Professional Documents

Culture Documents

Quality Alert1 - Revised 2017

Quality Alert1 - Revised 2017

Uploaded by

Faraj KhanCopyright:

Available Formats

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Sample FMEA - MachiningDocument20 pagesSample FMEA - MachiningHemantNo ratings yet

- Check List AlimakDocument2 pagesCheck List Alimakmaria elena100% (4)

- SMCHS Boys Soccer Practice SessionsDocument57 pagesSMCHS Boys Soccer Practice SessionsSS Lazio100% (6)

- Calibracion de Valvulas Mercedes Benz Om 314 352 352a 355 355a 360 360a 362la 364 366 366a 366la PDFDocument6 pagesCalibracion de Valvulas Mercedes Benz Om 314 352 352a 355 355a 360 360a 362la 364 366 366a 366la PDFZezinyo de Montserrat57% (7)

- Quality Alert - Revised 2017Document4 pagesQuality Alert - Revised 2017Faraj KhanNo ratings yet

- Quality Alert - Revised 2017Document2 pagesQuality Alert - Revised 2017Faraj KhanNo ratings yet

- Quality Alert 4 - Revised 2017Document2 pagesQuality Alert 4 - Revised 2017Faraj KhanNo ratings yet

- Quality Alert 4 - Revised 2017Document2 pagesQuality Alert 4 - Revised 2017Faraj Khan100% (1)

- Dimensional Inspection Report: Status: Surface: Units: AS Received Final Radial Axial Millimeters InchesDocument9 pagesDimensional Inspection Report: Status: Surface: Units: AS Received Final Radial Axial Millimeters InchesAditya PrajasNo ratings yet

- Layout InspectionDocument1 pageLayout InspectionKalki KalkiNo ratings yet

- Sample - RP Commissioning Form (Dialog)Document2 pagesSample - RP Commissioning Form (Dialog)Mohd Firdaus Mohd ShukriNo ratings yet

- 8D Double Punch in WW 17mmDocument1 page8D Double Punch in WW 17mmmoonlight toolsNo ratings yet

- Corrective and Preventive Action (8D) Report: Cust. Complaint Serial Number Cust. Complaint Ref. No. & DateDocument1 pageCorrective and Preventive Action (8D) Report: Cust. Complaint Serial Number Cust. Complaint Ref. No. & DateDeepak HoleNo ratings yet

- Pmi ReportDocument5 pagesPmi ReportMANIMARAN QCNo ratings yet

- ExampleDocument1 pageExampleNantoNo ratings yet

- Orifice Cal. Rev.2Document75 pagesOrifice Cal. Rev.2waheed2286No ratings yet

- QC-A-F86 Rev0 J FormDocument12 pagesQC-A-F86 Rev0 J FormMohd Soufian KamarudinNo ratings yet

- 8D Report: D 1. Description of The ProblemDocument8 pages8D Report: D 1. Description of The Problemalfredo.martinezNo ratings yet

- Not For Approval: Thyssenkrupp Industrial Solutions (Usa), IncDocument25 pagesNot For Approval: Thyssenkrupp Industrial Solutions (Usa), IncJorge SalazarNo ratings yet

- 8D - Bend IssueDocument3 pages8D - Bend Issuemoonlight toolsNo ratings yet

- YS2-03-C10017-TL-DTS-M-003 Rev 0 (6 Inch Mobile Pig Launcher)Document4 pagesYS2-03-C10017-TL-DTS-M-003 Rev 0 (6 Inch Mobile Pig Launcher)Gajendra PatilNo ratings yet

- YS2-03-C10017-TL-DTS-M-004 Rev 0 (6 Inch Mobile Pig Receiver)Document4 pagesYS2-03-C10017-TL-DTS-M-004 Rev 0 (6 Inch Mobile Pig Receiver)Gajendra PatilNo ratings yet

- Check Sheet Inspection: Pt. DffiDocument2 pagesCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- Failure Analysis Report: SIMS InformationDocument13 pagesFailure Analysis Report: SIMS InformationHasby PotterNo ratings yet

- 1046A Sraf No.Document1 page1046A Sraf No.Imran KhanNo ratings yet

- Stock Level Change: MM - Inventory ManagementDocument2 pagesStock Level Change: MM - Inventory ManagementPatrick HillmanNo ratings yet

