Professional Documents

Culture Documents

CDTS Presentation Latest

CDTS Presentation Latest

Uploaded by

kr_abhijeet72356587Copyright:

Available Formats

You might also like

- MCM Diagrama Electronico Detroit Diesel Serie 60 Ddec VIDocument1 pageMCM Diagrama Electronico Detroit Diesel Serie 60 Ddec VIJohn MkCito KI91% (70)

- Diagrama de Motor Ddec ViDocument1 pageDiagrama de Motor Ddec ViJohn MkCito KI91% (32)

- Detroit Diesel Engines Fault CodesDocument6 pagesDetroit Diesel Engines Fault CodesAmilcar Rodas100% (2)

- MCM Wiring Diagram: DDC ResponsibilityDocument1 pageMCM Wiring Diagram: DDC ResponsibilityRicardo BolañosNo ratings yet

- TraneDocument33 pagesTranejake1000100% (1)

- Engine Base & BlockDocument47 pagesEngine Base & Blockkr_abhijeet7235658750% (2)

- ICF Bogie 10.3.08Document101 pagesICF Bogie 10.3.08kr_abhijeet72356587100% (6)

- Service Manual: Affinity Horizontalaxis Washer 6000 & 7000 SeriesDocument100 pagesService Manual: Affinity Horizontalaxis Washer 6000 & 7000 SeriesravasamaNo ratings yet

- Invoice # 1Document2 pagesInvoice # 1Fadi YasinNo ratings yet

- Whirlpool Awm 6121Document18 pagesWhirlpool Awm 6121Ненад Митровић100% (1)

- C7Document72 pagesC7victorhernandezrega94% (35)

- End Matriz y AliviosDocument270 pagesEnd Matriz y AliviosJavier Jaya CamachoNo ratings yet

- 6ALBR5233JQODocument23 pages6ALBR5233JQOpinticaniulian9042No ratings yet

- Process Study SheetDocument14 pagesProcess Study SheetBalachandar SathananthanNo ratings yet

- Whirlpool AWM 5080 ManualDocument21 pagesWhirlpool AWM 5080 ManualCharles ThompsonNo ratings yet

- SCMCS #5 CubicleDocument9 pagesSCMCS #5 CubicleErwin SambasNo ratings yet

- D7 Parts Book 9853619020Document897 pagesD7 Parts Book 9853619020wawa100% (2)

- CL - ClutchDocument22 pagesCL - ClutchIlarion CiobanuNo ratings yet

- 2 Egi System: 2-1 Preparation of Instruments 2-2 Outline of SystemDocument126 pages2 Egi System: 2-1 Preparation of Instruments 2-2 Outline of Systemremont78No ratings yet

- Dom InpDocument4 pagesDom InpcrackenhNo ratings yet

- Isolation List GTDocument16 pagesIsolation List GTMaziatol Jasnim Abdul SaariNo ratings yet

- LavDocument93 pagesLavPamela RodriguezNo ratings yet

- Spare Parts Catalogue Catalogue de Pièces de Rechange: 471 1544-67 Doc. No. EDITION 46.2000Document89 pagesSpare Parts Catalogue Catalogue de Pièces de Rechange: 471 1544-67 Doc. No. EDITION 46.2000carlos lopesNo ratings yet

- Whirlpool ManualDocument14 pagesWhirlpool ManualRene Antonio Delgado SobalvarroNo ratings yet

- GC9520Document12 pagesGC9520Aleksander AlexanderNo ratings yet

- Hydraulic Power Packs: Hydraulic Pump Hydraulic Valve Hydraulic AccessoryDocument6 pagesHydraulic Power Packs: Hydraulic Pump Hydraulic Valve Hydraulic Accessoryrlnjay2003No ratings yet

- V SeguridadDocument8 pagesV SeguridadARJONA_JGNo ratings yet

- Awm 8121Document22 pagesAwm 8121borlixNo ratings yet

- Service Manual: Dishwasher Adp 542 WHDocument12 pagesService Manual: Dishwasher Adp 542 WHninoslavnNo ratings yet

- BJ 63Document131 pagesBJ 63anuarazam100% (1)

- SCMCS #3 CubicleDocument9 pagesSCMCS #3 CubicleErwin SambasNo ratings yet

- SideWinder 42 62 82 CHMCL PMP IOMDocument4 pagesSideWinder 42 62 82 CHMCL PMP IOMSH McNo ratings yet

