Professional Documents

Culture Documents

Presentasi Wulan Rev.03

Presentasi Wulan Rev.03

Uploaded by

Amin RizkyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Presentasi Wulan Rev.03

Presentasi Wulan Rev.03

Uploaded by

Amin RizkyCopyright:

Available Formats

Confidential

Improvement for Inventory Control Sparepart

on SAGE Systems

By Using Scan QR code & E-Bon

for Daily Activities on Spareparts Inventory

Presented by Wulan

Advisor : Mr. Suzuki

Mr. Sutaryo

2023/02/xx Mrs. Ekes

Supported by : Mr. Amin

1st BACKGROUND

Operator They need Go to Operator

Eng. Repair some parts WH.S’part Eng.Write Bon PIC WH.

Machine for Taking part Spart Input

2 minutes Bon to

System

Inventory

2 minutes

PIC WH. S’part

take part 5 minutes/bon

at same day

OR

5 minutes/bon at

Continue for next day, depend on

repairing having sparetime to

Given Request input or not.

parts needed to There’s GAP Time

Operator Eng. here

Current Workflow

2 /12 ©2015 Sumitomo Electric Industries, Ltd. All Rights

Reserved

2nd BACKGROUND

Figure Bon Manual Problem effect

Writing bon by manual

usually not clearly to Probabilty

read to

mistake

In Bon Manual, not input type

mention Item Number, of part in

which is needed for system

inputting the system

Current BON

We can’t get

Writen by Purpose repair for data how

operator number machine not many parts &

engineer

input in system cost to repair

Figure Inputting system each machine

actually

Number Bon Administration

filled in, after control still

input system manual

3 /12 ©2015 Sumitomo Electric Industries, Ltd. All Rights

Reserved

PLAN

Operator Eng.

Operator Eng. They need Go to Only Request Additional flow :

Repair Machine some parts WH.S’part Verbally weekly report

PIC W/h Spareparts

Print e-Bon (save make weekly report

as pdf file) Internal usage to

Spv.Eng

&

Given Request Report print out by system

Continue for parts needed

repairing to Operator

Eng.

PIC WH. S’part

take part & Scan

QR Code Directly

Next Workflow Automatic

Input in

system

4 /12 ©2015 Sumitomo Electric Industries, Ltd. All Rights

Reserved

DO

Consultation with

Microtec(provider

system)

Microtec has function barcode

system for All Transaction, We need

only function barcode of

I/C Internal Usage

5 /12 ©2015 Sumitomo Electric Industries, Ltd. All Rights

Reserved

Benefits

Reduce Risk Probability Operator WH.S’part can reduce time for

1 mistake input item code in 2 We can download data 3 inputing Internal Usage, usual take time

realtime 1-2 days (current workflow)

system

We can do accurate analytical, because we have

data :

4 1. Buffer Stock Realtime

2. Detail Item S’part for repairing each machine number

3. Can calculate spend cost of parts for repairing each

machine yearly.

6 /12 ©2015 Sumitomo Electric Industries, Ltd. All Rights

Reserved

Action

1. Buying Scanner QR code

2. Change Manual Code Item to QR Code in the

Warehouse Spareparts

3. Make Bon Internal Usage by system, with

additional column “Repair Machine Number”

4/7 ©2015 Sumitomo Electric Industries, Ltd. All Rights

Reserved

Action

Change Manual Item to QR code

Before After

5/7 ©2015 Sumitomo Electric Industries, Ltd. All Rights

Reserved

Action

Change Manual Item to QR code

For Hanged Item

S’Part, QR Code

Laminated and

hang it

Before After

6/7 ©2015 Sumitomo Electric Industries, Ltd. All Rights

Reserved

Action

Make Bon Internal Usage by system

10 /12 ©2015 Sumitomo Electric Industries, Ltd. All Rights

Reserved

Benefits

1. Accurate Data

Reducing mistake choose Item Number in system.

2. Realtime Input

PIC Sparepart have to input directly, because after picking the part must be scanned QR Code.