- Isir - (00003)Document1 pageIsir - (00003)ducthangspktNo ratings yet

- Control Plan FormatDocument1 pageControl Plan FormatMagesh WaranNo ratings yet

- GRP Drainage Piping System FabricationDocument5 pagesGRP Drainage Piping System FabricationkahootNo ratings yet

- Sample Test PackageDocument18 pagesSample Test PackageAKHIL RAJNo ratings yet

- Prensa 11Document1 pagePrensa 11jose JacoboNo ratings yet

- VIR Hot TapDocument2 pagesVIR Hot TapCak NhassNo ratings yet

- Amapetco-Seal Unit - 001: Signature DateDocument4 pagesAmapetco-Seal Unit - 001: Signature DateMohamed HashemNo ratings yet

- DPT ReportDocument3 pagesDPT ReportMANIMARAN QCNo ratings yet

- Field Service FormDocument1 pageField Service FormMark JokerNo ratings yet

- D8R Abk D802Document6 pagesD8R Abk D802SMKN 6 SAMARINDA PANGESTUNo ratings yet

- DGN-205 Doc. Rev.03 PDFDocument3 pagesDGN-205 Doc. Rev.03 PDFHEMANTNo ratings yet

- FAR 8600041294 - PTP - Engine Black Smoke 16DZ0186Document7 pagesFAR 8600041294 - PTP - Engine Black Smoke 16DZ0186Fros DiamonNo ratings yet

- Failure Analysis Report: Information - 01Document4 pagesFailure Analysis Report: Information - 01Budi ArtantoNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- Pueblo Viejo Project Barrick Gold - Dominican Republic CM 001Document6 pagesPueblo Viejo Project Barrick Gold - Dominican Republic CM 001Silvia Quispe CerinNo ratings yet

- Check Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportDocument1 pageCheck Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportJovianto PrisilaNo ratings yet

- Cs1 Rundown Aplicacion - VacioDocument3 pagesCs1 Rundown Aplicacion - VacioJulio HuancaNo ratings yet

- Elbow 0,5-3000 NPT - OKDocument1 pageElbow 0,5-3000 NPT - OKJovianto PrisilaNo ratings yet

- Mold Repair Form: Repair Request Information Request By: Req Category: Mold Defect InformationDocument3 pagesMold Repair Form: Repair Request Information Request By: Req Category: Mold Defect InformationUmang Srivastava100% (1)

- Check Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportDocument2 pagesCheck Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportJovianto PrisilaNo ratings yet

- Failure Analysis Report AFA 1Document5 pagesFailure Analysis Report AFA 1bartanto59No ratings yet

- 8D Report B1102870006Document2 pages8D Report B1102870006ronneyhirve621No ratings yet

- Idabb PSSS: Inspection and Test Record Diesel Generators 1 Katolight Corporation 2Document2 pagesIdabb PSSS: Inspection and Test Record Diesel Generators 1 Katolight Corporation 2nana arya sumardjaNo ratings yet

- Bleeding Line Mbe 6 WTRDocument8 pagesBleeding Line Mbe 6 WTRMuhamad Hifni SyahbanaNo ratings yet

- NDE-6407 Rev0Document116 pagesNDE-6407 Rev0konazoiNo ratings yet

- Intarder 386 - e - 3626-011200 - en - Rev.5Document108 pagesIntarder 386 - e - 3626-011200 - en - Rev.5Herdre Van NiekerkNo ratings yet

- Elbow 12 XS 90D LR - OkDocument1 pageElbow 12 XS 90D LR - OkJovianto PrisilaNo ratings yet

- Data Book de BombaDocument7 pagesData Book de BombaSharon Botiny100% (1)

- Position Actual Dimension Remark Drawing / Sketch:: Ba BTDocument1 pagePosition Actual Dimension Remark Drawing / Sketch:: Ba BTJovianto PrisilaNo ratings yet

- Check Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportDocument1 pageCheck Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportJovianto PrisilaNo ratings yet

- Gom STP Ins Pid 01013 1Document30 pagesGom STP Ins Pid 01013 1Nikhil PatilNo ratings yet

- 2953 Thrad TightDocument6 pages2953 Thrad TightRohit QualityNo ratings yet

- Elbow 8 STD s40 90d LR - OkDocument1 pageElbow 8 STD s40 90d LR - OkJovianto PrisilaNo ratings yet

- Al Yamamah Solar Power System FactoryDocument1 pageAl Yamamah Solar Power System FactoryFaraj KhanNo ratings yet

