Professional Documents

Culture Documents

Part 10 - Materials and Manufacturing Elements

Part 10 - Materials and Manufacturing Elements

Uploaded by

REYNALD MILO0 ratings0% found this document useful (0 votes)

15 views101 pagesThis document contains 25 multiple choice questions about materials and manufacturing elements from an exclusive mechanical engineering review. Each question is followed by an answer key. The questions cover topics such as alloys, metals, steels, stainless steels, and other engineering materials. The document is a quiz intended for members of a mechanical engineering review.

Original Description:

Original Title

PART 10 - MATERIALS AND MANUFACTURING ELEMENTS

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains 25 multiple choice questions about materials and manufacturing elements from an exclusive mechanical engineering review. Each question is followed by an answer key. The questions cover topics such as alloys, metals, steels, stainless steels, and other engineering materials. The document is a quiz intended for members of a mechanical engineering review.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

15 views101 pagesPart 10 - Materials and Manufacturing Elements

Part 10 - Materials and Manufacturing Elements

Uploaded by

REYNALD MILOThis document contains 25 multiple choice questions about materials and manufacturing elements from an exclusive mechanical engineering review. Each question is followed by an answer key. The questions cover topics such as alloys, metals, steels, stainless steels, and other engineering materials. The document is a quiz intended for members of a mechanical engineering review.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 101

MATERIALS AND

MANUFACTURING

ELEMENTS

PART 10

ES MECHANICAL ENGINEERING REVIEW

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

1

MEMBERS

1. _____ is an intimate mixture of two single phase

solids.

A. Molecular Structure

B. Eutetic Structure

C. Crystalline Structure

D. Amorphous Structure

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

2

MEMBERS

2. The combination of a slip plane and its direction

of slip is known as:

A. Anistropic

B. Twinning

C. Slip system

D. Ductile

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

3

MEMBERS

3. _____ is use to describe such phenomena,

because the embrittling element is in liquid state.

A. Grain-boundary embrittlement

B. Grain-boundary sliding

C. Liquid-boundary embrittlement

D. Solid-metal embrittlement

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

4

MEMBERS

4. The lowest temperature at which the material is

totally liquid.

A. Solidus line

B. Solvus line

C. Liquidus line

D. Steamus line

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

5

MEMBERS

5. The absolute value of the ratio in the specimen

of the lateral strain to the longitudinal strain is

known as:

A. Modulus of elasticity

B. Poisson's ratio

C. Ductility

D. Toughness

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

6

MEMBERS

6. The stress at fractule in bending is known as the:

A. Shear strain or modulus of rigidity

B. Bend or flexure test

C. Modulus of rupture

D. Hardness

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

7

MEMBERS

7. The stresses resulting from a loading of a structure

component decrease in magnitude over a period of time,

even though the dimensions of the component remain

constant.

A. Endurance limit or fatigue limit

B. Creep

C. Rupture or creep rupture

D. Stress relaxation

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

8

MEMBERS

8. In polycrystalline metals, the fracture paths most

commonly observed are

A. Transgranular

B. Intergranular

C. Fatigue fracture

D. Stress-corrosion cracking

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

9

MEMBERS

9. A quantity that describes the resistance of a

material to fracture or crack growth/

A. Gray cast iron

B. Weldability

C. Fracture toughness

D. Manufacturing defects

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

10

MEMBERS

10. It is defined as the voltage required per unit

distance for electrical breakdown.

A. Low-expansion alloys

B. Invar Effect

C. Conductors

D. Dielectric strength

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

11

MEMBERS

11. _____ is composed of two or more chemical

elements, at least one of which is a metal.

A. Alloy

B. Bonding

C. Blends

D. Mixture

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

12

MEMBERS

12. The right boundary represents ___, which is

100% iron carbide, having a carbon content of

6.67%.

A. Gamma iron or austenite

B. Cementile or Carbide

C. Cementite

D. Pearlite

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

13

MEMBERS

13. If the ferrite and cementite lamellae in the

perlite structure of the eutectoid steel are thin and

closely packed, the microstructure is called:

A. Fine pearlite

B. Coarse pearlite

C. Spheroidites

D. Bainite

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

14

MEMBERS

14. The End-quenched hardenability test is

commonly used is:

A. Jominy test

B. Morse test

C. Impact test

D. End test

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

15

MEMBERS

15. This method is particularly useful for improving

resistance to surface indentation, fatigue and wear.

