Professional Documents

Culture Documents

Cracking

Cracking

Uploaded by

Muhammad HAmAd Qureshi0 ratings0% found this document useful (0 votes)

71 views32 pagesThermal cracking involves decomposing large hydrocarbon molecules into smaller molecules through heat. It is normally conducted between 455-730°C. Important reactions include C-C bond scission, dehydrogenation, isomerization, and polymerization. Coke formation is also a reaction. Delayed coking and fluid coking are two main thermal cracking processes that fully convert residual products like tar and pitch into lighter fractions like gas, naphtha, and coke. Catalytic cracking uses a catalyst to crack heavy fractions into lighter, more valuable products like gasoline. Fluidized catalytic cracking is the most widely used catalytic cracking process.

Original Description:

Original Title

Cracking.pptx

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThermal cracking involves decomposing large hydrocarbon molecules into smaller molecules through heat. It is normally conducted between 455-730°C. Important reactions include C-C bond scission, dehydrogenation, isomerization, and polymerization. Coke formation is also a reaction. Delayed coking and fluid coking are two main thermal cracking processes that fully convert residual products like tar and pitch into lighter fractions like gas, naphtha, and coke. Catalytic cracking uses a catalyst to crack heavy fractions into lighter, more valuable products like gasoline. Fluidized catalytic cracking is the most widely used catalytic cracking process.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

71 views32 pagesCracking

Cracking

Uploaded by

Muhammad HAmAd QureshiThermal cracking involves decomposing large hydrocarbon molecules into smaller molecules through heat. It is normally conducted between 455-730°C. Important reactions include C-C bond scission, dehydrogenation, isomerization, and polymerization. Coke formation is also a reaction. Delayed coking and fluid coking are two main thermal cracking processes that fully convert residual products like tar and pitch into lighter fractions like gas, naphtha, and coke. Catalytic cracking uses a catalyst to crack heavy fractions into lighter, more valuable products like gasoline. Fluidized catalytic cracking is the most widely used catalytic cracking process.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 32

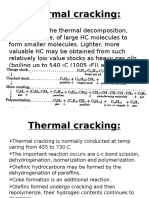

Thermal cracking:

Is defined as the thermal decomposition, under

pressure, of large HC molecules to form smaller

molecules. Lighter, more valuable HC may be obtained

from such relatively low value stocks as heavy gas oils

(boiling up to 540 oC (1005 oF)) and residues.

Thermal cracking:

Thermal cracking is normally conducted at temp varing

from 455 to 730 C.

The important reaction occurs are c-c bond scission,

dehydrogenation, isomerization and polymerization.

Olefinic hydrocarbons may be formed by the

dehydrogenation of paraffins.

Coke formation is an additional reaction.

Olefins formed undergo cracking and then repolymerize,

their hydrogen contents continues to decrease.

Gasoline Yeild

Thermal cracking:

1) Coking

Coking are severe cracking operations designed to completely convert

residual products such as pitch or tar into gas, naphtha, heating oil, gas

oil, and coke.

The gas oil fraction represents the major product obtained used as a

feed stock for catalytic cracking units. The C 5-220 oC naphtha may be

used as a gasoline blending agent, although its octane no. quality from

65 to 80 RON (unleaded), is lower than the desirable, the coke is usually

used as fuel.

After something like a ten year gap, there has been a renewed interest

in coking; key reasons are the diminishing relative demand for fuel oils

and the increasing concentration on reducing atmospheric pollution.

For the later coking not only concentrated feed stock sulfur in the coke

but yields products which can be readily desulfurized.

The main uses of petroleum coke are as follows:

1. Fuel

2. Manufacture of anodes for electrolytic cell reduction of alumina

3. Direct use as chemical carbon source for manufacture of elemental phosphorus, calcium carbide, and silicon

carbide

4. Manufacture of electrodes for use in electric furnace production of elemental phosphorus, titanium dioxide,

calcium carbide, and silicon carbide

5. Manufacture of graphite

The major coking processes in use today:

1) Delayed Coking : A semi- continuous process in which the heated charge is transferred to large soaking ( or

coking ) drums which provide the long residence time needed to allow the cracking reactions to proceed to

completion, the feed to these units is normally an atmospheric residue, although cracked tars and heavy

catalytic cycle oils may be also used.

Process Description — Delayed Coking

Hot fresh liquid feed is charged to the fractionator two to four trays above the bottom vapor zone. This

accomplishes the following:

1. The hot vapors from the coke drum are quenched by the cooler feed liquid thus preventing any significant

amount of coke formation in the fractionator and simultaneously condensing a portion of the heavy ends

which are recycled.

