Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

16 viewsPart 8 - Materials and Manufacturing Elements

Part 8 - Materials and Manufacturing Elements

Uploaded by

REYNALD MILOThe document contains 26 multiple choice questions about materials and manufacturing elements. It tests knowledge on various metal alloys like Monel, properties of materials like crystal structure and single crystals, deformation processes like grain boundary sliding, and material characteristics such as creep, fracture toughness, and hardenability. The questions cover alloy compositions, corrosion resistance mechanisms, heat treatments, steel production methods, and classifications of metal groups.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You might also like

- ExamsGrade API-571 Exam Questions AnswersDocument10 pagesExamsGrade API-571 Exam Questions AnswersLamont Bauch100% (6)

- Machine Design TermsDocument301 pagesMachine Design Termsitsmechelle100% (1)

- Material Disasters Nik ChawlaDocument57 pagesMaterial Disasters Nik ChawlaFirzana AmiraNo ratings yet

- Part 7 - Materials and Manufacturing ElementsDocument101 pagesPart 7 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 1 - Materials and Manufacturing ElementsDocument101 pagesPart 1 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 2 - Materials and Manufacturing ElementsDocument101 pagesPart 2 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 3 - Materials and Manufacturing ElementsDocument101 pagesPart 3 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 9 - Materials and Manufacturing ElementsDocument101 pagesPart 9 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 10 - Materials and Manufacturing ElementsDocument101 pagesPart 10 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Test 5Document5 pagesTest 5John Michael JucdongNo ratings yet

- Test 1Document5 pagesTest 1John Michael JucdongNo ratings yet

- Machine Shop Practice Reviewer 1Document15 pagesMachine Shop Practice Reviewer 1Ruth LauronNo ratings yet

- Machine Shop Practice Reviewer 2Document7 pagesMachine Shop Practice Reviewer 2Ruth LauronNo ratings yet

- Test 2Document3 pagesTest 2John Michael JucdongNo ratings yet

- Test 4Document5 pagesTest 4John Michael JucdongNo ratings yet

- 5Document36 pages5Mari CarNo ratings yet

- MDSP ElementsDocument71 pagesMDSP ElementsFernan MacusiNo ratings yet

- Machine Shop Practice Reviewer 3Document11 pagesMachine Shop Practice Reviewer 3Ruth LauronNo ratings yet

- Test 3Document6 pagesTest 3John Michael JucdongNo ratings yet

- 1 API 571 Exam QuestionsDocument10 pages1 API 571 Exam Questionskorichi100% (1)

- 6Document16 pages6Mari CarNo ratings yet

- Part 5 - Pipe Terms ContiDocument157 pagesPart 5 - Pipe Terms ContiJay Mark Cayonte100% (1)

- MDSP Elements Part 1Document101 pagesMDSP Elements Part 1Kira YagamiNo ratings yet

- API 571 DemoDocument9 pagesAPI 571 Demoمبشر أحمد100% (1)

- API-571 Mockup Test-02-QuestionsDocument12 pagesAPI-571 Mockup Test-02-QuestionsMetzer LLC100% (1)

- Terms - Engineering-MaterialsDocument11 pagesTerms - Engineering-Materialsskz linoNo ratings yet

- API 571 QuizDocument28 pagesAPI 571 Quizmohamed100% (2)

- Test 1Document30 pagesTest 1Mari CarNo ratings yet

- TRB Test MachinesDocument3 pagesTRB Test MachinessivakumarNo ratings yet

- Aircraft Materials Class Test 1 & 2Document5 pagesAircraft Materials Class Test 1 & 2SeanRiniFernandoNo ratings yet

- 1000 ElementsDocument42 pages1000 ElementsAeron AntonioNo ratings yet

- Api 571Document41 pagesApi 571majid100% (1)

- Multi Choice - Paper - CSWIP 3.1 - 00Document19 pagesMulti Choice - Paper - CSWIP 3.1 - 00miteshNo ratings yet

- MD Elements1Document22 pagesMD Elements1Ben LopezNo ratings yet

- Section 5Document22 pagesSection 5annexe gameNo ratings yet

- Api - 571 - Q&a - 407Document28 pagesApi - 571 - Q&a - 407guruNo ratings yet

- Test 6Document21 pagesTest 6Mari CarNo ratings yet

- Sec 1Document16 pagesSec 1annexe gameNo ratings yet

- IMP Probable CIE QuestionsDocument11 pagesIMP Probable CIE QuestionsJustine Kyla OlivarNo ratings yet

- Machine-Design TermsDocument183 pagesMachine-Design TermsQuinxxNo ratings yet

- TestDocument51 pagesTestNiaz KilamNo ratings yet

- Mockup - Questions - Test - 4 - For API 571Document12 pagesMockup - Questions - Test - 4 - For API 571Metzer LLC100% (1)

- Heat Treatment 434445Document28 pagesHeat Treatment 434445Dev ThakorNo ratings yet

- Api 570 240-402Document52 pagesApi 570 240-402NIMANo ratings yet

- Cswip 3.2 Q&aDocument3 pagesCswip 3.2 Q&aMoses_Jakkala100% (3)

