Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

6 viewsPresentation1 1

Presentation1 1

Uploaded by

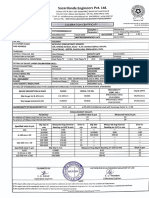

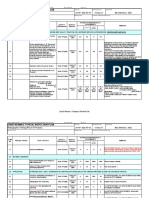

Ravitej ReddyThis kaizen form documents improvements made to reduce waste in the CCA-01 cutting process. Specifically, an individual program was implemented for cutting child parts like fins, rudders, and landing gear instead of manual cutting. This addressed issues like 40% material waste and 20% reduced material lifespan from manual cutting errors. The automated program helped standardize the process, prevent waste, and save material and man hours compared to the previous status.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You might also like

- LBO Analysis TemplateDocument11 pagesLBO Analysis TemplateBobby Watkins75% (4)

- Valid SOP: Standard Operating ProceduresDocument10 pagesValid SOP: Standard Operating ProceduresShahid Raza100% (2)

- IPCRF - ITO 1 Revised PIDocument6 pagesIPCRF - ITO 1 Revised PIJekyll Dupio CadungogNo ratings yet

- Bakhtiar Saffuan B Baharudin: Curriculum VitaeDocument5 pagesBakhtiar Saffuan B Baharudin: Curriculum Vitaethiwa karanNo ratings yet

- XVFC Work Order Monitoring Format NewDocument2 pagesXVFC Work Order Monitoring Format Newకొల్లి రాఘవేణిNo ratings yet

- 000-Za-E-M09412 - A Ms For Fiber Optic Cable Installation - 13!08!2019Document20 pages000-Za-E-M09412 - A Ms For Fiber Optic Cable Installation - 13!08!2019syam prasadNo ratings yet

- Vax Consultants Pvt. LTD.: Foundation & Structural EngineersDocument1 pageVax Consultants Pvt. LTD.: Foundation & Structural Engineersmohana tNo ratings yet

- Gemss e 28 r01 (0) Cable TraysDocument6 pagesGemss e 28 r01 (0) Cable TraysAdel KlkNo ratings yet

- December Outhouse 2022Document4 pagesDecember Outhouse 2022Forrulh AbdullahNo ratings yet

- Corrective Preventive Action Procedure 000-Za-E-209608-1Document4 pagesCorrective Preventive Action Procedure 000-Za-E-209608-1ghada gattouch100% (1)

- Integrated Departmental Manual Caustic Soda UnitDocument2 pagesIntegrated Departmental Manual Caustic Soda UnitSANJAY AGRAHARINo ratings yet

- MQP - Fiber Optic CableDocument6 pagesMQP - Fiber Optic CableSiva KumarNo ratings yet

- Location Wise FGD Projects in IndiaDocument16 pagesLocation Wise FGD Projects in IndiaVibhas KumarNo ratings yet

- Installation of Light Fitting.Document68 pagesInstallation of Light Fitting.Anandu AshokanNo ratings yet

- CC 1nd and Part BillDocument10 pagesCC 1nd and Part Billse rwsNo ratings yet

- 000-Za-E-M09411 - A Ms For Cable Glanding and TerminationDocument28 pages000-Za-E-M09411 - A Ms For Cable Glanding and Terminationsyam prasad100% (1)

- Vernier Calibration 08122020Document1 pageVernier Calibration 08122020Nevil Consultancy ServicesNo ratings yet

- Machining FMEA Rev.01 Dated 10.02.2022Document1 pageMachining FMEA Rev.01 Dated 10.02.2022GARIMA CASTINGS, JAIPURNo ratings yet

- Adobe Scan 04-Apr-2024Document1 pageAdobe Scan 04-Apr-2024ssetexchjbpNo ratings yet

- TS Track Works TA06 Track ChangesDocument95 pagesTS Track Works TA06 Track ChangesAlexYoungNo ratings yet

- SP132B Tky Prim - 3Document4 pagesSP132B Tky Prim - 3luwekbinotNo ratings yet

- Estimate For 1st RA Bill of Khonjonighona GPSDocument11 pagesEstimate For 1st RA Bill of Khonjonighona GPSTushar AjantaNo ratings yet

- Machining FMEA - Rev.01 - Dated 10.02.2022Document1 pageMachining FMEA - Rev.01 - Dated 10.02.2022GARIMA CASTINGS, JAIPURNo ratings yet

- IC Project Charter With Example Data 8556 - PowerPointDocument9 pagesIC Project Charter With Example Data 8556 - PowerPointDanang SetiawanNo ratings yet

- 2 Fin2016 Annual Investment Plan - A - eDocument173 pages2 Fin2016 Annual Investment Plan - A - eDuane de MesaNo ratings yet

