Professional Documents

Culture Documents

Parametros

Parametros

Uploaded by

SEETHARAMA MURTHYOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Parametros

Parametros

Uploaded by

SEETHARAMA MURTHYCopyright:

Available Formats

SUBMERGED ARC FURNACES – OPTIMAL

ELECTRICAL PARAMETERS

Author : Luis Ricardo Jaccard

jaccard@uol.com.br

Introduction

Between 1923 and 1975, Andreae, Morkramer, Kelly, Persson and

many others who have studied the operation of submerged arc

furnaces concluded that the values of voltage and current best

suited to the operation of these furnaces depended strongly on

the diameter of the electrodes.

But Westly, the author of factor C3, in 1975, presented a technical

paper on which he showed that had not found relationship

between ideal current and voltage with the diameter of the

electrodes.

The main objectives of this presentation are: to show that the

factor C3 of Westly does not reflect reality, to rescue the

concept of Andreae´s factor k and contribute with a more

simple formula to be applied to find the values of optimal

voltage and current.

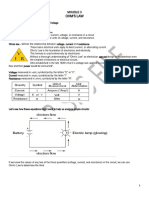

Submerged arc furnace

Reactance

Eletrode

I (A)

Ore and coal

V transformer cold charge

Reaction

zone

Hearth

V = Electrode to hearth voltage

Power and resistance

• The active power for each electrode is: P = V x I

• The resistivity r of the charge depends

especially on the percentage of coal

necessary for each process. The higher the

percentage of coal, the lower the load resistivity

and for a specific position of the electrode,

the lower the electrical resistance of the load.

•The load resistance is proportional to

resistivity and electrode-distance : R r. H

• The distance H at which the electrode will be positioned will be:

HR/r, but, R = V/I, so to have a predetermined position H of the

electrode it will be needed a certain V/I value, which will depend

on the resistivity r of the charge: V / I H.r. The greater the

resistivity of the material, the higher the V/I to keep certain H.

Electrode optimal position

It can be proved that for each material there is an

electrode position H in which the chemical

reactions are carried out more efficiently. When the

electrode is in that position, the specific power

(kW/ton) transferred to the load, in the reaction

zone, is the ideal. If H is less than ideal, the kW/ton

are higher than necessary, and when H are higher

than ideal, the kW/ton are less than the ideal value.

In both cases, the energy consumption increases

and there is deposition of undesirable material on

the hearth.

The question is what are the values of V and I (or R = V / I) needed to

achieve the electrode optimal position for each material and for each

value of power P = V. I.

Optimal V and I - Andreae

In 1923, Andreae found that the values of V/I

appropriate to achieve the optimal position

depended on the diameter of the electrodes. For

equal power, a larger diameter electrode required

to operate with a V/I also higher.

Andreae called power density “pd” the relation

“power/electrode cross section” and found that by increasing

the power density was necessary to reduce V/I.

Andreae defined a factor "k"= (V/I) . D . p representing the

values of V and I that allowed to operate the furnace with the

electrode in the ideal position for each raw material and for

each power density at the electrode tip.

Optimal V and I - Kelly

• Between 1940 and 1952, Kelly charts the optimum operating

points for different values of power density on the electrode

(pd = P/SE ) and for different materials, where SE = the

electrode section = p. D² /4

• Kelly graph for FeSi75

K = V/I . D . Pi

0,35

0,16

1,9 3,1 pd (kW/pol2)

Optimal V and I - Kelly

• The graph shows that as the power density is increased, to

maintain ideal H is necessary to reduce R = V / I.

• For a furnace that has a certain diameter electrodes, operating

with higher values of P requires lower values of R (increasing

current and reducing voltage).

• For each power, increasing the diameter of the electrodes

allows operation with higher voltages and lower currents.

Optimal V and I – Our formula

• After studying the work of Andreae, Kelly, Morkramer, Westly and

Persson, we decided to conduct tests on cassiterite (tin production)

furnaces and, between 2005 and 2006, we found that the optimum

position of the electrode was obtained with values of V D/P1/4 and

also that this formula is almost perfectly suited to graphics by Kelly,

especially for FeSi75 and CaC2.

• The former means that in a given furnace, to maintain the optimal

position of the electrode, the increase in power should be performed

with reduced electrode-to-hearth voltage (V D/P1/4 ) and with

increasing current (I P5/4).