- and 68070 S2012 Final v2 No AnswersDocument42 pagesand 68070 S2012 Final v2 No AnswersZadrin TuckerNo ratings yet

- Corrosion QDocument10 pagesCorrosion Qkihal zohirNo ratings yet

- Test No 4ccDocument4 pagesTest No 4ccSalman GhaffarNo ratings yet

- Chemical-Engineering-Basics Section 1-9Document34 pagesChemical-Engineering-Basics Section 1-9NOELA PATALANNo ratings yet

- Test 2Document11 pagesTest 2Mari CarNo ratings yet

- Multichoice Paper OneDocument4 pagesMultichoice Paper OneAhmed ShakirNo ratings yet

- Practice Problems 8 Engineering MaterialsDocument6 pagesPractice Problems 8 Engineering MaterialsJayve BasconNo ratings yet

- MATERIALDocument13 pagesMATERIALnhut.nguyenbocoffee38No ratings yet

- Module 6 MCQDocument68 pagesModule 6 MCQlipibhaiNo ratings yet

- API-571 Mockup Test-01-QuestionsDocument13 pagesAPI-571 Mockup Test-01-QuestionsMonday100% (1)

- Wa0084Document33 pagesWa0084miteshNo ratings yet

- Sec 8Document21 pagesSec 8annexe gameNo ratings yet

- Machine Design Examination 19Document4 pagesMachine Design Examination 19SYBRELLE CRUZNo ratings yet

- Shielded Metal Arc Welding NC Ii 3 Final ExaminationDocument2 pagesShielded Metal Arc Welding NC Ii 3 Final ExaminationJessa AquitanNo ratings yet

- CompreDocument4 pagesCompreSiddhant KatariaNo ratings yet

- Mechanic and Dielectric Properties: Advances in Research and DevelopmentFrom EverandMechanic and Dielectric Properties: Advances in Research and DevelopmentMaurice H. FrancombeNo ratings yet

- Part 9 - Materials and Manufacturing ElementsDocument101 pagesPart 9 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 10 - Materials and Manufacturing ElementsDocument101 pagesPart 10 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 7 - Materials and Manufacturing ElementsDocument101 pagesPart 7 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 3 - Materials and Manufacturing ElementsDocument101 pagesPart 3 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 2 - Materials and Manufacturing ElementsDocument101 pagesPart 2 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 1 - Materials and Manufacturing ElementsDocument101 pagesPart 1 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Multiple Choice Quiz For Groover BookDocument36 pagesMultiple Choice Quiz For Groover BooktitanfallkillofweekNo ratings yet

- ASME IIC SFA5.16 - TiDocument10 pagesASME IIC SFA5.16 - TitragaldabasNo ratings yet

- 004aisi4140 - 105KDocument4 pages004aisi4140 - 105Ksundaramoorthy kamanNo ratings yet

- ASTM A789A789M - pdqv6897Document4 pagesASTM A789A789M - pdqv6897Nayth Andres GalazNo ratings yet

- Wagner, Karl Edward - Gothic TouchDocument14 pagesWagner, Karl Edward - Gothic TouchmartynekNo ratings yet

- C Purlin Data SheetDocument6 pagesC Purlin Data SheetAkhil VNNo ratings yet

- Process Planning AssimentDocument9 pagesProcess Planning Assimentዮሐንስ ታደሰNo ratings yet

- Introduction To Stainless SteelDocument19 pagesIntroduction To Stainless Steelkrishna chiruNo ratings yet

- Wires For Submerged Arc Welding of Creep Resistant Steels: Copper Coated Low Alloy Steel Solid WiresDocument6 pagesWires For Submerged Arc Welding of Creep Resistant Steels: Copper Coated Low Alloy Steel Solid WiresDeepak BhatiNo ratings yet

- Valve Standards ANSI BS APIDocument6 pagesValve Standards ANSI BS APIBenysetiyawanNo ratings yet

- Krishna Engineering College Department of Mechanical EngineeringDocument4 pagesKrishna Engineering College Department of Mechanical EngineeringVivek BajpaiNo ratings yet

- Asme Section Ii A-2 Sa-995Document4 pagesAsme Section Ii A-2 Sa-995Anonymous GhPzn1xNo ratings yet

- MQ SP P 5024Document16 pagesMQ SP P 5024jaseel kNo ratings yet

- Hardness Examination StandardDocument3 pagesHardness Examination StandardMohd Akmal Shafie100% (1)

- 2 Catalouge-1 PDFDocument43 pages2 Catalouge-1 PDFArif TandraNo ratings yet

- Astm e 2016 WireDocument29 pagesAstm e 2016 WireDavid KlinkenbergNo ratings yet

- Soporte Silleta Con Abrazadera UDocument1 pageSoporte Silleta Con Abrazadera UPaola LopezNo ratings yet

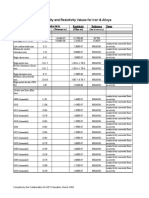

- Conductivity and Resistivity Values For Iron & AlloysDocument6 pagesConductivity and Resistivity Values For Iron & AlloysrexNo ratings yet

- Lecture 1 - Types of Materials and Its ClassificationDocument32 pagesLecture 1 - Types of Materials and Its ClassificationShakeel AhmadNo ratings yet

