Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

12 views4-Screw Thread Measurement

4-Screw Thread Measurement

Uploaded by

Adarsh KhotThe document discusses the tool maker's microscope, which is used to measure parallel screw threads and gears. It describes how the microscope works by projecting a shadow image through prisms onto a ground glass screen, where measurements are made using cross lines. The procedure for measuring thread pitch involves focusing the microscope on a hacksaw blade, taking an initial reading when a cross line aligns with one edge, then moving the table to align with the next edge and recording the difference as the pitch. The tool maker's microscope can be used to measure lengths, angles, threads, and compare profiles.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You might also like

- Business Plan Security CompanyDocument27 pagesBusiness Plan Security CompanyJiji100% (3)

- Report Experiment ThreadDocument11 pagesReport Experiment Threadsparklingstars2705No ratings yet

- Uppers Various Info DatabaseDocument54 pagesUppers Various Info DatabaseJason BexonNo ratings yet

- Nissan 5 Forces PresentationDocument13 pagesNissan 5 Forces Presentationkomala_sekhar0% (1)

- Peterbilt Rear Air Suspensions AdjustmentDocument42 pagesPeterbilt Rear Air Suspensions AdjustmentCellblocX83% (6)

- Family ResourcesDocument33 pagesFamily ResourcesJackie S LaymanNo ratings yet

- Unit 2 Screw Thread - Gear Elements - Surface FinishDocument53 pagesUnit 2 Screw Thread - Gear Elements - Surface FinishDeepak MisraNo ratings yet

- 1.tool Makers MicroscopeDocument7 pages1.tool Makers MicroscopeelavarasanNo ratings yet

- Screw Thread MeasurementsDocument77 pagesScrew Thread MeasurementsSridhar SreeNo ratings yet

- Instrumentation CH3Document84 pagesInstrumentation CH3muru0105No ratings yet

- The ToolmakeeerDocument31 pagesThe ToolmakeeerVarunNo ratings yet

- Experiment No. 1A Tool Maker'S MicroscopeDocument4 pagesExperiment No. 1A Tool Maker'S MicroscopePraveen KumaarNo ratings yet

- MTM Metro Expt1 ManualDocument10 pagesMTM Metro Expt1 ManualBhargav DindukurthiNo ratings yet

- Angle Measurement PDFDocument85 pagesAngle Measurement PDFSnigdhaNo ratings yet

- UNIT VII Angular MeasurementsDocument99 pagesUNIT VII Angular MeasurementsAkash PatilNo ratings yet

- Unit 3Document120 pagesUnit 3ramesh_h2002No ratings yet

- Experiment No. 4 Study and Applications of Tool Maker'S MicroscopeDocument4 pagesExperiment No. 4 Study and Applications of Tool Maker'S MicroscopeAbdulaziz almasoudiNo ratings yet

- 07-Surface CharacteristicsDocument63 pages07-Surface CharacteristicsClash GodNo ratings yet

- Metrology: BY A.Radha Krishna, Hod, Dept. of Mech. MietDocument28 pagesMetrology: BY A.Radha Krishna, Hod, Dept. of Mech. MietRadha KrishnaNo ratings yet

- MI Tool Makers MicroscopeDocument9 pagesMI Tool Makers MicroscopeGurpreet KaurNo ratings yet

- Screw Thread MeasurementDocument55 pagesScrew Thread MeasurementMadhuNo ratings yet

- Screwthreadmeasurement 170418161010 PDFDocument30 pagesScrewthreadmeasurement 170418161010 PDFejkiranNo ratings yet

- ScrewDocument20 pagesScrewIxora MyNo ratings yet

- Tool Makers MicroscopeDocument7 pagesTool Makers MicroscopeAnand Babu100% (2)

- The Tool MakerDocument4 pagesThe Tool MakerRitesh YadavNo ratings yet

- Form Measurement: Unit 3Document68 pagesForm Measurement: Unit 3Rama SamyNo ratings yet

- Unit-4 MMDocument74 pagesUnit-4 MMRama SamyNo ratings yet

- Unit-4: Screw Thread and Gear Measurement: Hareesha N Gowda Dept of Aeronautical Engineering DSCE, Bangalore-78Document77 pagesUnit-4: Screw Thread and Gear Measurement: Hareesha N Gowda Dept of Aeronautical Engineering DSCE, Bangalore-78Elavarasan SivaNo ratings yet

