Professional Documents

Culture Documents

Portal Frame

Portal Frame

Uploaded by

akankshapenOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Portal Frame

Portal Frame

Uploaded by

akankshapenCopyright:

Available Formats

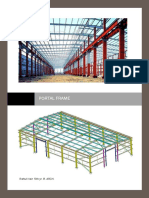

PORTAL FRAME THEORY Frame works:

A portal frame may be defined as a continuous or rigid frame which has the basic characteristics of a rigid or restrained joint between the supporting members or column and the spanning member or beam. The object of this continuity of the portal frame is to reduce bending moment in the spanning member by allowing the frame to act as one structural entity, thus distribution the stresses throughout the frame. If a conventional simply supported beam was used (over a large span) an excessive bending moment would occur at mid-span which would necessitate a deep heavy beam or a beam shaped to give a large cross section at midspan. Alternatively a deep cross member of lattice struts and ties could be used. The main advantage of the simple supported frame lies in the fact that the column loading is for all practicable purposes axial and therefore no bending is induced into the supporting members, which may well case design problems since it would be statically determinate, but does not necessarily produce an economic structure. Furthermore the use of a portal frame eliminates the need for a lattice of struts and ties within the roof space, giving a greater usable volume to the structure and generally a more pleasing internal appearance.

Hinges: 1. Fixed or rigid portal frameall connections between frame members are rigid. This will give bending moments of lower magnitude more evenly distributed than other forms. Used for small to medium size frames where the moments transferred to the foundations will not be excessive.

2. Two pin portal framehinges are used at the base connections to eliminate the tendency of the base rotate. The bending moments resisted by the supporting members will be greater than those encountered in the rigid portal frame. Main use is where high base moments and weak ground conditions are encountered.

3. Three pin portal framethis form of the frame has high hinged joints at the base connections and at the centre of the spinning member. The effect of the third hinge is to reduce the bending moments in the spanning member but to increase deflection. To overcome this latter disadvantage a deeper beam must be given a moderate pitch to raise the apex well above the eaves level. Two other advantages of the three pin portal frame are that the design is simplified since the frame is statically determined and on the site they are easier to erect, particularly when preformed in sections. Portal frames constructed of steel, concrete or timber can take the form of the usual roof profiles used for single or multi-span buildings such as flat, pitched, north light, monitor and arch. The frames are generally connected over the spanning members with purlins designed to carry and accept the fixing of lightweight roof coverings or decking. The walls can be of similar material fixed to sheeting rails attached to the supporting members or alternatively clad with brick or infill panels.

SACHIN.G.POKHARE ROLL NO-5

Concrete portal frames

Concrete portal frames are invariably manufactured from high quality precast concrete suitably reinforced. In the main use of precast concrete portal frames is confined to low pitch (4 to 22) single a wide range of design from only a few standard components. Wall finishes can be varied and intermixed since they are non-load bearing and therefore have to provide only the degree of resistance required for fire, thermal and sound insulation, act as a barrier to the elements and resist positive and negative wind pressures.

Foundations and fixings

The foundation for a precast concrete portal frame usually consists of a reinforced concrete isolated base or pad designed to suit loading and ground bearing conditions. The frame can be connected to the foundations by variety of methods:

1. Pocket connections-

the foot of the supporting member is located and housed in a void or pocket formed in the base so that there is an all round clearance of 25mm to allow for plumbing and final adjustment before the column is grouted into the foundation base.

2.Base plate connection-

a steel base plate is welded to the main reinforcement of the supporting members, or alternatively it could be cast into the column using fixing lugs welded to the back of the base plate. Holding down bolts are cast into the foundation base; the erection and fixing procedure follows that described for structural steelwork.

3.Pin joint or hinged connection-

a special or bearing palte is bolted to the foundation and the mechanical connection is made when the frames are erected. The choice of connection method depends largely upon the degree of fixity required and the method adopted by the manufacturer of the his particular system.

Advantages:

Maintenance not usually requiredOwn built in resistance to fireWind resistance is such that wind bracing is not required Aesthetically pleasing

Steel portal frames:

Steel portal frames can be fabricated from standard universal beam, column and box sections. Alternatively a lattice construction of flats, angles or tubular can be used. Most forms of roof profiles can be designed and constructed giving a competitive range when compared with other materials used in portal frame construction. The majority of systems employ welding techniques for the fabrication of components which are joined together on site using bolts or welding. An alternative system uses special knee joint, apex joint and base joint components which are joined on site to square cut standard beam or column sections supplied by the main contractor or by the manufacturer producing the jointing pieces. The frames are designed to carry lightweight roof coverings of the same loading conditions as those given for pre cast concrete portal frame.

SACHIN.G.POKHARE ROLL NO-5

Foundations and fixings:

The foundation is usually a reinforced concrete isolated base or pad foundation designed to suit loading and ground bearing conditions. The connection of the frame to the foundation can be by,

1. Pocket connection:

The foot of the supporting member is supported and grouted into a pocket formed in the concrete foundation as described for pre cast portal frames. To facilitate leveling, some designs have gussets welded to the flanges of the column.