- Hec Project ReportDocument30 pagesHec Project ReportSudhanshu KumarNo ratings yet

- Presentation - JOINERY HARDWAREDocument159 pagesPresentation - JOINERY HARDWAREKeya JainNo ratings yet

- RM01 - 23 Case Study Friction Stir WeldingDocument49 pagesRM01 - 23 Case Study Friction Stir WeldingAnonymous cgcKzFtXNo ratings yet

- PHSS-ES-5096 Valve SpecificationDocument268 pagesPHSS-ES-5096 Valve SpecificationAfif FadhliNo ratings yet

- List of IndustryDocument14 pagesList of Industrybokul1No ratings yet

- Solid and Flux Cored Welding WiresDocument29 pagesSolid and Flux Cored Welding WiresAli TalebiNo ratings yet

- Astm A681 08 2022Document7 pagesAstm A681 08 2022sridevi72.puppalaNo ratings yet

- Soldering, Brazing and Braze Welding: Ag Metals I Welding Principles & ApplicationsDocument51 pagesSoldering, Brazing and Braze Welding: Ag Metals I Welding Principles & ApplicationsAd Man GeTigNo ratings yet

- Rolling MillsDocument11 pagesRolling MillsSudhir KumarNo ratings yet

- In General, The MIG/MAG Mode of Transfer Best Suited For Welding Thick Sheet Is Spray TransferDocument4 pagesIn General, The MIG/MAG Mode of Transfer Best Suited For Welding Thick Sheet Is Spray TransferLe TuanNo ratings yet

Part 8 - Materials and Manufacturing Elements

Part 8 - Materials and Manufacturing Elements

Uploaded by

REYNALD MILO0 ratings0% found this document useful (0 votes)

16 views101 pagesThe document contains 26 multiple choice questions about materials and manufacturing elements. It tests knowledge on various metal alloys like Monel, properties of materials like crystal structure and single crystals, deformation processes like grain boundary sliding, and material characteristics such as creep, fracture toughness, and hardenability. The questions cover alloy compositions, corrosion resistance mechanisms, heat treatments, steel production methods, and classifications of metal groups.

Original Description:

Original Title

PART 8 - MATERIALS AND MANUFACTURING ELEMENTS

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document contains 26 multiple choice questions about materials and manufacturing elements. It tests knowledge on various metal alloys like Monel, properties of materials like crystal structure and single crystals, deformation processes like grain boundary sliding, and material characteristics such as creep, fracture toughness, and hardenability. The questions cover alloy compositions, corrosion resistance mechanisms, heat treatments, steel production methods, and classifications of metal groups.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

16 views101 pagesPart 8 - Materials and Manufacturing Elements

Part 8 - Materials and Manufacturing Elements

Uploaded by

REYNALD MILOThe document contains 26 multiple choice questions about materials and manufacturing elements. It tests knowledge on various metal alloys like Monel, properties of materials like crystal structure and single crystals, deformation processes like grain boundary sliding, and material characteristics such as creep, fracture toughness, and hardenability. The questions cover alloy compositions, corrosion resistance mechanisms, heat treatments, steel production methods, and classifications of metal groups.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 101

MATERIALS AND

MANUFACTURING

ELEMENTS

PART 8

ES MECHANICAL ENGINEERING REVIEW

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

1

MEMBERS

1. Is primarily an alloy of nickel and copper.

A. Monel

B. Zemak-5

C. Babbit 23-49

D. Hastelloy B

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

2

MEMBERS

2. The atoms are arrange in a regular geometric

array know as:

A. Molecular Structure

B. Lattice

C. Unit Cell

D. Crystal Structure

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

3

MEMBERS

3. A single crystal is:

A. Anistropic

B. Twinning

C. Slip System

D. Ductile

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

4

MEMBERS

4. At elevated temperatures, and in materials

whose properties depend on the deformation also

takes place by means of:

A. Grain boundaries

B. Grain boundary sliding

C. Polycrystals

D. Nucleation

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

5

MEMBERS

5. The ratio of working temperature and melting

temperature is known as:

A. Warm-working

B. Homologous temperature

C. Doping

D. Diffusion

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

6

MEMBERS

6. The ratio stress to strain in the elastic region is

called:

A. Modulus of elasticity

B. Poisson’s Ratio

C. Ductility

D. Toughness

The answer is: a

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

7

MEMBERS

7. The ratio of shear stress to the shear strain in

the elastic range is:

A. Shear stress or modulus of rigidity

B. Blend or flexure test

C. Modulus of rapture

D. Hardness

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

8

MEMBERS

8. Permanent elongation of a component under a

static load maintained for a period of time.

A. Endurance limit or Fatigue limit

B. Creep

C. Rupture or creep rupture

D. Stress relaxation

The answer is: b

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

9

MEMBERS

9. An important factor in fracture is the presence

of:

A. Granular

B. Brittle fracture

C. Defects

D. Catastrophic failure

The answer is: c

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

10

MEMBERS

10. Quantity that describes resistance of a material

to fracture or crack growth

A. Gray cast iron

B. weldability

C. Fracture toughness

D. Manufacturing defects

The answer is: c

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

11

MEMBERS

11. Invar itself typically has a composition 64% iron

and _____

A. 32% nickel

B. 34% nickel

C. 36% nickel

D. 38% nickel

The answer is: c

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

12

MEMBERS

12. Is exhibited in the corrosion resistance of

aluminium, titanium, and stainless steels.