A. Case hardening

B. Age hardening

C. Precipitation hardening

D. Strain hardening

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

16

MEMBERS

16. The workpiece is annealed to restore its

ductility, part of all which may have been exhausted

by work hardening during cold working.

A. Full annealing

B. Normalizing

C. Process annealing

D. Stress-relief annealing

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

17

MEMBERS

17. The three basic materials used in iron and steel

making is/are:

A. Iron ore

B. Limestone

C. Coke

D. All of these

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

18

MEMBERS

18. An ore of calcium magnesium carbonate.

A. Dolomite

B. Charging the furnace

C. Blastfurnace

D. Pig iron

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

19

MEMBERS

19. Traditionally, the next step in the steelmaking

process is the shaping of the molten steel into a

solid form called:

A. Vacuum furnace

B. Continuous casting

C. Ingots

D. Soaking pits

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

20

MEMBERS

20. Improves resistance to atmospheric corrosion

and, to a lesser extent, increases strength, with little

loss in ductility; it adversely affects hot-working

characteristics and surface quality.

A. Chromium

B. Cobalt

C. Copper

D. Lead

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

21

MEMBERS

21. Has 0.3% to 0.6% carbon. It is generally used in applications

requiring higher strength than is available in low carbon steels,

such as in machinery, in automotive and agricultural equipement

parts (gears, axles, connecting rods, crankshafts) in railroad

equipment.

A. Low carbon steel

B. Medium carbon steel

C. High carbon steel

D. Resulfurized and Phosphorized carbon steels

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

22

MEMBERS

22. The most ductile of all stainless steels.

A. Austenitic stainless steels

B. Ferritic stainless steel

C. Martensitic stainless steels

D. Precipitation-hardening stainless steels

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

23

MEMBERS

23. First developed in the early 1900s, they

maintain their hardness and strength at elevated

operating temperatures:

A. Tool and tie steels

B. High-speed steels (HSS)

C. Molydenum (M-series) and Tungsten (T-series)

D. M-series

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

24

MEMBERS

24. Molybdenum, niobium (columbium), tungsten,

and tantalum; high strength at high temperatures.

A. Superalloys

B. Titanium

C. Refractory materials

D. Precious metals

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

25

MEMBERS

25. _____ is an alloy of copper and tin:

A. Brasses and bronzes

B. Bronze

C. Red brass

D. Cartridge brass

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

26

MEMBERS

26. _____ have high strength and corrosion

resistance at elevated temperatures.

A. Nickel

B. Sulfide and Oxide ores

C. Superalloys

D. Monel K-500

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

27

MEMBERS

27. _____ have good resistance to corrosion, to

mechanical and thermal fatigue, to mechanical and

thermal shock, to creep, and to erosion at elevated

temperatures.

A. Nichrome

B. Sulfide and Oxide ores

C. Superalloys

D. Monel K-500

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

28

MEMBERS

28. These alloys are used in rockets and missiles

and in nuclear, chemical, and superconductor

applications.

A. Niobium

B. Tungsten

C. Tantalum

D. Beryllium

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

29

MEMBERS

29. _____ is an alloying element in solders, steels

and copper alloys; it promotes corrosion resistance

and machinability.

A. Unalloyed Berylium

B. Zirconium

C. Lead

D. Zinc

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

30

MEMBERS

30. _____ is a ductile metal, and it has the highest

electrical and thermal conductivity of any metal.

A. Silver

B. Sterling silver

C. Platinum

D. Shape-memory alloys

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

31

MEMBERS

31. _____ is the basic building block of a polymer.

A. Monomer

B. Polymerization reaction

C. Condensation polymerization

D. Step-growth

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

32

MEMBERS

32. May be added to polymers to reduce friction during

their subsequent processing into useful products and to

prevent parts from sticking to the molds.

A. Plasticizers

B. Fillers

C. Fluorocarbons

D. Lubricants

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

33

MEMBERS

33. _____ have a good mechanical, chemical and

electrical properties.

A. Polysters

B. Silicones

C. Biodegradablility

D. Elastomer

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

34

MEMBERS

34. High strength and toughness; thermal

expansion close to cast iron; suitable for heat

engine components.

