Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

25 viewsCrashing Test

Crashing Test

Uploaded by

himura kenshinThis document describes the test procedure used to determine the aggregate crushing value of coarse aggregates. The test subjects aggregates sized 12.5-10mm to a gradually applied 40-tonne load in a compression testing machine. The crushed material passing through a 2.36mm sieve is weighed and the aggregate crushing value is the percentage of crushed material by weight. A lower crushing value indicates stronger aggregates suitable for uses like cement concrete pavement, while a higher value still meets requirements for road surfaces. The test is repeated twice and the average reported to assess coarse aggregates for different types of road construction.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You might also like

- Pharmacy Practice I BriefingDocument35 pagesPharmacy Practice I BriefingSharmila LamisharNo ratings yet

- BS 11 1985Document48 pagesBS 11 1985Fenner Electromechanical100% (1)

- Determination of Aggregate Crushing ValueDocument13 pagesDetermination of Aggregate Crushing Valuealeena4100% (2)

- Artificial Intelligence and Consciousness - Subhash Kak - MediumDocument10 pagesArtificial Intelligence and Consciousness - Subhash Kak - MediumDestruction DerbyNo ratings yet

- Crushing Test PDFDocument4 pagesCrushing Test PDFAshishJamadarNo ratings yet

- Aggregate Crushing Value Test ApparatusDocument2 pagesAggregate Crushing Value Test ApparatusBiplab dattaNo ratings yet

- Aggregate Crushing ValueDocument2 pagesAggregate Crushing Valuekausik nathNo ratings yet

- Aggregate Crushing Value Test.Document2 pagesAggregate Crushing Value Test.Rajesh SharmaNo ratings yet

- Aggregate Crushing ValueDocument3 pagesAggregate Crushing ValuemuralidharanNo ratings yet

- Aggregate Crushing ValueDocument5 pagesAggregate Crushing ValuePRADEEPNo ratings yet

- Aggregate Crushing ValueDocument8 pagesAggregate Crushing ValueEngineeri TadiyosNo ratings yet

- Concrete & Highway Engineering Lab Manual: Vardhaman College of EngineeringDocument67 pagesConcrete & Highway Engineering Lab Manual: Vardhaman College of Engineeringsunil777tvpmNo ratings yet

- Road Materials Testing Lab Manual by Er. Hamender Singh ShekhawatDocument30 pagesRoad Materials Testing Lab Manual by Er. Hamender Singh ShekhawatHamendra Singh Shekhawat100% (19)

- 06) Section 6Document22 pages06) Section 6priyadarshanNo ratings yet

- K2 Lab ReportDocument10 pagesK2 Lab ReportNorRizan AbuOsman100% (1)

- 7 Lab Tests On Aggregate To Check Quality For Use in Road WorkDocument32 pages7 Lab Tests On Aggregate To Check Quality For Use in Road Workkumar814.dkNo ratings yet

- Highway Practical NdiiDocument18 pagesHighway Practical NdiiMuniru QudusNo ratings yet

- Deteremination of Aggregate Crushing ValueDocument1 pageDeteremination of Aggregate Crushing ValueXOXOXOXO XOXOXOXONo ratings yet

- Aggeragate Crushing Value TestDocument2 pagesAggeragate Crushing Value TestSanjeev KumarNo ratings yet

- PRCCCCCCCCCCCCCCCCCCCCCCC IIDocument24 pagesPRCCCCCCCCCCCCCCCCCCCCCCC IINomi khanNo ratings yet

- Experiment No. Name of The Experiment: Aggregate Impact Test AIM OF THE EXPERIMENT: To Determine The Aggregate Impact Value ofDocument4 pagesExperiment No. Name of The Experiment: Aggregate Impact Test AIM OF THE EXPERIMENT: To Determine The Aggregate Impact Value ofBibhuti B. BhardwajNo ratings yet

- Oel TransDocument19 pagesOel Transrazaain4305302No ratings yet

- Subjuct/Module: Level: Lab / Experiment NameDocument8 pagesSubjuct/Module: Level: Lab / Experiment NameTEDDYNo ratings yet