A. Tool and die materials

B. Oxidation

C. Passivation

D. Viscosity

The answer is: B

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

13

MEMBERS

13. Is stable only at very high temperatures an is of

non practical significance in engineering.

A. Alpha ferrite

B. Curie temperature

C. Hypoeutictoid

D. Delta ferrite

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

14

MEMBERS

14. The graphite in this structure is in the form of

short,thick,and interconnected flakes having

undulating surfaces and round extremities

A. Pearlitic malleable iron

B. Compacted Graphite iron

C. Nodular cast iron

D. White cast iron

The answer is: b

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

15

MEMBERS

15. The capability of an alloy to be hardened by

heat treatment is called:

A. Retained austenite

B. Mechanical properties

C. Tempering

D. Hardenability

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

16

MEMBERS

16. This is a precipitation hardening treatment for a

special group of high strength iron base alloys

A. Artificial aging

B. Natural Aging

C. Cryogenic treatment

D. Maraging

The answer is: d

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

17

MEMBERS

17. Is the term applied to the annealing of ferrous

alloys, generally low and medium carbon steels

A. Full annealing

B. Normalizing

C. Process annealing

D. Stress relief annealing

The answer is: a

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

18

MEMBERS

18. Hot forgings and hot steel-mill products have a

____ as a result m they may not respond

successfully to heat treatment

A. Continuous furnaces

B. Salt bath furnace

C. Fluidized beds

D. Decarburized skin

The answer is: d

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

19

MEMBERS

19. Limestone combines with the impurities and

form a:

A. Flux

B. To flow as fluid

C. Fuel for plant operations

D. Slag

The answer is: d

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

20

MEMBERS

20. Steel may also be melted in induction furnace

from which the air has been removed. Because the

process removes gaseous impurities from the

molten metal, vacuum melting produces high

quality steels

A. Vacuum furnace

B. Continuous casting

C. Ingots

The answer is: D

D. Soaking pits

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

21

MEMBERS

21. Improve toughness, hardenability, wear and

corrosion resistance, and high temperature

strength; it increases the depth of hardness

penetration resulting from the heat treatment, by

promoting carburization.

A. Chromium

B. Cobalt

C. Copper

The answer is: A

D. Lead EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

22

MEMBERS

22. The latest numbering system for all metals has

been developed cooperatively by several

organizations; it is know as the:

A. Unified Numbering Systems (UNS)

B. AISI

C. ASTM

D. SAE

The answer is: a

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

23

MEMBERS

23. They are non magnetic and have excellent

corrosion resistance, but they are susceptible to

stress corrosion cracking

A. Austenitic stainless steels

B. Ferritic stainless steels

C. Martensitic stainless steels

D. Precipitation hardening stainless steels

The answer is: a

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

24

MEMBERS

23. They are commonly used for forming and

machining of metals

A. Tool and die steels

B. High speed steels

C. Molybdenum and tungsten

D. M series

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

25

MEMBERS

25. Good strength and resistance to corrosion at

elevated temperatures: can be iron, cobalt and

nickel base

A. Superalloys

B. Titanium

C. Refractory materials

D. Precious metals

The answer is: a

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

26

MEMBERS

26. Can also be used as a solid lubricant in hot

metal forming operations

A. Pure copper

B. lead

C. tin

D. oil

The answer is: a

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

27

MEMBERS

27. Are used in high-temperature applications,

such as jet engine components, rockets, and

nuclear power plants, in food handling and

chemical processing equipment, in coins, and in

marine applications

A. Nickel

B. Superalloys

C. Nickel alloys

The answer is: c

D. Monel EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

28

MEMBERS

28 Are important in high-temperature applications.

A. Nichrome

B. Sulfide and oxide ores

C. Superalloys

D. Monel k500

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

29

MEMBERS

29. The main source of molybdenum is the:

Dislocations

A. Molybdenum

B. Titanium and Zirconium

C. Mineral molybdenite

D. Niobium

The answer is: c

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

30

MEMBERS

30. An alloy of antimony and tin

A. Unalloyed berylium

B. Zirconium

C. Lead

D. Zinc

The answer is: c

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

31

MEMBERS

31. Is soft and ductile, and it has good corrosion

resistance at any temperature.

A. Cassiterite

B. Pewter

C. Gold, silver and platinum

D. Gold

The answer is: d

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

32

MEMBERS

32. Only carbon and hydrogen atoms are involved.

A. Ethylene

B. Acetylene

C. Polyethylene

D. Polymers

The answer is: c

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

33

MEMBERS

33. Plastics that do not burn:

A.Plasticizers

B. Fillers

C.Fluorocarbons

D.Lubricants

The answer is: c

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

34

MEMBERS

34. Have excellent mechanical and electrical

properties, and good dimensional stability, strong

adhesive properties and good resistance to heat

and chemicals.

