Professional Documents

Culture Documents

Assqc 3

Assqc 3

Uploaded by

AKSHAY NATH0 ratings0% found this document useful (0 votes)

12 views23 pagesThe document discusses developing standards and specifications for products. It explains that standards define expectations for materials, characteristics, quality and performance, while specifications provide more detailed information. Product standards and specifications help ensure materials and design work together to meet consumer expectations and satisfaction. They address factors like construction, fit, design, and how materials integrate for proper internal and external integrity.

Original Description:

Original Title

ASSQC 3

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses developing standards and specifications for products. It explains that standards define expectations for materials, characteristics, quality and performance, while specifications provide more detailed information. Product standards and specifications help ensure materials and design work together to meet consumer expectations and satisfaction. They address factors like construction, fit, design, and how materials integrate for proper internal and external integrity.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

0 ratings0% found this document useful (0 votes)

12 views23 pagesAssqc 3

Assqc 3

Uploaded by

AKSHAY NATHThe document discusses developing standards and specifications for products. It explains that standards define expectations for materials, characteristics, quality and performance, while specifications provide more detailed information. Product standards and specifications help ensure materials and design work together to meet consumer expectations and satisfaction. They address factors like construction, fit, design, and how materials integrate for proper internal and external integrity.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 23

DEVELOPING STANDARDS AND

SPECIFICATIONS FOR PRODUCTS

Introduction

Materials standards and specification helps ensure

that appropriate materials will be used in a product

to meet the needs of the target market.

These standards and specifications define

expectations for each material type, characteristics,

quality, appearance, and performance.

Standards and specifications are developed so that

the materials in a product will not adversely affect

consumer satisfaction.

Three factors which generally influence product

performance and consumer satisfaction-

– Construction

– Fit

– Design

Product Integrity

• Product integrity is the way the materials and

other aspects of the product work together to

affect consumer satisfaction.

• Two major components are-

– Internal integrity

– External integrity

Internal integrity- addresses the consistency among

the materials, the product’s function, and its

structure

External integrity- addresses the consistency

between a product’s performance and consumer

expectations.

Standards & Specifications

• A standard helps a company describe a quality

level for the product it sells and ensures

consistency in quality.

• Standards which reflect the company’s

philosophy and business objectives and the

target market expectations for the product, are

often stated in general terms that describe

characteristics and performance aspects for a

product line.

Specifications include details for specific

products. Specs reflect standards, but include

more specific information describing

characteristics and performance level that must

be met and procedures that describe the

evaluation process.

Tolerances describe the acceptable range of

variation from a specification. When reviewing

specs for products, tolerances are more likely to

be listed as ranges of behavior than as

minimum, as was the situation with materials.

Relationship to Material Standards &

Specifications

Standards and specifications for products build on

an understanding of the materials that will be used

to manufacture the product.

Often, changes in materials and products occur

during the product development process, when

team members begin to integrate material

characteristics and performance with design, target

market expectations and business objectives.

Materials evaluation ensures that they are able to

produce a product that meets these requirements,

but success also depends on the manner in the

materials interact with each other and the

contributions each materials makes to meeting the

requirements for design, production and the target

market.

Thus the company and its suppliers must use

product standards and specifications to determine

the degree to which a product meets expectations.

Product

Significant attributes that contribute to the internal

integrity of the finished product-

– Design

– Function

– Appearance

– Size

– Fit

– Construction

– Finishing

– Zoning

– Packaging

Design

Design is the details, features and characteristics of

the finished product. Design works with the entire

product from a holistic perspective and considers

how the various parts of the product contribute to

the aesthetic perception of the whole.

Design standards and specs focus on the aesthetics

and fashion characteristics of the product.

Design specs address such as features as collars,

pockets, and fabric motifs.

Function

Function defines how well a product does what it is

designed to do. It can address a specific set of

performance for a specialized end use, as for many

functional clothing items, or it can address a more

generalized set of requirements for a consumer

product.

Function or functional specs and standards address the

ability of a product to perform well in its intended end

use or to meet or exceed claims made in advertising or

guarantees.

Appearance

Appearance is how the product looks when an

individual views it from a near

perspective.Appearance addresses features that

would be noticed when an individual interacts.

Appearance standards emphasize the way the

finished product looks from outside and may

describe in which design details, plaids, stripes

or other material motifs match.

Size

Size can be used to describe several aspects of

product. Essentially, size, refers to the important

length, width, depth, circumference and vertical

dimensions of a product.

