Professional Documents

Culture Documents

9.1 Food Industry - Smoczynski Michal

9.1 Food Industry - Smoczynski Michal

Uploaded by

Purshottam SoniCopyright:

Available Formats

You might also like

- Water and Wastewater Treatment in The Alcoholic BeverageDocument33 pagesWater and Wastewater Treatment in The Alcoholic BeverageJeanne Kamille Evangelista PiniliNo ratings yet

- Process Flow Diagram of Bar SoapDocument9 pagesProcess Flow Diagram of Bar SoapAndrea Cabungcal0% (1)

- A Guide To Engineered Wood ProductsDocument12 pagesA Guide To Engineered Wood ProductsCeyanezNo ratings yet

- Slaughterhouse & Meet ProcessingDocument15 pagesSlaughterhouse & Meet Processingazhar mohammedNo ratings yet

- EE - Chapter 3 (Revised With Images and Illustration)Document42 pagesEE - Chapter 3 (Revised With Images and Illustration)Ghaydah Hamed Rashid Al-AbriNo ratings yet

- Industrial PollutionDocument7 pagesIndustrial Pollutionashish mauryaNo ratings yet

- BlaDocument264 pagesBlaReymandha Aprilia Hutami100% (1)

- Pulp and Paper Mill Waste: Ajay Kumar Verma 2010PCH 116 Sanjay Verma 2010PCH 102Document15 pagesPulp and Paper Mill Waste: Ajay Kumar Verma 2010PCH 116 Sanjay Verma 2010PCH 102jefferson atienzaNo ratings yet

- 2 Industrial Waste Water TreatmentDocument26 pages2 Industrial Waste Water TreatmentPrashanthjpachu 17No ratings yet

- Group 10Document17 pagesGroup 10074 Md. Jubayer HossainNo ratings yet

- Bharati Vidyapeeth Deemed University, Pune Department of Chemical EngineeringDocument18 pagesBharati Vidyapeeth Deemed University, Pune Department of Chemical EngineeringSnehal Dawkhar patilNo ratings yet

- Industrial Effluent Agri-Food Industries - Degremont®Document11 pagesIndustrial Effluent Agri-Food Industries - Degremont®Mahmudul HasanNo ratings yet

- Chapter 2 Principle of Industrial Waste Water TreatmentDocument11 pagesChapter 2 Principle of Industrial Waste Water Treatmentmazlina85100% (6)

- 03 Food Processing Ind CanneryDocument14 pages03 Food Processing Ind CanneryHemu RaoNo ratings yet

- Difference Between Industrial Wastewater and Municipal WastewaterDocument11 pagesDifference Between Industrial Wastewater and Municipal WastewaterSupatmono NAINo ratings yet

- Resource For Greening Food and Beverage Manufacturing Pollution Prevention InformationDocument13 pagesResource For Greening Food and Beverage Manufacturing Pollution Prevention InformationShoheli Dil AfrozNo ratings yet

- Lec-2-Week (1) (Water Pollution)Document30 pagesLec-2-Week (1) (Water Pollution)Arsalan AliNo ratings yet

- Module - Ii: Environmental Pollution & IssuesDocument43 pagesModule - Ii: Environmental Pollution & IssuesVidhya MohananNo ratings yet

- Module - 5: StructureDocument26 pagesModule - 5: StructureShriNo ratings yet

- Topic 1 Waste and Waste TypeDocument56 pagesTopic 1 Waste and Waste TypeKarolina DermawanNo ratings yet

- 06 Chapter1Document13 pages06 Chapter1Praful N KNo ratings yet

- Unit 3 Waste Water CharacteristicsDocument63 pagesUnit 3 Waste Water CharacteristicsDevang ParmarNo ratings yet

- Chapter 3 Waste and Wastewater ManagementDocument52 pagesChapter 3 Waste and Wastewater Managementjhoward2012npNo ratings yet

- Liquid Wastes ManagementDocument114 pagesLiquid Wastes ManagementWakil MNo ratings yet

- 1 Industrial Wastewater Treatment MergedDocument20 pages1 Industrial Wastewater Treatment MergedLingraj ChangtiNo ratings yet

- Sla 5 PDFDocument12 pagesSla 5 PDFPablo Vladimir Millanao FuentesNo ratings yet

- Challenges and Recommendations For Pakistan Sugar IndustryDocument9 pagesChallenges and Recommendations For Pakistan Sugar Industrymms_mzNo ratings yet

- Pulp and Paper Mill WasteDocument15 pagesPulp and Paper Mill WasteManu Jain100% (1)

- Waste WaterDocument106 pagesWaste WaterLing Li100% (1)

- Industrial Waste TreatmentDocument26 pagesIndustrial Waste TreatmentthannuhNo ratings yet

- Topic 2.0 3.0 WW FlowsDocument16 pagesTopic 2.0 3.0 WW FlowsikhwanstorageNo ratings yet

- Sago Industry: Wastes and Environmental ProblemsDocument12 pagesSago Industry: Wastes and Environmental ProblemsSRI100% (1)

- Sugar IndustryDocument27 pagesSugar IndustryChali HaineNo ratings yet

- Consideration of Waste Water Characteristics Parameters: Dr. Savita DubeyDocument3 pagesConsideration of Waste Water Characteristics Parameters: Dr. Savita DubeyShivaraj IsarannavarNo ratings yet

- Iwwt Main TopicsDocument7 pagesIwwt Main TopicsBhanu Kishore VemulaNo ratings yet

- Sector U FoodDocument10 pagesSector U FoodRASHEED YUSUFNo ratings yet

- FDM Bref 0806Document682 pagesFDM Bref 0806Ahmed WafiqNo ratings yet

- Cerveceria TreatmenteDocument40 pagesCerveceria TreatmenteJulio TovarNo ratings yet