- 8/20/2014 1 Hareesha N Gowda, DSCE, Blore-78Document77 pages8/20/2014 1 Hareesha N Gowda, DSCE, Blore-78Santosh DabholeNo ratings yet

- Screw ThreadDocument46 pagesScrew Threadmohd mansoor100% (1)

- Angular MeasumentDocument51 pagesAngular MeasumentVinay PanditNo ratings yet

- Metrology Assignment 2Document14 pagesMetrology Assignment 2Aadish vikramNo ratings yet

- 5.EMM Lab ManualDocument38 pages5.EMM Lab ManualRakeshkumarcegNo ratings yet

- Machinetools 6Document40 pagesMachinetools 6Archit GyaneshwarNo ratings yet

- L27 - Optical Measuring InstrumentsDocument14 pagesL27 - Optical Measuring Instrumentschaitanyamohod2020No ratings yet

- Thread Cutting, Tapping and BroachingDocument95 pagesThread Cutting, Tapping and BroachingKundan PatilNo ratings yet

- Unit III NewDocument21 pagesUnit III NewsathiaNo ratings yet

- Tool Maker MicroscopeDocument4 pagesTool Maker MicroscopeShyam SenthilNo ratings yet

- Lab Manual: Machining Processes and Metrology Lab (MEE211L)Document27 pagesLab Manual: Machining Processes and Metrology Lab (MEE211L)Agnivesh SharmaNo ratings yet

- Tool Makers MicroscopeDocument2 pagesTool Makers Microscopesukriti dhauni100% (1)

- Government Engineering College: Angular MeasurementDocument23 pagesGovernment Engineering College: Angular Measurementanjum malekNo ratings yet

- Linear MeasurementsDocument52 pagesLinear MeasurementsO20 0023 Chandrasekaran. S. [PT]No ratings yet

- BTM2133-Chapter 7 Angle Measurement PDFDocument41 pagesBTM2133-Chapter 7 Angle Measurement PDFAswaja313No ratings yet

- Screw Thread Measurement New1 (Autosaved)Document67 pagesScrew Thread Measurement New1 (Autosaved)Aditi KaradeNo ratings yet

- Metrology Lab ManualDocument36 pagesMetrology Lab Manualuvrsunil_kumar100% (2)

- MetrologyDocument135 pagesMetrologySai Bharath Velpuri100% (3)

- Production Technoloy Lab 012110045519 1Document35 pagesProduction Technoloy Lab 012110045519 1raajeeradha@gmail.comNo ratings yet

- A Review Paper On Pitch Screw Gauge Working: Vikas Chauhan, Muneesh Chauhan, Sahil Verma, Raman KumarDocument6 pagesA Review Paper On Pitch Screw Gauge Working: Vikas Chauhan, Muneesh Chauhan, Sahil Verma, Raman KumarMuskan MalikNo ratings yet

- Thread Cutting, Tapping and Broaching: Nainik Shah - 171040075 Ajinkya Shah - 171040076 Ameya Iyer - 171040089Document87 pagesThread Cutting, Tapping and Broaching: Nainik Shah - 171040075 Ajinkya Shah - 171040076 Ameya Iyer - 171040089Kundan PatilNo ratings yet

- 3.metrology 153Document28 pages3.metrology 153alinader20022No ratings yet

- Straightness, Flatness, ParallelismDocument31 pagesStraightness, Flatness, ParallelismLiaqat Ahamed100% (5)

- Form Measurement: Vishal Nair Assistant Professor-Mechanical Mesce KuttipuramDocument67 pagesForm Measurement: Vishal Nair Assistant Professor-Mechanical Mesce KuttipuramSivaperumal MNo ratings yet

- MMM Ex 2 and 3Document6 pagesMMM Ex 2 and 3SANDEEP BUDANIANo ratings yet

- MicrometerDocument21 pagesMicrometerSulficker AliNo ratings yet

- Vernier To ComparatorDocument78 pagesVernier To ComparatorAtul GaurNo ratings yet

- Chapter1 Linearmeasurements 7 June 2020Document39 pagesChapter1 Linearmeasurements 7 June 2020Rayuth KEATNo ratings yet

- #4 Pengukuran Geometri 2: Metrologi Industri & Kontrol KualitasDocument87 pages#4 Pengukuran Geometri 2: Metrologi Industri & Kontrol KualitasChegg Cek akunNo ratings yet