A. Zirconia

B. Tungsten carbide

C. Silicon carbide

D. Cubic boron nitride

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

35

MEMBERS

35. _____ are products of the reaction of silica with

oxides of aluminum, magnesium, calcium,

potassium, sodium and iron.

A. Diamond

B. Quartz

C. Silicates

D. High speed steel

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

36

MEMBERS

36. Glass in bulk form has a strength of less than

A. 150 Mpa

B. 145 Mpa

C. 150 Mpa

D. 155 Mpa

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

37

MEMBERS

37. _____ can be developed when the liquid metal

solidifies and shrinks between dendrites and

between dendrite branches.

A. Solidification time

B. Shrinkage

C. Microporosity

D. Pickling

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

38

MEMBERS

38. A commonly aramid is marketed under the trade

name:

A. Kevlar

B. Aramids

C. Whiskers

D. Spectra

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

39

MEMBERS

39. Those grains that have favourable orientation

will grow preferentially and are called:

A. Columnar grains

B. Homogeneous nucleation

C. Macrosegregation

D. Inverse segregation

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

40

MEMBERS

40. _____ is the length of the solidifies metal in the

spiral passage.

A. Fluidity index

B. Solidification time

C. Metallic projections

D. Cavities

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

41

MEMBERS

41. _____ are often used in steel foundries for their

low thermal expansion.

A. Zircon

B. Olivine

C. Iron silicate

D. All of these

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

42

MEMBERS

42. Used to anchor the core in place.

A. Core prints

B. Chaplets

C. Jolting

D. Hand hammering

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

43

MEMBERS

43. Tensions can be applied to the strip either at the

exit zone known as:

A. Draft

B. Back tension

C. Front tension

D. Steckel rolling

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

44

MEMBERS

44. _____ are the result of roll bending. The strip is

thinner along its edges than at its center.

A. Leveling rolls

B. Wavy edges

C. Alligatoring

D. Gage number

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

45

MEMBERS

45. Spray casting is also known as:

A. Mannesmann process

B. Tube rolling

C. Pilger mill

D. Osprey process

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

46

MEMBERS

46. _____ of parts with letters and numbers can be

done rapidly by a process similar to coining.

A. Marking

B. Heading

C. Headers

D. Piercing

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

47

MEMBERS

47. A round specimen is twisted continuously in the

same direction until it falls.

A. Hot-twist test

B. Hydraulic presses

C. Mechanical press

D. Screw presses

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

48

MEMBERS

48. _____ is carried out at elevated temperatures for

metals and alloys that do not have sufficient ductility at

room temperature, or in order to reduce the forces

required.

A. Coaxing extrusion of cladding

B. Square dies

C. Hot extrusion

D. Glass

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

49

MEMBERS

49. _____ consists of piercing a larger number of

closely spaced holes.

A. Piercing and Blanking

B. Perforating

C. Parting

D. Notching

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

50

MEMBERS

50. Parts requiring multiple operations, such as

punching, blanking, and notching, can be made at

high production rates.

A. Subpress dies

B. Tailor-Welded blanks

C. Compound dies

D. Progressive dies

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

51

MEMBERS

51. The periphery of the sheet metal is bent into the

cavity of a die.

A. Beading

B. Flanging

C. Dimpling

D. Hemming

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

52

MEMBERS

52. The pressure over rubber membrane is

controlled throuhgout the forming cycle, with the

maximum pressure of up to 100 Mpa.

A. Electroforming

B. Hydroform or fluid-forming process

C. Spinning

D. Conventional spinning

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

53

MEMBERS

53. Utilizes either aqueous solutions or fused salts.

A. Atomization

B. Electrolytic deposition

C. Screening

D. Aspect ratio

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

54

MEMBERS

54. Powder-metal parts may be subjected to other

finishing operations, including the following:

A. Heat treating

B. Machining and Grinding

C. Plating

D. All of these

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

55

MEMBERS

55. _____ is used to make plastic products with a

solid outer skin and cellular inner structure.

A. Oxide powder in tube

B. Structural-foam molding

C. Blow molding

D. Rotational molding

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

56

MEMBERS

56. The deformation of the material takes place

along a narrow shear zone.

A. Continuous chips

B. Primary shear zone

C. Secondary shear zone

D. Chip-breaker

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

57

MEMBERS

57. Utilizes a piezoelectric transducer attached to a

tool holder.