A. Alkyds

B. Aminos

C. Epoxies

D. Phenolics

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

35

MEMBERS

35. A group of crystalline minerals consisting of inum

silicates plus potassium, calcium, or sodium

A. Corundum or emery

B. Flint

C. Feldspar

D. Alumina

The answer is: c

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

36

MEMBERS

36. The most common form of silica is

A.Diamond

B.Quartz

C. Silicates

D.High speed steel

The answer is: b

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

37

MEMBERS

37. Poisson's ratio of glass is from

A. 0.16 to 0.28

B. 0.16 to 0.30

C. 0.16 to 0.32

D. 0.16 to 0.34

The answer is: a

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

38

MEMBERS

38. Is a function of the volume of a casting and its

surface area

A. Solidification time

B. Shrinkage

C. Microporosity

D. Pickling

The answer is: a

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

39

MEMBERS

39. Fibers has elastic modulus of:

A. 35 Gpa to 600

B. 35 Gpa to 700 Gpa

C. 35 Gpa to 800 Gpa

D. 36 Gpa to 900 Gpa

The answer is: c

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

40

MEMBERS

40. Are another important development in

engineering materials because of their resistance

to high temperatures and corrosive environments.

A. Formica

B. Epoxies

C. Reinforced plastic

D. Ceramic matrix

The answer is: d

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

41

MEMBERS

41. Used to describe the one with which a metal

can be cast to obtain a part with good quality

A. Aspiration

B. Choke

C. Castability

D. Spiral mold

The answer is: c

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

42

MEMBERS

42. Clay is also known as

A. Silica sand

B. Collapsibility

C. Mulling machine

D. Bentonite

The answer is: d

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

43

MEMBERS

43. Are a popular type of mounted pattern in which

two-piece patterns are constructed by securing

each half of one or more split patterns to the

opposite side o the single plate

A. Parting agent

B. Split patterns

C. One-piece pattern

D. Match-plate patterns

The answer is: d

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

44

MEMBERS

44. Defined as the difference between the initial

and final thickness.

A. Draft

B. Back tension

C. Front tension

D. Steckel rolling

The answer is: a

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

45

MEMBERS

45. Temper rolling is also known as:

A. Wire rods

B.Cold rolling

C.Pack rolling

D.Skin pass

The answer is: d

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

46

MEMBERS

46. The diameter and thickness of tubes and pipes

can be reduced by

A. Mannesmann process

B. Tube rolling

C. Pilgermill

D. Osprey process

The answer is: b

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

47

MEMBERS

47. Essentially is a closed-die forging process

typically used in minting coins, medallions, and

jewelry.

A. Blocking

B. Flashless

C. Coining

D. Sizing

The answer is: c

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

48

MEMBERS

48. Are necessary in almost all forging dies, in order

to facilitate the removal of the part from the die.

A. Tube swaging

B. Parting line

C. Draft angles

D. Forgeability

The answer is: c

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

49

MEMBERS

49. Coaxial billets are extruded together, provided

that the strength and ductility of the two metals are

compatible.

a. Coaxing extrusion of cladding

B. Square dies

C. Hot extrusion

d. Glass

The answer is: a

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

50

MEMBERS

50. Die cutting is a shearing process that consists of

the following operations:

A.Perforating

B. parting

C. notching and lancing,

D. All of these

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

51

MEMBERS

51. Consisting of two or more pieces of flat sheet

metal butt-welded together, these are becoming

increasingly important particularly to the

automotive industry.

A.Subpress dies

B. Tailor-Welded blanks

C. Compound dies

D. Progressive dies The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

52

MEMBERS

52. This process, plates are bent using a set rolls. By

adjusting the distance between the three rolls, various

curvatures can be obtained.

A.Bending

b. Anisotropy

C. Roll bending

d. Bending in a 4-slide machine

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

53

MEMBERS

53. Is a press working process in which raised

lettering or other designs are impressed in sheet

material.

A.Drawbeads

B. Ironing

C. Redrawing

D. Embossing

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

54

MEMBERS

54. Has been widely used for ease of tool and

workpiece accessibility.

A.Laser-assisted forming

B. Electrohydraulic forming

C. Honeycomb structure

D. C-frame

The answer is: d

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

55

MEMBERS

55. An important development is the use of performed

and sintered alloy powder compacts, which are

subsequently cold or hot forged to the

desired final shapes.

A. Pressureless compaction

B. Sintering

C. Coining and sizing

D. Impact forging

The answer is: d

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

56

MEMBERS

56. Shallow dish-shaped or highly embossed glass

parts can be made by:

A.Blowing

B. Pressing

C. Spinning

D. Sagging

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

57

MEMBERS

57. Is a measure how thick the chip has become

compared to the depth of cut.

A.Chips

B. Cutting-off

C. Slab-milling

D. Chip compression ratio

The answer is: d

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

58

MEMBERS

58. Is the term used to describe the breaking away of

a small piece from the cutting edge of the tool, a

phenomenon similar to breaking the tip of a sharp

pencil.

A.Flank wear

B. Crater wear

C. Chipping

D. Mechanical shock and Thermal fatigue

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

59

MEMBERS

59. Ceramics are sintered at about:

A.1600°F

B. 1700°F

C. 1800°F

D. 1900°F

The answer is: c

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

60

MEMBERS

60. Has higher wear resistance than tungsten

carbide but is not as tough.