- CEA March 2022Document45 pagesCEA March 2022Sumiran BansalNo ratings yet

- Ijbtpartment of Qebutatton: .Ltepublit of TL Ilipp TLFFDocument13 pagesIjbtpartment of Qebutatton: .Ltepublit of TL Ilipp TLFFjeanNo ratings yet

- DNV Kick Off Meeting - 20220623 NYDocument58 pagesDNV Kick Off Meeting - 20220623 NYjoekaledaNo ratings yet

- Project ReportDocument18 pagesProject Reportmonika mahajanNo ratings yet

- Prime Minister Globas SDGs Achievement Programe 2016-18 LG&CD OKARADocument10 pagesPrime Minister Globas SDGs Achievement Programe 2016-18 LG&CD OKARABilal LiaqatNo ratings yet

- Price Bid - CoringDocument2 pagesPrice Bid - CoringVisu RaoNo ratings yet

- Last Five Years Hse Statistics As On July 2020: Year Manhours Worked No of Lti No of Total Lost DaysDocument1 pageLast Five Years Hse Statistics As On July 2020: Year Manhours Worked No of Lti No of Total Lost DayspjosesmNo ratings yet

- For Information: Jawaharpur Vidyut Utpadan Nigam LimitedDocument18 pagesFor Information: Jawaharpur Vidyut Utpadan Nigam Limiteddattasudipto4339No ratings yet

- Meritlistdi&cDocument362 pagesMeritlistdi&cOCILABS Origin & Cause InvestigationNo ratings yet

- Claimspaid 2021Document72 pagesClaimspaid 2021sNo ratings yet

- GEMSS-C-03 Design Parameters For Civil Works (Rev 01)Document23 pagesGEMSS-C-03 Design Parameters For Civil Works (Rev 01)algie mendozaNo ratings yet

- Tackling FSRU Operational ChallengesDocument22 pagesTackling FSRU Operational ChallengesAnonymous icnhaNsFNo ratings yet

- To Construct Chemical Storage Shelter and Lube Oil Drums at Dcu Unit 32 Area 3Document15 pagesTo Construct Chemical Storage Shelter and Lube Oil Drums at Dcu Unit 32 Area 3MUHAMAD ROZEE MAT AZMINo ratings yet

- SMS - 67390 8jb0a - K2MCDocument21 pagesSMS - 67390 8jb0a - K2MCmani sNo ratings yet

- Boiler Foundation (Unit#1 & Unit#2) - Analysis and Design of Foundation - Pile Group AnalysisDocument15 pagesBoiler Foundation (Unit#1 & Unit#2) - Analysis and Design of Foundation - Pile Group AnalysisMRITYUNJOY DUTTANo ratings yet

- 000-ZA-E-M09407 - B MS For Cabinets, Panels, Cubicle & Power & Lighting Panel-Boards - RECTIFIEDDocument20 pages000-ZA-E-M09407 - B MS For Cabinets, Panels, Cubicle & Power & Lighting Panel-Boards - RECTIFIEDsyam prasadNo ratings yet

- 04th September 2021 (Ashar Metro)Document30 pages04th September 2021 (Ashar Metro)avinash rathodNo ratings yet

- E-021 SLDDocument1 pageE-021 SLDSyedNo ratings yet

- Dewan: Corrective and Preventive Action FormDocument12 pagesDewan: Corrective and Preventive Action Formareib_hassan100% (1)

- MS For PEB Erection R1Document16 pagesMS For PEB Erection R1Gabriel GabeNo ratings yet

- OS 2024-25-Unlocked-CompressedDocument16 pagesOS 2024-25-Unlocked-Compressedatulshubh2407No ratings yet

- Pep 20083221Document221 pagesPep 20083221imri ssNo ratings yet

- Surveillance Finding Summary: Directorate General of Civil Aviation Directorate of Airworthiness and Aircraft OperationsDocument3 pagesSurveillance Finding Summary: Directorate General of Civil Aviation Directorate of Airworthiness and Aircraft OperationsPuttra ArdiansyahNo ratings yet

- Saudi Aramco Typical Inspection Plan: Radiographic Testing (RT) On IK Projects Satip-Nde-Rt-01 15-Nov-17 Mechanical - NdeDocument11 pagesSaudi Aramco Typical Inspection Plan: Radiographic Testing (RT) On IK Projects Satip-Nde-Rt-01 15-Nov-17 Mechanical - NdeSyed Mohammed Abdul Aleem SoofiyaniNo ratings yet

- Single Line - Padukka Town-LayoutDocument1 pageSingle Line - Padukka Town-Layoutsajeevi piumikaNo ratings yet

