Professional Documents

Culture Documents

Motorcycle Parts and Function

Motorcycle Parts and Function

Uploaded by

Selazinap Lpt0 ratings0% found this document useful (0 votes)

81 views13 pagesThe document summarizes the key components of a motorcycle brake system. It discusses the master cylinder, brake lines, brake caliper, brake pads, brake discs/drums, brake fluid, brake disc rotors, and vacuum bleeders. The master cylinder converts mechanical force to hydraulic pressure, which is transmitted through brake lines to the caliper. The caliper multiplies the force and uses pistons to press brake pads against the discs/drums, slowing the motorcycle through friction. Brake fluid transmits pressure through the system, and vacuum bleeders help empty fluid from the lines when replacing hydraulic components.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document summarizes the key components of a motorcycle brake system. It discusses the master cylinder, brake lines, brake caliper, brake pads, brake discs/drums, brake fluid, brake disc rotors, and vacuum bleeders. The master cylinder converts mechanical force to hydraulic pressure, which is transmitted through brake lines to the caliper. The caliper multiplies the force and uses pistons to press brake pads against the discs/drums, slowing the motorcycle through friction. Brake fluid transmits pressure through the system, and vacuum bleeders help empty fluid from the lines when replacing hydraulic components.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

81 views13 pagesMotorcycle Parts and Function

Motorcycle Parts and Function

Uploaded by

Selazinap LptThe document summarizes the key components of a motorcycle brake system. It discusses the master cylinder, brake lines, brake caliper, brake pads, brake discs/drums, brake fluid, brake disc rotors, and vacuum bleeders. The master cylinder converts mechanical force to hydraulic pressure, which is transmitted through brake lines to the caliper. The caliper multiplies the force and uses pistons to press brake pads against the discs/drums, slowing the motorcycle through friction. Brake fluid transmits pressure through the system, and vacuum bleeders help empty fluid from the lines when replacing hydraulic components.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 13

Good morning

Brake System of motor

cycle

Your motorcycle brakes have a tough job. We riders expect a

firm pull on the lever to shed our speed in less time and distance

than it took the engine to build it. What's amazing is that it does.

(The Bavarian Engine Works company) BMW's S1000XR for

example. From a standstill it accelerates to 100 mph in 6.1

seconds and 497 feet. Yet it slows to a complete stop in just five

seconds and in less than two-thirds the distance. That

impressive performance is due to the power and resilience of the

modern hydraulic brake system, which is comprised of the

following components.

One of the first motorcycles to have any sort of braking mechanism was made by

Steffey Motorcycles of Philadelphia in 1902

Considered to be the foundation of the modern braking system, the mechanical

drums brake was developed by Louis Renault. But had been invented earlier by

Gottieb Daimler

MASTER

CYLINDER

Whether operated by your right hand or your right foot, this converts

mechanical force into hydraulic pressure via a lever acting on a piston

that presses on a fluid. The force with which you pull the lever, the lever’s

leverage ratio, and the size of the master-cylinder piston determine the

amount of pressure imparted on the system, which may exceed 150 psi.

BRAKE LINES

These multilayer hoses transmit pressure from the master cylinder

to the calipers and typically utilize a Teflon inner lining surrounded

by a braided-nylon, Kevlar, or stainless-steel reinforcing layer

that’s then wrapped in a protective sheathing. The stronger the

hoses the better, since any expansion under pressure will reduce

braking force and feel. Because rubber hoses lose their strength

over time, most manufacturers recommend replacing them every

four years.

BRAKE CALIPER

The brake caliper is where the multiplying power of

hydraulics comes into play. Since pressure applied to a

confined liquid is transmitted undiminished and with equal

force to all surfaces within the system, the pressure from the

master cylinder is exerted uniformly on the much larger area

of the caliper pistons, increasing the force many fold.

BRAKE DISC CALIPER PISTON

The piston in brake caliper are responsible for the

brake pads making contact with the brake dacs and

consenquently slowing the motorcycle

BRAKE PADS

f any part of the brake system deserves sympathy, it’s the pads. Their job

is to convert your bike’s kinetic energy into heat by way of friction. And

we want them to do it quietly and repeatedly and without getting too hot.