- Tests On AggregateDocument94 pagesTests On AggregateRamen KishoreNo ratings yet

- Experiments On Coarse AggregatesDocument9 pagesExperiments On Coarse AggregatesRuthra ManickamNo ratings yet

- ACV TFV and AIVDocument7 pagesACV TFV and AIVBernard KitosiNo ratings yet

- TransportationmmDocument25 pagesTransportationmmUaj AvhaNo ratings yet

- Tre Lab ManualDocument36 pagesTre Lab ManualRushi NaikNo ratings yet

- Transpo Lab ManualDocument27 pagesTranspo Lab Manualbaba pappuNo ratings yet

- Experiment No 2 Crushing ValueDocument5 pagesExperiment No 2 Crushing Valuefaiz19aaNo ratings yet

- EXPERIMENT NO 2 (Aggregate Crushing Value)Document3 pagesEXPERIMENT NO 2 (Aggregate Crushing Value)ADENIRAN firdausNo ratings yet

- CBR TestDocument23 pagesCBR TestAamir Kalim QaisraniNo ratings yet

- Splitting Tensile Strength of Cylindrical Concrete Specimens DetailedDocument4 pagesSplitting Tensile Strength of Cylindrical Concrete Specimens DetailedYasirNo ratings yet

- Lecture 6 BmcDocument7 pagesLecture 6 Bmcjatin saiwalNo ratings yet

- Aggregate Crushing Value Test For AggregateDocument2 pagesAggregate Crushing Value Test For AggregateMastani BajiraoNo ratings yet

- LabDocument7 pagesLabpro leongNo ratings yet

- Institute of Engineering Department CivilDocument27 pagesInstitute of Engineering Department CivilSabbir HossainNo ratings yet

- Material TestingDocument22 pagesMaterial Testing22Patil RiyaNo ratings yet

- Highway Enginering TestsDocument4 pagesHighway Enginering TestsanjaleebrcNo ratings yet

- Aggregate Crushing Value Test For AggregateDocument2 pagesAggregate Crushing Value Test For AggregateQuality JamNo ratings yet

- Tranportation All ExperimentDocument55 pagesTranportation All ExperimentMaiwand KhanNo ratings yet

- REPORTDocument10 pagesREPORTMUHAMMAD ZEESHANNo ratings yet

- 3 (D) Workability of Concrete - Flow Table TestDocument11 pages3 (D) Workability of Concrete - Flow Table TestFrank JohnNo ratings yet

- T Lab 03Document6 pagesT Lab 03Qaim ShahNo ratings yet

- Bldg. Sanitation, Code & RulesDocument8 pagesBldg. Sanitation, Code & RulesNick GeneseNo ratings yet

- Aggregate Impact ValueDocument4 pagesAggregate Impact ValueAmira Ab RahmanNo ratings yet

- Transportation LabDocument23 pagesTransportation LabSiddharth kumar SinghNo ratings yet

- Unit 4 MaterialsDocument17 pagesUnit 4 MaterialsYuvaraj DhanasekarNo ratings yet

- Aggregate Abrasion ValueDocument1 pageAggregate Abrasion ValueAntonio M. Chua Jr.No ratings yet

- Highway Materials and Construction Practice: UNIT-4Document54 pagesHighway Materials and Construction Practice: UNIT-4RawandAlbarodyNo ratings yet

- Aggregate TestDocument10 pagesAggregate TestAnuj ChandiwalaNo ratings yet

- Crusing Value Test Procedure PDFDocument2 pagesCrusing Value Test Procedure PDFMohsinNo ratings yet

- Flexural Test On Concrete Based On The ASTM Standards Are ExplainedDocument9 pagesFlexural Test On Concrete Based On The ASTM Standards Are ExplainedTesfayeNo ratings yet

- What Is Flexure StrengthDocument5 pagesWhat Is Flexure Strengthhimanshu tonkNo ratings yet

- 20 Patil Riya ReportNo.02 - Material TestingDocument23 pages20 Patil Riya ReportNo.02 - Material Testing22Patil RiyaNo ratings yet