3. Reduce Time for Input

4. Can calculate Qty& type of parts for each repair

machine in a year

5. Data can used for analyzed requirement of parts for

next period

7/7 ©2015 Sumitomo Electric Industries, Ltd. All Rights

Reserved

Confidential

Thank You

You might also like

- Carson Histotecnologia PDFDocument417 pagesCarson Histotecnologia PDFPaola Froster100% (1)

- 100 Questões Comentadas de PO PDFDocument31 pages100 Questões Comentadas de PO PDFMag NetoNo ratings yet

- 240 Preventive Check Sheet of Tube Bending Machine ReDocument4 pages240 Preventive Check Sheet of Tube Bending Machine ReAjayNo ratings yet

- VNP SHEQ Consulting Proposal Audit Gambling BoardDocument3 pagesVNP SHEQ Consulting Proposal Audit Gambling BoardVictorNo ratings yet

- Floridi. Por Una Filosofía de La Información.Document12 pagesFloridi. Por Una Filosofía de La Información.Nadia_Karina_C_9395No ratings yet

- Toll Free Nos. 1860 3000 1600 1800 425 0011: Parts ReplacedDocument1 pageToll Free Nos. 1860 3000 1600 1800 425 0011: Parts ReplacedSOUMITRA DASNo ratings yet

- MGK Flowchart - DrawioDocument1 pageMGK Flowchart - Drawioevaluasi pelaporanNo ratings yet

- CAPA Incomplete Part MixDocument16 pagesCAPA Incomplete Part MixRohtash fastnerNo ratings yet

- Procedure For Maintenance PDF Systems Theory Information TechnologyDocument1 pageProcedure For Maintenance PDF Systems Theory Information Technologynmctrr55b7No ratings yet

- 148-Issuance of Equipment Rental Request OrderDocument5 pages148-Issuance of Equipment Rental Request OrderHand SamNo ratings yet

- Imagerunner Advance C3530i IIDocument16 pagesImagerunner Advance C3530i IIMakram RahaliNo ratings yet

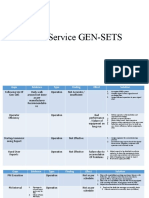

- Field Service GEN-SETSDocument6 pagesField Service GEN-SETSJoeNo ratings yet

- GAP ANALYSIS NewDocument1 pageGAP ANALYSIS NewMUHAMMADNo ratings yet

- Mamata Scheme AWC Monthly Report: New RegistrationsDocument1 pageMamata Scheme AWC Monthly Report: New RegistrationsPrabhakar PandaNo ratings yet

- Captura de Pantalla 2023-02-21 A La(s) 13.16.01Document1 pageCaptura de Pantalla 2023-02-21 A La(s) 13.16.01Hector EspinosaNo ratings yet

- DOLE IT Equipment Assessment Report Regional 2Document2 pagesDOLE IT Equipment Assessment Report Regional 2Nestor Adrian LatogaNo ratings yet

- Pixma Ip5300Document60 pagesPixma Ip5300Tarra Ramakrishna RaoNo ratings yet

- Manual de Guillotina Toledo BOLEITADocument137 pagesManual de Guillotina Toledo BOLEITAyoanacgwNo ratings yet

- 4m Status CheckDocument13 pages4m Status CheckdatyaksinteredllpNo ratings yet

- imagePRESS C700, C800, C750, C850 Series Preventative Maintenance GuideDocument29 pagesimagePRESS C700, C800, C750, C850 Series Preventative Maintenance GuideAndres CotrinoNo ratings yet

- S4HANA UT PP 01 02 Master Data Change Bill of Material V1.0Document6 pagesS4HANA UT PP 01 02 Master Data Change Bill of Material V1.0Karunamoorthy PeriasamyNo ratings yet

- Setup Task Lists and TasksDocument11 pagesSetup Task Lists and TasksManu SethumadhavanNo ratings yet

- Of Eeg It 003 Every 3 Month Copy Machine Maintanance ScheduleDocument1 pageOf Eeg It 003 Every 3 Month Copy Machine Maintanance ScheduleJoshua CooperNo ratings yet

- Working Level Cost Control: Section 6Document44 pagesWorking Level Cost Control: Section 6abdelkader benabdallahNo ratings yet