- Electrical Materials List For ERPDocument341 pagesElectrical Materials List For ERPDhilip AnNo ratings yet

- 31-9254 GE-Top-Load-WasherDocument83 pages31-9254 GE-Top-Load-WasherAngel RosadoNo ratings yet

- DPT-2500N Service ManualDocument16 pagesDPT-2500N Service ManualJuan Gonzales100% (1)

- Emission Control SystemDocument21 pagesEmission Control SystemdanyNo ratings yet

- System Design: Pressure Loss in Fittings and ValvesDocument3 pagesSystem Design: Pressure Loss in Fittings and ValvesGuillaume BoyerNo ratings yet

- Service Manual: Steam Generator GC9245Document12 pagesService Manual: Steam Generator GC9245Aleksander AlexanderNo ratings yet

- Psme Sa Short Course CHWDocument3 pagesPsme Sa Short Course CHWArt JamesNo ratings yet

- Service Manual: Dishwasher GSF 4761 TW-WSDocument27 pagesService Manual: Dishwasher GSF 4761 TW-WSOfer FolkmarNo ratings yet

- 1614 6423 00Document2 pages1614 6423 00UbanAirlanggaNo ratings yet

- SideWinder 40 60 80 CHMCL PMP BrchreDocument4 pagesSideWinder 40 60 80 CHMCL PMP BrchreSH McNo ratings yet

- DailyDocument16 pagesDailyajiesoko2No ratings yet

- Cameron Hyd Drilling ChokeDocument2 pagesCameron Hyd Drilling ChokeGonzalo Guzman JaimesNo ratings yet

- AWM8143Document22 pagesAWM8143pinticaniulian9042100% (1)

- Whirlpool Service Manual Dishwasher ADP9521WHMDocument28 pagesWhirlpool Service Manual Dishwasher ADP9521WHMcarlammartins100% (1)

- Replacementparts Listwith Lubricationguide: 7.1 MechanicalpartsDocument8 pagesReplacementparts Listwith Lubricationguide: 7.1 MechanicalpartsanthonypardoNo ratings yet

- Whirlpool Awm 8125 (ET)Document17 pagesWhirlpool Awm 8125 (ET)winamax69No ratings yet

- Electrical Panel Load Calculation (22.8.12)Document28 pagesElectrical Panel Load Calculation (22.8.12)Erfan AhmedNo ratings yet

- Boomer L2D PDFDocument84 pagesBoomer L2D PDFUmaprasad Chatterjee100% (1)

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersFrom EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersRating: 4.5 out of 5 stars4.5/5 (2)

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Analytical Troubleshooting of Process Machinery and Pressure Vessels: Including Real-World Case StudiesFrom EverandAnalytical Troubleshooting of Process Machinery and Pressure Vessels: Including Real-World Case StudiesRating: 3 out of 5 stars3/5 (1)

- Maintain and Improve Your Powerboat: 100 Ways to Make Your Boat BetterFrom EverandMaintain and Improve Your Powerboat: 100 Ways to Make Your Boat BetterNo ratings yet

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- Advanced Thermoforming: Methods, Machines and Materials, Applications and AutomationFrom EverandAdvanced Thermoforming: Methods, Machines and Materials, Applications and AutomationRating: 5 out of 5 stars5/5 (1)

- 75th Conference on Glass Problems: A Collection of Papers Presented at the 75th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 3-6, 2014From Everand75th Conference on Glass Problems: A Collection of Papers Presented at the 75th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 3-6, 2014S. K. SundaramNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Overview of 140T CraneDocument163 pagesOverview of 140T Cranekr_abhijeet72356587100% (2)

- Rail Wheel Interaction 02Document44 pagesRail Wheel Interaction 02kr_abhijeet723565870% (1)

- M.A. (Persian) Part-II (Annual)Document5 pagesM.A. (Persian) Part-II (Annual)kr_abhijeet72356587No ratings yet

- Dictionary of Quran HindiDocument268 pagesDictionary of Quran HindiSaajan VermaNo ratings yet

- Wagon ManualDocument511 pagesWagon ManualSusanta Baidya100% (1)

- Primer On Cyber Laws in India - Rajnish KumarDocument9 pagesPrimer On Cyber Laws in India - Rajnish Kumarkr_abhijeet72356587No ratings yet