A. Acoustic emmission

B. Austenitic steels (300 series)

C. Surface finish

D. Integrity of the machine part

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

58

MEMBERS

58. _____ are becoming the norm in the

metalworking industry because coating can

consistently improve tool life 200%, 300% or more.

A. Ceramics

B. Tool steels

C. Ceramics

D. Coated tools

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

59

MEMBERS

59. Most inserts are honed to a radius of about:

A. 0.015 mm

B. 0.025 mm

C. 0.035 mm

D. 0.045 mm

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

60

MEMBERS

60. To enlarge a hole or cylindrical cavity made by

a previous process or to produce circular internal

grooves.

A. Turning

B. Facing

C. Form tools

D. Boring

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

61

MEMBERS

61. Moves radially in and out, controlling the radial

position of the cutting tool in operations such as

facing.

A. Carriage

B. Cross-slide

C. Apron

D. Headstock

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

62

MEMBERS

62. _____ are used to hold smooth cold-rolled bar

stock or machined workpiece more accurately than

with regular chucks.

A. Three-jaw chuck

B. Four-jaw chuck

C. Power chucks

D. Collet

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

63

MEMBERS

63. _____ is short and is used to produce the hole

at the end of a piece stock so that it may be

mounted between centers in a lathe.

A. Horizontal boring machines

B. Center drill

C. Spot drill

D. Spade drill

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

64

MEMBERS

64. _____ are made that can drill two or more

diameters, or drill and countersink and/or

counterbore, in a single operation.

A. Combination drills

B. Crankshaft drills

C. Trepanning

D. Reaming

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

65

MEMBERS

65. _____ is a process of internal thread rolling

using a forming tap.

A. Finishing reamers

B. Tap

C. Tapered taps

D. Chipless tapping

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

66

MEMBERS

66. _____ are relatively thin, usually less than 5

mm.

A. Slitting saws

B. Profilers

C. T-slot cutters

D. Key seat cutters

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

67

MEMBERS

67. A large broach can remove materials as deep

as _____ in one stroke.

A. 32 mm

B. 34 mm

C. 36 mm

D. 38 mm

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

68

MEMBERS

68. In a process in which a mild-steel blade, or disk,

rubs against the workpiece at speeds of up to 7600

m/min.

A. Cold sawing

B. Band saws

C. Friction sawing

D. Filling

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

69

MEMBERS

69. _____ is generally caused by some periodic

applied force present in the machine tool, such as

that from gear drives.

A. Granite-epoxy composite

B. Stiffness

C. Resin bonding

D. Force vibration

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

70

MEMBERS

70. _____ is a chip-removal process that uses an

individual abrasive grain as the cutting tool.

A. Reinforced wheels

B. Rubber

C. Grinding

D. Exothermic reactions

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

71

MEMBERS

71. _____ is a dressing operation by which a wheel

is restored to its original shape.

A. Truing

B. Grindability

C. Surface grinding

D. Plunge grinding

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

72

MEMBERS

72. _____ are self-contained units and are usually

attached to the tool post of a lathe.

A. Infeed grinding

B. End-feed grinding

C. Universal tool and cutter grinders

D. Tool-post grinders

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

73

MEMBERS

73. _____ is an operation used primarily to give

holes a fine surface finish.

A. Sandpaper and emery cloth

B. Belt grinding

C. Wire brushing process

D. Honing

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

74

MEMBERS

74. The equipment used is similar to a conventional

grinder, except that the wheel is a rotating cathode

embedded with abrasive particles.

A. Electrochemical machining

B. Electrochemical grinding

C. Electrochemical honing

D. Spark-erosion machining or Electrodischarge

machining

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

75

MEMBERS

75. _____ is defined as the melting together and

coalescing of materials by means of heat; filler

metals may or may not be used.

A. Fusion welding

B. Solid-state welding

C. Adhesive bonding

D. Fasteners

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

76

MEMBERS

76. In gas metal-arc welding (GMAW), developed

the 1950s and formerly called

A. SMAW process

B. Submerged arc welding

C. Metal Inert Gas (MIG) welding

D. Spray transfer

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

77

MEMBERS

77. Developed in the 1960s, a concentrated

plasma arc is produced and is aimed at the weld

area.