Size specs include more detailed dimensions,

tolerances, allowed within a size range, and

descriptions of the procedures to be followed in

measuring product size.

FIT

Fit is how the product dimensions relate to the

three dimensional form, body.

Fit for apparel refers to how the garment relates to

the individual’s shape, while allowing general or

specific range of movement.

Fit standards include such features as how much

ease or extra amount is needed for movement,

how product features relate to the body and how

the product drapes on the body.

Construction

Construction is the way the various parts,

components, and materials of a product are

combined in a permanent fashion to create a

finished product.

Construction specs should include details related to

stitch type, seam type, thread type, seam allowance,

etc.

Specifications for construction are sometimes

referred to as engineered specs

Finishing

When construction is completed for a product, several

additional steps may be needed to achieve the final

look.

Finishing include basic procedures related to trimming

of threads, pressing, steaming.

Finishing also refers to any product processing steps,

such as abrasive washes, product dyeing, etc.

Zoning for Defects & Appearance

In product zoning, the company recognizes that

some parts of a product are more critical in

terms of appearance that other parts. Those

parts of zones that are most visible are of

greater importance than the parts that are

visible.

Zone 1- Areas with extremely high visibility that are

likely to viewed from a close distance at the time of

purchase. Cosmetic flaws located in this zone would

be considered major and would cause rejection of

the product.

Zone 2- Areas which are not visibly dominant, but

are visible in normal use. Cosmetic flaws in this

zone would be evaluated based upon the size of

the defect, color and intended end use of the

product to determine acceptability.

Zone 3- Areas normally hidden in everyday use,

but could be visible in occasion. Cosmetic flaws

in this zones are more acceptable that in any

other location. Flaws occurring in this zone

would be evaluated based upon the intended

use of the garment.

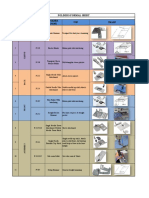

Examples of Product zones

Packaging

Packaging is the manner in which a product is

prepared for transportation, shipped and

presented to the consumer.

Packaging standards often describe general

aspects of how the product is packaged ,whereas

packaging specs describe the material that

should be used and the manner in which the

product should be folded, etc.

You might also like

- Chapter 7 Global Product PolicyDocument28 pagesChapter 7 Global Product PolicyMadihah MazhanNo ratings yet

- Men's Prints & Graphics Forecast A/W 23/24: Care CultureDocument17 pagesMen's Prints & Graphics Forecast A/W 23/24: Care CultureAKSHAY NATHNo ratings yet

- Estabilish Quality Standards Module @2012Document16 pagesEstabilish Quality Standards Module @2012FelekePhiliphosNo ratings yet

- Product StrategyDocument15 pagesProduct StrategyMadiha AhmedNo ratings yet

- Technical Training For GPQ and Floor Quality Auditor: Presented By, Md. AL Arafat HossainDocument40 pagesTechnical Training For GPQ and Floor Quality Auditor: Presented By, Md. AL Arafat Hossainrummanbsc8923No ratings yet

- Sears - IsO 9001Document6 pagesSears - IsO 9001Zia ShahidNo ratings yet

- 1 Dimensions of QualityDocument13 pages1 Dimensions of QualityAivee Manalo AñonuevoNo ratings yet

- 1.what Are The Characteristics of Good Product Design?Document5 pages1.what Are The Characteristics of Good Product Design?Breev AldenNo ratings yet

- Product Standards & SpecificationsDocument57 pagesProduct Standards & SpecificationsANEESHA PANDANo ratings yet

- Fabric Science - Standards and SpecificationsDocument6 pagesFabric Science - Standards and SpecificationsAneesha PandaNo ratings yet

- Session 2c - Quality Specification & TolerancesDocument28 pagesSession 2c - Quality Specification & TolerancesSweetu NancyNo ratings yet

- Operations Management ReportDocument54 pagesOperations Management ReportMj GutierrezNo ratings yet

- Introduction To QualityDocument5 pagesIntroduction To QualityJan Lou PayeNo ratings yet

- Sqa LecturesDocument21 pagesSqa LecturesVanessa SarahNo ratings yet

- Estabilish Quality Standards Module @2013Document21 pagesEstabilish Quality Standards Module @2013feleke philiphosNo ratings yet

- c1 1 Design Specifications ActivityDocument3 pagesc1 1 Design Specifications Activityapi-295098018No ratings yet