- Introduction To LHB CoachDocument68 pagesIntroduction To LHB Coachkr_abhijeet72356587100% (4)

- M.A Political ScienceDocument8 pagesM.A Political Sciencekr_abhijeet72356587No ratings yet

- Introduction To Welding - 1 GCDocument66 pagesIntroduction To Welding - 1 GCkr_abhijeet72356587No ratings yet

- Rail Wheel Int. TOTPDocument93 pagesRail Wheel Int. TOTPkr_abhijeet72356587100% (3)

- Modified Fiat Bogie Presentation 5Document57 pagesModified Fiat Bogie Presentation 5kr_abhijeet7235658783% (12)

- Nanotech PaintingDocument16 pagesNanotech Paintingkr_abhijeet72356587No ratings yet

- Icf CoachDocument25 pagesIcf Coachkr_abhijeet72356587No ratings yet

- Intro To DSL LocoDocument26 pagesIntro To DSL Locokr_abhijeet72356587100% (2)

- MechatronicsDocument32 pagesMechatronicskr_abhijeet72356587No ratings yet

- ICF BogieDocument89 pagesICF Bogiekr_abhijeet72356587100% (8)

- Modified Fiat Bogie Presentation 4Document56 pagesModified Fiat Bogie Presentation 4kr_abhijeet7235658767% (3)

- Quality Audit of BOXNHL Wagon Production at SPJDocument27 pagesQuality Audit of BOXNHL Wagon Production at SPJkr_abhijeet72356587100% (1)

- MC-97 For SS Welding GC-08Document20 pagesMC-97 For SS Welding GC-08kr_abhijeet72356587No ratings yet

- Heat Treatment GC - 08Document54 pagesHeat Treatment GC - 08kr_abhijeet72356587No ratings yet

- Disk BrakeDocument42 pagesDisk Brakekr_abhijeet7235658783% (6)

- Diesel Lay-Out PDCDocument34 pagesDiesel Lay-Out PDCkr_abhijeet72356587100% (3)

- Energy Conservation MGMT BILWCDocument68 pagesEnergy Conservation MGMT BILWCkr_abhijeet72356587No ratings yet

- Friction WedgesDocument7 pagesFriction Wedgeskr_abhijeet72356587No ratings yet

- Development in WagonDocument142 pagesDevelopment in Wagonkr_abhijeet7235658783% (6)

CDTS Presentation Latest

CDTS Presentation Latest

Uploaded by

kr_abhijeet72356587Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CDTS Presentation Latest

CDTS Presentation Latest

Uploaded by

kr_abhijeet72356587Copyright:

Available Formats

1

SCR

SCR

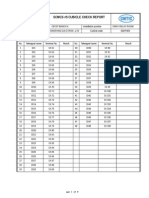

Population of CDTS Coaches

Make VCW AIKON Total BZA Depot 35 8 43 HYB Depot 8 44 52 Total 43 52 95

3 SNo 1 2 3 4 5 6

Summary of Problems on CDTS

Nature of defects No of defects

SCR

%ge of defects

7 8 9 10 11 12 13 14 15

Bottom slide valve jam with bottles and clothes Press to Flush not working No power supply Pressurizer valve defective Inlet valve jam due bottles and clothes Pressurizer leaking water leaking from commode pan emergency flush knob defective Solenoid valve leaking emergency flush knob missing Control box door worked out Control box door missing Emergency flush knob leaking wall protector pipe defective Air leaking in panel board

945 102 91 60 55 54 49 45 44 38 36 35 23 22 21

55.01% 5.94% 5.30% 3.49% 3.20% 3.14% 2.85% 2.62% 2.56% 2.21% 2.10% 2.04% 1.34% 1.28% 1.22% Contd

4 SNo 16 17 18 19 20 21 Nature of defects No of defects %ge of defects

SCR

22 23 24 25 26

27 28 29 30 31 32

speed sensor wire disconnected Pressurizer valve pipe worked out Control box wires disconnected Feed pipe leaking No water supply door lock defective Control panel water leaking inside pipe broken No air supply Solenoid valve missing CDTS tank bottom loose Converter defective Y-1 valve defective Pressurizer tank bracket welding given up Y-1,2 valve defective Inlet valve closing with heavy noise Y-3 valve defective Grand Total