- List of Candidate Selected Based On Written Test Cum Interview Held On 16.03.2019 at C-Dac Silchar Against Advt. No. Cdacs/01/2018 Dated 26.12.2018Document1 pageList of Candidate Selected Based On Written Test Cum Interview Held On 16.03.2019 at C-Dac Silchar Against Advt. No. Cdacs/01/2018 Dated 26.12.2018VillageSchool FoundationNo ratings yet

- TDM Be MW Sub Asgc MSD 7805 r0 BDocument20 pagesTDM Be MW Sub Asgc MSD 7805 r0 ByasirNo ratings yet

- Oil and Gas - SOGT Back in The Spotlight - 23/6/2010Document2 pagesOil and Gas - SOGT Back in The Spotlight - 23/6/2010Rhb InvestNo ratings yet

- BCI20200813161126 - C2 TMD Trip UnitDocument4 pagesBCI20200813161126 - C2 TMD Trip Unitranj kNo ratings yet

- Rev2 - MRA-TEC-P02 HATS (GENERAL)Document10 pagesRev2 - MRA-TEC-P02 HATS (GENERAL)Mohd Harraz AbbasyNo ratings yet

- Proposed Budget 2020 Rev 2Document11 pagesProposed Budget 2020 Rev 2MarieNo ratings yet

- DMPB CardDocument1 pageDMPB Cardindrajit mondalNo ratings yet

- High 5 PQDocument175 pagesHigh 5 PQsyed hadiNo ratings yet

- WCE - MOS - Installation of Reinforced Earth Wall 2Document28 pagesWCE - MOS - Installation of Reinforced Earth Wall 2Lim Yi SernNo ratings yet

- StarLAN Technology ReportFrom EverandStarLAN Technology ReportRating: 3 out of 5 stars3/5 (1)

- Guidebook for Demand Aggregation: Way Forward for Rooftop Solar in IndiaFrom EverandGuidebook for Demand Aggregation: Way Forward for Rooftop Solar in IndiaNo ratings yet

- Aspire Fees Approval Note-11Aug21Document2 pagesAspire Fees Approval Note-11Aug21Ravitej ReddyNo ratings yet

- Yathisha ResumeDocument2 pagesYathisha ResumeRavitej ReddyNo ratings yet

- New AssignDocument11 pagesNew AssignRavitej ReddyNo ratings yet

- Case Study - HULDocument22 pagesCase Study - HULRavitej ReddyNo ratings yet

- Assignment On Project Management - PGCBM-40 - Group-4Document16 pagesAssignment On Project Management - PGCBM-40 - Group-4Ravitej ReddyNo ratings yet

- International Management Assignment - RaviTej Reddy H - TB21003Document7 pagesInternational Management Assignment - RaviTej Reddy H - TB21003Ravitej ReddyNo ratings yet

- ILE Assignment - RaviTej Reddy H - TB21003Document2 pagesILE Assignment - RaviTej Reddy H - TB21003Ravitej ReddyNo ratings yet

- ACFrOgDWiRRcUD5GHtpzyfruX1Hvg3C5pkT13cnZ9RcNdqmAMd0T2Ls2 WHO GihEerK 5ChA3zr46zCxc6XIzi4eCibQbqnhaSBCCm3nHHKlcZ2fqzDlmcBCMCz a4aPiVZkuhl6dWgDha82X0cDocument5 pagesACFrOgDWiRRcUD5GHtpzyfruX1Hvg3C5pkT13cnZ9RcNdqmAMd0T2Ls2 WHO GihEerK 5ChA3zr46zCxc6XIzi4eCibQbqnhaSBCCm3nHHKlcZ2fqzDlmcBCMCz a4aPiVZkuhl6dWgDha82X0cRavitej ReddyNo ratings yet

- BSBHRM506 Student AssessmentDocument81 pagesBSBHRM506 Student Assessmentklm klmNo ratings yet

- Iii. Industry Analysis: 3.1 Industry Size, Segments and MaturityDocument8 pagesIii. Industry Analysis: 3.1 Industry Size, Segments and MaturityMans LaderaNo ratings yet

- Healthcare Marketing (Pre Read)Document20 pagesHealthcare Marketing (Pre Read)Himadri MamgainNo ratings yet

- Korn Ferry RPO EbookDocument30 pagesKorn Ferry RPO EbookHafizNo ratings yet

- Tunku Puteri Intan Safinaz School of Accountancy Semester A192 Bkan1013 Basic Accounting Exercise 2Document4 pagesTunku Puteri Intan Safinaz School of Accountancy Semester A192 Bkan1013 Basic Accounting Exercise 2Muhammad HakimiNo ratings yet

- Sharekhan On Britannia Industries 2Document7 pagesSharekhan On Britannia Industries 2Himanshu BisaniNo ratings yet