- Linear MeasurementsDocument54 pagesLinear MeasurementsNaman Dave100% (1)

- Angle Measuring DevicesDocument17 pagesAngle Measuring DevicesIqbal Singh ParmarNo ratings yet

- Angle Measurement 2Document7 pagesAngle Measurement 2Jonathan Da Costa100% (1)

- Unit No. 04: Angular MeasurementDocument9 pagesUnit No. 04: Angular MeasurementKrishna NikamNo ratings yet

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingFrom EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingRating: 5 out of 5 stars5/5 (2)

- Prompting Science and Engineering Students in Practical TrigonometryFrom EverandPrompting Science and Engineering Students in Practical TrigonometryNo ratings yet

- Optics and Optical Instruments: An IntroductionFrom EverandOptics and Optical Instruments: An IntroductionRating: 4 out of 5 stars4/5 (5)

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Assignment of Innovation and Entrepreneurship of XiaomiDocument14 pagesAssignment of Innovation and Entrepreneurship of XiaomiMd Shoumik HasanNo ratings yet

- New Salary Scales Updated February 2023 NAC ExtendedDocument2 pagesNew Salary Scales Updated February 2023 NAC ExtendedIon NNo ratings yet

- Zeos-Ad: Analogue Algorithmic Addressable Fire DetectorDocument2 pagesZeos-Ad: Analogue Algorithmic Addressable Fire DetectorMariusNo ratings yet

- Micro TeachingDocument7 pagesMicro TeachingMuhammed SahadNo ratings yet

- Air Handling UnitDocument6 pagesAir Handling UnitAgung SetiajiNo ratings yet

- Tender Document - Haryana Data CentreDocument58 pagesTender Document - Haryana Data CentreBullzeye StrategyNo ratings yet

- Chapter 3Document5 pagesChapter 3Sheila ShamimiNo ratings yet

- Rule 11 Gregslangmalakas Copy 2Document12 pagesRule 11 Gregslangmalakas Copy 2Gregorio AchanzarNo ratings yet

- Diploma in MarineDocument18 pagesDiploma in MarineKaung Min MoNo ratings yet

- Addressing & Network Protocols - PreQuiz - Attempt ReviewDocument4 pagesAddressing & Network Protocols - PreQuiz - Attempt Reviewvinay Murakambattu100% (1)

- Class002 - 201200394-201000327-201000542Document46 pagesClass002 - 201200394-201000327-201000542api-286690957No ratings yet

- B3-201-2018 - Developing and Using Justifiable Asset Health Indices For Tactical and Strategic Risk ManagementDocument10 pagesB3-201-2018 - Developing and Using Justifiable Asset Health Indices For Tactical and Strategic Risk ManagementNamLeNo ratings yet

- Bp344 Rules: Department of ArchitectureDocument11 pagesBp344 Rules: Department of ArchitectureMarie BacasNo ratings yet

- Migrate DHCP Scope(s) To Windows Server 2022 - PeteNetLiveDocument6 pagesMigrate DHCP Scope(s) To Windows Server 2022 - PeteNetLiveYudy KurniawanNo ratings yet

- Chapter No 03 Class 6th Notes For Computer Science English MediumDocument5 pagesChapter No 03 Class 6th Notes For Computer Science English MediumAbid HussainNo ratings yet

- Irs Wtc2020Document73 pagesIrs Wtc2020Himanshu SinghNo ratings yet

- Attorney General v. Joseph, (2006) CCJ 1 (AJ)Document97 pagesAttorney General v. Joseph, (2006) CCJ 1 (AJ)TiffanyNo ratings yet

- Coupled Level-Set and Volume of Fluid (CLSVOF) Solver ForDocument18 pagesCoupled Level-Set and Volume of Fluid (CLSVOF) Solver ForBharath kumarNo ratings yet

- How To Merge Two Switches With Different Active Zone SetsDocument3 pagesHow To Merge Two Switches With Different Active Zone SetslpuliceNo ratings yet

- NDT - Piping GuideDocument262 pagesNDT - Piping GuideCarlos CastilloNo ratings yet

- CC 2Document43 pagesCC 2iamsabaalyNo ratings yet

- 24 Micro-Cap Multibagger Stocks To Buy Now PDFDocument11 pages24 Micro-Cap Multibagger Stocks To Buy Now PDFPravin YeluriNo ratings yet