A. Atomic hydrogen welding

B. Plasma-arc wielding

C. Thermit welding

D. Electron-beam welding

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

78

MEMBERS

78. _____ is similar to seam welding, except that

high-frequency current is employed.

A. Resistance seam welding

B. High-frequency resistance welding

C. Resistance Projection welding

D. Flash welding

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

79

MEMBERS

79. Because of localized heating and cooling during

welding, expansion and contraction of the weld are

causes:

A. Hot cracks

B. Cold cracks

C. Lamellar tears

D. Residual stresses

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

80

MEMBERS

80. The shear strength of braze joints can reach:

A. 700 Mpa

B. 800 Mpa

C. 900 Mpa

D. 600 Mpa

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

81

MEMBERS

81. Polyurethanes, silicons, epoxies,

cyanoacrylates are examples of:

A. Inorganic adhesive

B. Synthetic organic adhesives

C. Chemically reactive

D. Pressure sensitive

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

82

MEMBERS

82. _____ is defined as closed spaced, irregular

deviations on a scale smaller than that of waviness.

A. Flaws

B. Lay

C. Roughness

D. Waiveness

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

83

MEMBERS

83. _____ is caused when the surface of a material

is subjected to cyclic loading.

A. Abrasive wear

B. Hardness

C. Corrosive wear

D. Fatigue wear

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

84

MEMBERS

84. The surfaces are subjected to high transient pressure

through the placement and detonation of a layer of

explosive sheet directly on the workpiece surface.

A. Roller brushing

B. Ballizing

C. Explosive hardening

D. Cladding

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

85

MEMBERS

85. _____ is particularly suitable for low production

quantities or intricate parts made of nickel, copper,

gold, and silver.

A. Chromium plating

B. Electroless plating

C. Electroforming process

D. Anodizing

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

86

MEMBERS

86. The amount of offset is usually for steel,

aluminum and magnesium alloys.

A. 0.1%

B. 0.2%

C. 0.3%

D. 0.4%

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

87

MEMBERS

87. _____ is the processing of deforming a metal

plastically at a temperature below the crystallization

temperature and at a rate to produce strain hardening.

A. Cold working

B. Damping capacity

C. Decarburization

D. Ductility

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

88

MEMBERS

88. _____ is a material's susceptability to extreme

deformation in rolling or hammering. Gold and

aluminum are quite malleable

A. Killed steel

B. Rimmed steel

C. Machinability

D. Malleability

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

89

MEMBERS

89. _____ is a condition produced in a non-ferrous

metal by mechanical or thermal treatment.

A. Solution Heat Treatment

B. Stiffness

C. Strain Hardening

D. Temper

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

90

MEMBERS

90. _____ is done by immersing the piece of steel in a molten bath

of sodium cyanide from 3 to 5 minutes depending on the size of

the piece of work and the depth of penetration desired. It is then

quenched in water, brine, or oil until a very hard skin or casing,

0.01 to 0.015 inch thick, is formed.

A. Cyaniding

B. Case Hardening

C. Nitriding

D. Annealing

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

91

MEMBERS

91. Carbon steels with free cutting, Manganese

steels

A. 10XX

B. 11XX

C. X13XX

D. T13XX

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

92

MEMBERS

92. Basic and acid open-hearth and acid Bessemer

carbon steel grades non-sulphurized

A. 10XX

B. 11XX

C. 12XX

D. 13XX

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

93

MEMBERS

93. Chromium - vanadium

A. 52XX

B. 61XX

C. 86XX

D. 92XX

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

94

MEMBERS

94. _____ is an efficient de-oxidizer, an alloy in

nitriding steels and promotes fine grain size.

A. High-carbon Alloy Steels

B. High Alloy Steels

C. Aluminum

D. Boron

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

95

MEMBERS

95. Typically contains 1.2% C and 12-13% Mn and

responds to work hardening most readily.

A. Titanium

B. Tungsten

C. Vanadium

D. Austenetic manganese

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

96

MEMBERS

96. _____ is usually to provide a hard, wear

resistant surface while retaining great toughness in

the core.