• The formula shows that the values of V and I, needed for optimum

positioning of the electrode, depend on D, confirming what was

predicted by Andreae, Kelly, Persson, Morkramer and others who

studied this subject between 1923 and 1975.

VD/P1/4 formula deduction

The goal is to position the electrode at a certain height H

for different values of R = V / I.

Dc is the diameter of reaction zone

Dc2 is proportional to the power P.

Therefore, Dc P1/2 (1)

If Dc>> D, the load resistance R is inversely proportional to

Dc: Rr.H/Dc (2).

Substituting (1) in (2): Rr. H/P1/2 (3)

But it was proven that the resistivity r is inversely

proportional to power density: r1/(P/D²) (4)

From (3) and (4): RD² . H / P3/2 . And, for certain H:

RD²/P3/2 (5). But, R = V²/P (6).

Then, from (5) and (6):

V D / P1/4

VD/P1/4 formula explanation

Conceptually, the formula can be explained as follows:

By increasing the power of a furnace that operates

with a certain diameter electrodes, the electrical

resistance of the load decreases for two reasons: a)

because the resistivity of the load decreases due to

increased power density in the area of contact with

the electrode tip (pdP/D²) and b) because the

diameter of the reaction zone increases with P1/2 .

By increasing the diameter of the electrode of a furnace that

operates with a certain power, the resistivity of the load increases

because the power density in the area of contact with the electrode

decreases (pdP/D²). If the load resistance increases, to maintain

equal H is necessary to increase V/I.

C3 Fator - Westly

• In 1975, Westly presented a paper in which concluded that there is

no relationship between the optimal electrical parameters of the

operation and the diameter of the electrode. He said verbatim:

"When a furnace is operated on say 20 MW, the operating

resistance will be the same whether the electrode diameter is

1250 mm (49 in.) or 1550 mm (61 in.) provided the raw material

are the same. Apparently in conflict with the Andreae concept this

conclusion certainly gave rise to concern. But we have to accept it

as experience confirmed that it was really so. Then what about the

Andreae concept?".

• After the presentation, at the discussions, Westly was harshly

questioned by J. A. Persson and in the end, Westly seemed to agree

with Persson.

C3 Fator - Westly

• Westly concluded that the optimal voltage and current

depended only on power, arriving to the following

relationships: IP2/3 and V1/P1/3 . He called the coefficient

“I/P2/3” factor C3.

• If the Westly (factor C3) formula were correct, a FeSi75

furnace that operated with 23 MW and 83 kA could use

700 mm graphite electrodes, since they bear a current of

83 kA. However, according to all the theory before the year

1975 if the current of 83 kA were used with the electrode of

700 mm for the 23 MW (92 V) power, the electrode tip would

be too far from the furnace hearth (high H) causing deposition

of material and high specific energy consumption.

C3 Fator - Westly

• But why is believed that the factor C3 formula is correct and,

sometimes, when used, are not noticed large discrepancies with

reality?

1. One reason is the fact that most furnaces operate with the maximum

admissible current through the electrodes. Westly in his work

mentions that factor C3 suitable for FeSi75 furnaces is 10.8. This value

is correct when operating with maximum power densities at the

electrode and the voltages and currents coincide with the k factor

value found by Kelly, for the power density of 3.1/3.2 kW per square

inch, but are completely different when the electrode diameter is

increased or the power is diminished (lower power density).

C3 Fator - Westly

2. Similarly, because of the furnaces operate with maximum current

density we have the false impression that the relationship I P2/3 is

correct. Here´s an example:

A FeSi75 furnace with 1150 mm electrodes operates correctly with 70

kA and active power of 17.7 MW. Want to increase power to 23

MW, and applying the formula of C3 factor, it is concluded that the

current must be increased to 83 kA. By our formula, if the diameter

of the electrode remained the same, the current should be increased

to 91 kA. However, since the currents of 83 kA or 91 kA are too high

for the electrode of 1150 mm, will probably be decided to increase

the diameter, for example, to 1250 mm. Thus, by our formula with

this diameter, the current to maintain the optimal position of the

electrode should be of 83.7 kA, similar to that calculated with the

factor C3.

Comparison with Kelly

• For FeSi75 production, our formula VD / P1/4 comes to results

almost identical to the representation of the factor k performed by

Kelly. The formula of factor C3, for low power densities, shows

completely different results to those found by Kelly.