- Aggregate Crushing Value: IS: 2386 (Part IV) - 1963)Document1 pageAggregate Crushing Value: IS: 2386 (Part IV) - 1963)SANJAY KUMAR SINGHNo ratings yet

- Aggregate Impact ValueDocument5 pagesAggregate Impact Valueonline researchNo ratings yet

- Conducting A Compressive Strength TestDocument8 pagesConducting A Compressive Strength TestCeleste Amor FactorNo ratings yet

- Compressive Strength Test ProcedureDocument9 pagesCompressive Strength Test ProcedureAnique Ur RehmanNo ratings yet

- Basic Equipment in Material Testing - SubilDocument6 pagesBasic Equipment in Material Testing - Subiljohn ian subilNo ratings yet

- Compressive Strength of Concrete: 1. ObjectiveDocument6 pagesCompressive Strength of Concrete: 1. ObjectivedavyordersNo ratings yet

- Field Tests of Common Building MaterialsDocument4 pagesField Tests of Common Building Materialshimura kenshinNo ratings yet

- Impact and Soundness TestDocument11 pagesImpact and Soundness Testhimura kenshinNo ratings yet

- Shape Test of Course AggregateDocument8 pagesShape Test of Course Aggregatehimura kenshinNo ratings yet

- Gradation of AggregatesDocument9 pagesGradation of Aggregateshimura kenshinNo ratings yet

- CMTC136REPORTG3Document5 pagesCMTC136REPORTG3himura kenshinNo ratings yet

- CMT128REPORTG3Document3 pagesCMT128REPORTG3himura kenshinNo ratings yet

- CMTC127REPORTG3Document4 pagesCMTC127REPORTG3himura kenshinNo ratings yet

- Front Garden DesignsDocument1 pageFront Garden Designshimura kenshinNo ratings yet

- Home Plan 1Document1 pageHome Plan 1himura kenshinNo ratings yet

- DLL F2FDocument3 pagesDLL F2FJeffrey VigonteNo ratings yet

- Introduction To Sustainability Final QuizDocument13 pagesIntroduction To Sustainability Final QuizedNo ratings yet

- MATLABDocument8 pagesMATLABDipak KaleNo ratings yet

- IMO Level1 Mock5 Class6Document17 pagesIMO Level1 Mock5 Class6Saket KhuranaNo ratings yet

- Frantz FanonDocument2 pagesFrantz FanonAlex BojovicNo ratings yet

- Stock Trading Ideas Ingress of Planets in Various Nakshatras or Lunar MansionsDocument4 pagesStock Trading Ideas Ingress of Planets in Various Nakshatras or Lunar MansionsAJ SinghNo ratings yet

- ULTIMA X5000 - 10177362 - Rev01 - USDocument22 pagesULTIMA X5000 - 10177362 - Rev01 - USAlberto GuillenNo ratings yet

- Geotech ReportDocument43 pagesGeotech ReportShahab Ali0% (1)

- Rational Equation, Inequality and FunctionDocument5 pagesRational Equation, Inequality and FunctionMichaelle BunaoNo ratings yet

- Int Stats For Eco - Assignment Question PaperDocument2 pagesInt Stats For Eco - Assignment Question PaperAryan AroraNo ratings yet

- 58-Reliability Centered MaintenanceDocument32 pages58-Reliability Centered MaintenanceAlejandro Bartolo Yañez100% (1)

- Student Leadership: Provided by Digital Education Resource ArchiveDocument19 pagesStudent Leadership: Provided by Digital Education Resource ArchiveHeavenly SinNo ratings yet

- Taller 14 PDFDocument2 pagesTaller 14 PDFSofía EscobarNo ratings yet

- Advantages and Limitations of Confocal Chromatic SensorsDocument13 pagesAdvantages and Limitations of Confocal Chromatic SensorsGilmar A. NogueiraNo ratings yet

- Form 2 Math HourDocument2 pagesForm 2 Math HourDavidson isaackNo ratings yet

- Opportunities and Challenges For Improving The Productivity of Swamp Buffaloes in Southeastern AsiaDocument8 pagesOpportunities and Challenges For Improving The Productivity of Swamp Buffaloes in Southeastern AsiaAndre RiansyahNo ratings yet