- New Product DevelopmentDocument4 pagesNew Product DevelopmentKhan ArotusNo ratings yet

- OperasiDocument33 pagesOperasiErika santia ayuNo ratings yet

- Unit3 PDDDocument27 pagesUnit3 PDDHAFIZA LASKAR (RA2051001010010)No ratings yet

- Unit 1 Design FolioDocument20 pagesUnit 1 Design Folioapi-220785381No ratings yet

- Introduction To Quality Control and AssuranceDocument8 pagesIntroduction To Quality Control and AssuranceSIMERA GABRIELNo ratings yet

- Unit-3-1 Product & Service DesignDocument113 pagesUnit-3-1 Product & Service DesignalmazwmbashiraNo ratings yet

- Unit 3 OMDocument7 pagesUnit 3 OMAsegid gezehagnNo ratings yet

- Second Chapter: Product and Service DesignDocument8 pagesSecond Chapter: Product and Service DesignMominul MominNo ratings yet

- ChaPter V - 20231208 - 155040 - 0000Document24 pagesChaPter V - 20231208 - 155040 - 0000Kurt BongolNo ratings yet

- Unit Ii OmDocument40 pagesUnit Ii Om1234 KrjrNo ratings yet

- Product and Service DesignDocument46 pagesProduct and Service DesignKim TaengoossNo ratings yet

- Chapter 5-Marketing Mix ElementsDocument29 pagesChapter 5-Marketing Mix Elementstemesgen yohannesNo ratings yet

- Importance of QualityDocument10 pagesImportance of QualityjaveljamaicaNo ratings yet

- ASSQCDocument180 pagesASSQCAbhishek RajNo ratings yet

- Edited Unit 3 OMDocument17 pagesEdited Unit 3 OMermiasnasirtaleginNo ratings yet

- Product Design - Meaning - Characteristics of Good Product DesignDocument36 pagesProduct Design - Meaning - Characteristics of Good Product DesignRishabh KumarNo ratings yet

- Product Design and DevelopmentDocument14 pagesProduct Design and Developmentajay3480100% (1)

- Operations Management (Busi2002) : 1. Product Style and Product DevelopmentDocument3 pagesOperations Management (Busi2002) : 1. Product Style and Product DevelopmentRANDEEP KAURNo ratings yet

- Unit 3 Notes (PM) by SSDocument17 pagesUnit 3 Notes (PM) by SSupadhyaypriyam.50No ratings yet

- Handouts of QualityDocument8 pagesHandouts of QualitySiddhi PisalNo ratings yet

- CHAPTER SIX Purchase DescriptionDocument13 pagesCHAPTER SIX Purchase DescriptionTessema TeshomeNo ratings yet

- Chapter 4 - Product and Service DesignDocument3 pagesChapter 4 - Product and Service DesignCJ De LunaNo ratings yet

- Role of Design SpecificationDocument3 pagesRole of Design SpecificationAung Kyaw ZallNo ratings yet

- Product DesignDocument43 pagesProduct DesignShivakami RajanNo ratings yet

- System Design: Dr. Mohammed Shamim Uddin Khan Professor and Chairman Department of Finance University of ChittagongDocument84 pagesSystem Design: Dr. Mohammed Shamim Uddin Khan Professor and Chairman Department of Finance University of ChittagongShafayet JamilNo ratings yet

- Unit 3 - Design of The Operation System Part One.Document32 pagesUnit 3 - Design of The Operation System Part One.Birhanu AdmasuNo ratings yet

- Chapter 4 Handouts Product and Service DesignDocument8 pagesChapter 4 Handouts Product and Service DesignAbigail BagnesNo ratings yet

- PDD Industrial DesignDocument10 pagesPDD Industrial DesignMkNo ratings yet

- Chapter 3 OM EditedDocument19 pagesChapter 3 OM EditedSeid KassawNo ratings yet

- Product Technology 2Document22 pagesProduct Technology 2Jay Loid CNo ratings yet

- 3 Chapter 3 PDDDocument30 pages3 Chapter 3 PDDdesnetselomonNo ratings yet

- Introduction To QualityDocument51 pagesIntroduction To QualityAmsalu SeteyNo ratings yet

- Quality Control and Assurance (FP 321)Document27 pagesQuality Control and Assurance (FP 321)Richard Simon KisituNo ratings yet

- Different Customers Have Different Tastes, Preferences, and Product NeedsDocument95 pagesDifferent Customers Have Different Tastes, Preferences, and Product NeedsGemechis BussaNo ratings yet