À Tungsten carbide

B. titanium carbide

C. Carbide

D. Diamond

The answer is: b

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

61

MEMBERS

61. If the tool is fed at 90° to the axis of rotation tool

that is wider than the width of the cut, the using a tool

the is operation is called:

A.Turning

B. Facing

G. Form tools

D. Boring

The answer is: b

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

62

MEMBERS

62. Supports all major components of the lathe.

A.Lathes

B. Engine lathe

C. Engine lathe

D. Bed

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

63

MEMBERS

63. Actuated pneumatically of hydraulically, are used

in automated equipment for high production rates,

including loading of parts using industrial robots.

A.Three-jaw chuck

B. Four-jaw chuck

C. Power chucks

D. Collet chuck

The answer is: c

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

64

MEMBERS

64. Are also available for cutting straight or tampered

screw threads.

A. Screw thread

B. Tapered threads

C. Tapping

D. Solid threading dies

The answer is: d

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

65

MEMBERS

65. is done to provide a smooth bearing are on an

otherwise rough surface at the opening of a hole

and normal to its axis.

A. Counterboring’

B. Countersinking

C. Spot facing

D. Reaming

The answer is: c

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

66

MEMBERS

66. Are for tapping blind holes to their full depth.

A.Finishing reamers

B. Tap

C. Tapered taps

D. Bottoming taps

The answer is: d

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

67

MEMBERS

67. Produces curved profile, uses cutters that have

specially shaped teeth; such cutters are also used for

cutting gear teeth.

A.End milling

B. Straddle milling

C. Form milling

D. Circular cutters

The answer is:c

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

68

MEMBERS

68. Is similar to shaping with multiple teeth and is

used to machine internal and external surfaces, such

as holes of circular, square, or irregular section.

A.Planning

B. Shaping

C. Slotters or Vertical shapers

D. Broaching

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

69

MEMBERS

69. Is very commonly used particularly in large

cross section

A. Cold sawing

B. Band saws

C. Friction sawing

D. Filling

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

70

MEMBERS

70. Is a function of the dimensions and geometry of

the structural components and the elastic modulus of

the material.

A. Granite-epoxy composite

B. Stillness

C. Resin bonding

D. Force vibration

The answer is: b

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

71

MEMBERS

71. The most flexible bond used in abrasive wheels.

A.Reinforced wheels

B. Rubber

C. Grinding

D. Exothermic reactions

The answer is: b

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

72

MEMBERS

72. These process erode away very thin layers of

the metal bond, exposing new diamond cutting

edges

A. Diamond point tool

B. Star shaped steel disk

C. Electrical charge and electrochemical

D. Crush dressing

The answer is: c

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

73

MEMBERS

73. Tapered pieces are centerless ground by:

A.Infeed grinding

B. End-feed grinding

C. Universal tool and cutter grinders

D. Tool-post grinders

The answer is: b

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

74

MEMBERS

74. The workpiece is held against a circular wire

brush that rotates at high speed.

A.Sandpaper and emery cloth

B. Belt grinding

C. Wire brushing process

D. Honing

The answer is: c

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

75

MEMBERS

75. Also called photoetching, is a modification of

chemical milling.

A.Chemical machining

B. Chemical milling

C. Chemical blanking

D. Photochemical blanking

The answer is: d

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

76

MEMBERS

76. Involves the generation and manipulation of

structures with characteristic lengths less than 1 um.

A. Plasma-arc cutting

B. Abrasive water-jet machining

C. Abrasive-jet machining

D. Nanofabrication

The answer is: d

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

77

MEMBERS

77.Has the advantage of being relatively simple and

versatile and of requiring a small variety of electrodes

A.SMAW process

B. Submerged arc welding

C. Metal Inert Gas (MIG) welding

D. Spray transfer

The answer is: a

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

78

MEMBERS

78. Is used for a wide variety of metals and

applications, particularly aluminum, magnesium,

titanium, and other refractory materials.

A.Electroslag Welding

B. Tungsten electrode

C. TIG welding

D. GTAW process

The answer is: d

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

79

MEMBERS

79. Is widely used for fabricating sheet metal parts.

A.Friction Stir welding

B. Resistance welding

C. Resistance spot welding

D. Spot welding

The answer is: d

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

80

MEMBERS

80. Develop after the weld metal has solidified.

A.Hot cracks

B. Cold cracks

C. Lamellar tears

D. Residual stresses

The answer is: b

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

81

MEMBERS

81. Is carried out in a furnace where, with a proper

control of temperature and time, the filler metal

diffuses into the laying surfaces of the components

to be joined

A. Diffusion brazing

B. braze welding

C.Soldering

D.Capillary action

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

82

MEMBERS

82.Adhesive such as sodium silicate and

magnesium oxychloride.

A.Inorganic adhesive

b. Synthetic organic adhesives

C. Chemically reactive

D. Pressure sensitive

The answer is: a

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

83

MEMBERS

83 Are random Irregularities, such as scratches,

cracks, holes, depressions, seams, tears, or

Inclusions

A.Flaws

B. Lay

C. Roughness

D. waiveness

The answer is: a

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

84

MEMBERS

84. The abrasive wear resistance of pure metals

and ceramics is directly proportional to their:

A. Abrasive wear

B. Hardness

C. Corrosive wear

D. Fatigue wear

The answer is: b

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

85

MEMBERS

85. This process is used on various flat or conical

surfaces.