Fator k de Andreae, conforme gráfico original de Kelly,

comparado com k baseado em J e em C3

0,35

F a to r k d e A n d re a e

0,33

0,31

0,29

0,27

k J

0,25 k Kelly

0,23 k C3

0,21

0,19

0,17

0,15

1,8 1,9 2,0 2,1 2,2 2,3 2,4 2,5 2,6 2,7 2,8 2,9 3,0 3,1 3,2

Densidade de potência ( kW / pol² )

Optimal V and I – Comparison C3 and J

• We compare the values of V and I that would be calculated with the

Westly formula (C3), where V = P1/3 / C3 , and those calculated with

our formula (J), where V D / P1/4 .

We start from a known optimal operation in which the electrode

diameter is 1150 mm (45 inches), the power is 15 MW (3

phases), current of 65 kA and power factor 0.69. Shown are the

values of V and I that would be calculated with C3 and J for two

cases: a) equal power (15 MW), larger diameter electrode (1350

mm) and, b) lower power (7,5 MW) without change the electrode

diameter (1150 mm). Are calculated the power factors that would

be achieved in each case for a reactance of 1.23 mOhm.

See table at the next slide

Optimal V and I – Comparison C3 and J

P (MW) D (mm) V c/C3 kA c/C3 V c/J kA c/J FP c/C3 FP c/J

15 1150 76,9 65,0 76,9 65,0 0,69 0,69

15 1350 76,9 65,0 90,2 55,4 0,69 0,80

7,5 1150 61,1 40,9 91,5 27,3 0,77 0,94

• It notes that according with Westly after increasing of the electrode

diameter, the furnace, for equal power, should continue operating with

the same electrical parameters. By our formula and by the k factor to

maintain the optimal position of the electrode after the increase in

diameter, the electrode-to-hearth voltage should be increased and the

current decreased.

• By reducing the power, keeping the diameter of the electrode,

according to our formula or with the factor k, the current should be

decreased to a greater extent than predicted by the formula of Westly

and voltage should be increased rather than decreased.

Conclusions

1. The C3 factor formula (I = C3.P2/3) of Westly, in our assessment does not

correspond to reality.

2. The Andreae k factor = (V/I).D.p) and graphics on this factor by Kelly,

performed for different materials and different power densities, more

accurately represent the points of optimal operation of the furnaces.

3. The formula we derived and called factor J (VD / P1/4 ) obtain results

similar to those found by Kelly for the factor k with the advantage of

being simpler to understand and apply.

4. It can be concluded that the operation with electrodes of larger

diameter allows optimal positioning with higher voltage and lower

current values, and therefore greater power factors, with the following

advantages:

4.1. Greater electrical efficiency.

4.2. Lower consumption of electrodes.

4.3. Minor deviations from the ideal position of the electrode.

References

• Andreae, F. V.: Trans A.I.E.E. 69, 557 (1950) – Trans. Electrochem Soc. 52 152 (1927).

• Translation from Swedish of a General Treatment of Ferroalloy Technology and electric

furnace design principles – Unknown authors.

• Kelly, W.M.: “Design and Construction of the Submerged Arc Furnace” Carbon and

graphite News (1952), Vol 5, Nº1.

• Persson, J.A.:”The Significance of Electrode to Hearth Voltage in Electric Smelting

Furnaces” AIME Electric Furnaces Proceeding, 28, 174 (1970).

• Westly J.: “Critical Parameters in Design and Operation of the Submerged Arc

Furnaces” Electric Furnaces Proceedings (1975) – AIME Meeting.

• Jaccard, L. R.: “Correlação entre tensão ideal, potência e diâmetro de eletrodos nos

fornos de arco submerso – Fator “J” - XXXVIII° Seminário de Aciaria – Internacional –

Belo Horizonte – Brasil (2007).

• Downing J.H, Urban, L.: “Electrical Conduction in Submerged Arc Furnaces” AIME

Electric Furnace Proceedings, (1965).

• Schwabe, W.E. “The mechanics of consumption of graphite electrodes in electric steel

furnaces” Jornal of Metals (1972).

• Jaccard L.R. “Consumo específico de eletrodos em fornos elétricos a arco – Correlação

com os fatores de operação” – 43º Congresso Anual – ABM – Belo Horizonte – Brasil

(1988).