- Lab Report Beetroots FDocument10 pagesLab Report Beetroots FSafwan OthmanNo ratings yet

- How To Describe Our Group?: Quantitative SummarizeDocument16 pagesHow To Describe Our Group?: Quantitative Summarizeirdina athirahNo ratings yet

- PS 6 SolDocument4 pagesPS 6 SolCan DilsizNo ratings yet

- Troubleshooting Guide by John Dolan PDFDocument28 pagesTroubleshooting Guide by John Dolan PDFVenkatesh AllaNo ratings yet

- Chapter 9 EcosystemDocument18 pagesChapter 9 EcosystemRasigaaNo ratings yet

- Celtic Astrology - Early Irish Astrology - An Historical Argument by Peter Berresford EllisDocument7 pagesCeltic Astrology - Early Irish Astrology - An Historical Argument by Peter Berresford Ellisryder grayNo ratings yet

- Academic Performance of Night-Shift Students and Its Relationship With The Sleep-Wake CycleDocument4 pagesAcademic Performance of Night-Shift Students and Its Relationship With The Sleep-Wake CycleJohn Paul Loria LlanzanaNo ratings yet

- Browiner MX30 Mobile DR Service Manual 2016.11.10Document91 pagesBrowiner MX30 Mobile DR Service Manual 2016.11.10Imecsa HondurasNo ratings yet

- Forces and Motion: Unit 4: Module 1: Topic 2Document65 pagesForces and Motion: Unit 4: Module 1: Topic 2jabrielle ellice alunanNo ratings yet

- Barrowman 2014, Correlation, Causation, and ConfusionDocument28 pagesBarrowman 2014, Correlation, Causation, and ConfusionPeter ThomsenNo ratings yet

- Certified Reliability EngineerDocument9 pagesCertified Reliability EngineervishnuNo ratings yet

Crashing Test

Crashing Test

Uploaded by

himura kenshin0 ratings0% found this document useful (0 votes)

25 views11 pagesThis document describes the test procedure used to determine the aggregate crushing value of coarse aggregates. The test subjects aggregates sized 12.5-10mm to a gradually applied 40-tonne load in a compression testing machine. The crushed material passing through a 2.36mm sieve is weighed and the aggregate crushing value is the percentage of crushed material by weight. A lower crushing value indicates stronger aggregates suitable for uses like cement concrete pavement, while a higher value still meets requirements for road surfaces. The test is repeated twice and the average reported to assess coarse aggregates for different types of road construction.

Original Description:

crashing-test

Original Title

crashing-test

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document describes the test procedure used to determine the aggregate crushing value of coarse aggregates. The test subjects aggregates sized 12.5-10mm to a gradually applied 40-tonne load in a compression testing machine. The crushed material passing through a 2.36mm sieve is weighed and the aggregate crushing value is the percentage of crushed material by weight. A lower crushing value indicates stronger aggregates suitable for uses like cement concrete pavement, while a higher value still meets requirements for road surfaces. The test is repeated twice and the average reported to assess coarse aggregates for different types of road construction.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

25 views11 pagesCrashing Test

Crashing Test

Uploaded by

himura kenshinThis document describes the test procedure used to determine the aggregate crushing value of coarse aggregates. The test subjects aggregates sized 12.5-10mm to a gradually applied 40-tonne load in a compression testing machine. The crushed material passing through a 2.36mm sieve is weighed and the aggregate crushing value is the percentage of crushed material by weight. A lower crushing value indicates stronger aggregates suitable for uses like cement concrete pavement, while a higher value still meets requirements for road surfaces. The test is repeated twice and the average reported to assess coarse aggregates for different types of road construction.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 11

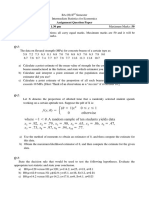

CRUSHING TEST

Coarse aggregate crushing value is the percentage

by weight of the crushed material obtained when

test aggregates are subjected to a specified load

under standardized conditions.

