Professional Documents

Culture Documents

MOTIP 03 Paper 67

MOTIP 03 Paper 67

Uploaded by

brotodhegdoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MOTIP 03 Paper 67

MOTIP 03 Paper 67

Uploaded by

brotodhegdoCopyright:

Available Formats

RISK ASSESSMENT IN PURIFIED

WATER SYSTEM (PWS) USING

FMEA AND FUZZY

PRIORITIZATION AT

PHARMACEUTICAL COMPANY

Broto Dhegdo Haris Pranoto

Mohammad Arif Rohman

Introduction

• Water is a major part of the pharmaceutical

industry and water is used to prepare sterile

and non-sterile product materials, wash

hands during production and before the

drug production process (Sandle, 2015).

• There have been some problems during the

existing operation of PWS consist of not

optimal flow process, filter blocking which

causes growth of microorganism, inaccurate

chemical adjustment during operation.

• The main source of water used in the

• Fuzzy FMEA is the development of the FMEA pharmaceutical industry to make

method which provides flexibility to medicines is water produced from the

accommodate uncertainty due to the vagueness purification process using the Purified

of the information possessed or subjective Water System (PWS)

preference elements used in the assessment of

the failure mode that occurs (Braglia et al. 2003).

The 3rd International Conference on Management of Technology, Innovation, and Project

Literature review

PWS in PT XYZ

Quality Risk Management United States Pharmacopeia (USP)

process according to ICH and the Indonesia Food and Drug

Q9 Administration (BPOM)

The 3rd International Conference on Management of Technology, Innovation, and Project

1 Methodology

Initiate Quality Risk Management

2.1

(QRM)

Identifying risks and fuzzy comparison matrixes for

occurrence, severity, and detection

2.2

Determining importance coefficients (weight

2 vectors) by fuzzy prioritization method

The stages of Failure Mode and Effect Analysis

(FMEA) 2.3

Converting the importance coefficients (weight

vectors) into FMEA degrees

2.4

Finding Risk Priority Number (RPN) values

The 3rd International Conference on Management of Technology, Innovation, and Project

Result and Discussion

• As a result, 22 Risk identified for new

purified water system an RPN value which

are higher than 72.

• Risk reduction or control actions are

required. Risk control recommendations

for all high and medium risks must be

reviewed and approved by Decision

Makers.

• Proposed risk control actions and

individual or group responsibilities for

these actions must be documented. If a

high risk cannot be further reduced,

formal acceptance must be documented

and approved by Site Quality and

Operations Head.

• This process can be realized by

investments to be made on the equipment,

employees, and supplier.

The 3rd International Conference on Management of Technology, Innovation, and Project

Conclusion

Suggestion

o The total risks identified in the new purified water system at PT o The results of the research can be used as input

XYZ are 23 risks, of which 22 have a Risk Priority Number and reference for PT XYZ in conducting risk

(RPN) value of more than 72.Therefore this requires mitigation assessments of several critical processes or tools

actions that need to be monitored through the risk register. that exist in similar industries.

o Risk response in the form of risk mitigation, which is based on o Risks identified in this study are not limited to other

data or experience during old purified water system operations studies to ascertain the potential risks during the

starting from mitigation in the form of administration operation of the purified water system, because the

(procedure creation), procurement or storage of spare parts if potential risks can differ according to the critical

the main component is damaged, design (Valve, Reverse processes and parameters that are used as

Osmosis type), and the determination of the parameters of the references during the operation process.

level indicator (chemicals, temperature and pressure).

o Risk communication has followed quality risk management

according to the International Conference on Harmonization

(ICH Q9), starting from initiation, assessment, control to risk

assessment from the new purified water system to decision

makers at PT XYZ, at every stage of the process.

The 3rd International Conference on Management of Technology, Innovation, and Project

THANK YOU

brotodhegdo@gmail.com , arif@ce.its.ac.id

You might also like

- Contamination Control StrategyDocument21 pagesContamination Control Strategyvaibhav gosaviNo ratings yet

- 015 Risk Assessment - Painting WorksDocument5 pages015 Risk Assessment - Painting WorksVipul Shankar91% (11)

- Iso13485 QOP4101 RiskMng PDFDocument4 pagesIso13485 QOP4101 RiskMng PDFQuality and Safety Consultants Co.No ratings yet

- Asce 7-22 CH 01 - For PCDocument17 pagesAsce 7-22 CH 01 - For PCsharethefiles100% (1)