A. Case hardening

B. Hardenability

C. Carburizing

D. Pack and gas carburzing

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

97

MEMBERS

97. The product contains some 1-3% slag and less

than

A. Wrought iron

B. 0.1% carbon

C. Cast iron

D. Gray cast iron

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

98

MEMBERS

98. Austenitic steels (200 and 300 series) - that

includes for its stabilizing of austinite.

A. 3.5 to 22% nickel

B. 2.5% maximum

C. 4 to 26%

D. 3.5 to 22% nickel for its stabilizing of austenite

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

99

MEMBERS

99. Spring, bolts and screws, firing pins, dies,

surgical instruments, spark resistance tools

A. Admiralty metal

B. Aluminum bronze

C. Berylium copper

D. Cartridge brass

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

100

MEMBERS

100. When plastic deformation are involve. the

criterion for design at a particular operating

temperature is the:

A. Creep strength

B. Endurance strength

C. Izod

D. Ultimate strength

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

101

MEMBERS

You might also like

- ExamsGrade API-571 Exam Questions AnswersDocument10 pagesExamsGrade API-571 Exam Questions AnswersLamont Bauch100% (6)

- Tutorial 3Document3 pagesTutorial 3THABILE MUSWEDENo ratings yet

- Machine Design TermsDocument301 pagesMachine Design Termsitsmechelle100% (1)

- AAMA 907-05: Voluntary Specification For Corrosion Resistant Coatings On Carbon Steel ComponentsDocument4 pagesAAMA 907-05: Voluntary Specification For Corrosion Resistant Coatings On Carbon Steel ComponentsMarian Joyce MacadineNo ratings yet

- Part 8 - Materials and Manufacturing ElementsDocument101 pagesPart 8 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 2 - Materials and Manufacturing ElementsDocument101 pagesPart 2 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 9 - Materials and Manufacturing ElementsDocument101 pagesPart 9 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 1 - Materials and Manufacturing ElementsDocument101 pagesPart 1 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 7 - Materials and Manufacturing ElementsDocument101 pagesPart 7 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 3 - Materials and Manufacturing ElementsDocument101 pagesPart 3 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- MDSP Elements Part 1Document101 pagesMDSP Elements Part 1Kira YagamiNo ratings yet

- Machine Shop Practice Reviewer 1Document15 pagesMachine Shop Practice Reviewer 1Ruth LauronNo ratings yet

- Test 5Document5 pagesTest 5John Michael JucdongNo ratings yet

- Machine Shop Practice Reviewer 2Document7 pagesMachine Shop Practice Reviewer 2Ruth LauronNo ratings yet

- Test 2Document3 pagesTest 2John Michael JucdongNo ratings yet

- Test 1Document5 pagesTest 1John Michael JucdongNo ratings yet

- MDSP ElementsDocument71 pagesMDSP ElementsFernan MacusiNo ratings yet

- Part 5 - Pipe Terms ContiDocument157 pagesPart 5 - Pipe Terms ContiJay Mark Cayonte100% (1)

- 6Document16 pages6Mari CarNo ratings yet

- Machine-Design TermsDocument183 pagesMachine-Design TermsQuinxxNo ratings yet

- MD Elements1Document22 pagesMD Elements1Ben LopezNo ratings yet

- Test 4Document5 pagesTest 4John Michael JucdongNo ratings yet

- 5Document36 pages5Mari CarNo ratings yet

- TRB Test MachinesDocument3 pagesTRB Test MachinessivakumarNo ratings yet

- API 571 DemoDocument9 pagesAPI 571 Demoمبشر أحمد100% (1)

- and 68070 S2012 Final v2 No AnswersDocument42 pagesand 68070 S2012 Final v2 No AnswersZadrin TuckerNo ratings yet

- Test 1Document30 pagesTest 1Mari CarNo ratings yet

- Test 6Document21 pagesTest 6Mari CarNo ratings yet

- Test 3Document6 pagesTest 3John Michael JucdongNo ratings yet

- Machine Design Examination 19Document4 pagesMachine Design Examination 19SYBRELLE CRUZNo ratings yet

- 1 API 571 Exam QuestionsDocument10 pages1 API 571 Exam Questionskorichi100% (1)

- Machine Shop Practice Reviewer 3Document11 pagesMachine Shop Practice Reviewer 3Ruth LauronNo ratings yet

- Heat Treatment 434445Document28 pagesHeat Treatment 434445Dev ThakorNo ratings yet