- Al Yamamah Solar Power System FactoryDocument1 pageAl Yamamah Solar Power System FactoryFaraj KhanNo ratings yet

- Quality Alert - Revised 2017Document2 pagesQuality Alert - Revised 2017Faraj KhanNo ratings yet

- Quality Alert 4 - Revised 2017Document2 pagesQuality Alert 4 - Revised 2017Faraj Khan100% (1)

- Quality Alert - Revised 2017Document4 pagesQuality Alert - Revised 2017Faraj KhanNo ratings yet

- Quality Alert 4 - Revised 2017Document2 pagesQuality Alert 4 - Revised 2017Faraj KhanNo ratings yet

- 8 Yoga Mudras To Overcome Any AilmentsDocument7 pages8 Yoga Mudras To Overcome Any AilmentsSaravanan ThiruvalathaanNo ratings yet

- Adrian RobinsonDocument4 pagesAdrian RobinsonRemi DrigoNo ratings yet

- The History of NASCARDocument25 pagesThe History of NASCARJoe WhitleyNo ratings yet

- Inactive. CustDocument59 pagesInactive. CustDreamtel jalandharNo ratings yet

- Wizard - School of ConjurationDocument1 pageWizard - School of ConjurationThe Specialist (ATZS Gaming)No ratings yet

- FINAL - AMEA HIEX Uniform Brand Guidelines (Excl Australia) - Jan2018 PDFDocument36 pagesFINAL - AMEA HIEX Uniform Brand Guidelines (Excl Australia) - Jan2018 PDFNuptial NidoNo ratings yet

- Article Best Lenses Sport P 1Document5 pagesArticle Best Lenses Sport P 1Umanath R PoojaryNo ratings yet

- Gas TransportDocument10 pagesGas TransportDaveNo ratings yet

- Brother (1) Jack Jack. He's Only 1 Years OldDocument1 pageBrother (1) Jack Jack. He's Only 1 Years OldLaura Camelo100% (1)

- Los 500 Exitos Del Rock and Pop de Radio OxigenoDocument14 pagesLos 500 Exitos Del Rock and Pop de Radio OxigenoMoises Mendoza Fernandez BacaNo ratings yet

- Testy Gramatyka 09Document3 pagesTesty Gramatyka 09remikNo ratings yet

- Energy Drinks and Sport DrinksDocument30 pagesEnergy Drinks and Sport DrinksMerryo SetyawanNo ratings yet

- Katalog Honeywell GabunganDocument8 pagesKatalog Honeywell GabunganAnugrah FebrinoNo ratings yet

- Adeptus TitanicusDocument3 pagesAdeptus Titanicuspyro100% (1)

- HC VermaDocument18 pagesHC VermaChosen OneNo ratings yet

- Requirement For Bop Control Unit Lying at Uctc Yard: 6nos 22NOS 16NOSDocument1 pageRequirement For Bop Control Unit Lying at Uctc Yard: 6nos 22NOS 16NOSfarman ali ahmedNo ratings yet

- The Genius FilesDocument50 pagesThe Genius FilesEpicReads0% (2)

- Key of The RavenDocument3 pagesKey of The RavenpereNo ratings yet

- Wheel Alignment Fundamentals: © 2012 Delmar, Cengage LearningDocument23 pagesWheel Alignment Fundamentals: © 2012 Delmar, Cengage Learningmichael majadasNo ratings yet

- Year MOBDII Generic Communication Protocols by Manufacturer OdelsDocument6 pagesYear MOBDII Generic Communication Protocols by Manufacturer Odelsroberto caiadoNo ratings yet

- 11111111111Document658 pages11111111111ramoschavesdavidNo ratings yet

- Engineering Mechanics March 2014r13Document14 pagesEngineering Mechanics March 2014r13api-248483124No ratings yet

- Sword of The Berserk Guts Rage 2000 U - PDF RoomDocument13 pagesSword of The Berserk Guts Rage 2000 U - PDF RoomFederico MaciasNo ratings yet

- Ea FC 24 Squad Builder FutbinDocument1 pageEa FC 24 Squad Builder FutbinSanti LopezNo ratings yet

- IPL New Microsoft Office Word DocumentDocument4 pagesIPL New Microsoft Office Word Documentanon_136728171No ratings yet