- Quality Risk Management Ich q9 Iso 14971Document40 pagesQuality Risk Management Ich q9 Iso 14971drmohamed120100% (1)

- Risk Identification For Aseptic ProcessingDocument42 pagesRisk Identification For Aseptic Processingmmmmm100% (3)

- Hazard Identification and Risk Assessment With Controls (Hirac) in OilDocument5 pagesHazard Identification and Risk Assessment With Controls (Hirac) in OilJustamacacaNo ratings yet

- Risk-Management-Sandle EsterilesDocument31 pagesRisk-Management-Sandle EsterilesLeyvert De JesusNo ratings yet

- CALIDAD EN EL DISEÑO-QbDDocument24 pagesCALIDAD EN EL DISEÑO-QbDSilvia OrdazNo ratings yet

- 22c8 PDFDocument6 pages22c8 PDFDHAVALESH AMNo ratings yet

- LPG Terminal SafetyDocument4 pagesLPG Terminal SafetyIsioma1No ratings yet

- Workplace Safety GuideDocument29 pagesWorkplace Safety Guidejohn doeNo ratings yet

- Obsolescence Risk Assessment-2012Document10 pagesObsolescence Risk Assessment-2012Soltan AmelNo ratings yet

- Sustainability-14-09618 FMEA Filling Station SterileDocument13 pagesSustainability-14-09618 FMEA Filling Station SterileXavierNo ratings yet

- Chapter 1 - Chemical Process QRADocument56 pagesChapter 1 - Chemical Process QRANitesh KirnakeNo ratings yet

- BTA ChemicalsDocument10 pagesBTA ChemicalsMindfulnessNo ratings yet

- Risk Based Maintenance - Khan and HaddaraDocument14 pagesRisk Based Maintenance - Khan and Haddaragkvish@gmail.com100% (1)

- Quantitative Risk Assessment in Distribution System Maintenance Management Using Bow-Tie ModelingDocument7 pagesQuantitative Risk Assessment in Distribution System Maintenance Management Using Bow-Tie ModelingWildan PNo ratings yet

- Arvind Sharma (QRM)Document35 pagesArvind Sharma (QRM)Arvind Kumar SharmaNo ratings yet

- Iww 5Document12 pagesIww 5zemen TadesseNo ratings yet

- Probability Bow-Ties A Transparent Risk Management ToolDocument10 pagesProbability Bow-Ties A Transparent Risk Management ToolRmz ExeNo ratings yet

- Quality Risk Management of Purified WateDocument6 pagesQuality Risk Management of Purified WateQA Doon100% (1)

- Risk Based Inspection Jacketed PlatformsDocument19 pagesRisk Based Inspection Jacketed PlatformsronfrendNo ratings yet

- MOTIP 03 Paper 67Document11 pagesMOTIP 03 Paper 67brotodhegdoNo ratings yet

- Risk Based Inspection Implementation inDocument8 pagesRisk Based Inspection Implementation inMekineNo ratings yet

- Appendix g.3 Qra Modelling r2Document10 pagesAppendix g.3 Qra Modelling r2ext.diego.paulinoNo ratings yet

- New 3Document9 pagesNew 3Girish GVNo ratings yet

- RBIDocument19 pagesRBIseth_007No ratings yet

- Msa - QSP - 01 - Risk Assessment and Mitigation PlanDocument11 pagesMsa - QSP - 01 - Risk Assessment and Mitigation PlanVasudevan GovindarajNo ratings yet

- QBD To Continous Manufacturing-2Document71 pagesQBD To Continous Manufacturing-2Vivek SinghNo ratings yet

- Obsolescence Risk Assessment Process Best PracticeDocument12 pagesObsolescence Risk Assessment Process Best Practiceعلي الاسمريNo ratings yet

- Application of Risk Based Inspection Methodology T PDFDocument11 pagesApplication of Risk Based Inspection Methodology T PDFAdamSultansyahNo ratings yet

- Risk-Based Inspection and Maintenance (RBIM) (Khan-Canada-2004)Document14 pagesRisk-Based Inspection and Maintenance (RBIM) (Khan-Canada-2004)juan diazNo ratings yet

- Pharmaceutical 06 enDocument9 pagesPharmaceutical 06 ensasirkumar1No ratings yet

- Mary Kay O'Connor Manuscript - Fabio Oshiro Jun 2020Document16 pagesMary Kay O'Connor Manuscript - Fabio Oshiro Jun 2020Fabio Kazuo OshiroNo ratings yet