- Module 5 - IWT-1Document39 pagesModule 5 - IWT-1Jayesh mheraNo ratings yet

- WasteDocument24 pagesWasteTina SorianoNo ratings yet

- Classification of SOLID WASTEDocument43 pagesClassification of SOLID WASTEjan isobel hidalgoNo ratings yet

- Sustainable Production: Effluent Treatment PlantDocument12 pagesSustainable Production: Effluent Treatment PlantKush SharmaNo ratings yet

- l3Document40 pagesl3hayder khanNo ratings yet

- EVS - Unit 3 - Environmental PollutionDocument32 pagesEVS - Unit 3 - Environmental Pollutionr1u2No ratings yet

- Environmental Pollution (Water, Soil & Noise)Document33 pagesEnvironmental Pollution (Water, Soil & Noise)ABID REZA KhanNo ratings yet

- Environmental Awareness.: What Is Environment?Document3 pagesEnvironmental Awareness.: What Is Environment?Shafie ZubierNo ratings yet

- Pollution Control in Refineries and Fertilizer IndustriesDocument18 pagesPollution Control in Refineries and Fertilizer IndustriesTinu Paul Jepin100% (1)

- Charateristics and Treatment of Waste Generated by Sugar Industry 2Document19 pagesCharateristics and Treatment of Waste Generated by Sugar Industry 2ayushi693shindeNo ratings yet

- Nipro Presentation - HDF Technical Aspect and Water QualityDocument29 pagesNipro Presentation - HDF Technical Aspect and Water QualityAhmad Fuad Halimi100% (1)

- FDM Bref 2019 PDFDocument820 pagesFDM Bref 2019 PDFMohammed HammoudehNo ratings yet

- Types and Sources of Food Industry WasteDocument14 pagesTypes and Sources of Food Industry WasteTanu GuptaNo ratings yet

- FT - Ácido FosforicoDocument3 pagesFT - Ácido FosforicoBlutch0100% (1)

- Air Limbah DomestikDocument40 pagesAir Limbah DomestikI Gede Herry PurnamaNo ratings yet

- Waste Water Treatment in Brewery Industry, Review: IJEDR1801124 716Document7 pagesWaste Water Treatment in Brewery Industry, Review: IJEDR1801124 716AA0809No ratings yet

- Handling of By-Products and Treatment of WasteDocument7 pagesHandling of By-Products and Treatment of WastezalabiNo ratings yet

- Water Treatment PRO - Lesson 1Document56 pagesWater Treatment PRO - Lesson 1Guy SelaNo ratings yet

- Wastewater TreatmentDocument8 pagesWastewater TreatmentbekkuNo ratings yet

- Biological Sludge Minimization and Biomaterials/Bioenergy Recovery TechnologiesFrom EverandBiological Sludge Minimization and Biomaterials/Bioenergy Recovery TechnologiesEtienne PaulNo ratings yet

- Solid and Hazardous WasteDocument58 pagesSolid and Hazardous WastePurshottam SoniNo ratings yet

- Title: Rebound Hammer Test: I Practical Significance of GCOEJDocument6 pagesTitle: Rebound Hammer Test: I Practical Significance of GCOEJPurshottam SoniNo ratings yet

- PDF Solid and Hazardous Waste - CompressDocument14 pagesPDF Solid and Hazardous Waste - CompressPurshottam SoniNo ratings yet

- DTE Sopnsored training-GCoE Nagpur-Bulding An Ecosystem of Innovation and StartupDocument2 pagesDTE Sopnsored training-GCoE Nagpur-Bulding An Ecosystem of Innovation and StartupPurshottam SoniNo ratings yet

- Meteorological Factors AND Plume-Behaviour: by DR - Pallavi Das Assistant Professor Deptt. of Environmental Science IgntuDocument27 pagesMeteorological Factors AND Plume-Behaviour: by DR - Pallavi Das Assistant Professor Deptt. of Environmental Science IgntuPurshottam SoniNo ratings yet

- Public Health EngineeringDocument10 pagesPublic Health EngineeringSkylar LoveeNo ratings yet

- Msbtes E-Content: Program - Civil Engineering Program Code - Ce Course-Environmental Studies Course Code - 22447Document19 pagesMsbtes E-Content: Program - Civil Engineering Program Code - Ce Course-Environmental Studies Course Code - 22447Purshottam SoniNo ratings yet

- PHE Final 02-05-19 Mail 6-5-19Document148 pagesPHE Final 02-05-19 Mail 6-5-19Purshottam SoniNo ratings yet

- (LECT 17,18) Prestressed Concrete Pipes and TanksDocument40 pages(LECT 17,18) Prestressed Concrete Pipes and TanksSushil Mundel50% (4)

- Types of Mining: Stripping Ratio Mass of Burden/mass of MineralDocument6 pagesTypes of Mining: Stripping Ratio Mass of Burden/mass of MineralHILLARY FRANCIS SHENJERENo ratings yet

- Corrosion Characteristics of ASTM A106 Grade B Carbon Steel Pipelines Exposed To Sodium Sulfate SolutionsDocument16 pagesCorrosion Characteristics of ASTM A106 Grade B Carbon Steel Pipelines Exposed To Sodium Sulfate SolutionsAndres rodriguezNo ratings yet

- RCPC Report G1Document35 pagesRCPC Report G1Jancarl TelanNo ratings yet

- Types of AzeotropesDocument2 pagesTypes of AzeotropesTrixter SalvadorNo ratings yet

- 200 TOP MOST Steam Boilers, Engines, Nozzles and Turbines - Mechanical Engineering Multiple Choice Questions and AnswersDocument35 pages200 TOP MOST Steam Boilers, Engines, Nozzles and Turbines - Mechanical Engineering Multiple Choice Questions and AnswersAshish AgarwalNo ratings yet

- Oerlikon Products & ServicesDocument32 pagesOerlikon Products & Servicesvikas gowdaNo ratings yet