A.Roller bushing,

B. Ballizing

c. Explosive hardening

D. Cladding

The answer is:a

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

86

MEMBERS

86. Is used in copper-plating aluminum wire and nolic

boards for printed circuits, chrome plating of

hardware.

A.Chemical vapour deposition

B. Ion implant

c. Diffusion coating

D. Electroplating

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

87

MEMBERS

87. The stress at which a low or medium carbon steel

undergoes a marked elongation without an increase

in load is called the:

A.Ultimate stress

B. Yield strength

C. Yield point

D. Elastic limit

The answer is: b

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

88

MEMBERS

88. Is one in which a specimen, supported at both

ends as a simple beam, is broken by the impact of a

falling pendulum.

A. Anisotropy

B. Brittleness

C. Charpytest

D. Cold shortness

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

89

MEMBERS

89. Non-killed steel is

A.Killed steel

B. Rimmed steel

C. Machinability

D. Malleability

The answer is: b

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

90

MEMBERS

90. It is measured by the modulus of elasticity in

the elastic range

A.Solution Heat Treatment

B. Stiffness

C. Strain Hardening

D. Temper

The answer is: b

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

91

MEMBERS

91. Is a reheating of hardened or normalized steel to

a temperature below the transformation range,

followed by any desired rate of cooling.

A.Spheroidizing

B. Stress Relieving

C. Tempering

D. Transformation range

The answer is: C

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

92

MEMBERS

92. Plain Carbon steels

A.10XX

B. 11XX

C. X13XX

D. T13XX

The answer is: a

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

93

MEMBERS

93. Chromium Vanadium steel

A.6XXX

B. 7XXX

C. 8XXX

D. 9XXX

The answer is: A

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

94

MEMBERS

94. Medium - chromium

A.46XX

B. 48XX

C. 50XX

D. 51XX

The answer is: d

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

95

MEMBERS

95.Ordinarily heat treated to hardness between

375 and 500 Brinell, for use as springs, wear

resisting parts.

A.High-carbon Alloy Steels

B. High Alloy Steels

C. Aluminum

D. Boron

The answer is: a

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

96

MEMBERS

96. Increases hardenability marked in small amounts

and improves hardness and strength at high

temperature.

A.Titanium

B. Tungsten

C. Vanadium

D. Austenetic manganese

The answer is: b

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

97

MEMBERS

97. Is the capacity of steel to through-harde

d from above its transformation range.

A.Case hardening

B. Hardenability

C. Carburizing

D. rack and gas carburizing

The answer is: b

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

98

MEMBERS

98. Is the result of a metal being stressed at some

point into its plastic rango, usually ordinary

temperature

A. Carbonitriding

B. Induction Hardening

C. Flame Hardening

D.Work Hardening

The answer is: D

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

99

MEMBERS

99. However, many steel castings with carbon

are used in the as-cast condition

A.less than 0.10

B. less than 0.20

C. loss than 0.30

D. loss than 0.40

The answer is: b

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

100

MEMBERS

100. Condenser and other heat-exchanger tubes and

plates

A. Admiralty metal

B. Aluminum Bronze

C. Beryllum Copper

D. Cartridge Brass

The answer is: a

EXCLUSIVE ONLY TO ES MECHANICAL ENGINEERING REVIEW

101

MEMBERS

You might also like

- ExamsGrade API-571 Exam Questions AnswersDocument10 pagesExamsGrade API-571 Exam Questions AnswersLamont Bauch100% (6)

- Machine Design TermsDocument301 pagesMachine Design Termsitsmechelle100% (1)

- Material Disasters Nik ChawlaDocument57 pagesMaterial Disasters Nik ChawlaFirzana AmiraNo ratings yet

- Part 7 - Materials and Manufacturing ElementsDocument101 pagesPart 7 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 1 - Materials and Manufacturing ElementsDocument101 pagesPart 1 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 2 - Materials and Manufacturing ElementsDocument101 pagesPart 2 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 3 - Materials and Manufacturing ElementsDocument101 pagesPart 3 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 9 - Materials and Manufacturing ElementsDocument101 pagesPart 9 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 10 - Materials and Manufacturing ElementsDocument101 pagesPart 10 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Test 5Document5 pagesTest 5John Michael JucdongNo ratings yet

- Test 1Document5 pagesTest 1John Michael JucdongNo ratings yet

- Machine Shop Practice Reviewer 1Document15 pagesMachine Shop Practice Reviewer 1Ruth LauronNo ratings yet

- Machine Shop Practice Reviewer 2Document7 pagesMachine Shop Practice Reviewer 2Ruth LauronNo ratings yet

- Test 2Document3 pagesTest 2John Michael JucdongNo ratings yet

- Test 4Document5 pagesTest 4John Michael JucdongNo ratings yet

- 5Document36 pages5Mari CarNo ratings yet

- MDSP ElementsDocument71 pagesMDSP ElementsFernan MacusiNo ratings yet

- Machine Shop Practice Reviewer 3Document11 pagesMachine Shop Practice Reviewer 3Ruth LauronNo ratings yet