- BattleTech - Operation Lancaster Record SheetsDocument542 pagesBattleTech - Operation Lancaster Record SheetsJérôme ChaniolNo ratings yet

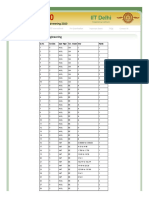

- Gate Iitd Ac in EEKey PHPDocument2 pagesGate Iitd Ac in EEKey PHPshagun gargNo ratings yet

- Trunk - Left Side - Rear SAM Module (N10/2) : W211fuses - Ods 06/18/2019 01:12:03Document2 pagesTrunk - Left Side - Rear SAM Module (N10/2) : W211fuses - Ods 06/18/2019 01:12:03Mario KirilovNo ratings yet

Quality Alert1 - Revised 2017

Quality Alert1 - Revised 2017

Uploaded by

Faraj KhanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Alert1 - Revised 2017

Quality Alert1 - Revised 2017

Uploaded by

Faraj KhanCopyright:

Available Formats

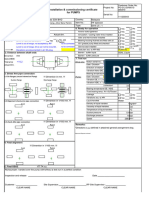

UALITY ALERT In-house/Customer/Warranty

MODEL : S101 Gasoline AREA : S101 Line 8 D Ref no:- 04

PART NAME : Tail pipe assly DATE : 15.12.16 Log book ref no:-

PROBLEM : COUNTERMEASURE TAKEN

1. Spatter on stud found at customer end .

Reed switch to be

Spatter on Stud tightened

Root cause Effective monitoring Countermeasure allocation

Effectiveness monitoring Qty. :

Man

Day D1 D2 D3 D4 D5 D6 D7

1.Reed switch Date Machine

to be tightened. Prod. Qty.

Matl

Measurement

Def. Qty. Method

Format no: QA/F/034

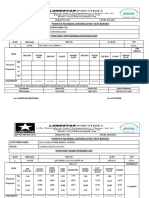

UALITY ALERT In-house/Customer/Warranty

MODEL : S101 AREA : S101 Line 8 D Ref no:- 01

ARM LOWER CONTROL COMP

PART NAME : LH DATE : 19.01.2017 Log book ref no:-

PROBLEM : COUNTERMEASURE TAKEN

1.Fittment issue at cutomer end ( sleeve bend observed) Toggle clamp pressure increased

Toggle clamp

pressure increased

Root cause Effective monitoring Countermeasure allocation

Effectiveness monitoring Qty. :

Man

1) Toggle clamp Day D1 D2 D3 D4 D5 D6 D7

Machine

Date

resting Face Matl

Prod. Qty.

wear out Def. Qty. Method Measurement

Format no: QA/F/034

UALITY ALERT In-house/Customer/Warranty

MODEL : W201 AREA : Welding Lathe 8 D Ref no:- 01

PART NAME : W201 Twin Muffler Assly DATE : 19.01.2017 Log book ref no:-

PROBLEM : COUNTERMEASURE TAKEN

Fittment issue at customer end due to muffler resting Muffler Clamp to be provided

improper

Toggle clamp

pressure increased

Root cause Effective monitoring Countermeasure allocation

Effectiveness monitoring Qty. :

Man

1) Toggle clamp Day D1 D2 D3 D4 D5 D6 D7

Machine

Date

resting Face Matl

Prod. Qty.

wear out Def. Qty. Method Measurement

Format no: QA/F/034

UALITY ALERT In-house/Customer/Warranty

MODEL : W201( export) AREA : Tail end Welding 8 D Ref no:- 01/17

PART NAME : W201 Twin Muffler Assly DATE : 14.2.17 Log book ref no:-

PROBLEM : L” L Punch mark missing COUNTERMEASURE TAKEN

Marking done by

L Punch mark

operator for

missing

confirmation

Root cause Effective monitoring Countermeasure allocation

Effectiveness monitoring Qty. :

Man

1)Operation Day D1 D2 D3 D4 D5 D6 D7

Machine

Date

missed by Matl

Prod. Qty.

operator Def. Qty. Method Measurement

Format no: QA/F/034

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Sample FMEA - MachiningDocument20 pagesSample FMEA - MachiningHemantNo ratings yet

- Check List AlimakDocument2 pagesCheck List Alimakmaria elena100% (4)

- SMCHS Boys Soccer Practice SessionsDocument57 pagesSMCHS Boys Soccer Practice SessionsSS Lazio100% (6)