- Patel PK, Patel NM, Patel PM. An Overview On Cleaning Validation PDFDocument3 pagesPatel PK, Patel NM, Patel PM. An Overview On Cleaning Validation PDFRouag AbdelkarimNo ratings yet

- Quality Risk Management Manajemen Risiko Mutu (QRM/MRM)Document42 pagesQuality Risk Management Manajemen Risiko Mutu (QRM/MRM)Dian NovitasariNo ratings yet

- A Multi Objective Genetic Algorithm ForDocument43 pagesA Multi Objective Genetic Algorithm ForJoseNo ratings yet

- Risk Analysis & Mitigation MatrixDocument7 pagesRisk Analysis & Mitigation MatrixGhanta Ranjith KumarNo ratings yet

- Failure Mode and Effects: AnalysisDocument17 pagesFailure Mode and Effects: AnalysisDelfina SugandiNo ratings yet

- A New Concept To Evaluate Risk in Preliminary Design StageDocument6 pagesA New Concept To Evaluate Risk in Preliminary Design StageEmad ElgebesyNo ratings yet

- JVT2004 - RiskManagement SIA CCA and RA PDFDocument17 pagesJVT2004 - RiskManagement SIA CCA and RA PDFAdi SunnyNo ratings yet

- Risk Managment Matrice 3x3 enDocument17 pagesRisk Managment Matrice 3x3 enKavitha G3100% (1)

- A Roadmap For Implementing QRM Principles in Drug Substance ManufacturingDocument7 pagesA Roadmap For Implementing QRM Principles in Drug Substance ManufacturingAYMEN GOODKidNo ratings yet

- Probability Bow-Ties - A Transparent Risk Management ToolDocument10 pagesProbability Bow-Ties - A Transparent Risk Management ToolSachin SikkaNo ratings yet

- Case Study RMWG-07 Defining Process Space1Document6 pagesCase Study RMWG-07 Defining Process Space1Yourecheck NhyoNo ratings yet

- Reduced-Method Robustness Testing of Analytical Methods Driven by A Risk-Based Approach (Phil Borman Et Al., PharmTech, 2010) PDFDocument8 pagesReduced-Method Robustness Testing of Analytical Methods Driven by A Risk-Based Approach (Phil Borman Et Al., PharmTech, 2010) PDFMostafa AfifyNo ratings yet

- Ejbmr 2092 GalleyDocument6 pagesEjbmr 2092 Galleydeeksha.arbol03No ratings yet

- Guidelines For Process Safety Hazard Assessment Based On Process InformationDocument19 pagesGuidelines For Process Safety Hazard Assessment Based On Process InformationtyoNo ratings yet

- Failure Modes and Effects Analysis of Chemical StoDocument6 pagesFailure Modes and Effects Analysis of Chemical StogirishNo ratings yet

- Australia Guidelines For Wastewater Projects Risk AssessmentsDocument36 pagesAustralia Guidelines For Wastewater Projects Risk AssessmentsJeferson BraxtonNo ratings yet

- Assessing: A Simplified Methodology For Prejob Planning in Oil & Gas ProductionDocument8 pagesAssessing: A Simplified Methodology For Prejob Planning in Oil & Gas ProductionAlexNo ratings yet

- Risk Based Inspection Demonstrating ValueDocument10 pagesRisk Based Inspection Demonstrating Valueingmetal9104100% (1)

- Hazard Operability Study (HAZOP) in A Fertiliser Plant: K. Muthukumar, M. Suman MohanDocument7 pagesHazard Operability Study (HAZOP) in A Fertiliser Plant: K. Muthukumar, M. Suman MohanŘëhmàñ ÀĺîNo ratings yet

- Oil Refinery 2Document10 pagesOil Refinery 2dbNo ratings yet

- A Risk-Based Tool To Support The Inspection Management Inchemical PlantsDocument29 pagesA Risk-Based Tool To Support The Inspection Management Inchemical PlantsThanh Dat DoanNo ratings yet

- Filter Risk Assessment in Vaccine Processes Merck Life ScincesDocument34 pagesFilter Risk Assessment in Vaccine Processes Merck Life ScincesVijay Kumar NandagiriNo ratings yet

- Five Fatal Flaws in API RP 581: The Hague, Netherlands Helle@corrosioncontrol - NuDocument12 pagesFive Fatal Flaws in API RP 581: The Hague, Netherlands Helle@corrosioncontrol - NuCALLESJNo ratings yet

- Food Control System Assessment Tool: Dimension D – Science/Knowledge Base and Continuous ImprovementFrom EverandFood Control System Assessment Tool: Dimension D – Science/Knowledge Base and Continuous ImprovementNo ratings yet