- Purchasing SpecificationsDocument2 pagesPurchasing Specificationsounomercy2No ratings yet

- Chapter 4 OpmanwithTQMDocument29 pagesChapter 4 OpmanwithTQMDaniel HuetNo ratings yet

- Topic 3Document6 pagesTopic 3dephencegeneralNo ratings yet

- Product Design - BasicsDocument18 pagesProduct Design - BasicsVijay KumarNo ratings yet

- RJS Product & Service DesignDocument36 pagesRJS Product & Service DesignramjanmsinghNo ratings yet

- BA4204 Operations ManagementDocument7 pagesBA4204 Operations Managementkumarakannan.reNo ratings yet

- 4 Product SpecificationDocument8 pages4 Product SpecificationDillipPanigrahiNo ratings yet

- 19 Establish Quality StandardsDocument35 pages19 Establish Quality Standardsolyad ahmedinNo ratings yet

- Quality Issues: Product Quality and DimensionsDocument4 pagesQuality Issues: Product Quality and DimensionsprojectessNo ratings yet

- Activity 3.1.4Document4 pagesActivity 3.1.4Plum Buzzard4096No ratings yet

- Cluster Final Doc 2018Document63 pagesCluster Final Doc 2018AKSHAY NATHNo ratings yet

- UntitledDocument8 pagesUntitledAKSHAY NATHNo ratings yet

- Assignment 1 Toyota Supply Chain ManagementDocument24 pagesAssignment 1 Toyota Supply Chain ManagementAKSHAY NATH50% (2)

- Men'S Prints & Graphics Forecast A/W 23/24: NatureverseDocument17 pagesMen'S Prints & Graphics Forecast A/W 23/24: NatureverseAKSHAY NATHNo ratings yet

- TechnologyDocument19 pagesTechnologyAKSHAY NATHNo ratings yet

- Fashion Marketing 7ps - 1Document9 pagesFashion Marketing 7ps - 1AKSHAY NATHNo ratings yet

- Fabric BOMDocument1 pageFabric BOMAKSHAY NATHNo ratings yet

- Brand Analysisof AdidasDocument21 pagesBrand Analysisof AdidasAKSHAY NATHNo ratings yet

- Print Out AEM 2Document2 pagesPrint Out AEM 2AKSHAY NATHNo ratings yet

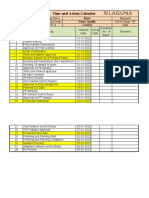

- Time and Action CalendarDocument2 pagesTime and Action CalendarAKSHAY NATHNo ratings yet

- Men's Prints & Graphics Forecast A/W 23/24: Creative ResetDocument17 pagesMen's Prints & Graphics Forecast A/W 23/24: Creative ResetAKSHAY NATHNo ratings yet

- Research Design-Data Resources - 2Document2 pagesResearch Design-Data Resources - 2AKSHAY NATHNo ratings yet

- Shirt FoldersDocument1 pageShirt FoldersAKSHAY NATHNo ratings yet

- Assqc 1Document25 pagesAssqc 1AKSHAY NATHNo ratings yet

- Trims BOMDocument2 pagesTrims BOMAKSHAY NATHNo ratings yet

- Assqc 4Document17 pagesAssqc 4AKSHAY NATHNo ratings yet

- Order SummaryDocument1 pageOrder SummaryAKSHAY NATHNo ratings yet

- OB ShirtDocument2 pagesOB ShirtAKSHAY NATHNo ratings yet

- Costing SheetDocument3 pagesCosting SheetAKSHAY NATHNo ratings yet

- Mid Term Assignment 1Document18 pagesMid Term Assignment 1AKSHAY NATHNo ratings yet

- Trend Spotting Theroies of Social MediaDocument11 pagesTrend Spotting Theroies of Social MediaAKSHAY NATHNo ratings yet

- FCBO Assignment 2 SubcultureDocument20 pagesFCBO Assignment 2 SubcultureAKSHAY NATHNo ratings yet

- Final GPDocument127 pagesFinal GPAKSHAY NATHNo ratings yet

- Mid Term Assignment 2.pptmDocument17 pagesMid Term Assignment 2.pptmAKSHAY NATHNo ratings yet

- Circular For Day Scholar StudentsDocument1 pageCircular For Day Scholar StudentsAKSHAY NATHNo ratings yet

- Entrepreneurship - MEESHODocument16 pagesEntrepreneurship - MEESHOAKSHAY NATHNo ratings yet