- GS Dig Assets Stratbook - Crypto Blockuccino 12apr2024 PDFDocument19 pagesGS Dig Assets Stratbook - Crypto Blockuccino 12apr2024 PDFjosephdingzNo ratings yet

- Business Mathematics Lesson 3 Key Concepts in Buying and Selling Part 1 Mark-Up, Markdown, and Mark-On (Week6)Document18 pagesBusiness Mathematics Lesson 3 Key Concepts in Buying and Selling Part 1 Mark-Up, Markdown, and Mark-On (Week6)Dearla Bitoon100% (5)

- Michael Mitku - Dry-Coffee ProposalDocument35 pagesMichael Mitku - Dry-Coffee Proposalsofoniesrom48No ratings yet

- DownloadDocument127 pagesDownloadBlack BullsNo ratings yet

- Lec. 4 - Debit Credit - PRMG 030Document15 pagesLec. 4 - Debit Credit - PRMG 030Ahmad SharaawyNo ratings yet

- ICM (Communication Work)Document6 pagesICM (Communication Work)Rifki Warri ZainNo ratings yet

- Marketplace Tracker v2Document23 pagesMarketplace Tracker v2Sandi IrawanNo ratings yet

- 1 Assignment TO BIG TOO FAILDocument2 pages1 Assignment TO BIG TOO FAILHaroon Z. ChoudhryNo ratings yet

- Solved Some Events Change Aggregate Demand From Ad0 To Ad1 DescribeDocument1 pageSolved Some Events Change Aggregate Demand From Ad0 To Ad1 DescribeM Bilal SaleemNo ratings yet

- Natnael Zekarias: Work ExperienceDocument2 pagesNatnael Zekarias: Work ExperiencentnlzekariasNo ratings yet

- Introduction To Consumer Behavior: Unit IDocument39 pagesIntroduction To Consumer Behavior: Unit ILalith Sai Yaswanth YadavNo ratings yet

- Retail Offer Advantage Through Brand Orienttaion in Luxury High Fashion StoresDocument161 pagesRetail Offer Advantage Through Brand Orienttaion in Luxury High Fashion StoresSugan PragasamNo ratings yet

- Stock in Transit (GR - IR Regrouping - Reclassification) - SAP BlogsDocument7 pagesStock in Transit (GR - IR Regrouping - Reclassification) - SAP BlogsusamaNo ratings yet

- Strategic Audit and Strategy Evaluation & ControlDocument47 pagesStrategic Audit and Strategy Evaluation & Controlshweta_4666493% (14)

- Business Law & RegulationDocument2 pagesBusiness Law & RegulationAshley Kate HapeNo ratings yet

- EOI For Garib Kalyan Rojgar Abhiyaan (GKRA)Document68 pagesEOI For Garib Kalyan Rojgar Abhiyaan (GKRA)Dilip MishraNo ratings yet

- Group 9Document10 pagesGroup 9normieotaku2001No ratings yet

- Digital Communications & Customer EngagementDocument9 pagesDigital Communications & Customer EngagementAlexander Frahm-FetherstonNo ratings yet

- Acca f6 Taxation Vietnam 2012 Dec QuestionDocument13 pagesAcca f6 Taxation Vietnam 2012 Dec QuestionNguyễn GiangNo ratings yet

- 2017 January 08Document36 pages2017 January 08siva kNo ratings yet

- Bacostmx-3tay2021-Quiz 1Document10 pagesBacostmx-3tay2021-Quiz 1Marjorie Nepomuceno100% (1)

- Entrep 1Document5 pagesEntrep 1Eddie PagalanNo ratings yet

- Shopify WL in Pakistan by Sheikh DaniyalDocument3 pagesShopify WL in Pakistan by Sheikh Daniyalyahyababar98No ratings yet

Presentation1 1

Presentation1 1

Uploaded by

Ravitej Reddy0 ratings0% found this document useful (0 votes)

6 views1 pageThis kaizen form documents improvements made to reduce waste in the CCA-01 cutting process. Specifically, an individual program was implemented for cutting child parts like fins, rudders, and landing gear instead of manual cutting. This addressed issues like 40% material waste and 20% reduced material lifespan from manual cutting errors. The automated program helped standardize the process, prevent waste, and save material and man hours compared to the previous status.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis kaizen form documents improvements made to reduce waste in the CCA-01 cutting process. Specifically, an individual program was implemented for cutting child parts like fins, rudders, and landing gear instead of manual cutting. This addressed issues like 40% material waste and 20% reduced material lifespan from manual cutting errors. The automated program helped standardize the process, prevent waste, and save material and man hours compared to the previous status.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