It’s not uncommon for the brakes on an aggressively ridden streetbike to

heat up to 350 degrees Fahrenheit, while the pads and discs on a racebike

may exceed 600 degrees. For an explanation of the main types of brake

pad material, see the “Pick Your Flavor” sidebar.

BRAKE DISC (OR DRUM)

Transferring the brake pads’ resistance to motion to the wheels and on

to the tires’ contact patches are the brake discs or drums. Discs are

typically made from stainless steel, while drums are lined with cast

iron. Both materials provide a durable, heat-resistant surface for the

brake pads to press against. Modern brake discs are relieved, and or

drilled, to assist in cooling and to help shed water and debris.

BRAKE

FLUID This is the elixir that allows it all to happen. Brake fluid is responsible for

transmitting force from the brake lever to the back of the brake pads. It

needs to be non-compressible to effectively transmit pressure, have low

viscosity to be compatible with ABS components, have good lubricity for

master-cylinder and caliper pistons seals, offer corrosion resistance, and

also have a very high boiling point.

BRAKE DICS ROTOR

Disc brake rotors have large surfaces that create friction

enough to slow down the movement of your motorcycle. In

this article, you will get to know about the different types

of brake rotors, signs of bad rotors, and many more.

Vaccum breeder

Even in the best-case scenario, changing hydraulic lines is messy.

Since brake fluid can damage paint and other shiny stuff on your

bike, you should remove or cover any vulnerable painted surfaces.

You will also want to get the system as empty of fluid as possible

before removing the lines. A vacuum bleeder is ideal for this. Begin

by sucking the extra fluid out of the reservoir. Then attach the hose

to a caliper’s bleeder valve. Give the bleeder a couple of pumps to

build up the suction and crack the valve until fluid starts to be drawn

into the catch tank. Keep pumping until the system is dry. Do this

for all calipers that will receive new lines.

You might also like

- Rifle Reloading Data - Handloading - Rifle Calibers - Centerfire Rifle Bullets - Reload Your Own Ammo - VihtavuoriDocument12 pagesRifle Reloading Data - Handloading - Rifle Calibers - Centerfire Rifle Bullets - Reload Your Own Ammo - Vihtavuorirémi13No ratings yet

- Standard Conversion From Inches To MM PDFDocument3 pagesStandard Conversion From Inches To MM PDFShahnawaz BateyNo ratings yet

- Resto Tips Part 31Document10 pagesResto Tips Part 31rodolfocv92359100% (1)

- Lab Report # 2Document6 pagesLab Report # 2zainyousafzai100% (1)

- Software User's Manual: Tony Foale Designs © 2006-2018Document62 pagesSoftware User's Manual: Tony Foale Designs © 2006-2018faizNo ratings yet

- Bosch GST 75 E ProfessionalDocument167 pagesBosch GST 75 E ProfessionalAdriana AlvesNo ratings yet

- Money OrigamiDocument33 pagesMoney Origamimkdi6rNo ratings yet

- Camd Manual18me36a FinalDocument44 pagesCamd Manual18me36a FinalDANISH ME-18-40No ratings yet

- Folding Picnic Table PlansDocument11 pagesFolding Picnic Table PlansDanie GarciaNo ratings yet

- Dowel Maker - Homemade Dowel Maker Consisting of A Maple BloDocument5 pagesDowel Maker - Homemade Dowel Maker Consisting of A Maple BloBeddek AmiroucheNo ratings yet

- 360 Sled Kit Project Plans: Included ItemsDocument12 pages360 Sled Kit Project Plans: Included ItemsJaime Montiel100% (1)

- Veneered Checkerboard EZPlanDocument4 pagesVeneered Checkerboard EZPlanGülbaharNo ratings yet

- Make A Motorised Pan and Rotate Camera SliderDocument11 pagesMake A Motorised Pan and Rotate Camera SliderAjanth RayanNo ratings yet

- BL 11-16 MergedDocument351 pagesBL 11-16 MergedShreshtha MalhotraNo ratings yet

- Bat House InstructionsDocument3 pagesBat House Instructionsrramalho1No ratings yet

- Diy SeismographDocument3 pagesDiy SeismographFlorence May L. GarciaNo ratings yet

- Crest LED Lighting Catalogue 2015 PDFDocument98 pagesCrest LED Lighting Catalogue 2015 PDFMuhammad Mubashar100% (1)