You might also like

- Abc of Capacitors: Basic PrinciplesFrom EverandAbc of Capacitors: Basic PrinciplesWürth ElektronikNo ratings yet

- Joule HeatingDocument6 pagesJoule HeatingzzaanNo ratings yet

- 5.4.2 - Induction and Dielectric Heating 1Document27 pages5.4.2 - Induction and Dielectric Heating 1Milan AcharyaNo ratings yet

- Electrostatics: Applied EM by Ulaby, Michielssen and RavaioliDocument60 pagesElectrostatics: Applied EM by Ulaby, Michielssen and RavaioliKamugasha KagonyeraNo ratings yet

- Class 10 - Electricity - Term IDocument6 pagesClass 10 - Electricity - Term IravilullaNo ratings yet

- WK 7 - Q3 - GP2 - GSJDocument59 pagesWK 7 - Q3 - GP2 - GSJildeanne GNo ratings yet

- Dielectric Constant, k: Permittivity (ε)Document4 pagesDielectric Constant, k: Permittivity (ε)adylanNo ratings yet

- Physics2 10Document29 pagesPhysics2 10BayuNo ratings yet

- Question 543500 3Document8 pagesQuestion 543500 3Nabaratna BiswalNo ratings yet

- EE CompiledDocument111 pagesEE CompiledSonah AlcarazNo ratings yet

- Dielectrics: Unit V Dielectric MaterialsDocument20 pagesDielectrics: Unit V Dielectric MaterialsSpyx MeniNo ratings yet

- 1261 XII Physics Support Material Study Notes and VBQ 2014 15Document370 pages1261 XII Physics Support Material Study Notes and VBQ 2014 15RajdeepNo ratings yet

- Elc Cur Vad MedDocument19 pagesElc Cur Vad MedMergen BahtyyarowNo ratings yet

- Chapter 11 Class 10 ScienceDocument8 pagesChapter 11 Class 10 Sciencenihalrajpurohit02No ratings yet

- f5 Chapter 2 ElectricityDocument7 pagesf5 Chapter 2 ElectricityWONG YIIK HOON MoeNo ratings yet

- E CH Erence Energydiff Ifference Potentiald: Allan RiddickDocument7 pagesE CH Erence Energydiff Ifference Potentiald: Allan RiddickAngel LaoNo ratings yet

- p6 ReviewerDocument18 pagesp6 ReviewerSherie Hazzell BasaNo ratings yet

- 10 Physics ch12 Electricity Ncert SolutioDocument19 pages10 Physics ch12 Electricity Ncert SolutiothemidnightismNo ratings yet

- 7 e Applied EMCh 4Document61 pages7 e Applied EMCh 4alaayousefmmNo ratings yet

- MODULE 5, Part1 - INDUCTOR & CAPACITORDocument29 pagesMODULE 5, Part1 - INDUCTOR & CAPACITORJOHN BRYNDON LANDICHONo ratings yet

- Electronics Module 3Document10 pagesElectronics Module 3Mary Ann Yongco CalalinNo ratings yet

- Potential Diff ResistanceDocument26 pagesPotential Diff Resistancea_s_1_5No ratings yet

- Electric Arc Furnace1Document8 pagesElectric Arc Furnace1havejsnjNo ratings yet

- ElectrochemistryDocument25 pagesElectrochemistryNani NaniNo ratings yet

- Chapter 01 DC CircuitsDocument42 pagesChapter 01 DC CircuitsRAJANo ratings yet

- XII Physics Support Material Study Notes and VBQ 2014 15Document370 pagesXII Physics Support Material Study Notes and VBQ 2014 15vinod.shringi787050% (2)

- Active Transducers - ThermocoupleDocument29 pagesActive Transducers - ThermocoupleKritika GuptaNo ratings yet

- Basic Electro-Mechanical Engineering (EE-170) : Lecture#02Document41 pagesBasic Electro-Mechanical Engineering (EE-170) : Lecture#02Hassnain MassidNo ratings yet

- Directenergyconversion V 170516082607 PDFDocument78 pagesDirectenergyconversion V 170516082607 PDFMeikandan MegarajNo ratings yet

- Electric Furnace 1971 - 043Document14 pagesElectric Furnace 1971 - 043lamisma09No ratings yet

- Electricity One Shot Class10Document49 pagesElectricity One Shot Class10saracastic123No ratings yet