6 views1 pagePresentation1 1

Presentation1 1

Uploaded by

Ravitej ReddyThis kaizen form documents improvements made to reduce waste in the CCA-01 cutting process. Specifically, an individual program was implemented for cutting child parts like fins, rudders, and landing gear instead of manual cutting. This addressed issues like 40% material waste and 20% reduced material lifespan from manual cutting errors. The automated program helped standardize the process, prevent waste, and save material and man hours compared to the previous status.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 1

NAL program individual program implemented

Kaizen No :K- 07007

KAIZEN FORM

DEPARTME AREA/LOCATION OF

Sl. No TEAM MEMBERS NT Emp ID IMPROVEMENT IMPROVEMENT IN KAIZEN DETAILS

1 Jayashree KR PPC 816410

Sachin Sadlapur ME 817227 Initiator Name, Emp. Jayashree KR

2 Sidharth Roy Program 816365 CCA-01 Throughput Quality

ID & Department 816410 PPC

34 Ragupathi S Production 817271

OTHERS3M

Department POC Start date 21/03/2022

Safety

Cost Date of

Ravitej Reddy 02/06/2022

implementation

STATUS BEFORE STATUS AFTER BENEFITS

1.The majority of the child parts in CCA-01 cutting 1. The majority of child parts individual program 1. 40% Cost of material wastage FY2022.

on manual, including the Fin, Rudder, and MLG implemented 2. 20% Material RT life savings .

AFT & FWD . 2. This type of issue can be avoided implemented for

lectra cutting and making the DXF programs accordingly

2. Manual cutting issues leading to material to prevent manual cutting from being stopped. As a

waste and material RT life loss, travel time losses,

and lost man hours result, material RT life can be saved, un wanted

material is wasted, and manpower traveling of material

can be greatly reduced .

PHOTO BEFORE PHOTO AFTER STANDARDISATION

NA

HORIZONTAL DEPLOYMENT

Applicable for NAL CCA-01 .

You might also like

- LBO Analysis TemplateDocument11 pagesLBO Analysis TemplateBobby Watkins75% (4)

- Valid SOP: Standard Operating ProceduresDocument10 pagesValid SOP: Standard Operating ProceduresShahid Raza100% (2)

- IPCRF - ITO 1 Revised PIDocument6 pagesIPCRF - ITO 1 Revised PIJekyll Dupio CadungogNo ratings yet

- Bakhtiar Saffuan B Baharudin: Curriculum VitaeDocument5 pagesBakhtiar Saffuan B Baharudin: Curriculum Vitaethiwa karanNo ratings yet

- XVFC Work Order Monitoring Format NewDocument2 pagesXVFC Work Order Monitoring Format Newకొల్లి రాఘవేణిNo ratings yet

- 000-Za-E-M09412 - A Ms For Fiber Optic Cable Installation - 13!08!2019Document20 pages000-Za-E-M09412 - A Ms For Fiber Optic Cable Installation - 13!08!2019syam prasadNo ratings yet

- Vax Consultants Pvt. LTD.: Foundation & Structural EngineersDocument1 pageVax Consultants Pvt. LTD.: Foundation & Structural Engineersmohana tNo ratings yet

- Gemss e 28 r01 (0) Cable TraysDocument6 pagesGemss e 28 r01 (0) Cable TraysAdel KlkNo ratings yet

- December Outhouse 2022Document4 pagesDecember Outhouse 2022Forrulh AbdullahNo ratings yet

- Corrective Preventive Action Procedure 000-Za-E-209608-1Document4 pagesCorrective Preventive Action Procedure 000-Za-E-209608-1ghada gattouch100% (1)

- Integrated Departmental Manual Caustic Soda UnitDocument2 pagesIntegrated Departmental Manual Caustic Soda UnitSANJAY AGRAHARINo ratings yet

- MQP - Fiber Optic CableDocument6 pagesMQP - Fiber Optic CableSiva KumarNo ratings yet

- Location Wise FGD Projects in IndiaDocument16 pagesLocation Wise FGD Projects in IndiaVibhas KumarNo ratings yet

- Installation of Light Fitting.Document68 pagesInstallation of Light Fitting.Anandu AshokanNo ratings yet

- CC 1nd and Part BillDocument10 pagesCC 1nd and Part Billse rwsNo ratings yet

- 000-Za-E-M09411 - A Ms For Cable Glanding and TerminationDocument28 pages000-Za-E-M09411 - A Ms For Cable Glanding and Terminationsyam prasad100% (1)

- Vernier Calibration 08122020Document1 pageVernier Calibration 08122020Nevil Consultancy ServicesNo ratings yet

- Machining FMEA Rev.01 Dated 10.02.2022Document1 pageMachining FMEA Rev.01 Dated 10.02.2022GARIMA CASTINGS, JAIPURNo ratings yet

- Adobe Scan 04-Apr-2024Document1 pageAdobe Scan 04-Apr-2024ssetexchjbpNo ratings yet

