meat Inspection in The PhilippinesDocument16 pagesAgric-114-Chapter Ii: Rules and Regulations Governing Meat Inspection in The PhilippinesAgrikultura 2600No ratings yet

- Food PreservationDocument32 pagesFood PreservationAnonymous PZnwzqMwNo ratings yet

- GCSE - Food Technology (AQA) : Food Safety and HygieneDocument17 pagesGCSE - Food Technology (AQA) : Food Safety and HygieneLy LyNo ratings yet

- Frozen and Refrigerated Food Saftey AspectsDocument45 pagesFrozen and Refrigerated Food Saftey AspectsAkshitha NSNo ratings yet

- Modul Pembelajaran-1-1Document37 pagesModul Pembelajaran-1-1Fitri AniNo ratings yet

- Maggi Removed MergedDocument81 pagesMaggi Removed MergedgoregaonapmlNo ratings yet

- Careerreadiness A2 Business Worksheet 571640Document2 pagesCareerreadiness A2 Business Worksheet 571640c_a_tabetNo ratings yet

- EP19 - Go Go Squid 2 - DT - Appledog's Time (WeTV)Document58 pagesEP19 - Go Go Squid 2 - DT - Appledog's Time (WeTV)'Dita PradanagaraNo ratings yet

- Roasting Machine Designs: Classic DrumDocument6 pagesRoasting Machine Designs: Classic Drumgusyahri001No ratings yet

- 1 Week 3Document23 pages1 Week 3Jenny BelarminoNo ratings yet

- Uyen 29Document8 pagesUyen 29trần phương uyênNo ratings yet

- SITHKOP010 CLARISSA Assessment TasksDocument28 pagesSITHKOP010 CLARISSA Assessment Tasksannykajcs011021No ratings yet

- LP MarinadesDocument10 pagesLP MarinadesMiriam Mangaoang DoñosNo ratings yet

- Baked Mac and Cheese With Bacon - Southern LivingDocument4 pagesBaked Mac and Cheese With Bacon - Southern LivingDebNo ratings yet

- Winter Soup Recipes 8 Copycat Simple Soup Recipes PDFDocument22 pagesWinter Soup Recipes 8 Copycat Simple Soup Recipes PDFwonderminaNo ratings yet

- Soal Bing Us - 13 UtamaDocument11 pagesSoal Bing Us - 13 UtamaRaffi NurhayadiNo ratings yet

- Final Exam Basic 2 FINAAALDocument5 pagesFinal Exam Basic 2 FINAAALJosé Carlos Rodriguez ZegarraNo ratings yet

- Describing Food British English StudentDocument3 pagesDescribing Food British English Studentteacher.mireyaNo ratings yet

- Program Sederhana VB NetDocument9 pagesProgram Sederhana VB NetparkcampNo ratings yet

- Broccoli Pasta - Chelsea's Messy ApronDocument2 pagesBroccoli Pasta - Chelsea's Messy ApronJim TsikasNo ratings yet

- Chemical Composition and Physicochemical Properties of Meatballs PreparedDocument8 pagesChemical Composition and Physicochemical Properties of Meatballs PreparedJinhwa KimNo ratings yet

- 2,000-Year-Old Butter: Grammar in The NewsDocument4 pages2,000-Year-Old Butter: Grammar in The NewsAbduljabar ALAmeriNo ratings yet

- Vocabulary Bank A1 Answer KeyDocument12 pagesVocabulary Bank A1 Answer KeyVirginia PazosNo ratings yet

- DIY Hair WaxDocument3 pagesDIY Hair WaxMariana PinheiroNo ratings yet

- Love To Make With Woman 39 S Weekly - November 2015Document76 pagesLove To Make With Woman 39 S Weekly - November 2015Xian-liNo ratings yet

- Oatmeal Pancakes: Recipe ServesDocument2 pagesOatmeal Pancakes: Recipe Servesblah blahNo ratings yet

- SD - REQ - LE SINQUET PropsDocument1 pageSD - REQ - LE SINQUET PropscitipaoNo ratings yet

- Sample Diet Chart For Weight LossDocument4 pagesSample Diet Chart For Weight Lossurfa masudNo ratings yet

- GROUP 2, TANGY-KIMCHI BUSINESS-PLAN FinalDocument20 pagesGROUP 2, TANGY-KIMCHI BUSINESS-PLAN FinalIan Rom TorresNo ratings yet