- Calibracion de Valvulas Mercedes Benz Om 314 352 352a 355 355a 360 360a 362la 364 366 366a 366la PDFDocument6 pagesCalibracion de Valvulas Mercedes Benz Om 314 352 352a 355 355a 360 360a 362la 364 366 366a 366la PDFZezinyo de Montserrat57% (7)

- Quality Alert - Revised 2017Document4 pagesQuality Alert - Revised 2017Faraj KhanNo ratings yet

- Quality Alert - Revised 2017Document2 pagesQuality Alert - Revised 2017Faraj KhanNo ratings yet

- Quality Alert 4 - Revised 2017Document2 pagesQuality Alert 4 - Revised 2017Faraj KhanNo ratings yet

- Quality Alert 4 - Revised 2017Document2 pagesQuality Alert 4 - Revised 2017Faraj Khan100% (1)

- Dimensional Inspection Report: Status: Surface: Units: AS Received Final Radial Axial Millimeters InchesDocument9 pagesDimensional Inspection Report: Status: Surface: Units: AS Received Final Radial Axial Millimeters InchesAditya PrajasNo ratings yet

- Layout InspectionDocument1 pageLayout InspectionKalki KalkiNo ratings yet

- Sample - RP Commissioning Form (Dialog)Document2 pagesSample - RP Commissioning Form (Dialog)Mohd Firdaus Mohd ShukriNo ratings yet

- 8D Double Punch in WW 17mmDocument1 page8D Double Punch in WW 17mmmoonlight toolsNo ratings yet

- Corrective and Preventive Action (8D) Report: Cust. Complaint Serial Number Cust. Complaint Ref. No. & DateDocument1 pageCorrective and Preventive Action (8D) Report: Cust. Complaint Serial Number Cust. Complaint Ref. No. & DateDeepak HoleNo ratings yet

- Pmi ReportDocument5 pagesPmi ReportMANIMARAN QCNo ratings yet

- ExampleDocument1 pageExampleNantoNo ratings yet

- Orifice Cal. Rev.2Document75 pagesOrifice Cal. Rev.2waheed2286No ratings yet

- QC-A-F86 Rev0 J FormDocument12 pagesQC-A-F86 Rev0 J FormMohd Soufian KamarudinNo ratings yet

- 8D Report: D 1. Description of The ProblemDocument8 pages8D Report: D 1. Description of The Problemalfredo.martinezNo ratings yet

- Not For Approval: Thyssenkrupp Industrial Solutions (Usa), IncDocument25 pagesNot For Approval: Thyssenkrupp Industrial Solutions (Usa), IncJorge SalazarNo ratings yet

- 8D - Bend IssueDocument3 pages8D - Bend Issuemoonlight toolsNo ratings yet

- YS2-03-C10017-TL-DTS-M-003 Rev 0 (6 Inch Mobile Pig Launcher)Document4 pagesYS2-03-C10017-TL-DTS-M-003 Rev 0 (6 Inch Mobile Pig Launcher)Gajendra PatilNo ratings yet

- YS2-03-C10017-TL-DTS-M-004 Rev 0 (6 Inch Mobile Pig Receiver)Document4 pagesYS2-03-C10017-TL-DTS-M-004 Rev 0 (6 Inch Mobile Pig Receiver)Gajendra PatilNo ratings yet

- Check Sheet Inspection: Pt. DffiDocument2 pagesCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- Failure Analysis Report: SIMS InformationDocument13 pagesFailure Analysis Report: SIMS InformationHasby PotterNo ratings yet

- 1046A Sraf No.Document1 page1046A Sraf No.Imran KhanNo ratings yet

- Stock Level Change: MM - Inventory ManagementDocument2 pagesStock Level Change: MM - Inventory ManagementPatrick HillmanNo ratings yet

- Isir - (00003)Document1 pageIsir - (00003)ducthangspktNo ratings yet

- Control Plan FormatDocument1 pageControl Plan FormatMagesh WaranNo ratings yet

- GRP Drainage Piping System FabricationDocument5 pagesGRP Drainage Piping System FabricationkahootNo ratings yet

- Sample Test PackageDocument18 pagesSample Test PackageAKHIL RAJNo ratings yet

- Prensa 11Document1 pagePrensa 11jose JacoboNo ratings yet

- VIR Hot TapDocument2 pagesVIR Hot TapCak NhassNo ratings yet

- Amapetco-Seal Unit - 001: Signature DateDocument4 pagesAmapetco-Seal Unit - 001: Signature DateMohamed HashemNo ratings yet