- TS Track Works TA06 Track ChangesDocument95 pagesTS Track Works TA06 Track ChangesAlexYoungNo ratings yet

- SP132B Tky Prim - 3Document4 pagesSP132B Tky Prim - 3luwekbinotNo ratings yet

- Estimate For 1st RA Bill of Khonjonighona GPSDocument11 pagesEstimate For 1st RA Bill of Khonjonighona GPSTushar AjantaNo ratings yet

- Machining FMEA - Rev.01 - Dated 10.02.2022Document1 pageMachining FMEA - Rev.01 - Dated 10.02.2022GARIMA CASTINGS, JAIPURNo ratings yet

- IC Project Charter With Example Data 8556 - PowerPointDocument9 pagesIC Project Charter With Example Data 8556 - PowerPointDanang SetiawanNo ratings yet

- 2 Fin2016 Annual Investment Plan - A - eDocument173 pages2 Fin2016 Annual Investment Plan - A - eDuane de MesaNo ratings yet

- CEA March 2022Document45 pagesCEA March 2022Sumiran BansalNo ratings yet

- Ijbtpartment of Qebutatton: .Ltepublit of TL Ilipp TLFFDocument13 pagesIjbtpartment of Qebutatton: .Ltepublit of TL Ilipp TLFFjeanNo ratings yet

- DNV Kick Off Meeting - 20220623 NYDocument58 pagesDNV Kick Off Meeting - 20220623 NYjoekaledaNo ratings yet

- Project ReportDocument18 pagesProject Reportmonika mahajanNo ratings yet

- Prime Minister Globas SDGs Achievement Programe 2016-18 LG&CD OKARADocument10 pagesPrime Minister Globas SDGs Achievement Programe 2016-18 LG&CD OKARABilal LiaqatNo ratings yet

- Price Bid - CoringDocument2 pagesPrice Bid - CoringVisu RaoNo ratings yet

- Last Five Years Hse Statistics As On July 2020: Year Manhours Worked No of Lti No of Total Lost DaysDocument1 pageLast Five Years Hse Statistics As On July 2020: Year Manhours Worked No of Lti No of Total Lost DayspjosesmNo ratings yet

- For Information: Jawaharpur Vidyut Utpadan Nigam LimitedDocument18 pagesFor Information: Jawaharpur Vidyut Utpadan Nigam Limiteddattasudipto4339No ratings yet

- Meritlistdi&cDocument362 pagesMeritlistdi&cOCILABS Origin & Cause InvestigationNo ratings yet

- Claimspaid 2021Document72 pagesClaimspaid 2021sNo ratings yet

- GEMSS-C-03 Design Parameters For Civil Works (Rev 01)Document23 pagesGEMSS-C-03 Design Parameters For Civil Works (Rev 01)algie mendozaNo ratings yet

- Tackling FSRU Operational ChallengesDocument22 pagesTackling FSRU Operational ChallengesAnonymous icnhaNsFNo ratings yet

- To Construct Chemical Storage Shelter and Lube Oil Drums at Dcu Unit 32 Area 3Document15 pagesTo Construct Chemical Storage Shelter and Lube Oil Drums at Dcu Unit 32 Area 3MUHAMAD ROZEE MAT AZMINo ratings yet

- SMS - 67390 8jb0a - K2MCDocument21 pagesSMS - 67390 8jb0a - K2MCmani sNo ratings yet

- Boiler Foundation (Unit#1 & Unit#2) - Analysis and Design of Foundation - Pile Group AnalysisDocument15 pagesBoiler Foundation (Unit#1 & Unit#2) - Analysis and Design of Foundation - Pile Group AnalysisMRITYUNJOY DUTTANo ratings yet

- 000-ZA-E-M09407 - B MS For Cabinets, Panels, Cubicle & Power & Lighting Panel-Boards - RECTIFIEDDocument20 pages000-ZA-E-M09407 - B MS For Cabinets, Panels, Cubicle & Power & Lighting Panel-Boards - RECTIFIEDsyam prasadNo ratings yet

- 04th September 2021 (Ashar Metro)Document30 pages04th September 2021 (Ashar Metro)avinash rathodNo ratings yet

- E-021 SLDDocument1 pageE-021 SLDSyedNo ratings yet

- Dewan: Corrective and Preventive Action FormDocument12 pagesDewan: Corrective and Preventive Action Formareib_hassan100% (1)

- MS For PEB Erection R1Document16 pagesMS For PEB Erection R1Gabriel GabeNo ratings yet

- OS 2024-25-Unlocked-CompressedDocument16 pagesOS 2024-25-Unlocked-Compressedatulshubh2407No ratings yet