16 14 10 10 9 6 5 5 4 4 3 3 3 2 2 1 1 1718

0.93% 0.81% 0.58% 0.58% 0.52% 0.35% 0.29% 0.29% 0.23% 0.23% 0.17% 0.17% 0.17% 0.12% 0.12% 0.06% 0.06% 100.00%

SCR

Design Problems

Common

SCR

Depth of Flapper Valve

Depth of flapper valve from throat of commode pan= 380 mm

Depth from top of commode pan to throat= 145mm

SCR

Location of Control Panel

Rubber Hose between commode pan and retention tank

SCR

VCW

AIKON

SCR

Retention tank Fitment

VCW

AIKON

10

Pulse Generator

SCR

AIKON VCW

LOCO

11

SCR

Feed Pipe Supply

12

SCR

Spring problem of Flush Valve

13

SCR

Emergency button-Bypass valves

AIKON

VCW

14

Water pressurizer

SCR

VCW

AIKON

15

SCR

VCW - Under gear

16

SCR

Pneumatic pipe connections

17

SCR

VCW-Bottom slide valve Single cylinder

18

SCR

AIKON- Bottom discharge valve cover rusting

19

SCR

Double Piston Metallic-Non metallic

20

SCR

Clogging- Strainer

21

SCR

Maintenance Problems

1. Human excreta at stations/station. Yard-transferred to pitline 2. Technician-safaiwala 3. Requires Heavy maintenance 4. OBHS Staff- training

22

SCR

Maintenance Problems

Requires test stands for the following subassemblies

PLC Converter Solenoid valve Flapper Valve Slide Valve Pulse generator Water Pressurizer

23

SCR

Maintenance Problems

Additional Technical staff and safaiwalas required Bench marking warranty period-spares warranty period-breakdown maintenance & schedules

24

AMC PROBLEMS

The AMC to includea. Daily Maintenance- Staff and materials. b. Spares & Test Stands both makes

SCR

c. Disassembling is to be done in 2 working days during B Schedule- B schedule within 6 hrs d. Minor Depot as min No of coaches is 32- CDTS coaches may be formed in rakes separately that too same make . Rake nomination e. Rooms for each manufacturer 4 rooms

You might also like

- MCM Diagrama Electronico Detroit Diesel Serie 60 Ddec VIDocument1 pageMCM Diagrama Electronico Detroit Diesel Serie 60 Ddec VIJohn MkCito KI91% (70)

- Diagrama de Motor Ddec ViDocument1 pageDiagrama de Motor Ddec ViJohn MkCito KI91% (32)

- Detroit Diesel Engines Fault CodesDocument6 pagesDetroit Diesel Engines Fault CodesAmilcar Rodas100% (2)

- MCM Wiring Diagram: DDC ResponsibilityDocument1 pageMCM Wiring Diagram: DDC ResponsibilityRicardo BolañosNo ratings yet

- TraneDocument33 pagesTranejake1000100% (1)

- Engine Base & BlockDocument47 pagesEngine Base & Blockkr_abhijeet7235658750% (2)

- ICF Bogie 10.3.08Document101 pagesICF Bogie 10.3.08kr_abhijeet72356587100% (6)

- Service Manual: Affinity Horizontalaxis Washer 6000 & 7000 SeriesDocument100 pagesService Manual: Affinity Horizontalaxis Washer 6000 & 7000 SeriesravasamaNo ratings yet

- Invoice # 1Document2 pagesInvoice # 1Fadi YasinNo ratings yet

- Whirlpool Awm 6121Document18 pagesWhirlpool Awm 6121Ненад Митровић100% (1)

- C7Document72 pagesC7victorhernandezrega94% (35)

- End Matriz y AliviosDocument270 pagesEnd Matriz y AliviosJavier Jaya CamachoNo ratings yet

- 6ALBR5233JQODocument23 pages6ALBR5233JQOpinticaniulian9042No ratings yet

- Process Study SheetDocument14 pagesProcess Study SheetBalachandar SathananthanNo ratings yet

- Whirlpool AWM 5080 ManualDocument21 pagesWhirlpool AWM 5080 ManualCharles ThompsonNo ratings yet

- SCMCS #5 CubicleDocument9 pagesSCMCS #5 CubicleErwin SambasNo ratings yet

- D7 Parts Book 9853619020Document897 pagesD7 Parts Book 9853619020wawa100% (2)