It is a numerical index of the strength of the

aggregate and it is used in contstruction of roads

and pavements.

Aggregate crushing value test on coarse

aggregates gives a relative measure of the

resistance of an aggregate crushing under

gradually applied compressive load.

OBJECTIVES

To determine the aggregate crushing value by

compressive testing machine.

Assess suitability of coarse aggregates for use in

different types of road.

APPARATUS

The apparatus of the aggregate crushing value test as per

IS: 2386 (Part IV)-1963 consists of:

1. A 15 cm diameter open ended steel cylinder with plunger

and base plate, of the general form and dimensions as

shown in figure 1.

2. A straight metal tamping rod circular cross-section 16mm

diameter and 45 to 60 cm long, rounded at one end.

3. A balance of capacity 3kg, readable and accurate up to 1g.

4. IS sieves of sizes 112.5,10 and 2.36mm.

5. A compression testing machine capable of applying a

load of 40 tonnes and which can be operated to give a

uniform rate of loading so that the maximum load is reached

in 10 minutes . The machine may be used with or without a

spherical seating.

6. For measuring the sample, cylindrical metal measure of

sufficient rigidity to retain its from under rough usage and of

the following internal dimensions:

Diameter- 11.5 cm

Height- 18.0 cm

PROCEDURES

The test sample: It consists of aggregates sized 12.5 mm –

10.0mm (minimum 3kg). The aggregates should be dried by

heating at 100-110 degrees celsius for a period of 4 hours and

cooled.

1. Sieve the material through 12.5 mm and 10 mm IS sieve.

The aggregates passing through 12.5 mm sieve and

retained on 10.0 mm sieve comprises the test material.

2. The cylinder of the test shall be put in position on the

base-plate and the test sample added in thirds, each third

being subjected to 25 strokes with the tamping rod.

3. The surface of the aggregate shall be levelled.

4. The plunger is inserted so that it rests horizontally on this

surface, care being taken to ensure that the plunger does

not jam in the cylinder.

5. The apparatus, with the test sample and plunger in position,

shall then be placed between the plates of the testing

machine.

6. The load is applied at a uniform as possible so that the total

load is reached in 10 mins. The total load shall be 40 tonnes.

7. The load shall be released and the whole of the material is

removed from the cylinder and sieved on 2.36mm IS sieve.

8. The fraction passing the sieve shall be weighed and recorded.

The above test is repeated on second sample of the same

weight. Thus two tests are made for the same specimen for

taking an average value.

RESULTS

The mean of the crushing value obtained in the two tests

is reported as the aggregate crushing value

LIMITS

The aggregate crushing value for cement concrete

pavement shall not exceed 30%.

The aggregate crushing value for wearing surfaces shall not

exceed 45%.

You might also like

- Pharmacy Practice I BriefingDocument35 pagesPharmacy Practice I BriefingSharmila LamisharNo ratings yet

- BS 11 1985Document48 pagesBS 11 1985Fenner Electromechanical100% (1)

- Determination of Aggregate Crushing ValueDocument13 pagesDetermination of Aggregate Crushing Valuealeena4100% (2)

- Artificial Intelligence and Consciousness - Subhash Kak - MediumDocument10 pagesArtificial Intelligence and Consciousness - Subhash Kak - MediumDestruction DerbyNo ratings yet

- Crushing Test PDFDocument4 pagesCrushing Test PDFAshishJamadarNo ratings yet

- Aggregate Crushing Value Test ApparatusDocument2 pagesAggregate Crushing Value Test ApparatusBiplab dattaNo ratings yet

- Aggregate Crushing ValueDocument2 pagesAggregate Crushing Valuekausik nathNo ratings yet

- Aggregate Crushing Value Test.Document2 pagesAggregate Crushing Value Test.Rajesh SharmaNo ratings yet

- Aggregate Crushing ValueDocument3 pagesAggregate Crushing ValuemuralidharanNo ratings yet

- Aggregate Crushing ValueDocument5 pagesAggregate Crushing ValuePRADEEPNo ratings yet