- Kalinga University at A Glance 1Document40 pagesKalinga University at A Glance 1Pranav Shukla PNo ratings yet

- 5.UART Serial Communication Module Design and SimulationDocument4 pages5.UART Serial Communication Module Design and Simulationvenkatahari babuNo ratings yet

- Globe Valves: Standard SpecificationDocument26 pagesGlobe Valves: Standard SpecificationHammad AshrafNo ratings yet

4-Screw Thread Measurement

4-Screw Thread Measurement

Uploaded by

Adarsh Khot0 ratings0% found this document useful (0 votes)

12 views37 pagesThe document discusses the tool maker's microscope, which is used to measure parallel screw threads and gears. It describes how the microscope works by projecting a shadow image through prisms onto a ground glass screen, where measurements are made using cross lines. The procedure for measuring thread pitch involves focusing the microscope on a hacksaw blade, taking an initial reading when a cross line aligns with one edge, then moving the table to align with the next edge and recording the difference as the pitch. The tool maker's microscope can be used to measure lengths, angles, threads, and compare profiles.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses the tool maker's microscope, which is used to measure parallel screw threads and gears. It describes how the microscope works by projecting a shadow image through prisms onto a ground glass screen, where measurements are made using cross lines. The procedure for measuring thread pitch involves focusing the microscope on a hacksaw blade, taking an initial reading when a cross line aligns with one edge, then moving the table to align with the next edge and recording the difference as the pitch. The tool maker's microscope can be used to measure lengths, angles, threads, and compare profiles.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

12 views37 pages4-Screw Thread Measurement

4-Screw Thread Measurement

Uploaded by

Adarsh KhotThe document discusses the tool maker's microscope, which is used to measure parallel screw threads and gears. It describes how the microscope works by projecting a shadow image through prisms onto a ground glass screen, where measurements are made using cross lines. The procedure for measuring thread pitch involves focusing the microscope on a hacksaw blade, taking an initial reading when a cross line aligns with one edge, then moving the table to align with the next edge and recording the difference as the pitch. The tool maker's microscope can be used to measure lengths, angles, threads, and compare profiles.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 37

Floating carriage micro meter

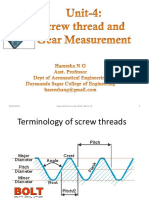

• DEFINITIONS RELATED TO PARALLEL SCREW THREADS

• Major Diameter: The diameter of an imaginary cylinder

(termed the major cylinder) which just embraces the crests

of the external thread or the roots of an internal thread.

• Minor Diameter: The diameter of an imaginary cylinder

(termed the minor cylinder) which just embraces the roots of

an external thread or the crests of an internal thread.

• Effective(or Pitch) Diameter: The diameter of an imaginary

cylinder(termed the pitch cylinder ) which intersects the

surface of the thread in such manner that the intercept on

an generator of the cylinder between the points where it

meets the opposite flanks of the thread groove is equal to

one half the basic of the thread

• The two methods for thread measurement as follows

Two wire method

Pitch Measurement

Tool Maker’s Microscope

Working

• A ray of light from a light source fig. b is reflected by a

mirror through 90’ It then passes through a transparent

glass plate (on which flat parts may be placed ).

• A shadow image of the outline or counter of the

workspaces passes through the objective of the optical

head and is projected by a system of three prisms to a

ground glass screen.

• Observations are made through an eyepiece.

Measurements are made by means of cross lines engraved

on the ground glass screen.

• The screen can be rotated through 360’; the angle of

rotation is read through an auxiliary eyepiece.

Procedure: -

A) Pitch Measurement: -

• 1) Take the hacksaw blade and mount on the moving

blade of tool maker’s Microscope in horizontal position.

• 2)Focus the microscope on the blade.

• 3)Make the cross line in the microscope coincided with

one of the edge of th blade.

• 4)Take a reading on ground glass screen, this is the initial

reading.

• 5) The table is again moved until the next edge of the

blade coincides with the cross-line on the screen and the

final reading takes.

• 6) The difference between initial and final reading gives

pitch of the blade.

Applications

• The large tool maker’s microscope is suitable for the

following fields of applications;

• Length measurement in Cartesian and polar co-ordinates.

• Angle measurements of tools; threading tools punches and

gauges, templates etc.

• Thread measurements i.e., profile major and minor

diameters, height of lead, thread angle, profile position with

respect to the thread axis and the shape of thread.