2. Base plate connection:

Traditional structural steel work column to foundation connection using a slab or a gusset base fixed to a reinforced concrete foundation with cast in holding down bolts.

3. Pin or hinge connection:

Special bearing plates designed to accommodate true pin or rocker devices are fixed by holding down bolts to the concrete foundation to give the required low degree of rigidity at the connection.

Advantages:

Standard range of manufactures systems Less overall dead load Good wind resistance Quick assembly

Disadvantages:

Corrosive material hence regular protective maintenance required Lower fire resistance

Timber portal frames:

Timber portal frames can be manufactured by several methods which produce a light, strong frame of pleasing appearance which renders them suitable for buildings such as churches, halls and gymnasiums where clear space and appearance are important. The common methods used are,

A. Glued laminated portal frames:

The main objective of forming a laminated member consisting of glued layers of thin section timber members is to obtain an overall increase in strength of the complete component over that which could be expected from a similar sized solid section of a particular species of timber. The selection of suitable quality softwoods of the right moisture content is important for a successful design. Site work is simple consisting of connecting the foot of the supporting member to the metal shoe fixing or to a pivot housing bolted to the concrete foundation and connecting the joint at the apex or crown with a bolt fixing or hinge device. Any form of walling can be used in conjunction with these frames as long as they comply with the applicable building regulations.

SACHIN.G.POKHARE ROLL NO-5

B. Plywood portal frames:

These frames are suitable for small halls, churches and schools with spans in the region of 9m. The portal frames are in boxed beams consisting of a skeleton core of softwood members faced on both sides with plywood which rakes the bending stresses. The hollow form of the construction enables electrical and other small services to be accommodated within the frame members.

C. Solid timber and plywood gussets:

These frames are placed close to each other and are clad with a plywood sheath so that the finished structure acts as a shell giving a lightweight building which is very rigid and strong. The foundations of this type of frame consist of a ground beam or alternatively the frames can be fixed to the edge of the raft slab. A timber spreader or a sole plate is used along the entire length of the building to receive and distribute the thrust loads of the frames. Connection to this spreader plate is made by using standard galvanized steel joists hangers or by using galvanized steel angle cleats.

Advantages:

Constructed from readily available materials at an economic cost. Light in weight Easy to transport and erect Can be trimmed and easily adjusted on site Protection against fungi can be done by impregnation Pleasing finish

SACHIN.G.POKHARE ROLL NO-5

You might also like

- Structural Integrity and FailureDocument12 pagesStructural Integrity and Failurecal2_uniNo ratings yet

- Comparative Study of Sections Used in Industrial Roof Truss and Portal FrameDocument5 pagesComparative Study of Sections Used in Industrial Roof Truss and Portal FrameIJCIRAS Research PublicationNo ratings yet

- Concrete PortalDocument6 pagesConcrete PortalolomizanaNo ratings yet

- Portal FrameDocument9 pagesPortal FrameAbhishek Rajgor100% (1)

- Portal FrameDocument16 pagesPortal FrameJoshua Mark MuhenyeriNo ratings yet

- Unit - 5 Portal FrameDocument12 pagesUnit - 5 Portal FrameRajiv Reddy100% (2)

- Portal FramesDocument33 pagesPortal Framesskpawar11No ratings yet

- Steel Portal Frames 4 PDFDocument37 pagesSteel Portal Frames 4 PDFPn EkanayakaNo ratings yet

- Bracings For Portal FramesDocument6 pagesBracings For Portal FramesJulianNo ratings yet

- Portal Frame ConstructionDocument2 pagesPortal Frame Constructionriz2010No ratings yet

- Steel Design To BS 5950Document100 pagesSteel Design To BS 5950Erwin LimNo ratings yet

- Analysis of Portal FrameDocument16 pagesAnalysis of Portal FrameKanchana RandallNo ratings yet

- Steelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiesDocument56 pagesSteelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiessubamanivelNo ratings yet

- Minimum Horizontal Loads For BalustradesDocument1 pageMinimum Horizontal Loads For Balustradessbandara77No ratings yet

- Flat SlabDocument31 pagesFlat SlabAnjani Kumar SinghNo ratings yet

- Basic Structural Design ConceptsDocument21 pagesBasic Structural Design Conceptscuterose95No ratings yet

- Limit State DesignDocument12 pagesLimit State DesignEzhil KumarNo ratings yet

- Design Example-Beam Compact SectionDocument13 pagesDesign Example-Beam Compact SectionManoj RautNo ratings yet

- Pile Cap DesignDocument4 pagesPile Cap DesignMohamed RifdyNo ratings yet

- Design of Steel Frames - BS 5950Document46 pagesDesign of Steel Frames - BS 5950Rashy PR100% (1)

- Portal Frames PDFDocument28 pagesPortal Frames PDFLingka100% (1)

- Design PDFDocument26 pagesDesign PDFLingkaNo ratings yet

- Shear Wall - BS8110-97-007Document4 pagesShear Wall - BS8110-97-007Kavin TamNo ratings yet