- Canon Advance DX C357if C257if Prev Maint ProcDocument14 pagesCanon Advance DX C357if C257if Prev Maint ProcKen LlacunaNo ratings yet

- Canon MP500 SeriesDocument66 pagesCanon MP500 SeriesGianluca MasalaNo ratings yet

- TINT022 MMI System Menu Navigation (RIDER)Document175 pagesTINT022 MMI System Menu Navigation (RIDER)Mahmoud MohamedNo ratings yet

- Ip5300 SMDocument60 pagesIp5300 SMМайор ДеяновNo ratings yet

- Computers Requirement ProformaDocument1 pageComputers Requirement ProformaSanjayNo ratings yet

- HICS 251 Facility System Status ReportDocument11 pagesHICS 251 Facility System Status ReportDavid MitchellNo ratings yet

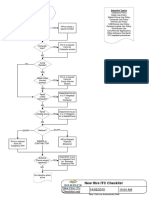

- New Hire ITC ChecklistDocument1 pageNew Hire ITC Checklistsolokinap_494172998No ratings yet

- Smartgen Hgm410n Hgm420n v1.2 en ManualDocument2 pagesSmartgen Hgm410n Hgm420n v1.2 en ManualLuis GonzalezNo ratings yet

- Tag No.: Asset Id: Machine Name: Area: TanggalDocument8 pagesTag No.: Asset Id: Machine Name: Area: TanggaldioNo ratings yet

- USER GUIDE - PM Module Page Wise Breakup 2.1 PDFDocument49 pagesUSER GUIDE - PM Module Page Wise Breakup 2.1 PDFrekhaNo ratings yet

- IT System and Network Access Request Form: Hfi TMM Online DeptDocument2 pagesIT System and Network Access Request Form: Hfi TMM Online DeptJeannylyn BurgosNo ratings yet

- Engineering Change Notice (Field Change Notice) : ECN No. 2010-E-0103Document3 pagesEngineering Change Notice (Field Change Notice) : ECN No. 2010-E-0103Adeel AbbasNo ratings yet

- Machine Tool Controller Design and Development Trend: Joe, Chien-Yi LeeDocument83 pagesMachine Tool Controller Design and Development Trend: Joe, Chien-Yi LeeFarzad MirzavandNo ratings yet

- SC-I 020.10.36 Control Points Before Reassembling For Induction Machines Ver BDocument1 pageSC-I 020.10.36 Control Points Before Reassembling For Induction Machines Ver BRafeek AliNo ratings yet

- Pixma - Ip4200 Service ManualDocument58 pagesPixma - Ip4200 Service ManualPepeNo ratings yet

- Onsite Service Call Report: Customer Signature: Engineer SignatureDocument2 pagesOnsite Service Call Report: Customer Signature: Engineer SignatureSuraj KumarNo ratings yet

- Pixma Mp500: Service ManualDocument66 pagesPixma Mp500: Service ManualNebi aktaşNo ratings yet

- Canon Ip5200 Service ManualDocument64 pagesCanon Ip5200 Service ManualCharles Doud100% (1)

- DG-2 Fitment Report Radico Khaitan SitapurDocument5 pagesDG-2 Fitment Report Radico Khaitan SitapurSanjit VermaNo ratings yet

- mp500 SMDocument82 pagesmp500 SMМайор ДеяновNo ratings yet

- Engineering Change Notice (Field Change Notice) : ECN No. 2015-E-0360Document2 pagesEngineering Change Notice (Field Change Notice) : ECN No. 2015-E-0360Đặng VĩNo ratings yet

- 237 Preventive Check Sheet of Lps Mechanical Press ReDocument5 pages237 Preventive Check Sheet of Lps Mechanical Press ReAjayNo ratings yet

- General Maintenance: Who Will Do? Process FlowDocument7 pagesGeneral Maintenance: Who Will Do? Process FlowSameer BagalkotNo ratings yet

- E-Field Service Report Inp (Rev)Document1 pageE-Field Service Report Inp (Rev)Marlini PasaribuNo ratings yet

- Cr-Ir 391 02e PDFDocument576 pagesCr-Ir 391 02e PDFSalvador Cajas100% (2)