(rounding, flattering, straightness of flanks)

• Comparison between centres and drawn patterns and

drawing of projected profiles.

Gear Measurement

Gear Terminology

Involute tooth profile

You might also like

- Business Plan Security CompanyDocument27 pagesBusiness Plan Security CompanyJiji100% (3)

- Report Experiment ThreadDocument11 pagesReport Experiment Threadsparklingstars2705No ratings yet

- Uppers Various Info DatabaseDocument54 pagesUppers Various Info DatabaseJason BexonNo ratings yet

- Nissan 5 Forces PresentationDocument13 pagesNissan 5 Forces Presentationkomala_sekhar0% (1)

- Peterbilt Rear Air Suspensions AdjustmentDocument42 pagesPeterbilt Rear Air Suspensions AdjustmentCellblocX83% (6)

- Family ResourcesDocument33 pagesFamily ResourcesJackie S LaymanNo ratings yet

- Unit 2 Screw Thread - Gear Elements - Surface FinishDocument53 pagesUnit 2 Screw Thread - Gear Elements - Surface FinishDeepak MisraNo ratings yet

- 1.tool Makers MicroscopeDocument7 pages1.tool Makers MicroscopeelavarasanNo ratings yet

- Screw Thread MeasurementsDocument77 pagesScrew Thread MeasurementsSridhar SreeNo ratings yet

- Instrumentation CH3Document84 pagesInstrumentation CH3muru0105No ratings yet

- The ToolmakeeerDocument31 pagesThe ToolmakeeerVarunNo ratings yet

- Experiment No. 1A Tool Maker'S MicroscopeDocument4 pagesExperiment No. 1A Tool Maker'S MicroscopePraveen KumaarNo ratings yet

- MTM Metro Expt1 ManualDocument10 pagesMTM Metro Expt1 ManualBhargav DindukurthiNo ratings yet

- Angle Measurement PDFDocument85 pagesAngle Measurement PDFSnigdhaNo ratings yet

- UNIT VII Angular MeasurementsDocument99 pagesUNIT VII Angular MeasurementsAkash PatilNo ratings yet

- Unit 3Document120 pagesUnit 3ramesh_h2002No ratings yet

- Experiment No. 4 Study and Applications of Tool Maker'S MicroscopeDocument4 pagesExperiment No. 4 Study and Applications of Tool Maker'S MicroscopeAbdulaziz almasoudiNo ratings yet

- 07-Surface CharacteristicsDocument63 pages07-Surface CharacteristicsClash GodNo ratings yet

- Metrology: BY A.Radha Krishna, Hod, Dept. of Mech. MietDocument28 pagesMetrology: BY A.Radha Krishna, Hod, Dept. of Mech. MietRadha KrishnaNo ratings yet

- MI Tool Makers MicroscopeDocument9 pagesMI Tool Makers MicroscopeGurpreet KaurNo ratings yet

- Screw Thread MeasurementDocument55 pagesScrew Thread MeasurementMadhuNo ratings yet

- Screwthreadmeasurement 170418161010 PDFDocument30 pagesScrewthreadmeasurement 170418161010 PDFejkiranNo ratings yet

- ScrewDocument20 pagesScrewIxora MyNo ratings yet

- Tool Makers MicroscopeDocument7 pagesTool Makers MicroscopeAnand Babu100% (2)

- The Tool MakerDocument4 pagesThe Tool MakerRitesh YadavNo ratings yet

- Form Measurement: Unit 3Document68 pagesForm Measurement: Unit 3Rama SamyNo ratings yet

- Unit-4 MMDocument74 pagesUnit-4 MMRama SamyNo ratings yet

- Unit-4: Screw Thread and Gear Measurement: Hareesha N Gowda Dept of Aeronautical Engineering DSCE, Bangalore-78Document77 pagesUnit-4: Screw Thread and Gear Measurement: Hareesha N Gowda Dept of Aeronautical Engineering DSCE, Bangalore-78Elavarasan SivaNo ratings yet

- 8/20/2014 1 Hareesha N Gowda, DSCE, Blore-78Document77 pages8/20/2014 1 Hareesha N Gowda, DSCE, Blore-78Santosh DabholeNo ratings yet

- Screw ThreadDocument46 pagesScrew Threadmohd mansoor100% (1)