- Earth & Life Science: First Quarter-Module 3: Minerals and RocksDocument25 pagesEarth & Life Science: First Quarter-Module 3: Minerals and RocksAyen xlisaNo ratings yet

- Kech106 PDFDocument32 pagesKech106 PDFPhantomAssaulterNo ratings yet

- 02 Purification, Classification and Organic Compounds Que. Final E - 0Document13 pages02 Purification, Classification and Organic Compounds Que. Final E - 0amitkumarghorelaNo ratings yet

- Chapter 2 Matter Test 2011-12Document4 pagesChapter 2 Matter Test 2011-12Sheryl Jane P. SilangNo ratings yet

- Green WaterTreatment Solution - PresentationDocument17 pagesGreen WaterTreatment Solution - Presentationsrekumar kumarNo ratings yet

- Ch12 Kitabcd Class 8 MSBHSE Science NotesDocument6 pagesCh12 Kitabcd Class 8 MSBHSE Science NotesONE CLICK COMPUTERNo ratings yet

- MR & GMRDocument4 pagesMR & GMRJaddu MSDNo ratings yet

- Jhangho Physics Book 4 CompleteDocument210 pagesJhangho Physics Book 4 CompleteThoko SimbeyeNo ratings yet

- Slope Stabilisation Using LimeDocument8 pagesSlope Stabilisation Using LimeMohammadreza HarirsazNo ratings yet

- Mixer Settler Type ExtractionDocument7 pagesMixer Settler Type ExtractionVirender RanaNo ratings yet

- 15 - GEST 92 171 Edition 6 - Personal Protective Equipment in The Chlorine IndustryDocument20 pages15 - GEST 92 171 Edition 6 - Personal Protective Equipment in The Chlorine IndustryAdemilson JuniorNo ratings yet

- OPSS 906 Feb93 ElectrodeDocument13 pagesOPSS 906 Feb93 ElectrodeHamid MansouriNo ratings yet

- Summary Welding Procedure QualificationsDocument1 pageSummary Welding Procedure QualificationsBoran YelkenciogluNo ratings yet

- Experiment 1 PH and Buffers Pre LabDocument12 pagesExperiment 1 PH and Buffers Pre LabMing mingNo ratings yet

- 3-C CU 5kV 115 NLEPR 133 Percent CPE MV-105.specDocument2 pages3-C CU 5kV 115 NLEPR 133 Percent CPE MV-105.specFrancisco Zanin FernandesNo ratings yet

- Science QuizDocument7 pagesScience QuizWeviNo ratings yet

- Enclosed List As Annex 5a and 5bDocument150 pagesEnclosed List As Annex 5a and 5bManoj TribhuwanNo ratings yet

- MEB Nptel Week 5 Assignment AnswersDocument4 pagesMEB Nptel Week 5 Assignment AnswersMeethiPotterNo ratings yet

- Gadus S5 V220 2Document2 pagesGadus S5 V220 2Luqman Cuopreakt'zNo ratings yet

- Fjeariing Maintenance/I: (Bearing Maintenance A",-R1-F C.I/OtiDocument8 pagesFjeariing Maintenance/I: (Bearing Maintenance A",-R1-F C.I/OtiTalhaMahmoodNo ratings yet

- Trifold fINAL - 082847Document7 pagesTrifold fINAL - 082847kohikat5019No ratings yet

- 1 s2.0 S2666893922000895 MainDocument10 pages1 s2.0 S2666893922000895 MainJeet LukhiNo ratings yet

9.1 Food Industry - Smoczynski Michal

9.1 Food Industry - Smoczynski Michal

Uploaded by

Purshottam SoniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9.1 Food Industry - Smoczynski Michal

9.1 Food Industry - Smoczynski Michal

Uploaded by

Purshottam SoniCopyright:

Available Formats

WATER AND SEWAGE MANAGEMENT

IN THE FOOD INDUSTRY

Smoczyński Michał

Associate Professor

Chair of Milk Science and Quality Management

Faculty of Food Sciences

Warmia and Mazury University in Olsztyn

michal.smoczynski@uwm.edu.pl

www.uwm.edu.pl

FOOD INDUSTRY:

A. Processing of animal products

meat processing

poultry

dairy industry

fish processing

B. Processing of agricultural products

processing of grain and pasta

processing of potatoes

vegetables and fruit processing

sugar industry

oil production

Water and sewage management in the food industry 2

FOOD INDUSTRY IN POLAND

Approx. 15% of the whole industrial production,

7% contribution to the GDP (Gross Domestic Product)

It employs more than half of million people

About 27 thousand companies

Only 350 large companies, and only 1400 had the status of medium-sized

companies

It provides 21% of the food products sold on the domestic market

Many processing plants are characterized by the seasonality of production

(mainly fruit, vegetable, sugar and starch industry)

Water and sewage management in the food industry 3

CONSUMPTION OF WATER IN THE FOOD INDUSTRY IN POLAND

(YEAR 2002)

Food industry branch Water consumption [mln m3]

Meat production 13,1

Fish processing industry 0,6

Fruit and vegetables industry 18,3

Production of oils and fats 1,7

Production of dairy products 23,3

Production of sugar 7,8

Production of beverages 15,3

Total: 82,8

Water and sewage management in the food industry 4

WATER CONSUMPTION OF DIFFERENT FOOD PRODUCTS

Production Water consumption [dm3/kg]

Jam 13-25

Canned bean 13

Frozen bean 12

Canned vegetables 10

Frozen fruits 7

Vegetable juices 16

Concentrated fruit juice 40

Puree 6-12

Pickles 9

Depends also on:

- type of production

- the applied technology

- implementation of closed loop water systems

Water and sewage management in the food industry 5

POLLUTION GENERATED BY THE SELECTED BRANCHES OF THE FOOD INDUSTRY

Pollutants emitted into the

Branch Type of wastewater Type of waste

atmosphere

-flue gases from coal fired - waste water from production - slaughterhouse

Meat boilers (CO, SO2, NO2), dust (technological), the storage of waste eg. skin,

industry hydrocarbons livestock, slaughtering and bristles, blood

- smoke from the smokehouse processing division, contains - used machine oils,

(over 250 compounds) organic substances (fat and scrap metal, etc.