- Chapter 3 Ohms Law and Kirchhoffs LawsDocument34 pagesChapter 3 Ohms Law and Kirchhoffs Lawsjeloserrano60No ratings yet

- Experiment ElectronicsDocument18 pagesExperiment ElectronicsAnshuman PanigrahiNo ratings yet

- Antenna LecDocument16 pagesAntenna Lecjosesag518No ratings yet

- Electricity Part 2 StudentsDocument14 pagesElectricity Part 2 StudentsSharvinder SinghNo ratings yet

- Physics Excellent QuestionsDocument98 pagesPhysics Excellent QuestionsShashank Rai0% (1)

- 5.4 - Methods of Electric HeatingDocument13 pages5.4 - Methods of Electric HeatingMilan AcharyaNo ratings yet

- Lesson 2 Analysing The Relationship Between Electric Current and Potential DifferenceDocument8 pagesLesson 2 Analysing The Relationship Between Electric Current and Potential DifferenceSean LeeNo ratings yet

- Polymer Dielectrics For Capacitor ApplicationDocument29 pagesPolymer Dielectrics For Capacitor ApplicationFerryTimothyNo ratings yet

- Electricity Key NotesDocument14 pagesElectricity Key NotesCool TreesNo ratings yet

- Current ElectricityDocument3 pagesCurrent Electricityluciuszogratis561No ratings yet

- Chapter 27. Current and ResistanceDocument23 pagesChapter 27. Current and ResistanceKent TongloyNo ratings yet

- Electricity-Current and ResistanceDocument4 pagesElectricity-Current and ResistanceLast UnknownNo ratings yet

- Thermoelectric Devices: Refrigeration and Power Generations With No Moving PartsDocument7 pagesThermoelectric Devices: Refrigeration and Power Generations With No Moving PartsGiuseppe FioreNo ratings yet

- 10TH-CHP 12-Elecricity (Notes) - 2Document8 pages10TH-CHP 12-Elecricity (Notes) - 2NavaneetDDeshpandeNo ratings yet

- 12 SDAV PHY Unit 2 5 Marks Notes 1596219784Document32 pages12 SDAV PHY Unit 2 5 Marks Notes 1596219784Hema VathyNo ratings yet

- Capacitors 2Document65 pagesCapacitors 2miniNo ratings yet

- CH 3 TestDocument8 pagesCH 3 Testakshatjadav11No ratings yet

- Central Board of School EducationDocument11 pagesCentral Board of School EducationADITYA SHARMANo ratings yet

- LESSON 7.2 Physics Form 5Document10 pagesLESSON 7.2 Physics Form 5Intan Nur DaniaNo ratings yet

- DC CircuitsDocument59 pagesDC CircuitsAbhishek ThakkarNo ratings yet

- Electricity Numerical StudyPhobia ExclusiveDocument39 pagesElectricity Numerical StudyPhobia ExclusiveYtnew SubNo ratings yet

- Eee3352 L2Document42 pagesEee3352 L2Desmond CheweNo ratings yet

- F5 Chapter 2 - ElectricityDocument50 pagesF5 Chapter 2 - ElectricitySudhan NairNo ratings yet

- ElectricityDocument66 pagesElectricitybhaveshjangaleNo ratings yet

- AQA Physics Unit 2 Electricity Student Progress SheetDocument6 pagesAQA Physics Unit 2 Electricity Student Progress SheetGabriel HoNo ratings yet

- Impedance Spectroscopy: Theory, Experiment, and ApplicationsFrom EverandImpedance Spectroscopy: Theory, Experiment, and ApplicationsEvgenij BarsoukovNo ratings yet

- The Standard Electrical Dictionary A Popular Dictionary of Words and Terms Used in the Practice of Electrical EngineeringFrom EverandThe Standard Electrical Dictionary A Popular Dictionary of Words and Terms Used in the Practice of Electrical EngineeringRating: 3.5 out of 5 stars3.5/5 (2)

- Slipping DeviceDocument11 pagesSlipping DeviceSEETHARAMA MURTHYNo ratings yet

- Bantubani ElectrodetechforbasemetalfurnacesDocument10 pagesBantubani ElectrodetechforbasemetalfurnacesSEETHARAMA MURTHYNo ratings yet

- UntitledDocument3 pagesUntitledSEETHARAMA MURTHYNo ratings yet

- SuccessReceipt - 2022-12-10T170136.602 PDFDocument1 pageSuccessReceipt - 2022-12-10T170136.602 PDFSEETHARAMA MURTHYNo ratings yet