- Lecture 5 Structural Steel Design MuDocument23 pagesLecture 5 Structural Steel Design MuPenelope MalilweNo ratings yet

- Portal FrameDocument8 pagesPortal Framegattu92No ratings yet

- Structure Engineer CertificateDocument1 pageStructure Engineer CertificateSantosh100% (2)

- Portal FrameDocument9 pagesPortal FrameRahul TomarNo ratings yet

- Pile DesignDocument15 pagesPile Designmohanty_anantakumar6332100% (1)

- Steelwork Framing C2Document26 pagesSteelwork Framing C2Luwalhati TomilasNo ratings yet

- Composite ConstructionDocument27 pagesComposite Constructionharsha333100% (1)

- Steel Structural System: Types of Portal FramesDocument2 pagesSteel Structural System: Types of Portal FramesSohanNo ratings yet

- Crack Width - BS 8007Document1 pageCrack Width - BS 8007nishchintNo ratings yet

- Marking Scheme Q6Document4 pagesMarking Scheme Q6dexterbox1No ratings yet

- Example - Pile Cap DesignDocument4 pagesExample - Pile Cap DesignAnonymous xcFcOgMiNo ratings yet

- Steel Structures Design Based On Eurocode 3Document38 pagesSteel Structures Design Based On Eurocode 3Oentoeng Kartono100% (1)

- Jacketing: Er. Shaikh Arshad Vjti Mtech CMDocument21 pagesJacketing: Er. Shaikh Arshad Vjti Mtech CMnazeer_mohdNo ratings yet

- Structural,: PDF Compression, Ocr, Web-Optimization With Cvision'S PdfcompressorDocument174 pagesStructural,: PDF Compression, Ocr, Web-Optimization With Cvision'S PdfcompressorZuhal ZaeemNo ratings yet

- A Multistory Building Higher Than 21m or 21 To 29 Floor Buildings With Unknown Height Described As HighDocument10 pagesA Multistory Building Higher Than 21m or 21 To 29 Floor Buildings With Unknown Height Described As HighTri Haryadi LinggialloNo ratings yet

- Lift ShaftDocument21 pagesLift Shaftvijking100% (2)

- GF SlabDocument8 pagesGF Slabcheligp1981No ratings yet

- Tied Foundations-Portal FrameDocument3 pagesTied Foundations-Portal FrameJaime Manalili LandinginNo ratings yet

- Structural LayoutDocument38 pagesStructural LayoutvijaystructuralNo ratings yet

- Exam Preparation Chartered Member Solutions 20080403Document36 pagesExam Preparation Chartered Member Solutions 20080403Jordy NgNo ratings yet

- Free Download Here: British Standard Code of Practice Cp110 PDFDocument2 pagesFree Download Here: British Standard Code of Practice Cp110 PDFخالد حسن0% (1)

- Standards & RegulationsDocument12 pagesStandards & RegulationsdantranzNo ratings yet

- Bridge Bearings, Expansion Joints & ParapetsDocument81 pagesBridge Bearings, Expansion Joints & ParapetsSAMNo ratings yet

- Design of Trusses With Light Gauge Cold Formed SteDocument13 pagesDesign of Trusses With Light Gauge Cold Formed SteShrikant PhatakNo ratings yet

- Joints in Steel Construction - Simple Connections - Part 01 PDFDocument4 pagesJoints in Steel Construction - Simple Connections - Part 01 PDFkakem61No ratings yet

- Comflor: Composite Floor DeckingDocument32 pagesComflor: Composite Floor DeckingjparsbNo ratings yet

- Analysis of Portal Frame Building in Accordance To EN 1993-1-1 (2005) 1 DescriptionDocument36 pagesAnalysis of Portal Frame Building in Accordance To EN 1993-1-1 (2005) 1 DescriptionSami Abdelgadir MohammedNo ratings yet

- Chapter 1.0 - StaircaseDocument31 pagesChapter 1.0 - StaircaseAzfar0% (1)

- Shear KeyDocument14 pagesShear KeyMbalekelwa MpembeNo ratings yet

- Design Guide For Steel Trusses (Part 1)Document4 pagesDesign Guide For Steel Trusses (Part 1)Baguma Grace GariyoNo ratings yet

- PDF Compression, Ocr, Web-Optimization With Cvision'S PdfcompressorDocument5 pagesPDF Compression, Ocr, Web-Optimization With Cvision'S Pdfcompressorpn0% (1)

- Combined Footing Design With Example and Types of Combined FootingDocument2 pagesCombined Footing Design With Example and Types of Combined FootingNick GeneseNo ratings yet

- BS 5950-2000 Example 001Document5 pagesBS 5950-2000 Example 001Anitha Hassan KabeerNo ratings yet

- Design CatalogueDocument78 pagesDesign CatalogueHuy Phạm Ngô HoàngNo ratings yet

- Design Principles For Composite BeamsDocument11 pagesDesign Principles For Composite BeamsNaftary GathimbaNo ratings yet

- Portal Frames Final - 2Document19 pagesPortal Frames Final - 2Ar Vivek KareliaNo ratings yet