2. Any remaining material lighter than the desired coke drum feed is stripped (vaporized) from the fresh liquid

feed.

3. The fresh feed liquid is further preheated making the process more energy efficient.

Vapors from the top of the coke drum return to the base of the fractionator.

These vapors consist of steam and the products of the thermal cracking reaction:

2) Fluid Coking :

A continuous process which uses the fluidized- solids

technique to convert residues to more valuable

products. The residue is coked by being sprayed into

a fluidized bed of hot, fine coke particles. The use of

a fluid bed permits the coking reaction to be

conducted at higher temperature and shorter

contact times than those in delayed coking; steam is

used for fluidizing the bed.

Delayed Coking Product Yields

Conradson carbon: A test used to determine the amount of carbon residue left after the

evaporation and pyrolysis of an oil under specified conditions. Expressed as weight percent;

ASTM D-189.

Example ( 1 ) : Develop preliminary estimate of product yields on the processing of 23760

BPD capacity. Conrad son carbon = 19%, 2.3% S, API = 10.7.

Example:-

What are the expected products from a delayed coker when running

100,000 bpd of the crude oil of 0.911 gravity?

Visbreaking Process

• Visbreaking, a mild form of thermal cracking, significantly lowers the viscosity of heavy

crude-oil residue without affecting the boiling point range. Residual from the atmospheric

distillation tower is heated (800°-950° F) at atmospheric pressure and mildly cracked in a

heater .

• It is then quenched with cool gas oil to control over cracking, and flashed in a distillation

tower. Visbreaking is used to reduce the pour point of waxy residues and reduce the

viscosity of residues used for blending with lighter fuel oils. Middle distillates may also be

produced, depending on product demand. The thermally cracked residue tar, which

accumulates in the bottom of the fractionation tower, is vacuum flashed in a stripper and

the distillate recycled.

• There are two types of visbreaker operations, coil and furnace cracking and soaker

cracking.

• Coil cracking (Figure 1) uses higher furnace outlet temperatures[885–930°F (473–500°C)]

and reaction times from one to three minutes,while soaker cracking (Figure 2)uses lower

furnace outlet temperatures [800–830°F (427–443°C)] and longer reaction times.

• The product yields and properties are similar, but the soaker operation with its lower

furnace outlet temperatures has the advantages of lower energy consumption and longer

run times before having to shut down to remove coke from the furnace tubes. Run times of

3–6 months are common for furnace visbreakers and 6–18 months for soaker visbreakers.

This apparent advantage for soaker visbreakers is at least partially balanced by the greater

difficulty in cleaning the soaking drum.

Figure 1: Coil Visbreaker

Figure 2: Soaker Visbreaker

Catalytic Cracking

• It has been the most important and widely used process for the

production of gasoline from heavy distillates and hence the major

means for increasing the ratio of light to heavy products from

crude oil. The catalytic-cracking processes in use today can all be

classified as either moving-bed or fluidized-bed units:

1) Moving Bed: In which the catalyst was allowed to fall slowly by

gravity through the reactor and a regenerator vessels and was

returned mechanically to the top.

2) Fluidized Bed: Is based on the fluidization propertied of fine

powders, which enabled the catalyst to be transported

continuously between the reactor and regenerator.

• The fluidized system has been more widely used than the moving

bed and now represents about 80 % of all cracking plants.

Catalytic Cracking

Catalyst : both systems use basically similar catalysts but produced in a

different form, in the shape of beds for moving bed and fine powder for

fluidized bed.

• Acid treated clays ground to a powder

• Synthetic silica- alumina catalysts of higher activity (amorphous)

• Crystalline synthetic silica – alumina catalyst called zealots or molecular

sieves.

The advantages of zealots over the natural and synthesis amorphous

catalyst are

1) Higher activity.

2) Higher gasoline yields at a given conversion.

3) Production of gasoline containing a larger % of paraffinic and aromatic HC.

4) Lower coke yield.

5) Increased iso-butane production.

6) Ability to go for higher conversion per pass without over cracking.

FCC unit (From Gary and Handwerk, 2001)

Catalytic Reforming

It is mainly used for the production of high- octane number hydrocarbons. In

catalytic reforming the change in the boiling point of the feed stock passed

through the unit is relatively small as the HC molecules are not cracked but

their structures are rearranged to form higher octane aromatics. Thus

catalytic reforming primarily increases the octane number of motor gasoline

rather than increasing its yield. Typical feed stock is HSR gasoline and

naphtha (180 to 375 oF).