- Machine Design 4Document6 pagesMachine Design 4Paul AbonitaNo ratings yet

- Section 5Document22 pagesSection 5annexe gameNo ratings yet

- Test 4Document8 pagesTest 4Chel QuietaNo ratings yet

- API 571 QuizDocument28 pagesAPI 571 Quizmohamed100% (2)

- Api 570 - 571 - Mock 1Document103 pagesApi 570 - 571 - Mock 1sheikmoin100% (5)

- TestDocument51 pagesTestNiaz KilamNo ratings yet

- 3rd Round - 2015 - Mock Nationa Exit ExamDocument20 pages3rd Round - 2015 - Mock Nationa Exit ExamteddiyfentawNo ratings yet

- Api - 571 - Q&a - 407Document28 pagesApi - 571 - Q&a - 407guruNo ratings yet

- A. B. C. D. Answer & ExplanationDocument16 pagesA. B. C. D. Answer & Explanationahmish kabbaxeNo ratings yet

- Api 571 Test QuestionsDocument10 pagesApi 571 Test QuestionsQaisir Mehmood100% (1)

- Unit V Electro Chemistry and Metal Corrosion, Its Prevent IonDocument15 pagesUnit V Electro Chemistry and Metal Corrosion, Its Prevent IonUmesh PatilNo ratings yet

- Api 571Document41 pagesApi 571majid100% (1)

- Test 2Document11 pagesTest 2Mari CarNo ratings yet

- Machine Design Examination 8Document5 pagesMachine Design Examination 8SYBRELLE CRUZNo ratings yet

- API-571 Mockup Test-02-QuestionsDocument12 pagesAPI-571 Mockup Test-02-QuestionsMetzer LLC100% (1)

- Mesl ElementsDocument110 pagesMesl ElementsJay Mark CayonteNo ratings yet

- Module 1 Esas Terms No AnswerDocument4 pagesModule 1 Esas Terms No AnswerGlendel Alivio EscuyosNo ratings yet

- Corrosion QDocument10 pagesCorrosion Qkihal zohirNo ratings yet

- Terms - Engineering-MaterialsDocument11 pagesTerms - Engineering-Materialsskz linoNo ratings yet

- Sec 8Document21 pagesSec 8annexe gameNo ratings yet

- Multi Choice - Paper - CSWIP 3.1 - 00Document19 pagesMulti Choice - Paper - CSWIP 3.1 - 00miteshNo ratings yet

- Chemistry For Engineers Set ADocument5 pagesChemistry For Engineers Set AMark Jecel RapirNo ratings yet

- Red BookDocument308 pagesRed BookQQR8 /trollNo ratings yet

- API-571 Mockup Test-01-QuestionsDocument13 pagesAPI-571 Mockup Test-01-QuestionsMonday100% (1)

- Practice Problems 8 Engineering MaterialsDocument6 pagesPractice Problems 8 Engineering MaterialsJayve BasconNo ratings yet

- MACDES Exit Exam 1Q1920 1 PDFDocument3 pagesMACDES Exit Exam 1Q1920 1 PDFJanelle Marie Benavidez100% (1)

- Manufacturing SummaryDocument27 pagesManufacturing SummaryShilca Geniel BarriosNo ratings yet

- Metal Properties and Destructive TestingDocument8 pagesMetal Properties and Destructive TestingKokoette Samuel EssienNo ratings yet

- Mechanic and Dielectric Properties: Advances in Research and DevelopmentFrom EverandMechanic and Dielectric Properties: Advances in Research and DevelopmentMaurice H. FrancombeNo ratings yet

- Part 8 - Materials and Manufacturing ElementsDocument101 pagesPart 8 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 9 - Materials and Manufacturing ElementsDocument101 pagesPart 9 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 7 - Materials and Manufacturing ElementsDocument101 pagesPart 7 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 2 - Materials and Manufacturing ElementsDocument101 pagesPart 2 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 3 - Materials and Manufacturing ElementsDocument101 pagesPart 3 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 1 - Materials and Manufacturing ElementsDocument101 pagesPart 1 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Environmental and Earth Sciences Research Journal: Received: 10 Accepted: 13 MaDocument9 pagesEnvironmental and Earth Sciences Research Journal: Received: 10 Accepted: 13 MaRichardNo ratings yet