- Statement of Axis Account No:918030113821568 For The Period (From: 01-03-2023 To: 12-03-2023)Document2 pagesStatement of Axis Account No:918030113821568 For The Period (From: 01-03-2023 To: 12-03-2023)SEETHARAMA MURTHYNo ratings yet

- Jentoft Diffusereflectance 101204Document56 pagesJentoft Diffusereflectance 101204Joe Vito MorabitoNo ratings yet

- ME 266 Lecture Slides 3 (Second Law of Thermodynamics)Document44 pagesME 266 Lecture Slides 3 (Second Law of Thermodynamics)Emmanuel AmoakoNo ratings yet

- 2 and 3 Force Member ExampleDocument11 pages2 and 3 Force Member ExampleNIYASNo ratings yet

- SeparatorDocument55 pagesSeparatorOsama HassanNo ratings yet

- NDT 5Document29 pagesNDT 5sugandha772No ratings yet

- chp1 AtdDocument3 pageschp1 AtdNivesh JalanNo ratings yet

- Bolted ConnectionDocument86 pagesBolted ConnectionPooja MistryNo ratings yet

- DLL - Science 9 - Q4Document32 pagesDLL - Science 9 - Q4Nazer M. LacaboNo ratings yet

- PRESTRESSED CONCRETE 03 Rev00Document4 pagesPRESTRESSED CONCRETE 03 Rev00Hussein MuslihNo ratings yet

- Sohail Villa - Ahu Technical ReportDocument30 pagesSohail Villa - Ahu Technical ReportAslamNo ratings yet

- Tarea 2 de Reacciones 2Document14 pagesTarea 2 de Reacciones 2Sait Marcos Orihuela OrihuelaNo ratings yet

- Critical Resolved Shear StressDocument31 pagesCritical Resolved Shear StressLumamba ChiyabiNo ratings yet

- Tut 2 2013Document2 pagesTut 2 2013iwineverythingNo ratings yet

- Rotary EvaporatorDocument3 pagesRotary EvaporatorJushiNo ratings yet

- Lakhmir Singh Solutions For Class 9 Chemistry Chapter 2Document91 pagesLakhmir Singh Solutions For Class 9 Chemistry Chapter 2SonuNo ratings yet

- 9TH Class Chemistry Guess PaperDocument11 pages9TH Class Chemistry Guess PaperMarkpiciNo ratings yet

- Work Energy Power StructuredDocument4 pagesWork Energy Power Structuredlogan bain100% (1)

- Mamography PPT Nov 15 - 2022Document23 pagesMamography PPT Nov 15 - 2022Fouzia NoorNo ratings yet

- Tracerline TP-9350 COBRADocument2 pagesTracerline TP-9350 COBRAmgmqroNo ratings yet

- Liquid Rocket Engine Design - CompressedDocument472 pagesLiquid Rocket Engine Design - CompressedArvind KrishnaNo ratings yet

- 6.7 Ferro-, Ferri - and Antiferromagnetism ImpDocument5 pages6.7 Ferro-, Ferri - and Antiferromagnetism ImpabdulmussuNo ratings yet

- Cryo Duplex SsDocument220 pagesCryo Duplex SssivaNo ratings yet

- Valence Bond Theory VBT.Document8 pagesValence Bond Theory VBT.agraharirajiv33No ratings yet

- ISO 3585 Juillet 1998Document12 pagesISO 3585 Juillet 1998Sam SamNo ratings yet

- Pearson Ch2 Answers-1Document12 pagesPearson Ch2 Answers-1Person GainableNo ratings yet

- Gr-6 Wk6-Sci Pure Substances and MixturesDocument64 pagesGr-6 Wk6-Sci Pure Substances and MixturesammarashahzadNo ratings yet

- HW #6Document2 pagesHW #6c_sierra340% (1)

- IB Çalışma SorularıDocument99 pagesIB Çalışma SorularıAziz Samet ZorluNo ratings yet

- Best Hybrid PDFDocument113 pagesBest Hybrid PDFÑõmý ÅwăņNo ratings yet

- Rigorous Steady-State Simulation of Acetone Production Using Aspen Hysys®Document9 pagesRigorous Steady-State Simulation of Acetone Production Using Aspen Hysys®eva apriliaNo ratings yet