In addition to a gasoline blending stock, reformate is the main source of

aromatic bulk chemicals such as benzene, toluene, xylene andethylbenzene

which have diverse uses, most importantly as raw materials for conversion

into plastics.

Catalytic Reforming

The commonly used catalytic reforming catalysts contain noble metals such as platinum

and/or rhenium, which are very susceptible to poisoning by sulfur and nitrogen compounds.

Therefore, the naphtha feedstock to a catalytic reformer is always pre-processed in

a hydrodesulfurization unit which removes both the sulfur and the nitrogen compounds.

Most catalysts require both sulphur and nitrogen content to be lower than 1 ppm.

There are many chemical reactions that occur in the catalytic reforming process

(PONA) {Paraffin, Olefin, Naphthene, Aromatic}

1) P → isomerizes to some extent converted to N, and N subsequently converted to aromatics.

2) O → saturated to form P which then react as in (1) {hydro-cracking}. The hydrocracking of paraffins is the

only one reforming reactions that consumes hydrogen.

3) N → converted to aromatics. {dehydrogenation}.

4) A→ unchanged.

Reforming are classified as :

1) Continuous : Catalyst can be regenerated continuously and maintained at a high activity . (Higher capital

cost).

2) Semi- regeneration: Regeneration is required at intervals 3 to 24 months depending on the severity of

operation. (Low capital cost).

High H2 recycle rates and operating pressure is utilized to minimize coke.

3) Cyclic: compromise between the two extremes having a swing reactor for regeneration.

• Reforming Catalyst : All of the reforming catalyst

contains platinum supported on a silica alumina

base. In most cases rhenium is combined with

platinum to form a more stable catalyst which

permits operation at lower pressure.

• Platinum serve as a catalytic site for hydrogenation

and dehydrogenation reactions.

• Chlorinated alumina provides an acids site for

isomerization and hydro- cracking reactions and

cyclization.

• Space velocity: The volume or weight of gas and /

or liquid passing through a given catalyst or reactor

space per unit time, divided by the volume or

(weight) of catalyst through which the fluid passes.

High space velocity corresponds to short reaction

time.

• WHSV: Weight hour space velocity = weight of feed

per hour per weight of catalyst.

• LHSV: Liquid hour space velocity = volume of feed

per hour per volume of catalyst

Problem

1- Calculate the length of time between

regeneration of catalyst in a reformer operating

at the following conditions:

• Liquid hourly space velocity (LHSV) _ 3.0 v/hr/v,

Feed rate = 5000

• BPSD, Feed gravity _ 55.0° API, Catalyst bulk

density = 50 lb/ftcube,

• Number of reactors = 3, Catalyst deactivates after

processing 90 barrels of feed per pound of

catalyst.

Calculate a) Diameter of a cracker b) Weight and volume of catalyst needed.

Hydrocracking

Hydrocracking is a two-stage process combining

catalytic cracking and hydrogenation, wherein

heavier feedstocks are cracked in the presence of

hydrogen to produce more desirable products. The

process employs high pressure, high temperature, a

catalyst, and hydrogen. Hydrocracking is used for

feedstocks that are difficult to process by either

catalytic cracking or reforming, since these

feedstocks are characterized usually by a high

polycyclic aromatic content and/or high

concentrations of the two principal catalyst poisons,

sulfur and nitrogen compounds.

Hydrocracking

• The hydrocracking process largely depends on the

nature of the feedstock and the relative rates of the

two competing reactions, hydrogenation and

cracking. Heavy aromatic feedstock is converted

into lighter productsn munder a wide range of very

high pressures (1,000-2,000 psi) and fairly high

temperatures (750°-1,500° F), in the presence of

hydrogen and special catalysts. When the feedstock

has a high paraffinic content, the primary function

of hydrogen is to prevent the formation of polycyclic

aromatic compounds.

Hydrocracking

• Another important role of hydrogen in the

hydrocracking process is to reduce tar formation

and prevent buildup of coke on the catalyst.

Hydrogenation also serves to convert sulfur and

nitrogen compounds present in the feedstock to

hydrogen sulfide and ammonia.

• Hydrocracking produces relatively large amounts of

isobutane for alkylation feedstock. Hydrocracking also

performs isomerization for pour-point control and

smoke-point control, both of which are important in

high-quality jet fuel.