- CL - ClutchDocument22 pagesCL - ClutchIlarion CiobanuNo ratings yet

- 2 Egi System: 2-1 Preparation of Instruments 2-2 Outline of SystemDocument126 pages2 Egi System: 2-1 Preparation of Instruments 2-2 Outline of Systemremont78No ratings yet

- Dom InpDocument4 pagesDom InpcrackenhNo ratings yet

- Isolation List GTDocument16 pagesIsolation List GTMaziatol Jasnim Abdul SaariNo ratings yet

- LavDocument93 pagesLavPamela RodriguezNo ratings yet

- Spare Parts Catalogue Catalogue de Pièces de Rechange: 471 1544-67 Doc. No. EDITION 46.2000Document89 pagesSpare Parts Catalogue Catalogue de Pièces de Rechange: 471 1544-67 Doc. No. EDITION 46.2000carlos lopesNo ratings yet

- Whirlpool ManualDocument14 pagesWhirlpool ManualRene Antonio Delgado SobalvarroNo ratings yet

- GC9520Document12 pagesGC9520Aleksander AlexanderNo ratings yet

- Hydraulic Power Packs: Hydraulic Pump Hydraulic Valve Hydraulic AccessoryDocument6 pagesHydraulic Power Packs: Hydraulic Pump Hydraulic Valve Hydraulic Accessoryrlnjay2003No ratings yet

- V SeguridadDocument8 pagesV SeguridadARJONA_JGNo ratings yet

- Awm 8121Document22 pagesAwm 8121borlixNo ratings yet

- Service Manual: Dishwasher Adp 542 WHDocument12 pagesService Manual: Dishwasher Adp 542 WHninoslavnNo ratings yet

- BJ 63Document131 pagesBJ 63anuarazam100% (1)

- SCMCS #3 CubicleDocument9 pagesSCMCS #3 CubicleErwin SambasNo ratings yet

- SideWinder 42 62 82 CHMCL PMP IOMDocument4 pagesSideWinder 42 62 82 CHMCL PMP IOMSH McNo ratings yet

- Electrical Materials List For ERPDocument341 pagesElectrical Materials List For ERPDhilip AnNo ratings yet

- 31-9254 GE-Top-Load-WasherDocument83 pages31-9254 GE-Top-Load-WasherAngel RosadoNo ratings yet

- DPT-2500N Service ManualDocument16 pagesDPT-2500N Service ManualJuan Gonzales100% (1)

- Emission Control SystemDocument21 pagesEmission Control SystemdanyNo ratings yet

- System Design: Pressure Loss in Fittings and ValvesDocument3 pagesSystem Design: Pressure Loss in Fittings and ValvesGuillaume BoyerNo ratings yet

- Service Manual: Steam Generator GC9245Document12 pagesService Manual: Steam Generator GC9245Aleksander AlexanderNo ratings yet

- Psme Sa Short Course CHWDocument3 pagesPsme Sa Short Course CHWArt JamesNo ratings yet

- Service Manual: Dishwasher GSF 4761 TW-WSDocument27 pagesService Manual: Dishwasher GSF 4761 TW-WSOfer FolkmarNo ratings yet

- 1614 6423 00Document2 pages1614 6423 00UbanAirlanggaNo ratings yet

- SideWinder 40 60 80 CHMCL PMP BrchreDocument4 pagesSideWinder 40 60 80 CHMCL PMP BrchreSH McNo ratings yet

- DailyDocument16 pagesDailyajiesoko2No ratings yet

- Cameron Hyd Drilling ChokeDocument2 pagesCameron Hyd Drilling ChokeGonzalo Guzman JaimesNo ratings yet

- AWM8143Document22 pagesAWM8143pinticaniulian9042100% (1)

- Whirlpool Service Manual Dishwasher ADP9521WHMDocument28 pagesWhirlpool Service Manual Dishwasher ADP9521WHMcarlammartins100% (1)

- Replacementparts Listwith Lubricationguide: 7.1 MechanicalpartsDocument8 pagesReplacementparts Listwith Lubricationguide: 7.1 MechanicalpartsanthonypardoNo ratings yet

- Whirlpool Awm 8125 (ET)Document17 pagesWhirlpool Awm 8125 (ET)winamax69No ratings yet

- Electrical Panel Load Calculation (22.8.12)Document28 pagesElectrical Panel Load Calculation (22.8.12)Erfan AhmedNo ratings yet