- ASTM B584 - Copper Alloy Sand Castings For General Applications (2009)Document7 pagesASTM B584 - Copper Alloy Sand Castings For General Applications (2009)정영우No ratings yet

- Density ChartDocument2 pagesDensity ChartPuneet SharmaNo ratings yet

- 9-Agglomeration of OresDocument29 pages9-Agglomeration of OresGRAHAM KUNDAI DENGEZANo ratings yet

- Astm E407-99 PDFDocument21 pagesAstm E407-99 PDFJORGE ARTURO TORIBIO HUERTANo ratings yet

- Iron and SteelDocument6 pagesIron and SteelkhansaaaNo ratings yet

- MercuryDocument9 pagesMercuryZaw Myo HtetNo ratings yet

- Pages From BPVC - IX-2021Document2 pagesPages From BPVC - IX-2021Ramona CrangasNo ratings yet

- MT 2 MCQDocument9 pagesMT 2 MCQRanjith GopalakrishnanNo ratings yet

- Mar 2019 Mpsa 2aDocument51 pagesMar 2019 Mpsa 2aLeicel John BelmesNo ratings yet

- Technology 3Document6 pagesTechnology 3ابومحمد الكناني100% (1)

- Understanding and Avoiding Costly Heat Exchanger FailuresDocument7 pagesUnderstanding and Avoiding Costly Heat Exchanger FailuresPankaj SinglaNo ratings yet

- Periodic Table ActivityDocument3 pagesPeriodic Table ActivityJanine Aytria SaleNo ratings yet

- Module 1 Topik 4 The Perodic Table of ElementsDocument1 pageModule 1 Topik 4 The Perodic Table of Elementsrudi_zNo ratings yet

- Heats of Formation and Chemical CompositionsDocument20 pagesHeats of Formation and Chemical CompositionsBenya SrisoogcharoenNo ratings yet

- UTP Bestseller PDFDocument28 pagesUTP Bestseller PDFdaha333No ratings yet

- Shell and Tube Heat ExchangerDocument54 pagesShell and Tube Heat ExchangerQOBITNo ratings yet

- 05-Proses Produksi (Dasar Proses Manufaktur) ARIODocument22 pages05-Proses Produksi (Dasar Proses Manufaktur) ARIOAlifNo ratings yet

- MinDiv31 NigMiningIndustry31Document25 pagesMinDiv31 NigMiningIndustry31Irmiya Samson AmokaNo ratings yet

- Goldschmidt Classification of Elements - Note 3Document10 pagesGoldschmidt Classification of Elements - Note 3Odebunmi PaulNo ratings yet

- Coek - Info Galvanic-CorrosionDocument29 pagesCoek - Info Galvanic-CorrosionnadaNo ratings yet

- Legend - Periodic TableDocument1 pageLegend - Periodic TableIrene SanchezNo ratings yet

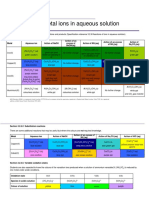

- Reactions of Metal Ions in Aqueous Solution: Chemistry A-Level (7405)Document2 pagesReactions of Metal Ions in Aqueous Solution: Chemistry A-Level (7405)SAMANNo ratings yet

- Reactions of Acids With Metals, Metal Carbonates, Metal Hydroxide and Metal OxidesDocument14 pagesReactions of Acids With Metals, Metal Carbonates, Metal Hydroxide and Metal OxidesOlajumokeNo ratings yet

- Steel, Sheet, Hot Rolled, Carbon, Commercial and Structural, Produced by The Twin-Roll Casting ProcessDocument7 pagesSteel, Sheet, Hot Rolled, Carbon, Commercial and Structural, Produced by The Twin-Roll Casting ProcessKannan MurugesanNo ratings yet

- Technical Information Papers: Coating and Graphic Arts 0100Document11 pagesTechnical Information Papers: Coating and Graphic Arts 0100venkNo ratings yet

- PDF RecordDocument392 pagesPDF Recordjsalamanca calderonNo ratings yet

- Early Stage Recovery of Lithium From Tailored Thermal Conditioned Black Mass Part I (Schwich Et Al 2021)Document30 pagesEarly Stage Recovery of Lithium From Tailored Thermal Conditioned Black Mass Part I (Schwich Et Al 2021)irdantoNo ratings yet