- Ashish KushwahaDesign TaskDocument25 pagesAshish KushwahaDesign TaskAshish KushwahaNo ratings yet

- Engineering Change Notice (Field Change Notice) : PAGE 1 of 3 K12N0028-6-JDocument7 pagesEngineering Change Notice (Field Change Notice) : PAGE 1 of 3 K12N0028-6-Jagozalez.eymNo ratings yet

- ERS en 2303 R03 NBDocument11 pagesERS en 2303 R03 NBSubbu Kannappan SrinivasanNo ratings yet

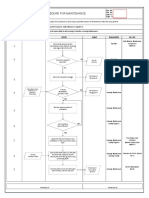

- 20) Process For Machine Maintenance.Document4 pages20) Process For Machine Maintenance.Sagar DaundNo ratings yet

- Procedure For MaintenanceDocument2 pagesProcedure For MaintenanceAnmol ChetriNo ratings yet

- NEMO Post Processing - 18dec2019Document6 pagesNEMO Post Processing - 18dec2019Shain SalimNo ratings yet

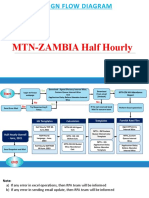

- Design Flow Diagram: MTN-ZAMBIA Half HourlyDocument3 pagesDesign Flow Diagram: MTN-ZAMBIA Half HourlyDhruvNo ratings yet

- 06-05-2021 Ops Dept MomDocument3 pages06-05-2021 Ops Dept MomErika Nell LachicaNo ratings yet

- Canon Pixma MP600 Service ManualDocument71 pagesCanon Pixma MP600 Service ManualAnonymous egTruyVdxvNo ratings yet

- FD Tial: Servicetechnical ReportDocument11 pagesFD Tial: Servicetechnical Reportnhatnguyen101No ratings yet

- BP 5000 User ManualDocument37 pagesBP 5000 User ManualrnxadityaNo ratings yet

- Sensation / Emotion: CT087/05/S Service Instruction CTDocument8 pagesSensation / Emotion: CT087/05/S Service Instruction CTAmmar SaadNo ratings yet

- 2011 E 0141 Upgrading Software For V2.1 BDocument195 pages2011 E 0141 Upgrading Software For V2.1 BOscar PelcastreNo ratings yet

- HP-Graphics Scitex BF Manual - Rev.1.7Document17 pagesHP-Graphics Scitex BF Manual - Rev.1.7Rolando LaferteNo ratings yet

- Annual Report Page-7Document1 pageAnnual Report Page-7Amin RizkyNo ratings yet

- Annual Report Page-3Document1 pageAnnual Report Page-3Amin RizkyNo ratings yet

- Annual Report Page-2Document1 pageAnnual Report Page-2Amin RizkyNo ratings yet

- Internet Message Access ProtocolDocument16 pagesInternet Message Access ProtocolAmin RizkyNo ratings yet

- Daily Progress Report ITDocument10 pagesDaily Progress Report ITAmin RizkyNo ratings yet

- Review Barcode System 28 Januari 2015Document26 pagesReview Barcode System 28 Januari 2015Amin RizkyNo ratings yet

- Folder Share WO Distribution - DennyDocument11 pagesFolder Share WO Distribution - DennyAmin RizkyNo ratings yet

- SLIDE 5 WHY - 22 JanDocument19 pagesSLIDE 5 WHY - 22 JanAmin RizkyNo ratings yet

- Penawaran Instalasi CCTV IP Cam & Fiber Optic (BPK Denny) 04-04-2022Document1 pagePenawaran Instalasi CCTV IP Cam & Fiber Optic (BPK Denny) 04-04-2022Amin RizkyNo ratings yet

- Campbell Systematic Reviews - 2011 - Morton - Youth Empowerment Programs For Improving Self Efficacy and Self Esteem ofDocument81 pagesCampbell Systematic Reviews - 2011 - Morton - Youth Empowerment Programs For Improving Self Efficacy and Self Esteem ofAndra ComanNo ratings yet

- AN1184 Application Note: Bu808Dfi in The Horizontal Deflection StageDocument13 pagesAN1184 Application Note: Bu808Dfi in The Horizontal Deflection StagetrmnmyNo ratings yet