- WOODWORKING Machines and ToolsDocument9 pagesWOODWORKING Machines and ToolsLudvig Vahn D. NiepezNo ratings yet

- Filling Shop ToolsDocument24 pagesFilling Shop ToolsMohsin Tariq100% (1)

- Gyprock Party Wall Manual Gyp513 2021 PDFDocument48 pagesGyprock Party Wall Manual Gyp513 2021 PDFMuz shirzaiNo ratings yet

- Parallel ClampsDocument19 pagesParallel ClampsMartin MartinezNo ratings yet

- Data Report 2021Document102 pagesData Report 2021Ramon CruzNo ratings yet

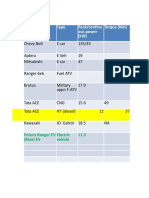

- ATV Type Torque (NM) Peak/continu Ous Power (KW)Document3 pagesATV Type Torque (NM) Peak/continu Ous Power (KW)RamniwasSinghNo ratings yet

- Case Study - Chair Step LadderDocument4 pagesCase Study - Chair Step LadderA Liz Marjorie T. TineoNo ratings yet

- Magentobluepress2022may 2022.PDF 4Document88 pagesMagentobluepress2022may 2022.PDF 4DWFNo ratings yet

- Trike Tech - 5 21 17Document114 pagesTrike Tech - 5 21 17Brian WarrenNo ratings yet

- Solutions: StorageDocument2 pagesSolutions: StorageOsvaldo MoraesNo ratings yet

- AT-420 Assembly GuideDocument10 pagesAT-420 Assembly GuidegdudgshsNo ratings yet

- Type of Saw and PorpuseDocument12 pagesType of Saw and PorpuseIman SadeghiNo ratings yet

- RTS10G 864 RDocument12 pagesRTS10G 864 RdigitaltextNo ratings yet

- Axminster 06 - Drilling Machines & Driil Bits - p185-p211Document27 pagesAxminster 06 - Drilling Machines & Driil Bits - p185-p211Pierre799esNo ratings yet

- Power ToolsDocument9 pagesPower ToolsEdwin CastañedaNo ratings yet

- WS21422 Tower BookcaseDocument11 pagesWS21422 Tower BookcaseclaudiuferezanNo ratings yet

- WR-217e In-Hub Motor SystemDocument110 pagesWR-217e In-Hub Motor Systempiyush PatilNo ratings yet

- Vacuum Forming Guide PDFDocument51 pagesVacuum Forming Guide PDFBobNo ratings yet

- 1 Power Band and Circular SawsDocument51 pages1 Power Band and Circular SawsJiggy Lawrence BathanNo ratings yet

- How To Make Powerfull Laser Engraver: Hello Guys Hello GuysDocument23 pagesHow To Make Powerfull Laser Engraver: Hello Guys Hello GuysVENOM LY100% (1)

- Meaker VI's Mark8Document13 pagesMeaker VI's Mark8zhonghua shiNo ratings yet

- 1099935205four SpeedDocument6 pages1099935205four SpeedchzhptopNo ratings yet

- Student Manual 1Document99 pagesStudent Manual 1Vardhan KatamoniNo ratings yet

- 03 Warping PDFDocument39 pages03 Warping PDFDAWOOD MALIKNo ratings yet

- Alignment Tests On LatheDocument63 pagesAlignment Tests On LatheSudhanwa KulkarniNo ratings yet

- Rear Trunnions Carriage Circular Saw Motor: VIEW14 (1: 5)Document23 pagesRear Trunnions Carriage Circular Saw Motor: VIEW14 (1: 5)pshtiwanNo ratings yet

- CountersinkDocument8 pagesCountersinkJoy TekNo ratings yet

- Table Saw Drum Mill: InstructablesDocument11 pagesTable Saw Drum Mill: InstructablesJazzy VaaltynNo ratings yet

- Thank You!: WOOD StoreDocument9 pagesThank You!: WOOD StoreJuanRodriguezNo ratings yet

- Andrew Harris Woodwork Patio TableDocument16 pagesAndrew Harris Woodwork Patio TableYamil Paladino100% (1)