- DPT ReportDocument3 pagesDPT ReportMANIMARAN QCNo ratings yet

- Field Service FormDocument1 pageField Service FormMark JokerNo ratings yet

- D8R Abk D802Document6 pagesD8R Abk D802SMKN 6 SAMARINDA PANGESTUNo ratings yet

- DGN-205 Doc. Rev.03 PDFDocument3 pagesDGN-205 Doc. Rev.03 PDFHEMANTNo ratings yet

- FAR 8600041294 - PTP - Engine Black Smoke 16DZ0186Document7 pagesFAR 8600041294 - PTP - Engine Black Smoke 16DZ0186Fros DiamonNo ratings yet

- Failure Analysis Report: Information - 01Document4 pagesFailure Analysis Report: Information - 01Budi ArtantoNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- Pueblo Viejo Project Barrick Gold - Dominican Republic CM 001Document6 pagesPueblo Viejo Project Barrick Gold - Dominican Republic CM 001Silvia Quispe CerinNo ratings yet

- Check Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportDocument1 pageCheck Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportJovianto PrisilaNo ratings yet

- Cs1 Rundown Aplicacion - VacioDocument3 pagesCs1 Rundown Aplicacion - VacioJulio HuancaNo ratings yet

- Elbow 0,5-3000 NPT - OKDocument1 pageElbow 0,5-3000 NPT - OKJovianto PrisilaNo ratings yet

- Mold Repair Form: Repair Request Information Request By: Req Category: Mold Defect InformationDocument3 pagesMold Repair Form: Repair Request Information Request By: Req Category: Mold Defect InformationUmang Srivastava100% (1)

- Check Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportDocument2 pagesCheck Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportJovianto PrisilaNo ratings yet

- Failure Analysis Report AFA 1Document5 pagesFailure Analysis Report AFA 1bartanto59No ratings yet

- 8D Report B1102870006Document2 pages8D Report B1102870006ronneyhirve621No ratings yet

- Idabb PSSS: Inspection and Test Record Diesel Generators 1 Katolight Corporation 2Document2 pagesIdabb PSSS: Inspection and Test Record Diesel Generators 1 Katolight Corporation 2nana arya sumardjaNo ratings yet

- Bleeding Line Mbe 6 WTRDocument8 pagesBleeding Line Mbe 6 WTRMuhamad Hifni SyahbanaNo ratings yet

- NDE-6407 Rev0Document116 pagesNDE-6407 Rev0konazoiNo ratings yet

- Intarder 386 - e - 3626-011200 - en - Rev.5Document108 pagesIntarder 386 - e - 3626-011200 - en - Rev.5Herdre Van NiekerkNo ratings yet

- Elbow 12 XS 90D LR - OkDocument1 pageElbow 12 XS 90D LR - OkJovianto PrisilaNo ratings yet

- Data Book de BombaDocument7 pagesData Book de BombaSharon Botiny100% (1)

- Position Actual Dimension Remark Drawing / Sketch:: Ba BTDocument1 pagePosition Actual Dimension Remark Drawing / Sketch:: Ba BTJovianto PrisilaNo ratings yet

- Check Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportDocument1 pageCheck Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportJovianto PrisilaNo ratings yet

- Gom STP Ins Pid 01013 1Document30 pagesGom STP Ins Pid 01013 1Nikhil PatilNo ratings yet

- 2953 Thrad TightDocument6 pages2953 Thrad TightRohit QualityNo ratings yet

- Elbow 8 STD s40 90d LR - OkDocument1 pageElbow 8 STD s40 90d LR - OkJovianto PrisilaNo ratings yet

- Al Yamamah Solar Power System FactoryDocument1 pageAl Yamamah Solar Power System FactoryFaraj KhanNo ratings yet

- Al Yamamah Solar Power System FactoryDocument1 pageAl Yamamah Solar Power System FactoryFaraj KhanNo ratings yet

- Quality Alert - Revised 2017Document2 pagesQuality Alert - Revised 2017Faraj KhanNo ratings yet

- Quality Alert 4 - Revised 2017Document2 pagesQuality Alert 4 - Revised 2017Faraj Khan100% (1)

- Quality Alert - Revised 2017Document4 pagesQuality Alert - Revised 2017Faraj KhanNo ratings yet