- Implementation of a Remote and Automated Quality Control Programme for Radiography and Mammography EquipmentFrom EverandImplementation of a Remote and Automated Quality Control Programme for Radiography and Mammography EquipmentNo ratings yet

- Risk PremiumDocument8 pagesRisk Premium22MBAB14 Cruz Slith Victor CNo ratings yet

- Asset AllocationDocument11 pagesAsset AllocationRenuka Shankar100% (2)

- Ashoka Concessions Limited - R - 16102020Document8 pagesAshoka Concessions Limited - R - 16102020DarshanNo ratings yet

- Health, Safety and Environmental Management System (HSE MS)Document68 pagesHealth, Safety and Environmental Management System (HSE MS)Abdullah Anar100% (1)

- Iso14971 ManualDocument43 pagesIso14971 ManualMachinfabrik- QCNo ratings yet

- Bab 16Document11 pagesBab 1621013010069 MUHAMMAD NOVIAN GILANG RAMADHANNo ratings yet

- HS 011 Hazardous Chemical Substances ControlDocument21 pagesHS 011 Hazardous Chemical Substances ControlgrantNo ratings yet

- INFORMATION STRATEGY PLANNING - Example (AyalaLand)Document7 pagesINFORMATION STRATEGY PLANNING - Example (AyalaLand)Maria Therese PrietoNo ratings yet

- SGS IND Address Booklet A6 EN 13Document50 pagesSGS IND Address Booklet A6 EN 13ARAVINDAN DNo ratings yet

- Tymba Notes 2Document6 pagesTymba Notes 2nur iman qurrataini abdul rahmanNo ratings yet

- Using Bench Grinder (WS)Document7 pagesUsing Bench Grinder (WS)John KalvinNo ratings yet

- Module - Financial Literacy ProgramDocument36 pagesModule - Financial Literacy ProgramErica FlorentinoNo ratings yet

- Ey Digital Transformation Drives Employee Background Checks in The New NormalDocument24 pagesEy Digital Transformation Drives Employee Background Checks in The New NormalnishantNo ratings yet

- Grammenidis Hiebl (2021) - Enterprise Risk Management in GermanyDocument19 pagesGrammenidis Hiebl (2021) - Enterprise Risk Management in GermanyBakht AzamNo ratings yet

- Textbook List November 2013Document20 pagesTextbook List November 2013Alan LuiNo ratings yet

- Codium, Bset 2a (Entrep)Document8 pagesCodium, Bset 2a (Entrep)Anjene BurgosNo ratings yet

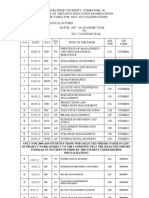

- School of Distance Education Examinations Time-Table For May 2012 ExaminationsDocument18 pagesSchool of Distance Education Examinations Time-Table For May 2012 ExaminationsAniel MaharjanNo ratings yet

- NainiDocument8 pagesNainiAnand Gaurav YadavNo ratings yet

- Safety GuideDocument53 pagesSafety GuideKhuda BukshNo ratings yet

- Interview With A Trading Legend Pts 1 4Document21 pagesInterview With A Trading Legend Pts 1 4Troy SchaulsNo ratings yet

- Osha NotesDocument4 pagesOsha NotesYee JingyeNo ratings yet

- Uncertainty in Network Design - 053045Document3 pagesUncertainty in Network Design - 053045Shreya cNo ratings yet

- Philequity Dividend Yield FundDocument1 pagePhilequity Dividend Yield Fundjovz castillonesNo ratings yet

- Superyeti - ICT High Probability Scalping SeriesDocument16 pagesSuperyeti - ICT High Probability Scalping SeriesAmirzeb BadshahNo ratings yet

- Two Sectors With Relatively Low Volatility: April 7, 2020Document3 pagesTwo Sectors With Relatively Low Volatility: April 7, 2020puchooNo ratings yet

- Determinants of Interest Rate Spreads Among Licensed Commercial Banks in KenyaDocument8 pagesDeterminants of Interest Rate Spreads Among Licensed Commercial Banks in KenyaViverNo ratings yet

- #5 - Chapter 4Document21 pages#5 - Chapter 4Hue MaiNo ratings yet

- A Comparative Analysis Between LIC of India & Private Insurance CompanyDocument8 pagesA Comparative Analysis Between LIC of India & Private Insurance CompanyJaishree SahuNo ratings yet