- Pep 20083221Document221 pagesPep 20083221imri ssNo ratings yet

- Surveillance Finding Summary: Directorate General of Civil Aviation Directorate of Airworthiness and Aircraft OperationsDocument3 pagesSurveillance Finding Summary: Directorate General of Civil Aviation Directorate of Airworthiness and Aircraft OperationsPuttra ArdiansyahNo ratings yet

- Saudi Aramco Typical Inspection Plan: Radiographic Testing (RT) On IK Projects Satip-Nde-Rt-01 15-Nov-17 Mechanical - NdeDocument11 pagesSaudi Aramco Typical Inspection Plan: Radiographic Testing (RT) On IK Projects Satip-Nde-Rt-01 15-Nov-17 Mechanical - NdeSyed Mohammed Abdul Aleem SoofiyaniNo ratings yet

- Single Line - Padukka Town-LayoutDocument1 pageSingle Line - Padukka Town-Layoutsajeevi piumikaNo ratings yet

- List of Candidate Selected Based On Written Test Cum Interview Held On 16.03.2019 at C-Dac Silchar Against Advt. No. Cdacs/01/2018 Dated 26.12.2018Document1 pageList of Candidate Selected Based On Written Test Cum Interview Held On 16.03.2019 at C-Dac Silchar Against Advt. No. Cdacs/01/2018 Dated 26.12.2018VillageSchool FoundationNo ratings yet

- TDM Be MW Sub Asgc MSD 7805 r0 BDocument20 pagesTDM Be MW Sub Asgc MSD 7805 r0 ByasirNo ratings yet

- Oil and Gas - SOGT Back in The Spotlight - 23/6/2010Document2 pagesOil and Gas - SOGT Back in The Spotlight - 23/6/2010Rhb InvestNo ratings yet

- BCI20200813161126 - C2 TMD Trip UnitDocument4 pagesBCI20200813161126 - C2 TMD Trip Unitranj kNo ratings yet

- Rev2 - MRA-TEC-P02 HATS (GENERAL)Document10 pagesRev2 - MRA-TEC-P02 HATS (GENERAL)Mohd Harraz AbbasyNo ratings yet

- Proposed Budget 2020 Rev 2Document11 pagesProposed Budget 2020 Rev 2MarieNo ratings yet

- DMPB CardDocument1 pageDMPB Cardindrajit mondalNo ratings yet

- High 5 PQDocument175 pagesHigh 5 PQsyed hadiNo ratings yet

- WCE - MOS - Installation of Reinforced Earth Wall 2Document28 pagesWCE - MOS - Installation of Reinforced Earth Wall 2Lim Yi SernNo ratings yet

- StarLAN Technology ReportFrom EverandStarLAN Technology ReportRating: 3 out of 5 stars3/5 (1)

- Guidebook for Demand Aggregation: Way Forward for Rooftop Solar in IndiaFrom EverandGuidebook for Demand Aggregation: Way Forward for Rooftop Solar in IndiaNo ratings yet

- Aspire Fees Approval Note-11Aug21Document2 pagesAspire Fees Approval Note-11Aug21Ravitej ReddyNo ratings yet

- Yathisha ResumeDocument2 pagesYathisha ResumeRavitej ReddyNo ratings yet

- New AssignDocument11 pagesNew AssignRavitej ReddyNo ratings yet

- Case Study - HULDocument22 pagesCase Study - HULRavitej ReddyNo ratings yet

- Assignment On Project Management - PGCBM-40 - Group-4Document16 pagesAssignment On Project Management - PGCBM-40 - Group-4Ravitej ReddyNo ratings yet

- International Management Assignment - RaviTej Reddy H - TB21003Document7 pagesInternational Management Assignment - RaviTej Reddy H - TB21003Ravitej ReddyNo ratings yet

- ILE Assignment - RaviTej Reddy H - TB21003Document2 pagesILE Assignment - RaviTej Reddy H - TB21003Ravitej ReddyNo ratings yet

- ACFrOgDWiRRcUD5GHtpzyfruX1Hvg3C5pkT13cnZ9RcNdqmAMd0T2Ls2 WHO GihEerK 5ChA3zr46zCxc6XIzi4eCibQbqnhaSBCCm3nHHKlcZ2fqzDlmcBCMCz a4aPiVZkuhl6dWgDha82X0cDocument5 pagesACFrOgDWiRRcUD5GHtpzyfruX1Hvg3C5pkT13cnZ9RcNdqmAMd0T2Ls2 WHO GihEerK 5ChA3zr46zCxc6XIzi4eCibQbqnhaSBCCm3nHHKlcZ2fqzDlmcBCMCz a4aPiVZkuhl6dWgDha82X0cRavitej ReddyNo ratings yet

- BSBHRM506 Student AssessmentDocument81 pagesBSBHRM506 Student Assessmentklm klmNo ratings yet