- odor (eg. ammonia, hydrogen protein), suspension, bacteria, - manure from

sulfide) coming from livestock, they get into the sewage in the storage of livestock,

slaughterhouses, fertilizers, form of blood, piece of meat, fat, slag, ash

wastewater treatment hair, soil, fertilizer, detergents etc. - sludge from sewage

burdensome for local society - non-production waste generated treatment plants,

- ammonia from special cooling during washing vehicles and communal living

systems, typically discharged equipment waste

into the atmosphere - sewage exceeds acceptable - packaging waste

levels of pH, BOD5, COD, dissolved

solids and slurries

Water and sewage management in the food industry 6

Pollutants

Branch emitted into the Type of wastewater Type of waste

atmosphere

- carbon - waste water resulting from washing - solid waste from

Fruit and monoxide (CO), the raw materials and blanching of agricultural products

vegetables sulfur dioxide - waste water resulting from washing - remnants of peeling

industry (SO2), dust from facilities and equipment vegetables and fruit

the boiler - waste water from the boiler and - ash and slag from boilers

- ammonia of cooling water systems - packaging waste

cooling systems - chemicals used in water treatment. - sludge from sewage

- specific indicators of pollution are: treatment plants

variable pH value, high value of BOD5,

high concentration of suspension

Water and sewage management in the food industry 7

Pollutants emitted into

Branch Type of wastewater Type of waste

the atmosphere

- carbon monoxide (CO), - waste water from washing of floors and - Ash and slag from

Dairy sulfur dioxide (SO2), equipment boilers fired with coal

industry solids from the coal fired - whey coming from cheese production - sludge from sewage

boiler - waste water from washing machines, treatment plants

- dust coming from boilers and cooling systems - rejects and scrap

manufacturing lines of - chemicals precipitated during water - packaging waste

dry milk and whey softening - municipal waste

- ammonia from cooling - types of pollution: variable pH, high

systems value BOD5, fats, total suspension

Water and sewage management in the food industry 8

Branch Pollutants emitted into the atmosphere Type of wastewater Type of waste

- carbon dioxide (CO2), sulfur dioxide - waste in the form of - sludge and solid

Sugar (SO2), nitrogen dioxide (NO2), dust and plant residues, dirt, sand, waste (beet and

industry dirt hydrocarbon from coal fired boilers oils and fats, chemicals, Packaging waste)

and pulp dryers additives, products and - liquid waste (waste

- dust created in lime (calcium oxide), detergents oils)

sugar dust created during the transport, - cooling water - slag, sand, stones

storage, packaging and briquetting of - sewage usually exceeds and contamination

sugar acceptable levels of COD, from beet

- carbon dioxide (CO2)and carbon BOD5, total nitrogen,

monoxide (CO) in bulk gases generated in suspended solids and

the saturation process dissolved solids

- sulfur dioxide (SO2)from the sulfur

furnace

Water and sewage management in the food industry 9

CONCENTRATION OF POLLUTANTS IN RAW SEWAGE FROM SELECTED FOOD

PLANTS

Ether Total Total

BOD5 COD TSS

Branch extract phosphorus nitrogen pH

[g O2/m3] [g O2/m3] [g/m3]

[g/m3] [g/m3] [g/m3]

Potato

400-2500 700-4000 No data 200-1800 10-60 20-250 5-8

industry

Sugar

600-1300 2500 No data 100-6500 10-70 10-200 6-9

industry

Meat and

poultry 200-1800 1000-3500 300-1000 400-1500 10-20 50-200 6-9

industry

Dairy

100-2500 1000-5000 45-110 800-1000 5-20 55-160 6-9

industry

Fruit and

vegetable 200-1500 400-2800 10-1400 50-800 <1 <5 6-9

industry

Fish

>7000 >10000 100-700 <3500 5-50 500 5-9

industry

Oil

>5300 >8700 >6300 >2400 <100 No data 9-11

industry

Water and sewage management in the food industry 10

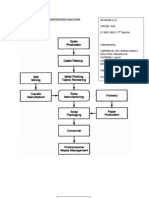

SEWAGE MANAGEMENT IN THE FOOD PROCESSING PLANTS

Wastewater and sewage from production

Factory sewage pre-treatment plant Other waste

Sewage system

Municipal wastewater treatment plant

Environment

Water and sewage management in the food industry 11

FOOD WASTEWATER IN THE ENVIRONMENT

Main problems:

organic substances (fat, oil, protein, carbohydrates)

residues of detergents and disinfectants

hot sewage, unfavorable pH

microflora (pathogens, viruses etc.)

How to reduce possible threats?

equalizing sewage

avoiding the wave discharges

work organization and cooperation

Water and sewage management in the food industry 12

BASIC OF WASTEWATER TREATMENT IN FOOD INDUSTRY

Dissolved Colloidal particles Suspension Rapidly sedimenting

particles suspension

Size of particle, µm <0.01 0.01-1 1-100 >100

Pre-treatment Biological treatment Specific

- mechanical - grates or sieves, settling including removal of ultrafiltration,

tanks, flotation units, grease biocompounds - reverse

interceptors nitrogen and osmosis

- mechanochemical - coagulants and phosphorus

polymers

- fermentation of raw sewer (biogas

recovery)