- Furniture of Yesterday and Today (1937)Document68 pagesFurniture of Yesterday and Today (1937)gmand68No ratings yet

- Balsa Propellers For ULS: Connector ChoiceDocument4 pagesBalsa Propellers For ULS: Connector ChoiceFabricio AmadoNo ratings yet

- Fabrication of Eccentric Hammer Cam Machanism For Industrial PurposeDocument38 pagesFabrication of Eccentric Hammer Cam Machanism For Industrial PurposeANAND KRISHNANNo ratings yet

- Passive Solar Heating Residences 1979Document300 pagesPassive Solar Heating Residences 1979q3rNo ratings yet

- #38 November 2013Document72 pages#38 November 2013OutdoorUAENo ratings yet

- Make A Pocket Hole JigDocument7 pagesMake A Pocket Hole JigJose AmentaNo ratings yet

- Easy Garage Shop Cabinets - LowerDocument17 pagesEasy Garage Shop Cabinets - LowerLonebeavNo ratings yet

- CAN Bus Sniffing and Broadcasting With ArduinoDocument6 pagesCAN Bus Sniffing and Broadcasting With ArduinoBurgadaNo ratings yet

- HySPAN Span Guide 28pp Sep11Document28 pagesHySPAN Span Guide 28pp Sep11Prasascribd100% (1)

- History of TIGDocument13 pagesHistory of TIGJayakrishna100% (1)

- Youngsters T Bucket Frame Plans V1 0Document24 pagesYoungsters T Bucket Frame Plans V1 0weirdbennyNo ratings yet

- Other Systems That Are Connected With The Brake SystemDocument13 pagesOther Systems That Are Connected With The Brake SystemEnoch MwesigwaNo ratings yet

- Braking ReportDocument15 pagesBraking ReportAshish ThakurNo ratings yet

- A Short Course On: BrakesDocument10 pagesA Short Course On: BrakesNdung'u Wa WaweruNo ratings yet

- VillanuevaDocument12 pagesVillanuevaSelazinap LptNo ratings yet

- Gas and Diesel Tune Up ModuleDocument38 pagesGas and Diesel Tune Up ModuleSelazinap LptNo ratings yet

- AUTOMOTIVE Module Internal CombustionDocument38 pagesAUTOMOTIVE Module Internal CombustionSelazinap LptNo ratings yet

- AUTOMOTIVEpower Drive Train MODULE 2Document17 pagesAUTOMOTIVEpower Drive Train MODULE 2Selazinap LptNo ratings yet

- AUTOMOTIVE POWERTRAIN COURSE OutlineDocument2 pagesAUTOMOTIVE POWERTRAIN COURSE OutlineSelazinap LptNo ratings yet

- Electronic EngineDocument16 pagesElectronic EngineSelazinap LptNo ratings yet

- Small Engine Syllabus 2Document21 pagesSmall Engine Syllabus 2Selazinap Lpt100% (1)

- Motorcycle Clutch SystemDocument15 pagesMotorcycle Clutch SystemSelazinap LptNo ratings yet

- AUTOMOTIVE Power Drive Train ModuleDocument26 pagesAUTOMOTIVE Power Drive Train ModuleSelazinap Lpt100% (1)

- Motor Cycle Suspension SystemDocument11 pagesMotor Cycle Suspension SystemSelazinap LptNo ratings yet

- CarburetorDocument19 pagesCarburetorSelazinap LptNo ratings yet

- Cooling SystemDocument25 pagesCooling SystemSelazinap LptNo ratings yet

- Driving Ncii Pre-ExaminationDocument42 pagesDriving Ncii Pre-ExaminationSelazinap LptNo ratings yet

- Lubrication SystemDocument25 pagesLubrication SystemSelazinap LptNo ratings yet

- Small Engine Day 2Document18 pagesSmall Engine Day 2Selazinap LptNo ratings yet

- Motor Cyle Day 1Document14 pagesMotor Cyle Day 1Selazinap LptNo ratings yet

- Tune Up Spark Plug GappingDocument26 pagesTune Up Spark Plug GappingSelazinap LptNo ratings yet

- Lubrication SystemDocument25 pagesLubrication SystemSelazinap LptNo ratings yet