You might also like

- Assignment NO 3:: Question 1: Define Cracking. Classify Cracking OperationsDocument6 pagesAssignment NO 3:: Question 1: Define Cracking. Classify Cracking OperationsMilan MoradiyaNo ratings yet

- My Presentation003 Catalyticcracking SteamcrackingDocument39 pagesMy Presentation003 Catalyticcracking SteamcrackingAiaru BektemirNo ratings yet

- Introduction To Petroleum Technology - 3Document21 pagesIntroduction To Petroleum Technology - 3Anish VazeNo ratings yet

- FALLSEM2020-21 CHE1014 TH VL2020210101682 Reference Material I 19-Aug-2020 Catalytic Cracking Different Types PDFDocument77 pagesFALLSEM2020-21 CHE1014 TH VL2020210101682 Reference Material I 19-Aug-2020 Catalytic Cracking Different Types PDFJateni GedaNo ratings yet

- Atmospheric Crude FractionatorDocument3 pagesAtmospheric Crude Fractionatornedian_2006No ratings yet

- Petroleumrefining2of3 190124033941 PDFDocument247 pagesPetroleumrefining2of3 190124033941 PDFsuman mukherjeeNo ratings yet

- Petroleum Fractionation-Overview PDFDocument35 pagesPetroleum Fractionation-Overview PDFRiyad AliNo ratings yet

- Fuels & Combustion: Presented By: Emmanuel A. Rosales Salvador Z. SiaDocument31 pagesFuels & Combustion: Presented By: Emmanuel A. Rosales Salvador Z. SiaEmmanuel RosalesNo ratings yet

- CPT - Lecture 9 - Oil Refinery - 2022Document28 pagesCPT - Lecture 9 - Oil Refinery - 2022Anjan KumarNo ratings yet

- Refinery Units PDFDocument2 pagesRefinery Units PDFPTKBTNo ratings yet

- Refining ProcessDocument15 pagesRefining Processtechy TalksNo ratings yet

- How Oil Refining WorksDocument6 pagesHow Oil Refining WorksAnonymous NyvKBWNo ratings yet

- Modelling of Naphtha Cracking For Olefins Production - Joao MarcosDocument9 pagesModelling of Naphtha Cracking For Olefins Production - Joao MarcosBahar MeschiNo ratings yet

- Petroleum Refining Crude Oil Refining Processes PDFDocument6 pagesPetroleum Refining Crude Oil Refining Processes PDFJAPAN NANAVATI0% (1)

- DCC EngDocument1 pageDCC Engwahaha06No ratings yet

- Fluid Catalytic Cracking Unit (FCCU)Document1 pageFluid Catalytic Cracking Unit (FCCU)Billy BlinksNo ratings yet

- Presentations 15Document44 pagesPresentations 15thirumalaiNo ratings yet

- Fluid Catalytic Craking Unit (Fccu)Document6 pagesFluid Catalytic Craking Unit (Fccu)Nitin VarshneyNo ratings yet

- US8349170 - Components of Riser and Reactor SectionDocument25 pagesUS8349170 - Components of Riser and Reactor SectionPraveen KumarNo ratings yet

- Process Data Sheet of Incinerator Package Unit 113X-X1: Biturox ProjectDocument15 pagesProcess Data Sheet of Incinerator Package Unit 113X-X1: Biturox ProjecthhvgNo ratings yet

- Chemistry of Ethylene Production From NaphthaDocument2 pagesChemistry of Ethylene Production From NaphthaKimal Wasalathilake0% (1)

- Crude Distillation & Desalting-IICHE Online Summer Training-05.06.2020 7 PMDocument30 pagesCrude Distillation & Desalting-IICHE Online Summer Training-05.06.2020 7 PMHarish GojiyaNo ratings yet

- Columns: An Introductory Guide To Columns For Chemical EngineersDocument53 pagesColumns: An Introductory Guide To Columns For Chemical EngineersHerawan Mulyanto100% (1)

- Pyrolysis Furnace Rev 1 PDFDocument11 pagesPyrolysis Furnace Rev 1 PDFKmajdianNo ratings yet

- Lecture 1Document22 pagesLecture 1Amit Narayan RaiNo ratings yet

- Learning About The of Nghi Son Refinery: Rude Istillation NitDocument17 pagesLearning About The of Nghi Son Refinery: Rude Istillation NitTrường Tùng LýNo ratings yet