- Advertisement in E-CommerceDocument49 pagesAdvertisement in E-CommerceKenz VillanuevaNo ratings yet

- G. Vrbová (Auth.), Professor Dr. W. A. Nix, Professor Dr. G. Vrbová (Eds.) - Electrical Stimulation and Neuromuscular Disorders-Springer-Verlag Berlin Heidelberg (1986)Document148 pagesG. Vrbová (Auth.), Professor Dr. W. A. Nix, Professor Dr. G. Vrbová (Eds.) - Electrical Stimulation and Neuromuscular Disorders-Springer-Verlag Berlin Heidelberg (1986)Harshavardhan SNo ratings yet

- Production of Germ Cell Spermatozoa From The Testis During Coitus Production of Male Sex Hormone Testosterone From The TestisDocument3 pagesProduction of Germ Cell Spermatozoa From The Testis During Coitus Production of Male Sex Hormone Testosterone From The Testisamelia niitaNo ratings yet

- Summer Farm: By: Norman Maccaig Group: Camila Luna and Estrella LinDocument8 pagesSummer Farm: By: Norman Maccaig Group: Camila Luna and Estrella LinJamieDuncanNo ratings yet

- 2023-2024 Biology Benchmark 1 BlueprintDocument2 pages2023-2024 Biology Benchmark 1 Blueprintapi-732514661No ratings yet

- Oracle Enterprise Asset ManagementDocument4 pagesOracle Enterprise Asset ManagementMH.SezanNo ratings yet

- Discovering Computers 2016: Digital Security, Ethics, and PrivacyDocument47 pagesDiscovering Computers 2016: Digital Security, Ethics, and Privacycabdicasiis cabdullahiNo ratings yet

- Ageing Aura and Vanitas in Art Greek LauDocument31 pagesAgeing Aura and Vanitas in Art Greek LautaraselbulbaNo ratings yet

- CirclesDocument54 pagesCirclestrishaNo ratings yet

- Intelligent Gesture Controlled Wireless Wheelchair For The Physically HandicappedDocument6 pagesIntelligent Gesture Controlled Wireless Wheelchair For The Physically HandicappedshivaramreddyNo ratings yet

- RTS Unit 1 NotesDocument24 pagesRTS Unit 1 NotesSAROJ RAJANo ratings yet

- VT572 Microwave Radar Motion Movement Sensor Detector Datasheet (Vutlan)Document16 pagesVT572 Microwave Radar Motion Movement Sensor Detector Datasheet (Vutlan)gm4984371No ratings yet

- D296 DetectorDocument4 pagesD296 Detectorventas2.fireproofcolNo ratings yet

- MatrixDocument30 pagesMatrixauras2065No ratings yet

- Vipin Pandey ProjectDocument112 pagesVipin Pandey ProjectmiakallenNo ratings yet

- 2046 - Decorative Synthetic Bonded Laminated SheetsDocument53 pages2046 - Decorative Synthetic Bonded Laminated SheetsKaushik SenguptaNo ratings yet

- Central Nervous System StimulantsDocument6 pagesCentral Nervous System StimulantsNathalia CabalseNo ratings yet

- About EthiopianDocument7 pagesAbout EthiopianTiny GechNo ratings yet

- Starkville Dispatch Eedition 11-4-18Document32 pagesStarkville Dispatch Eedition 11-4-18The DispatchNo ratings yet

- What Is Identity As We Now Use The WordDocument46 pagesWhat Is Identity As We Now Use The WordNurul RachmiNo ratings yet

- Evaluating Function GENERAL MATHEMATICSDocument4 pagesEvaluating Function GENERAL MATHEMATICSJane HembraNo ratings yet

- State Centric Theories of International Relations Belong To The Past in Security StudiesDocument3 pagesState Centric Theories of International Relations Belong To The Past in Security StudiesshoufiiNo ratings yet

- Part B Unit 3 DBMSDocument4 pagesPart B Unit 3 DBMSkaran.1888kNo ratings yet

- Tyler Street News November 2010Document4 pagesTyler Street News November 2010tsumcNo ratings yet