Water and sewage management in the food industry 13

CHEMICAL WASTEWATER TREATMENT PROCESS

involves application of selected chemical reagents, which due to their

characteristics can be divided into:

coagulants and flocculants

disinfectants

oxidizing agents

reagents for correction of pH

Chemicals 1992 Chemicals 2012

PIX PIX

Calcium Polymers

Iron blends

PAX

Aluminium blends

Iron aluminium coagulants

Water and sewage management in the food industry 14

EXAMPLE OF EFFICIENCY OF SEWAGE TREATMENT FOR MEAT

PLANT (SLUGHTER AND PROCESSING) WITH CHEMICAL

TREATMENT

[Flotation type DAF, PIX112 at a dose = 250 g/m3, flocculation with the anionic polyelectrolyte]

Sewage after Terms from municipal

Parameter Raw sewage

treatment treatment plant

COD [ mg O2/dm3] 1954 480 1000

TSS [mg/dm3] 458 75 330

Ether extract [mg/dm3] 922 19 50

Total solutes [mg/dm3] 1083 1166 1200

Sulfur [mg/dm3] 194 292 420

Phosphates [mg/dm3] 26 0,3 Not applicable

Water and sewage management in the food industry 15

SPECIAL CONSIDERATIONS OF CHEMICAL WASTEWATER TREATMENT IN

FOOD INDUSTRY

Branch Strategies for wastewater treatment

- wastewater from washing - due to the low content of COD/BOD5 application of coagulants

Fe (III) and Al is not necessary; they must be used for removal of hydrogen sulphide

particularly when pH <8 iron coagulants, optionally oxidizing agents

Potato

- technological sewage containing starch - the most common method is precipitation with

industry

the use of the coagulant and anionic or cationic polymer

- in the biological purification iron coagulants are especially effective, which additionally

eliminate hydrogen sulphide during dehydration and the storage of sludge

Spirit and

use of Fe (III) is most commonly recommended for removing of hydrogen sulphide from the

yeast

anaerobic processes

industry

Fruit and

removal of suspended solids with its simultaneous compaction with the use of Fe (III) salts

vegetables

and appropriate polymer

industry

- due to low content of suspensions and colloids, coagulants are not used.

Brewery

- in the presence of hydrogen sulphide salts of Fe (III) may be used or oxidizing agents

industry

containing sulphate (VI) iron (III) and nitric acid (V)

Water and sewage management in the food industry 16

Branch Strategies for wastewater treatment

Sugar Similarly to potato industry, but at pH<8 sewage comprising simple sugars, more easily

industry undergoes anaerobic processes, combined with the emitting of hydrogen sulphide

- mechanochemical pretreatment of wastewater by means of DAF flotation system,

involving salt of Fe (III) or Al and adjustment of the pH with the NaOH and the use of

anionic polymer; main objective is fat removal before biological treatment or discharge to

Meat industry

the sewage system

- polyaluminum chlorides and iron (III) compounds are used to remove phosphorus, scum

and swelling caused by bacteria

- the pretreatment of wastewater by means of DAF flotation assisted with chemical

coagulant and the polymer before discharge to sewer is used

Dairy industry

- coagulating compounds based on iron or aluminum are used during biological treatment

processes

- mechanochemical pretreatment is frequently used; problems and methods similar to

Fish industry

meat industry

Water and sewage management in the food industry 17

DAIRY WASTEWATER TREATMENT

11,183 million litres of milk were processed in Poland in

2011.

milk consumption amounted 194 litres (without milk used

for butter production) per capita

water consumption was 0,7-2,5 m3/t of processed milk

25.4 hm3 of sewage was formed, of which 13.8 hm3

wastewater was treated (9.0 hm3 biologically and 4.8 hm3

with increased nutrient removal) and removed to the

environment. The remaining 11.4 hm3 did not require

treatment or after pretreatment were discharged into the

sewer

BOD5 value of milk is equal to 104 000 mg O2/l

Water and sewage management in the food industry 18

THE SEQUENCE OF PROCESSES USED FOR CLEANING

pretreatment:

removal of the contaminants of large size – straining process

mineral removal – sedimentation on sand traps

removal of fat - flotation process,

averaging of wastewater

coagulation of colloidal particles

treatment

removal of impurities easily degradable – biological processes (aerobic and

anaerobic)

Water and sewage management in the food industry 19

FLOTATION

spontaneous flotation- spontaneous flow of fat to the surface

assisted flotation- fat is taken up on the surface by means of gas bubbles

(usually pressurized air)

Water and sewage management in the food industry 20

COAGULATION

In the initial treatment of dairy wastewater process of coagulation

may be used:

during pressurized air flotation (coagulants are dosed before the

flotation chamber)

during biological treatment, when the precipitation will greatly

reduce the pollution load

Water and sewage management in the food industry 21

ACTIVATED-SLUGDE METHOD

single-use bioreactor - working with the secondary settling tank and

a device for recirculation of sludge

three-stage biological reactor - the division into three chambers:

anaerobic, aerobic and hypoxic which allows for implementation of

biological phosphorus removal, denitrification and nitrification

Sequential Batch Reactor (SRB)

Water and sewage management in the food industry 22

EXAMPLES OF RESEARCH TRENDS FOR WASTEWATER MANAGEMENT IN

THE FOOD INDUSTRY

Short characteristic Reference

Parashar A., Jin Y., Mason B., Chae M., Bressler D.C. Incorporation

Use of whey as an addition to cereals in of whey permeate, a dairy effluent, in ethanol fermentation to

the production of ethyl alcohol provide a zero waste solution for the dairy industry. Journal of

Dairy Science, 2015, 99: 1859-1867

The use of condensate from UHT

Suarez A., Fidalgo T., Riera F.A. Recovery of dairy industry

process to provide high quality water

wastewaters by reverse osmosis. Production of boiler water.

for the boiler - purification by reverse

Separation and Purification Technology, 2014, 133: 204-211

osmosis

The possibility of using of a fat layer Sivakumar P., Anbarasu K., Renganathan S. Bio-diesel production

from dairy wastewater for production by alkali catalysed transesterification of dairy waste scum. Fuel,

of biodiesel 2011, 90: 147-151

Das B., Sarkar S., Sarkar A., Bhattacharjee S., Bhattacharjee C.