- Aggregate Crushing ValueDocument8 pagesAggregate Crushing ValueEngineeri TadiyosNo ratings yet

- Concrete & Highway Engineering Lab Manual: Vardhaman College of EngineeringDocument67 pagesConcrete & Highway Engineering Lab Manual: Vardhaman College of Engineeringsunil777tvpmNo ratings yet

- Road Materials Testing Lab Manual by Er. Hamender Singh ShekhawatDocument30 pagesRoad Materials Testing Lab Manual by Er. Hamender Singh ShekhawatHamendra Singh Shekhawat100% (19)

- 06) Section 6Document22 pages06) Section 6priyadarshanNo ratings yet

- K2 Lab ReportDocument10 pagesK2 Lab ReportNorRizan AbuOsman100% (1)

- 7 Lab Tests On Aggregate To Check Quality For Use in Road WorkDocument32 pages7 Lab Tests On Aggregate To Check Quality For Use in Road Workkumar814.dkNo ratings yet

- Highway Practical NdiiDocument18 pagesHighway Practical NdiiMuniru QudusNo ratings yet

- Deteremination of Aggregate Crushing ValueDocument1 pageDeteremination of Aggregate Crushing ValueXOXOXOXO XOXOXOXONo ratings yet

- Aggeragate Crushing Value TestDocument2 pagesAggeragate Crushing Value TestSanjeev KumarNo ratings yet

- PRCCCCCCCCCCCCCCCCCCCCCCC IIDocument24 pagesPRCCCCCCCCCCCCCCCCCCCCCCC IINomi khanNo ratings yet

- Experiment No. Name of The Experiment: Aggregate Impact Test AIM OF THE EXPERIMENT: To Determine The Aggregate Impact Value ofDocument4 pagesExperiment No. Name of The Experiment: Aggregate Impact Test AIM OF THE EXPERIMENT: To Determine The Aggregate Impact Value ofBibhuti B. BhardwajNo ratings yet

- Oel TransDocument19 pagesOel Transrazaain4305302No ratings yet

- Subjuct/Module: Level: Lab / Experiment NameDocument8 pagesSubjuct/Module: Level: Lab / Experiment NameTEDDYNo ratings yet

- Tests On AggregateDocument94 pagesTests On AggregateRamen KishoreNo ratings yet

- Experiments On Coarse AggregatesDocument9 pagesExperiments On Coarse AggregatesRuthra ManickamNo ratings yet

- ACV TFV and AIVDocument7 pagesACV TFV and AIVBernard KitosiNo ratings yet

- TransportationmmDocument25 pagesTransportationmmUaj AvhaNo ratings yet

- Tre Lab ManualDocument36 pagesTre Lab ManualRushi NaikNo ratings yet

- Transpo Lab ManualDocument27 pagesTranspo Lab Manualbaba pappuNo ratings yet

- Experiment No 2 Crushing ValueDocument5 pagesExperiment No 2 Crushing Valuefaiz19aaNo ratings yet

- EXPERIMENT NO 2 (Aggregate Crushing Value)Document3 pagesEXPERIMENT NO 2 (Aggregate Crushing Value)ADENIRAN firdausNo ratings yet

- CBR TestDocument23 pagesCBR TestAamir Kalim QaisraniNo ratings yet

- Splitting Tensile Strength of Cylindrical Concrete Specimens DetailedDocument4 pagesSplitting Tensile Strength of Cylindrical Concrete Specimens DetailedYasirNo ratings yet

- Lecture 6 BmcDocument7 pagesLecture 6 Bmcjatin saiwalNo ratings yet

- Aggregate Crushing Value Test For AggregateDocument2 pagesAggregate Crushing Value Test For AggregateMastani BajiraoNo ratings yet

- LabDocument7 pagesLabpro leongNo ratings yet

- Institute of Engineering Department CivilDocument27 pagesInstitute of Engineering Department CivilSabbir HossainNo ratings yet

- Material TestingDocument22 pagesMaterial Testing22Patil RiyaNo ratings yet

- Highway Enginering TestsDocument4 pagesHighway Enginering TestsanjaleebrcNo ratings yet