- CH 5 - Fractionating Column (Atm Vac) 2018 BDocument193 pagesCH 5 - Fractionating Column (Atm Vac) 2018 BayaNo ratings yet

- Distillation Rev41Document137 pagesDistillation Rev41rvkumar61No ratings yet

- By Product Co2 Recovery Flow PDFDocument1 pageBy Product Co2 Recovery Flow PDFtejcd1234No ratings yet

- PRT Lecture - 16 17Document30 pagesPRT Lecture - 16 17HimaNo ratings yet

- Cooling CalculationDocument3 pagesCooling CalculationDheerajKaushalNo ratings yet

- Hydrogen Technology BrochureDocument12 pagesHydrogen Technology Brochureramantal5No ratings yet

- PDFDocument6 pagesPDFjamy862004No ratings yet

- Naphtha Cracking For Light Olefins ProductionDocument5 pagesNaphtha Cracking For Light Olefins Productionbasura12345No ratings yet

- MG Air Separation PlantsDocument10 pagesMG Air Separation PlantsHatem AbdelnabiNo ratings yet

- Boiler Riser TubesDocument8 pagesBoiler Riser TubesSachinNo ratings yet

- Overview of Petrochemicals: & Naphtha CrackerDocument41 pagesOverview of Petrochemicals: & Naphtha CrackerAbhinav AjmaniNo ratings yet

- Waste Incineration Heat Recovery at Roche IrelandDocument12 pagesWaste Incineration Heat Recovery at Roche IrelandidrieshamidiNo ratings yet

- Article Low Cost and Reliable Sulphur Recovery PDFDocument4 pagesArticle Low Cost and Reliable Sulphur Recovery PDFpsnmurthy333No ratings yet

- Nps 38 CFDocument16 pagesNps 38 CFGauden Marie C. BangngayNo ratings yet

- Safety Talk: Fired HeatersDocument58 pagesSafety Talk: Fired HeatersSaleem ChohanNo ratings yet

- Crude Oil DistillationDocument109 pagesCrude Oil Distillationshreshth chawlaNo ratings yet

- Process Intensification in Industrial Wastewater Treatment FinalDocument10 pagesProcess Intensification in Industrial Wastewater Treatment FinalSantanu BiswasNo ratings yet

- H2 Supply Chain Evidence - Publication VersionDocument126 pagesH2 Supply Chain Evidence - Publication VersionNelly VanessaNo ratings yet

- Boiler Furnace PDFDocument8 pagesBoiler Furnace PDFசுந்தர மூர்த்தி சேப்பிளையார்No ratings yet

- Packinox Pyrolysis Gasoline HydrogenationDocument2 pagesPackinox Pyrolysis Gasoline HydrogenationCorneliuPopaNo ratings yet

- Main Combustion ChamberDocument31 pagesMain Combustion Chambershaliq28No ratings yet

- PresentationDocument17 pagesPresentationBinod Kumar PadhiNo ratings yet

- 2501-General Instructions For Thermal DesignDocument12 pages2501-General Instructions For Thermal DesignfarooqkhanerNo ratings yet

- Petroleum Refining Chemistry SlidsDocument61 pagesPetroleum Refining Chemistry SlidsJoyful GreenNo ratings yet

- Petroleum Refining Technology Unit-2: CHEG 437 4 Credit CourseDocument56 pagesPetroleum Refining Technology Unit-2: CHEG 437 4 Credit Courseprathamesh singhNo ratings yet

- Vacuum Distillation Colume: Mass Transfer Lab AssignmentDocument4 pagesVacuum Distillation Colume: Mass Transfer Lab AssignmentMalik HamidNo ratings yet

- Modern Spent-Caustic Wastewater Treatment Simulation by Aspen Plus in Electrolytic MediumDocument10 pagesModern Spent-Caustic Wastewater Treatment Simulation by Aspen Plus in Electrolytic MediumarmanNo ratings yet

- Industrial BoilersDocument22 pagesIndustrial BoilersAbdul Razzaq MughalNo ratings yet

- Refinery Process ChartDocument16 pagesRefinery Process ChartUsman AshrafNo ratings yet

- Boiler WaterDocument70 pagesBoiler Watertata_77No ratings yet

- Cooling Tower 434Document15 pagesCooling Tower 434arslan MaqboolNo ratings yet

- CrackingDocument28 pagesCrackingzaraNo ratings yet

- Cracking, Visbreaking, Coking and PropertiesDocument12 pagesCracking, Visbreaking, Coking and Propertiesteyiv23540No ratings yet