New methods for the recovery of whey Recovery of whey proteins and lactose from dairy waste: A step

proteins and lactose from the whey toward green waste management. Process Safety and

Environmental Protection, 2016, 101: 27-33

Water and sewage management in the food industry 23

Short characteristic Reference

Parashar A., Jin Y., Mason B., Chae M., Bressler D.C.

Use of whey as an addition to cereals in Incorporation of whey permeate, a dairy effluent, in ethanol

the production of ethyl alcohol fermentation to provide a zero waste solution for the dairy

industry. Journal of Dairy Science, 2015, 99: 1859-1867

The use of condensate from UHT

Suarez A., Fidalgo T., Riera F.A. Recovery of dairy industry

process to provide high quality water

wastewaters by reverse osmosis. Production of boiler water.

for the boiler - purification by reverse

Separation and Purification Technology, 2014, 133: 204-211

osmosis

The possibility of using of a fat layer Sivakumar P., Anbarasu K., Renganathan S. Bio-diesel

from dairy wastewater for production of production by alkali catalysed transesterification of dairy waste

biodiesel scum. Fuel, 2011, 90: 147-151

Das B., Sarkar S., Sarkar A., Bhattacharjee S., Bhattacharjee C.

New methods for the recovery of whey Recovery of whey proteins and lactose from dairy waste: A step

proteins and lactose from the whey toward green waste management. Process Safety and

Environmental Protection, 2016, 101: 27-33

Water and sewage management in the food industry 24

References:

Konieczny P., Szymański M. Ścieki przemyslu spożywczego –

charakterystyka, zagrożenia, korzyści. Eko-net.pl – Firma i środowisko,

2005, 3, 16-22.

Kasztelan A., Kierepka M. Oddziaływanie przemysłu spożywczego na

środowisko w Polsce. Stowarzyszenie Ekonomistów Rolnictwa i

Agrobiznesu, Roczniki Naukowe, 2014, 16(2), 109-116.

Puchlik M., Struk-Sokołowska J., Wołejko E., Wydro U. Problem

oczyszczania ścieków z przemysłu spożywczego w małych i średnich

przedsiębiorstwach. EKO-DOK 2016, VIII Konferencja

Interdyscyplinarne Zagadnienia w Inżynierii i Ochronie Środowiska,

2016.

Smoczyński M. Nowe trendy w gospodarce wodno-ściekowej w

przemyśle mleczarskim. Przegląd mleczarski, 2016, 7, 3-6.

Water and sewage management in the food industry 25

You might also like

- Water and Wastewater Treatment in The Alcoholic BeverageDocument33 pagesWater and Wastewater Treatment in The Alcoholic BeverageJeanne Kamille Evangelista PiniliNo ratings yet

- Process Flow Diagram of Bar SoapDocument9 pagesProcess Flow Diagram of Bar SoapAndrea Cabungcal0% (1)

- A Guide To Engineered Wood ProductsDocument12 pagesA Guide To Engineered Wood ProductsCeyanezNo ratings yet

- Slaughterhouse & Meet ProcessingDocument15 pagesSlaughterhouse & Meet Processingazhar mohammedNo ratings yet

- EE - Chapter 3 (Revised With Images and Illustration)Document42 pagesEE - Chapter 3 (Revised With Images and Illustration)Ghaydah Hamed Rashid Al-AbriNo ratings yet

- Industrial PollutionDocument7 pagesIndustrial Pollutionashish mauryaNo ratings yet

- BlaDocument264 pagesBlaReymandha Aprilia Hutami100% (1)

- Pulp and Paper Mill Waste: Ajay Kumar Verma 2010PCH 116 Sanjay Verma 2010PCH 102Document15 pagesPulp and Paper Mill Waste: Ajay Kumar Verma 2010PCH 116 Sanjay Verma 2010PCH 102jefferson atienzaNo ratings yet

- 2 Industrial Waste Water TreatmentDocument26 pages2 Industrial Waste Water TreatmentPrashanthjpachu 17No ratings yet

- Group 10Document17 pagesGroup 10074 Md. Jubayer HossainNo ratings yet

- Bharati Vidyapeeth Deemed University, Pune Department of Chemical EngineeringDocument18 pagesBharati Vidyapeeth Deemed University, Pune Department of Chemical EngineeringSnehal Dawkhar patilNo ratings yet

- Industrial Effluent Agri-Food Industries - Degremont®Document11 pagesIndustrial Effluent Agri-Food Industries - Degremont®Mahmudul HasanNo ratings yet

- Chapter 2 Principle of Industrial Waste Water TreatmentDocument11 pagesChapter 2 Principle of Industrial Waste Water Treatmentmazlina85100% (6)

- 03 Food Processing Ind CanneryDocument14 pages03 Food Processing Ind CanneryHemu RaoNo ratings yet

- Difference Between Industrial Wastewater and Municipal WastewaterDocument11 pagesDifference Between Industrial Wastewater and Municipal WastewaterSupatmono NAINo ratings yet

- Resource For Greening Food and Beverage Manufacturing Pollution Prevention InformationDocument13 pagesResource For Greening Food and Beverage Manufacturing Pollution Prevention InformationShoheli Dil AfrozNo ratings yet

- Lec-2-Week (1) (Water Pollution)Document30 pagesLec-2-Week (1) (Water Pollution)Arsalan AliNo ratings yet

- Module - Ii: Environmental Pollution & IssuesDocument43 pagesModule - Ii: Environmental Pollution & IssuesVidhya MohananNo ratings yet

- Module - 5: StructureDocument26 pagesModule - 5: StructureShriNo ratings yet

- Topic 1 Waste and Waste TypeDocument56 pagesTopic 1 Waste and Waste TypeKarolina DermawanNo ratings yet