- Quality Alert 4 - Revised 2017Document2 pagesQuality Alert 4 - Revised 2017Faraj KhanNo ratings yet

- 8 Yoga Mudras To Overcome Any AilmentsDocument7 pages8 Yoga Mudras To Overcome Any AilmentsSaravanan ThiruvalathaanNo ratings yet

- Adrian RobinsonDocument4 pagesAdrian RobinsonRemi DrigoNo ratings yet

- The History of NASCARDocument25 pagesThe History of NASCARJoe WhitleyNo ratings yet

- Inactive. CustDocument59 pagesInactive. CustDreamtel jalandharNo ratings yet

- Wizard - School of ConjurationDocument1 pageWizard - School of ConjurationThe Specialist (ATZS Gaming)No ratings yet

- FINAL - AMEA HIEX Uniform Brand Guidelines (Excl Australia) - Jan2018 PDFDocument36 pagesFINAL - AMEA HIEX Uniform Brand Guidelines (Excl Australia) - Jan2018 PDFNuptial NidoNo ratings yet

- Article Best Lenses Sport P 1Document5 pagesArticle Best Lenses Sport P 1Umanath R PoojaryNo ratings yet

- Gas TransportDocument10 pagesGas TransportDaveNo ratings yet

- Brother (1) Jack Jack. He's Only 1 Years OldDocument1 pageBrother (1) Jack Jack. He's Only 1 Years OldLaura Camelo100% (1)

- Los 500 Exitos Del Rock and Pop de Radio OxigenoDocument14 pagesLos 500 Exitos Del Rock and Pop de Radio OxigenoMoises Mendoza Fernandez BacaNo ratings yet

- Testy Gramatyka 09Document3 pagesTesty Gramatyka 09remikNo ratings yet

- Energy Drinks and Sport DrinksDocument30 pagesEnergy Drinks and Sport DrinksMerryo SetyawanNo ratings yet

- Katalog Honeywell GabunganDocument8 pagesKatalog Honeywell GabunganAnugrah FebrinoNo ratings yet

- Adeptus TitanicusDocument3 pagesAdeptus Titanicuspyro100% (1)

- HC VermaDocument18 pagesHC VermaChosen OneNo ratings yet

- Requirement For Bop Control Unit Lying at Uctc Yard: 6nos 22NOS 16NOSDocument1 pageRequirement For Bop Control Unit Lying at Uctc Yard: 6nos 22NOS 16NOSfarman ali ahmedNo ratings yet

- The Genius FilesDocument50 pagesThe Genius FilesEpicReads0% (2)

- Key of The RavenDocument3 pagesKey of The RavenpereNo ratings yet

- Wheel Alignment Fundamentals: © 2012 Delmar, Cengage LearningDocument23 pagesWheel Alignment Fundamentals: © 2012 Delmar, Cengage Learningmichael majadasNo ratings yet

- Year MOBDII Generic Communication Protocols by Manufacturer OdelsDocument6 pagesYear MOBDII Generic Communication Protocols by Manufacturer Odelsroberto caiadoNo ratings yet

- 11111111111Document658 pages11111111111ramoschavesdavidNo ratings yet

- Engineering Mechanics March 2014r13Document14 pagesEngineering Mechanics March 2014r13api-248483124No ratings yet

- Sword of The Berserk Guts Rage 2000 U - PDF RoomDocument13 pagesSword of The Berserk Guts Rage 2000 U - PDF RoomFederico MaciasNo ratings yet

- Ea FC 24 Squad Builder FutbinDocument1 pageEa FC 24 Squad Builder FutbinSanti LopezNo ratings yet

- IPL New Microsoft Office Word DocumentDocument4 pagesIPL New Microsoft Office Word Documentanon_136728171No ratings yet

- BattleTech - Operation Lancaster Record SheetsDocument542 pagesBattleTech - Operation Lancaster Record SheetsJérôme ChaniolNo ratings yet

- Gate Iitd Ac in EEKey PHPDocument2 pagesGate Iitd Ac in EEKey PHPshagun gargNo ratings yet

- Trunk - Left Side - Rear SAM Module (N10/2) : W211fuses - Ods 06/18/2019 01:12:03Document2 pagesTrunk - Left Side - Rear SAM Module (N10/2) : W211fuses - Ods 06/18/2019 01:12:03Mario KirilovNo ratings yet