- Angular MeasumentDocument51 pagesAngular MeasumentVinay PanditNo ratings yet

- Metrology Assignment 2Document14 pagesMetrology Assignment 2Aadish vikramNo ratings yet

- 5.EMM Lab ManualDocument38 pages5.EMM Lab ManualRakeshkumarcegNo ratings yet

- Machinetools 6Document40 pagesMachinetools 6Archit GyaneshwarNo ratings yet

- L27 - Optical Measuring InstrumentsDocument14 pagesL27 - Optical Measuring Instrumentschaitanyamohod2020No ratings yet

- Thread Cutting, Tapping and BroachingDocument95 pagesThread Cutting, Tapping and BroachingKundan PatilNo ratings yet

- Unit III NewDocument21 pagesUnit III NewsathiaNo ratings yet

- Tool Maker MicroscopeDocument4 pagesTool Maker MicroscopeShyam SenthilNo ratings yet

- Lab Manual: Machining Processes and Metrology Lab (MEE211L)Document27 pagesLab Manual: Machining Processes and Metrology Lab (MEE211L)Agnivesh SharmaNo ratings yet

- Tool Makers MicroscopeDocument2 pagesTool Makers Microscopesukriti dhauni100% (1)

- Government Engineering College: Angular MeasurementDocument23 pagesGovernment Engineering College: Angular Measurementanjum malekNo ratings yet

- Linear MeasurementsDocument52 pagesLinear MeasurementsO20 0023 Chandrasekaran. S. [PT]No ratings yet

- BTM2133-Chapter 7 Angle Measurement PDFDocument41 pagesBTM2133-Chapter 7 Angle Measurement PDFAswaja313No ratings yet

- Screw Thread Measurement New1 (Autosaved)Document67 pagesScrew Thread Measurement New1 (Autosaved)Aditi KaradeNo ratings yet

- Metrology Lab ManualDocument36 pagesMetrology Lab Manualuvrsunil_kumar100% (2)

- MetrologyDocument135 pagesMetrologySai Bharath Velpuri100% (3)

- Production Technoloy Lab 012110045519 1Document35 pagesProduction Technoloy Lab 012110045519 1raajeeradha@gmail.comNo ratings yet

- A Review Paper On Pitch Screw Gauge Working: Vikas Chauhan, Muneesh Chauhan, Sahil Verma, Raman KumarDocument6 pagesA Review Paper On Pitch Screw Gauge Working: Vikas Chauhan, Muneesh Chauhan, Sahil Verma, Raman KumarMuskan MalikNo ratings yet

- Thread Cutting, Tapping and Broaching: Nainik Shah - 171040075 Ajinkya Shah - 171040076 Ameya Iyer - 171040089Document87 pagesThread Cutting, Tapping and Broaching: Nainik Shah - 171040075 Ajinkya Shah - 171040076 Ameya Iyer - 171040089Kundan PatilNo ratings yet

- 3.metrology 153Document28 pages3.metrology 153alinader20022No ratings yet

- Straightness, Flatness, ParallelismDocument31 pagesStraightness, Flatness, ParallelismLiaqat Ahamed100% (5)

- Form Measurement: Vishal Nair Assistant Professor-Mechanical Mesce KuttipuramDocument67 pagesForm Measurement: Vishal Nair Assistant Professor-Mechanical Mesce KuttipuramSivaperumal MNo ratings yet

- MMM Ex 2 and 3Document6 pagesMMM Ex 2 and 3SANDEEP BUDANIANo ratings yet

- MicrometerDocument21 pagesMicrometerSulficker AliNo ratings yet

- Vernier To ComparatorDocument78 pagesVernier To ComparatorAtul GaurNo ratings yet

- Chapter1 Linearmeasurements 7 June 2020Document39 pagesChapter1 Linearmeasurements 7 June 2020Rayuth KEATNo ratings yet

- #4 Pengukuran Geometri 2: Metrologi Industri & Kontrol KualitasDocument87 pages#4 Pengukuran Geometri 2: Metrologi Industri & Kontrol KualitasChegg Cek akunNo ratings yet

- Linear MeasurementsDocument54 pagesLinear MeasurementsNaman Dave100% (1)

- Angle Measuring DevicesDocument17 pagesAngle Measuring DevicesIqbal Singh ParmarNo ratings yet

- Angle Measurement 2Document7 pagesAngle Measurement 2Jonathan Da Costa100% (1)