- Aggregate Crushing Value Test For AggregateDocument2 pagesAggregate Crushing Value Test For AggregateQuality JamNo ratings yet

- Tranportation All ExperimentDocument55 pagesTranportation All ExperimentMaiwand KhanNo ratings yet

- REPORTDocument10 pagesREPORTMUHAMMAD ZEESHANNo ratings yet

- 3 (D) Workability of Concrete - Flow Table TestDocument11 pages3 (D) Workability of Concrete - Flow Table TestFrank JohnNo ratings yet

- T Lab 03Document6 pagesT Lab 03Qaim ShahNo ratings yet

- Bldg. Sanitation, Code & RulesDocument8 pagesBldg. Sanitation, Code & RulesNick GeneseNo ratings yet

- Aggregate Impact ValueDocument4 pagesAggregate Impact ValueAmira Ab RahmanNo ratings yet

- Transportation LabDocument23 pagesTransportation LabSiddharth kumar SinghNo ratings yet

- Unit 4 MaterialsDocument17 pagesUnit 4 MaterialsYuvaraj DhanasekarNo ratings yet

- Aggregate Abrasion ValueDocument1 pageAggregate Abrasion ValueAntonio M. Chua Jr.No ratings yet

- Highway Materials and Construction Practice: UNIT-4Document54 pagesHighway Materials and Construction Practice: UNIT-4RawandAlbarodyNo ratings yet

- Aggregate TestDocument10 pagesAggregate TestAnuj ChandiwalaNo ratings yet

- Crusing Value Test Procedure PDFDocument2 pagesCrusing Value Test Procedure PDFMohsinNo ratings yet

- Flexural Test On Concrete Based On The ASTM Standards Are ExplainedDocument9 pagesFlexural Test On Concrete Based On The ASTM Standards Are ExplainedTesfayeNo ratings yet

- What Is Flexure StrengthDocument5 pagesWhat Is Flexure Strengthhimanshu tonkNo ratings yet

- 20 Patil Riya ReportNo.02 - Material TestingDocument23 pages20 Patil Riya ReportNo.02 - Material Testing22Patil RiyaNo ratings yet

- Aggregate Crushing Value: IS: 2386 (Part IV) - 1963)Document1 pageAggregate Crushing Value: IS: 2386 (Part IV) - 1963)SANJAY KUMAR SINGHNo ratings yet

- Aggregate Impact ValueDocument5 pagesAggregate Impact Valueonline researchNo ratings yet

- Conducting A Compressive Strength TestDocument8 pagesConducting A Compressive Strength TestCeleste Amor FactorNo ratings yet

- Compressive Strength Test ProcedureDocument9 pagesCompressive Strength Test ProcedureAnique Ur RehmanNo ratings yet

- Basic Equipment in Material Testing - SubilDocument6 pagesBasic Equipment in Material Testing - Subiljohn ian subilNo ratings yet

- Compressive Strength of Concrete: 1. ObjectiveDocument6 pagesCompressive Strength of Concrete: 1. ObjectivedavyordersNo ratings yet

- Field Tests of Common Building MaterialsDocument4 pagesField Tests of Common Building Materialshimura kenshinNo ratings yet

- Impact and Soundness TestDocument11 pagesImpact and Soundness Testhimura kenshinNo ratings yet

- Shape Test of Course AggregateDocument8 pagesShape Test of Course Aggregatehimura kenshinNo ratings yet

- Gradation of AggregatesDocument9 pagesGradation of Aggregateshimura kenshinNo ratings yet

- CMTC136REPORTG3Document5 pagesCMTC136REPORTG3himura kenshinNo ratings yet

- CMT128REPORTG3Document3 pagesCMT128REPORTG3himura kenshinNo ratings yet

- CMTC127REPORTG3Document4 pagesCMTC127REPORTG3himura kenshinNo ratings yet

- Front Garden DesignsDocument1 pageFront Garden Designshimura kenshinNo ratings yet

- Home Plan 1Document1 pageHome Plan 1himura kenshinNo ratings yet

- DLL F2FDocument3 pagesDLL F2FJeffrey VigonteNo ratings yet

- Introduction To Sustainability Final QuizDocument13 pagesIntroduction To Sustainability Final QuizedNo ratings yet