- Boomer L2D PDFDocument84 pagesBoomer L2D PDFUmaprasad Chatterjee100% (1)

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersFrom EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersRating: 4.5 out of 5 stars4.5/5 (2)

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Analytical Troubleshooting of Process Machinery and Pressure Vessels: Including Real-World Case StudiesFrom EverandAnalytical Troubleshooting of Process Machinery and Pressure Vessels: Including Real-World Case StudiesRating: 3 out of 5 stars3/5 (1)

- Maintain and Improve Your Powerboat: 100 Ways to Make Your Boat BetterFrom EverandMaintain and Improve Your Powerboat: 100 Ways to Make Your Boat BetterNo ratings yet

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- Advanced Thermoforming: Methods, Machines and Materials, Applications and AutomationFrom EverandAdvanced Thermoforming: Methods, Machines and Materials, Applications and AutomationRating: 5 out of 5 stars5/5 (1)

- 75th Conference on Glass Problems: A Collection of Papers Presented at the 75th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 3-6, 2014From Everand75th Conference on Glass Problems: A Collection of Papers Presented at the 75th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 3-6, 2014S. K. SundaramNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Overview of 140T CraneDocument163 pagesOverview of 140T Cranekr_abhijeet72356587100% (2)

- Rail Wheel Interaction 02Document44 pagesRail Wheel Interaction 02kr_abhijeet723565870% (1)

- M.A. (Persian) Part-II (Annual)Document5 pagesM.A. (Persian) Part-II (Annual)kr_abhijeet72356587No ratings yet

- Dictionary of Quran HindiDocument268 pagesDictionary of Quran HindiSaajan VermaNo ratings yet

- Wagon ManualDocument511 pagesWagon ManualSusanta Baidya100% (1)

- Primer On Cyber Laws in India - Rajnish KumarDocument9 pagesPrimer On Cyber Laws in India - Rajnish Kumarkr_abhijeet72356587No ratings yet

- Introduction To LHB CoachDocument68 pagesIntroduction To LHB Coachkr_abhijeet72356587100% (4)

- M.A Political ScienceDocument8 pagesM.A Political Sciencekr_abhijeet72356587No ratings yet

- Introduction To Welding - 1 GCDocument66 pagesIntroduction To Welding - 1 GCkr_abhijeet72356587No ratings yet

- Rail Wheel Int. TOTPDocument93 pagesRail Wheel Int. TOTPkr_abhijeet72356587100% (3)

- Modified Fiat Bogie Presentation 5Document57 pagesModified Fiat Bogie Presentation 5kr_abhijeet7235658783% (12)

- Nanotech PaintingDocument16 pagesNanotech Paintingkr_abhijeet72356587No ratings yet

- Icf CoachDocument25 pagesIcf Coachkr_abhijeet72356587No ratings yet

- Intro To DSL LocoDocument26 pagesIntro To DSL Locokr_abhijeet72356587100% (2)

- MechatronicsDocument32 pagesMechatronicskr_abhijeet72356587No ratings yet

- ICF BogieDocument89 pagesICF Bogiekr_abhijeet72356587100% (8)

- Modified Fiat Bogie Presentation 4Document56 pagesModified Fiat Bogie Presentation 4kr_abhijeet7235658767% (3)

- Quality Audit of BOXNHL Wagon Production at SPJDocument27 pagesQuality Audit of BOXNHL Wagon Production at SPJkr_abhijeet72356587100% (1)

- MC-97 For SS Welding GC-08Document20 pagesMC-97 For SS Welding GC-08kr_abhijeet72356587No ratings yet

- Heat Treatment GC - 08Document54 pagesHeat Treatment GC - 08kr_abhijeet72356587No ratings yet

- Disk BrakeDocument42 pagesDisk Brakekr_abhijeet7235658783% (6)

- Diesel Lay-Out PDCDocument34 pagesDiesel Lay-Out PDCkr_abhijeet72356587100% (3)

- Energy Conservation MGMT BILWCDocument68 pagesEnergy Conservation MGMT BILWCkr_abhijeet72356587No ratings yet

- Friction WedgesDocument7 pagesFriction Wedgeskr_abhijeet72356587No ratings yet

- Development in WagonDocument142 pagesDevelopment in Wagonkr_abhijeet7235658783% (6)