- Tune UpDocument20 pagesTune UpSelazinap LptNo ratings yet

- Arch Pipe With Rod TensionDocument4 pagesArch Pipe With Rod Tensionahm_shaabanNo ratings yet

- Madame DoubtfireDocument110 pagesMadame Doubtfire快乐无忧的阿俊yxNo ratings yet

- Norma IVet-5 Print 20200603Document2 pagesNorma IVet-5 Print 20200603Dani JuhaszNo ratings yet

- Theories of The UniverseDocument15 pagesTheories of The UniverseindakNo ratings yet

- W3LPL Improving Your 40 Through 10 Meter Antennas For The Declining Solar CycleDocument39 pagesW3LPL Improving Your 40 Through 10 Meter Antennas For The Declining Solar CycleAravind BalasubramanianNo ratings yet

- 37-160kW Operators ManualDocument85 pages37-160kW Operators ManualANDRESNo ratings yet

- Easy Giantess CalculatorDocument1 pageEasy Giantess CalculatorArthur Dutra ReccoNo ratings yet

- NetworkingDocument20 pagesNetworkingJaspreetSingh0% (1)

- Optimized For Best Performance in Clinical Chemistry TestingDocument18 pagesOptimized For Best Performance in Clinical Chemistry Testingvolodymyr saganenkoNo ratings yet

- Encyclopaedia of Popular Science (Steven N.shore)Document353 pagesEncyclopaedia of Popular Science (Steven N.shore)Muhammad Ali HaiderNo ratings yet

- Insulin TherapyDocument14 pagesInsulin TherapyElimar Alejandra David GilNo ratings yet

- Internet of Things: Digitize or Die!Document27 pagesInternet of Things: Digitize or Die!Muhammed MahmoodNo ratings yet

- Nano Satellite REPORTDocument9 pagesNano Satellite REPORTHemlata SharmaNo ratings yet

- Constance Vertical Forced Convection Oven (FCH 9006 Series)Document1 pageConstance Vertical Forced Convection Oven (FCH 9006 Series)Uswatul HasanahNo ratings yet

- Proceedings 10th Mountain Cheese DefDocument95 pagesProceedings 10th Mountain Cheese DefLazline BrownNo ratings yet

- ML145026 ML145027 ML145028: Encoder and Decoder PairsDocument19 pagesML145026 ML145027 ML145028: Encoder and Decoder PairsMilojko DrzevljaninNo ratings yet

- Learnings of PLC & ScadaDocument31 pagesLearnings of PLC & Scadakarthik prapannaNo ratings yet

- Manitou MSI (EN)Document8 pagesManitou MSI (EN)ManitouNo ratings yet

- Gr9-12-Full Food and NutritionDocument30 pagesGr9-12-Full Food and NutritionSpynyfexNo ratings yet

- GrundfosDocument16 pagesGrundfosKarthick SarathyNo ratings yet

- Cardiac Insufficiency Bisoprolol Study (CIBIS III) TrialDocument6 pagesCardiac Insufficiency Bisoprolol Study (CIBIS III) TrialClaudia TiffanyNo ratings yet

- UntitledDocument41 pagesUntitledJon EggersNo ratings yet

- APPLIED PHYSICS Bonding in Solids by CHARIS ISRAEL ANCHADocument17 pagesAPPLIED PHYSICS Bonding in Solids by CHARIS ISRAEL ANCHACharis Israel Ancha100% (1)

- The Fascinating World of AnimalsDocument2 pagesThe Fascinating World of AnimalsdilaydurmazNo ratings yet

- 7 E'sDocument9 pages7 E'sShiello JuanicoNo ratings yet

- P1-F Revision For Midyear - Listening - The Sydney Opera HouseDocument4 pagesP1-F Revision For Midyear - Listening - The Sydney Opera HouseYusuf Can SözerNo ratings yet

- The Pentagon Bio-Weapons - Dilyana - BGDocument34 pagesThe Pentagon Bio-Weapons - Dilyana - BGOn The PathNo ratings yet

- By: Howard Gardner: Multiple IntelligenceDocument1 pageBy: Howard Gardner: Multiple IntelligenceChenie CoronelNo ratings yet

- Apollo-Soyuz Test ProjectDocument120 pagesApollo-Soyuz Test ProjectAviation/Space History LibraryNo ratings yet