- 06 Chapter1Document13 pages06 Chapter1Praful N KNo ratings yet

- Unit 3 Waste Water CharacteristicsDocument63 pagesUnit 3 Waste Water CharacteristicsDevang ParmarNo ratings yet

- Chapter 3 Waste and Wastewater ManagementDocument52 pagesChapter 3 Waste and Wastewater Managementjhoward2012npNo ratings yet

- Liquid Wastes ManagementDocument114 pagesLiquid Wastes ManagementWakil MNo ratings yet

- 1 Industrial Wastewater Treatment MergedDocument20 pages1 Industrial Wastewater Treatment MergedLingraj ChangtiNo ratings yet

- Sla 5 PDFDocument12 pagesSla 5 PDFPablo Vladimir Millanao FuentesNo ratings yet

- Challenges and Recommendations For Pakistan Sugar IndustryDocument9 pagesChallenges and Recommendations For Pakistan Sugar Industrymms_mzNo ratings yet

- Pulp and Paper Mill WasteDocument15 pagesPulp and Paper Mill WasteManu Jain100% (1)

- Waste WaterDocument106 pagesWaste WaterLing Li100% (1)

- Industrial Waste TreatmentDocument26 pagesIndustrial Waste TreatmentthannuhNo ratings yet

- Topic 2.0 3.0 WW FlowsDocument16 pagesTopic 2.0 3.0 WW FlowsikhwanstorageNo ratings yet

- Sago Industry: Wastes and Environmental ProblemsDocument12 pagesSago Industry: Wastes and Environmental ProblemsSRI100% (1)

- Sugar IndustryDocument27 pagesSugar IndustryChali HaineNo ratings yet

- Consideration of Waste Water Characteristics Parameters: Dr. Savita DubeyDocument3 pagesConsideration of Waste Water Characteristics Parameters: Dr. Savita DubeyShivaraj IsarannavarNo ratings yet

- Iwwt Main TopicsDocument7 pagesIwwt Main TopicsBhanu Kishore VemulaNo ratings yet

- Sector U FoodDocument10 pagesSector U FoodRASHEED YUSUFNo ratings yet

- FDM Bref 0806Document682 pagesFDM Bref 0806Ahmed WafiqNo ratings yet

- Cerveceria TreatmenteDocument40 pagesCerveceria TreatmenteJulio TovarNo ratings yet

- Module 5 - IWT-1Document39 pagesModule 5 - IWT-1Jayesh mheraNo ratings yet

- WasteDocument24 pagesWasteTina SorianoNo ratings yet

- Classification of SOLID WASTEDocument43 pagesClassification of SOLID WASTEjan isobel hidalgoNo ratings yet

- Sustainable Production: Effluent Treatment PlantDocument12 pagesSustainable Production: Effluent Treatment PlantKush SharmaNo ratings yet

- l3Document40 pagesl3hayder khanNo ratings yet

- EVS - Unit 3 - Environmental PollutionDocument32 pagesEVS - Unit 3 - Environmental Pollutionr1u2No ratings yet

- Environmental Pollution (Water, Soil & Noise)Document33 pagesEnvironmental Pollution (Water, Soil & Noise)ABID REZA KhanNo ratings yet

- Environmental Awareness.: What Is Environment?Document3 pagesEnvironmental Awareness.: What Is Environment?Shafie ZubierNo ratings yet

- Pollution Control in Refineries and Fertilizer IndustriesDocument18 pagesPollution Control in Refineries and Fertilizer IndustriesTinu Paul Jepin100% (1)

- Charateristics and Treatment of Waste Generated by Sugar Industry 2Document19 pagesCharateristics and Treatment of Waste Generated by Sugar Industry 2ayushi693shindeNo ratings yet

- Nipro Presentation - HDF Technical Aspect and Water QualityDocument29 pagesNipro Presentation - HDF Technical Aspect and Water QualityAhmad Fuad Halimi100% (1)

- FDM Bref 2019 PDFDocument820 pagesFDM Bref 2019 PDFMohammed HammoudehNo ratings yet

- Types and Sources of Food Industry WasteDocument14 pagesTypes and Sources of Food Industry WasteTanu GuptaNo ratings yet

- FT - Ácido FosforicoDocument3 pagesFT - Ácido FosforicoBlutch0100% (1)

- Air Limbah DomestikDocument40 pagesAir Limbah DomestikI Gede Herry PurnamaNo ratings yet

- Waste Water Treatment in Brewery Industry, Review: IJEDR1801124 716Document7 pagesWaste Water Treatment in Brewery Industry, Review: IJEDR1801124 716AA0809No ratings yet

- Handling of By-Products and Treatment of WasteDocument7 pagesHandling of By-Products and Treatment of WastezalabiNo ratings yet

- Water Treatment PRO - Lesson 1Document56 pagesWater Treatment PRO - Lesson 1Guy SelaNo ratings yet

- Wastewater TreatmentDocument8 pagesWastewater TreatmentbekkuNo ratings yet

- Biological Sludge Minimization and Biomaterials/Bioenergy Recovery TechnologiesFrom EverandBiological Sludge Minimization and Biomaterials/Bioenergy Recovery TechnologiesEtienne PaulNo ratings yet

- Solid and Hazardous WasteDocument58 pagesSolid and Hazardous WastePurshottam SoniNo ratings yet

- Title: Rebound Hammer Test: I Practical Significance of GCOEJDocument6 pagesTitle: Rebound Hammer Test: I Practical Significance of GCOEJPurshottam SoniNo ratings yet

- PDF Solid and Hazardous Waste - CompressDocument14 pagesPDF Solid and Hazardous Waste - CompressPurshottam SoniNo ratings yet

- DTE Sopnsored training-GCoE Nagpur-Bulding An Ecosystem of Innovation and StartupDocument2 pagesDTE Sopnsored training-GCoE Nagpur-Bulding An Ecosystem of Innovation and StartupPurshottam SoniNo ratings yet