- Fashion Capital - ParisDocument120 pagesFashion Capital - ParisAKSHAY NATHNo ratings yet

- Entrepreneurship and Sustainable Business Assignment 1 Akshay Nath MFM - 22 - 379Document16 pagesEntrepreneurship and Sustainable Business Assignment 1 Akshay Nath MFM - 22 - 379AKSHAY NATHNo ratings yet

- FCBO End Term JuryDocument69 pagesFCBO End Term JuryAKSHAY NATHNo ratings yet

- Project On Marketing of TEA: Business StudiesDocument35 pagesProject On Marketing of TEA: Business StudiesDevanyaNo ratings yet

- POM Chapter - 8 - S15Document16 pagesPOM Chapter - 8 - S15Ashar ZiaNo ratings yet

- Principles of Marketing SLM Week12Document6 pagesPrinciples of Marketing SLM Week12Ash SatoshiNo ratings yet

- PRADA Marketing Mix (CARCASONA)Document2 pagesPRADA Marketing Mix (CARCASONA)Kylle JoelNo ratings yet

- Product Management Uniqlo Group 1 New Shoes 2Document42 pagesProduct Management Uniqlo Group 1 New Shoes 2Phuong Vuong MinhNo ratings yet

- Chapter 3 &4Document98 pagesChapter 3 &4Kebede ChallaNo ratings yet

- Chap 3Document30 pagesChap 3Thiru VenkatNo ratings yet

- L2M2 Procurement and Supply Operations-2Document162 pagesL2M2 Procurement and Supply Operations-2Rady KotbNo ratings yet

- B2B ChannelDocument36 pagesB2B Channel9667802447No ratings yet

- PrevDocument68 pagesPrevSamuelNo ratings yet

- Globant Sentinel Report 2022 - Blockchain PDFDocument36 pagesGlobant Sentinel Report 2022 - Blockchain PDFFederico CasalNo ratings yet

- Assign 2 MKT420 (Aina&ameera)Document18 pagesAssign 2 MKT420 (Aina&ameera)ainaNo ratings yet

- Module 1 Understanding Marketing ManagementDocument12 pagesModule 1 Understanding Marketing ManagementRichard CelesteNo ratings yet

- Prior Choice Economics by Gabriel GreenDocument20 pagesPrior Choice Economics by Gabriel GreenLibNo ratings yet

- Smart BackpackDocument33 pagesSmart BackpackAinnatul Nafizah Ismail- 2276No ratings yet

- Rural Marketing English VersionDocument137 pagesRural Marketing English VersionTanmay ShuklaNo ratings yet

- London School of CommerceDocument24 pagesLondon School of CommerceNuzhat AhmedNo ratings yet

- IPE 3109: Product Design-IDocument31 pagesIPE 3109: Product Design-IZahidul IslamNo ratings yet

- Business Plan Group 1Document34 pagesBusiness Plan Group 1Dre AclonNo ratings yet

- Entrepreneurship DevelopmentDocument18 pagesEntrepreneurship DevelopmentMiru JugNo ratings yet

- CHAPTER 18 - Managing Retailing, Wholesaling, and LogisticsDocument32 pagesCHAPTER 18 - Managing Retailing, Wholesaling, and LogisticsMayang SariNo ratings yet

- Debate On Marketing ManagementDocument3 pagesDebate On Marketing ManagementTang Zhen HaoNo ratings yet

- Test Bank For Marketing 2014 17th Edition PrideDocument32 pagesTest Bank For Marketing 2014 17th Edition PridestephenhuepjotNo ratings yet

- Big MachineDocument34 pagesBig MachineJawaharJasNo ratings yet

- Reverse Supply Chain Management: Dr. Peeyush Mehta Vipul MathurDocument12 pagesReverse Supply Chain Management: Dr. Peeyush Mehta Vipul Mathurabhishekgupta_limNo ratings yet

- Nadzratul Kamalia Binti Muhamad Hilal - 2021440616 - Nbo5a - Opm549 - Assgment1Document8 pagesNadzratul Kamalia Binti Muhamad Hilal - 2021440616 - Nbo5a - Opm549 - Assgment1Kamalia HilalNo ratings yet

- Marketing Management Mba Anna UniversityDocument77 pagesMarketing Management Mba Anna Universitysbvivekbala3No ratings yet

- Merchandising ProcessesDocument17 pagesMerchandising ProcessesvijayasethiiNo ratings yet