- MATLABDocument8 pagesMATLABDipak KaleNo ratings yet

- IMO Level1 Mock5 Class6Document17 pagesIMO Level1 Mock5 Class6Saket KhuranaNo ratings yet

- Frantz FanonDocument2 pagesFrantz FanonAlex BojovicNo ratings yet

- Stock Trading Ideas Ingress of Planets in Various Nakshatras or Lunar MansionsDocument4 pagesStock Trading Ideas Ingress of Planets in Various Nakshatras or Lunar MansionsAJ SinghNo ratings yet

- ULTIMA X5000 - 10177362 - Rev01 - USDocument22 pagesULTIMA X5000 - 10177362 - Rev01 - USAlberto GuillenNo ratings yet

- Geotech ReportDocument43 pagesGeotech ReportShahab Ali0% (1)

- Rational Equation, Inequality and FunctionDocument5 pagesRational Equation, Inequality and FunctionMichaelle BunaoNo ratings yet

- Int Stats For Eco - Assignment Question PaperDocument2 pagesInt Stats For Eco - Assignment Question PaperAryan AroraNo ratings yet

- 58-Reliability Centered MaintenanceDocument32 pages58-Reliability Centered MaintenanceAlejandro Bartolo Yañez100% (1)

- Student Leadership: Provided by Digital Education Resource ArchiveDocument19 pagesStudent Leadership: Provided by Digital Education Resource ArchiveHeavenly SinNo ratings yet

- Taller 14 PDFDocument2 pagesTaller 14 PDFSofía EscobarNo ratings yet

- Advantages and Limitations of Confocal Chromatic SensorsDocument13 pagesAdvantages and Limitations of Confocal Chromatic SensorsGilmar A. NogueiraNo ratings yet

- Form 2 Math HourDocument2 pagesForm 2 Math HourDavidson isaackNo ratings yet

- Opportunities and Challenges For Improving The Productivity of Swamp Buffaloes in Southeastern AsiaDocument8 pagesOpportunities and Challenges For Improving The Productivity of Swamp Buffaloes in Southeastern AsiaAndre RiansyahNo ratings yet

- Lab Report Beetroots FDocument10 pagesLab Report Beetroots FSafwan OthmanNo ratings yet

- How To Describe Our Group?: Quantitative SummarizeDocument16 pagesHow To Describe Our Group?: Quantitative Summarizeirdina athirahNo ratings yet

- PS 6 SolDocument4 pagesPS 6 SolCan DilsizNo ratings yet

- Troubleshooting Guide by John Dolan PDFDocument28 pagesTroubleshooting Guide by John Dolan PDFVenkatesh AllaNo ratings yet

- Chapter 9 EcosystemDocument18 pagesChapter 9 EcosystemRasigaaNo ratings yet

- Celtic Astrology - Early Irish Astrology - An Historical Argument by Peter Berresford EllisDocument7 pagesCeltic Astrology - Early Irish Astrology - An Historical Argument by Peter Berresford Ellisryder grayNo ratings yet

- Academic Performance of Night-Shift Students and Its Relationship With The Sleep-Wake CycleDocument4 pagesAcademic Performance of Night-Shift Students and Its Relationship With The Sleep-Wake CycleJohn Paul Loria LlanzanaNo ratings yet

- Browiner MX30 Mobile DR Service Manual 2016.11.10Document91 pagesBrowiner MX30 Mobile DR Service Manual 2016.11.10Imecsa HondurasNo ratings yet

- Forces and Motion: Unit 4: Module 1: Topic 2Document65 pagesForces and Motion: Unit 4: Module 1: Topic 2jabrielle ellice alunanNo ratings yet

- Barrowman 2014, Correlation, Causation, and ConfusionDocument28 pagesBarrowman 2014, Correlation, Causation, and ConfusionPeter ThomsenNo ratings yet

- Certified Reliability EngineerDocument9 pagesCertified Reliability EngineervishnuNo ratings yet