- Meteorological Factors AND Plume-Behaviour: by DR - Pallavi Das Assistant Professor Deptt. of Environmental Science IgntuDocument27 pagesMeteorological Factors AND Plume-Behaviour: by DR - Pallavi Das Assistant Professor Deptt. of Environmental Science IgntuPurshottam SoniNo ratings yet

- Public Health EngineeringDocument10 pagesPublic Health EngineeringSkylar LoveeNo ratings yet

- Msbtes E-Content: Program - Civil Engineering Program Code - Ce Course-Environmental Studies Course Code - 22447Document19 pagesMsbtes E-Content: Program - Civil Engineering Program Code - Ce Course-Environmental Studies Course Code - 22447Purshottam SoniNo ratings yet

- PHE Final 02-05-19 Mail 6-5-19Document148 pagesPHE Final 02-05-19 Mail 6-5-19Purshottam SoniNo ratings yet

- (LECT 17,18) Prestressed Concrete Pipes and TanksDocument40 pages(LECT 17,18) Prestressed Concrete Pipes and TanksSushil Mundel50% (4)

- Types of Mining: Stripping Ratio Mass of Burden/mass of MineralDocument6 pagesTypes of Mining: Stripping Ratio Mass of Burden/mass of MineralHILLARY FRANCIS SHENJERENo ratings yet

- Corrosion Characteristics of ASTM A106 Grade B Carbon Steel Pipelines Exposed To Sodium Sulfate SolutionsDocument16 pagesCorrosion Characteristics of ASTM A106 Grade B Carbon Steel Pipelines Exposed To Sodium Sulfate SolutionsAndres rodriguezNo ratings yet

- RCPC Report G1Document35 pagesRCPC Report G1Jancarl TelanNo ratings yet

- Types of AzeotropesDocument2 pagesTypes of AzeotropesTrixter SalvadorNo ratings yet

- 200 TOP MOST Steam Boilers, Engines, Nozzles and Turbines - Mechanical Engineering Multiple Choice Questions and AnswersDocument35 pages200 TOP MOST Steam Boilers, Engines, Nozzles and Turbines - Mechanical Engineering Multiple Choice Questions and AnswersAshish AgarwalNo ratings yet

- Oerlikon Products & ServicesDocument32 pagesOerlikon Products & Servicesvikas gowdaNo ratings yet

- Earth & Life Science: First Quarter-Module 3: Minerals and RocksDocument25 pagesEarth & Life Science: First Quarter-Module 3: Minerals and RocksAyen xlisaNo ratings yet

- Kech106 PDFDocument32 pagesKech106 PDFPhantomAssaulterNo ratings yet

- 02 Purification, Classification and Organic Compounds Que. Final E - 0Document13 pages02 Purification, Classification and Organic Compounds Que. Final E - 0amitkumarghorelaNo ratings yet

- Chapter 2 Matter Test 2011-12Document4 pagesChapter 2 Matter Test 2011-12Sheryl Jane P. SilangNo ratings yet

- Green WaterTreatment Solution - PresentationDocument17 pagesGreen WaterTreatment Solution - Presentationsrekumar kumarNo ratings yet

- Ch12 Kitabcd Class 8 MSBHSE Science NotesDocument6 pagesCh12 Kitabcd Class 8 MSBHSE Science NotesONE CLICK COMPUTERNo ratings yet

- MR & GMRDocument4 pagesMR & GMRJaddu MSDNo ratings yet

- Jhangho Physics Book 4 CompleteDocument210 pagesJhangho Physics Book 4 CompleteThoko SimbeyeNo ratings yet

- Slope Stabilisation Using LimeDocument8 pagesSlope Stabilisation Using LimeMohammadreza HarirsazNo ratings yet

- Mixer Settler Type ExtractionDocument7 pagesMixer Settler Type ExtractionVirender RanaNo ratings yet

- 15 - GEST 92 171 Edition 6 - Personal Protective Equipment in The Chlorine IndustryDocument20 pages15 - GEST 92 171 Edition 6 - Personal Protective Equipment in The Chlorine IndustryAdemilson JuniorNo ratings yet

- OPSS 906 Feb93 ElectrodeDocument13 pagesOPSS 906 Feb93 ElectrodeHamid MansouriNo ratings yet

- Summary Welding Procedure QualificationsDocument1 pageSummary Welding Procedure QualificationsBoran YelkenciogluNo ratings yet

- Experiment 1 PH and Buffers Pre LabDocument12 pagesExperiment 1 PH and Buffers Pre LabMing mingNo ratings yet

- 3-C CU 5kV 115 NLEPR 133 Percent CPE MV-105.specDocument2 pages3-C CU 5kV 115 NLEPR 133 Percent CPE MV-105.specFrancisco Zanin FernandesNo ratings yet

- Science QuizDocument7 pagesScience QuizWeviNo ratings yet

- Enclosed List As Annex 5a and 5bDocument150 pagesEnclosed List As Annex 5a and 5bManoj TribhuwanNo ratings yet

- MEB Nptel Week 5 Assignment AnswersDocument4 pagesMEB Nptel Week 5 Assignment AnswersMeethiPotterNo ratings yet

- Gadus S5 V220 2Document2 pagesGadus S5 V220 2Luqman Cuopreakt'zNo ratings yet

- Fjeariing Maintenance/I: (Bearing Maintenance A",-R1-F C.I/OtiDocument8 pagesFjeariing Maintenance/I: (Bearing Maintenance A",-R1-F C.I/OtiTalhaMahmoodNo ratings yet

- Trifold fINAL - 082847Document7 pagesTrifold fINAL - 082847kohikat5019No ratings yet

- 1 s2.0 S2666893922000895 MainDocument10 pages1 s2.0 S2666893922000895 MainJeet LukhiNo ratings yet