- Iii. Industry Analysis: 3.1 Industry Size, Segments and MaturityDocument8 pagesIii. Industry Analysis: 3.1 Industry Size, Segments and MaturityMans LaderaNo ratings yet

- Healthcare Marketing (Pre Read)Document20 pagesHealthcare Marketing (Pre Read)Himadri MamgainNo ratings yet

- Korn Ferry RPO EbookDocument30 pagesKorn Ferry RPO EbookHafizNo ratings yet

- Tunku Puteri Intan Safinaz School of Accountancy Semester A192 Bkan1013 Basic Accounting Exercise 2Document4 pagesTunku Puteri Intan Safinaz School of Accountancy Semester A192 Bkan1013 Basic Accounting Exercise 2Muhammad HakimiNo ratings yet

- Sharekhan On Britannia Industries 2Document7 pagesSharekhan On Britannia Industries 2Himanshu BisaniNo ratings yet

- GS Dig Assets Stratbook - Crypto Blockuccino 12apr2024 PDFDocument19 pagesGS Dig Assets Stratbook - Crypto Blockuccino 12apr2024 PDFjosephdingzNo ratings yet

- Business Mathematics Lesson 3 Key Concepts in Buying and Selling Part 1 Mark-Up, Markdown, and Mark-On (Week6)Document18 pagesBusiness Mathematics Lesson 3 Key Concepts in Buying and Selling Part 1 Mark-Up, Markdown, and Mark-On (Week6)Dearla Bitoon100% (5)

- Michael Mitku - Dry-Coffee ProposalDocument35 pagesMichael Mitku - Dry-Coffee Proposalsofoniesrom48No ratings yet

- DownloadDocument127 pagesDownloadBlack BullsNo ratings yet

- Lec. 4 - Debit Credit - PRMG 030Document15 pagesLec. 4 - Debit Credit - PRMG 030Ahmad SharaawyNo ratings yet

- ICM (Communication Work)Document6 pagesICM (Communication Work)Rifki Warri ZainNo ratings yet

- Marketplace Tracker v2Document23 pagesMarketplace Tracker v2Sandi IrawanNo ratings yet

- 1 Assignment TO BIG TOO FAILDocument2 pages1 Assignment TO BIG TOO FAILHaroon Z. ChoudhryNo ratings yet

- Solved Some Events Change Aggregate Demand From Ad0 To Ad1 DescribeDocument1 pageSolved Some Events Change Aggregate Demand From Ad0 To Ad1 DescribeM Bilal SaleemNo ratings yet

- Natnael Zekarias: Work ExperienceDocument2 pagesNatnael Zekarias: Work ExperiencentnlzekariasNo ratings yet

- Introduction To Consumer Behavior: Unit IDocument39 pagesIntroduction To Consumer Behavior: Unit ILalith Sai Yaswanth YadavNo ratings yet

- Retail Offer Advantage Through Brand Orienttaion in Luxury High Fashion StoresDocument161 pagesRetail Offer Advantage Through Brand Orienttaion in Luxury High Fashion StoresSugan PragasamNo ratings yet

- Stock in Transit (GR - IR Regrouping - Reclassification) - SAP BlogsDocument7 pagesStock in Transit (GR - IR Regrouping - Reclassification) - SAP BlogsusamaNo ratings yet

- Strategic Audit and Strategy Evaluation & ControlDocument47 pagesStrategic Audit and Strategy Evaluation & Controlshweta_4666493% (14)

- Business Law & RegulationDocument2 pagesBusiness Law & RegulationAshley Kate HapeNo ratings yet

- EOI For Garib Kalyan Rojgar Abhiyaan (GKRA)Document68 pagesEOI For Garib Kalyan Rojgar Abhiyaan (GKRA)Dilip MishraNo ratings yet

- Group 9Document10 pagesGroup 9normieotaku2001No ratings yet

- Digital Communications & Customer EngagementDocument9 pagesDigital Communications & Customer EngagementAlexander Frahm-FetherstonNo ratings yet

- Acca f6 Taxation Vietnam 2012 Dec QuestionDocument13 pagesAcca f6 Taxation Vietnam 2012 Dec QuestionNguyễn GiangNo ratings yet

- 2017 January 08Document36 pages2017 January 08siva kNo ratings yet

- Bacostmx-3tay2021-Quiz 1Document10 pagesBacostmx-3tay2021-Quiz 1Marjorie Nepomuceno100% (1)

- Entrep 1Document5 pagesEntrep 1Eddie PagalanNo ratings yet

- Shopify WL in Pakistan by Sheikh DaniyalDocument3 pagesShopify WL in Pakistan by Sheikh Daniyalyahyababar98No ratings yet