- Thermal CrackingDocument24 pagesThermal Crackingmihir kumar100% (1)

- IntroductionDocument4 pagesIntroductionMuhammad HAmAd QureshiNo ratings yet

- Lect 1Document63 pagesLect 1Muhammad HAmAd QureshiNo ratings yet

- Details About FypDocument3 pagesDetails About FypMuhammad HAmAd QureshiNo ratings yet

- Lessons From Man Search For MeaningDocument2 pagesLessons From Man Search For MeaningMuhammad HAmAd QureshiNo ratings yet

- Water Research Paper - Formatted FinalDocument4 pagesWater Research Paper - Formatted FinalMuhammad HAmAd QureshiNo ratings yet

- Al Hum Aidan 2013Document9 pagesAl Hum Aidan 2013Tya ArisandiNo ratings yet

- Refinery OverviewDocument79 pagesRefinery Overviewchikukotwal100% (1)

- Modular Refining Solutions Brochure 2022Document8 pagesModular Refining Solutions Brochure 2022H NNo ratings yet

- IOCL MAthura PDFDocument52 pagesIOCL MAthura PDFKavisha AgrawalNo ratings yet

- Storage Stability of Visbroken Residual Fuel Oils - Compositional Studies - 1990Document5 pagesStorage Stability of Visbroken Residual Fuel Oils - Compositional Studies - 1990Neil RNo ratings yet

- 17 - Residue Upgradation 1Document22 pages17 - Residue Upgradation 1SHREENo ratings yet

- Industrial Training ReportDocument56 pagesIndustrial Training ReportDipta Bhanu BakshiNo ratings yet

- 20 - Refining Margins and CostsDocument9 pages20 - Refining Margins and CostsBogdanAlinNo ratings yet

- Iocl 1Document80 pagesIocl 1Rishi KumarNo ratings yet

- Refinery BasicsDocument31 pagesRefinery Basicsanurag100% (1)

- DistillationDocument25 pagesDistillationMohammadAslam100% (1)

- Boiling Point Distribution of Crude Oils Based On TBP and Astm D-86 Distillation DataDocument17 pagesBoiling Point Distribution of Crude Oils Based On TBP and Astm D-86 Distillation DataFAH MANNo ratings yet

- IOCL MAthuraDocument52 pagesIOCL MAthuraUday Bhardwaj100% (3)

- Kumar Pre ReportDocument60 pagesKumar Pre ReportKr AyushNo ratings yet

- Shell Thermal Gasoil: AdvantagesDocument2 pagesShell Thermal Gasoil: AdvantagesIlyas KhanNo ratings yet

- Solvent ImportanceDocument6 pagesSolvent ImportanceAbhiNo ratings yet

- Thermal Cracking:: Stream Number Stream Make SourceDocument3 pagesThermal Cracking:: Stream Number Stream Make SourcejohnNo ratings yet

- Decoking TechniquesDocument8 pagesDecoking Techniquesah.elmagraby100% (1)

- Coking and Thermal ProcessDocument26 pagesCoking and Thermal Processkuldeep100% (3)

- Blending MainDocument84 pagesBlending Mainbasharat121No ratings yet

- BITUMEN ProjectDocument26 pagesBITUMEN ProjectAbood Buriahi100% (2)

- Towards The Development (Training Handbook) - 230504 - 132643Document643 pagesTowards The Development (Training Handbook) - 230504 - 132643Karim AbdelhadiNo ratings yet

- IOCL Report 2011Document56 pagesIOCL Report 2011Ajay ShekhawatNo ratings yet

- Delayed Coking A Review by JBJ ABP ICT PDFDocument25 pagesDelayed Coking A Review by JBJ ABP ICT PDFNishat M PatilNo ratings yet

- Ref 111Document111 pagesRef 111AbidHussainBhattiNo ratings yet

- A Master's Guide To Using Fuel Oil Onboard ShipsDocument74 pagesA Master's Guide To Using Fuel Oil Onboard Shipsanil.rai100% (1)

- Crude Oil ChemistryDocument411 pagesCrude Oil ChemistryHo Minh Viet100% (5)

- Vis BreakingDocument12 pagesVis BreakingMohit Arora100% (1)

- Utilities Report PARCODocument35 pagesUtilities Report PARCOMohammad Yasser RamzanNo ratings yet

- CH414 Petroleum Refinery EngineeringDocument14 pagesCH414 Petroleum Refinery EngineeringHaider AliNo ratings yet