- Unit No. 04: Angular MeasurementDocument9 pagesUnit No. 04: Angular MeasurementKrishna NikamNo ratings yet

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingFrom EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingRating: 5 out of 5 stars5/5 (2)

- Prompting Science and Engineering Students in Practical TrigonometryFrom EverandPrompting Science and Engineering Students in Practical TrigonometryNo ratings yet

- Optics and Optical Instruments: An IntroductionFrom EverandOptics and Optical Instruments: An IntroductionRating: 4 out of 5 stars4/5 (5)

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Assignment of Innovation and Entrepreneurship of XiaomiDocument14 pagesAssignment of Innovation and Entrepreneurship of XiaomiMd Shoumik HasanNo ratings yet

- New Salary Scales Updated February 2023 NAC ExtendedDocument2 pagesNew Salary Scales Updated February 2023 NAC ExtendedIon NNo ratings yet

- Zeos-Ad: Analogue Algorithmic Addressable Fire DetectorDocument2 pagesZeos-Ad: Analogue Algorithmic Addressable Fire DetectorMariusNo ratings yet

- Micro TeachingDocument7 pagesMicro TeachingMuhammed SahadNo ratings yet

- Air Handling UnitDocument6 pagesAir Handling UnitAgung SetiajiNo ratings yet

- Tender Document - Haryana Data CentreDocument58 pagesTender Document - Haryana Data CentreBullzeye StrategyNo ratings yet

- Chapter 3Document5 pagesChapter 3Sheila ShamimiNo ratings yet

- Rule 11 Gregslangmalakas Copy 2Document12 pagesRule 11 Gregslangmalakas Copy 2Gregorio AchanzarNo ratings yet

- Diploma in MarineDocument18 pagesDiploma in MarineKaung Min MoNo ratings yet

- Addressing & Network Protocols - PreQuiz - Attempt ReviewDocument4 pagesAddressing & Network Protocols - PreQuiz - Attempt Reviewvinay Murakambattu100% (1)

- Class002 - 201200394-201000327-201000542Document46 pagesClass002 - 201200394-201000327-201000542api-286690957No ratings yet

- B3-201-2018 - Developing and Using Justifiable Asset Health Indices For Tactical and Strategic Risk ManagementDocument10 pagesB3-201-2018 - Developing and Using Justifiable Asset Health Indices For Tactical and Strategic Risk ManagementNamLeNo ratings yet

- Bp344 Rules: Department of ArchitectureDocument11 pagesBp344 Rules: Department of ArchitectureMarie BacasNo ratings yet

- Migrate DHCP Scope(s) To Windows Server 2022 - PeteNetLiveDocument6 pagesMigrate DHCP Scope(s) To Windows Server 2022 - PeteNetLiveYudy KurniawanNo ratings yet

- Chapter No 03 Class 6th Notes For Computer Science English MediumDocument5 pagesChapter No 03 Class 6th Notes For Computer Science English MediumAbid HussainNo ratings yet

- Irs Wtc2020Document73 pagesIrs Wtc2020Himanshu SinghNo ratings yet

- Attorney General v. Joseph, (2006) CCJ 1 (AJ)Document97 pagesAttorney General v. Joseph, (2006) CCJ 1 (AJ)TiffanyNo ratings yet

- Coupled Level-Set and Volume of Fluid (CLSVOF) Solver ForDocument18 pagesCoupled Level-Set and Volume of Fluid (CLSVOF) Solver ForBharath kumarNo ratings yet

- How To Merge Two Switches With Different Active Zone SetsDocument3 pagesHow To Merge Two Switches With Different Active Zone SetslpuliceNo ratings yet

- NDT - Piping GuideDocument262 pagesNDT - Piping GuideCarlos CastilloNo ratings yet

- CC 2Document43 pagesCC 2iamsabaalyNo ratings yet

- 24 Micro-Cap Multibagger Stocks To Buy Now PDFDocument11 pages24 Micro-Cap Multibagger Stocks To Buy Now PDFPravin YeluriNo ratings yet

- Kalinga University at A Glance 1Document40 pagesKalinga University at A Glance 1Pranav Shukla PNo ratings yet

- 5.UART Serial Communication Module Design and SimulationDocument4 pages5.UART Serial Communication Module Design and Simulationvenkatahari babuNo ratings yet

- Globe Valves: Standard SpecificationDocument26 pagesGlobe Valves: Standard SpecificationHammad AshrafNo ratings yet