- Test 3Document6 pagesTest 3John Michael JucdongNo ratings yet

- 1 API 571 Exam QuestionsDocument10 pages1 API 571 Exam Questionskorichi100% (1)

- 6Document16 pages6Mari CarNo ratings yet

- Part 5 - Pipe Terms ContiDocument157 pagesPart 5 - Pipe Terms ContiJay Mark Cayonte100% (1)

- MDSP Elements Part 1Document101 pagesMDSP Elements Part 1Kira YagamiNo ratings yet

- API 571 DemoDocument9 pagesAPI 571 Demoمبشر أحمد100% (1)

- API-571 Mockup Test-02-QuestionsDocument12 pagesAPI-571 Mockup Test-02-QuestionsMetzer LLC100% (1)

- Terms - Engineering-MaterialsDocument11 pagesTerms - Engineering-Materialsskz linoNo ratings yet

- API 571 QuizDocument28 pagesAPI 571 Quizmohamed100% (2)

- Test 1Document30 pagesTest 1Mari CarNo ratings yet

- TRB Test MachinesDocument3 pagesTRB Test MachinessivakumarNo ratings yet

- Aircraft Materials Class Test 1 & 2Document5 pagesAircraft Materials Class Test 1 & 2SeanRiniFernandoNo ratings yet

- 1000 ElementsDocument42 pages1000 ElementsAeron AntonioNo ratings yet

- Api 571Document41 pagesApi 571majid100% (1)

- Multi Choice - Paper - CSWIP 3.1 - 00Document19 pagesMulti Choice - Paper - CSWIP 3.1 - 00miteshNo ratings yet

- MD Elements1Document22 pagesMD Elements1Ben LopezNo ratings yet

- Section 5Document22 pagesSection 5annexe gameNo ratings yet

- Api - 571 - Q&a - 407Document28 pagesApi - 571 - Q&a - 407guruNo ratings yet

- Test 6Document21 pagesTest 6Mari CarNo ratings yet

- Sec 1Document16 pagesSec 1annexe gameNo ratings yet

- IMP Probable CIE QuestionsDocument11 pagesIMP Probable CIE QuestionsJustine Kyla OlivarNo ratings yet

- Machine-Design TermsDocument183 pagesMachine-Design TermsQuinxxNo ratings yet

- TestDocument51 pagesTestNiaz KilamNo ratings yet

- Mockup - Questions - Test - 4 - For API 571Document12 pagesMockup - Questions - Test - 4 - For API 571Metzer LLC100% (1)

- Heat Treatment 434445Document28 pagesHeat Treatment 434445Dev ThakorNo ratings yet

- Api 570 240-402Document52 pagesApi 570 240-402NIMANo ratings yet

- Cswip 3.2 Q&aDocument3 pagesCswip 3.2 Q&aMoses_Jakkala100% (3)

- and 68070 S2012 Final v2 No AnswersDocument42 pagesand 68070 S2012 Final v2 No AnswersZadrin TuckerNo ratings yet

- Corrosion QDocument10 pagesCorrosion Qkihal zohirNo ratings yet

- Test No 4ccDocument4 pagesTest No 4ccSalman GhaffarNo ratings yet

- Chemical-Engineering-Basics Section 1-9Document34 pagesChemical-Engineering-Basics Section 1-9NOELA PATALANNo ratings yet

- Test 2Document11 pagesTest 2Mari CarNo ratings yet

- Multichoice Paper OneDocument4 pagesMultichoice Paper OneAhmed ShakirNo ratings yet

- Practice Problems 8 Engineering MaterialsDocument6 pagesPractice Problems 8 Engineering MaterialsJayve BasconNo ratings yet

- MATERIALDocument13 pagesMATERIALnhut.nguyenbocoffee38No ratings yet

- Module 6 MCQDocument68 pagesModule 6 MCQlipibhaiNo ratings yet

- API-571 Mockup Test-01-QuestionsDocument13 pagesAPI-571 Mockup Test-01-QuestionsMonday100% (1)

- Wa0084Document33 pagesWa0084miteshNo ratings yet

- Sec 8Document21 pagesSec 8annexe gameNo ratings yet

- Machine Design Examination 19Document4 pagesMachine Design Examination 19SYBRELLE CRUZNo ratings yet

- Shielded Metal Arc Welding NC Ii 3 Final ExaminationDocument2 pagesShielded Metal Arc Welding NC Ii 3 Final ExaminationJessa AquitanNo ratings yet

- CompreDocument4 pagesCompreSiddhant KatariaNo ratings yet

- Mechanic and Dielectric Properties: Advances in Research and DevelopmentFrom EverandMechanic and Dielectric Properties: Advances in Research and DevelopmentMaurice H. FrancombeNo ratings yet

- Part 9 - Materials and Manufacturing ElementsDocument101 pagesPart 9 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 10 - Materials and Manufacturing ElementsDocument101 pagesPart 10 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 7 - Materials and Manufacturing ElementsDocument101 pagesPart 7 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 3 - Materials and Manufacturing ElementsDocument101 pagesPart 3 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 2 - Materials and Manufacturing ElementsDocument101 pagesPart 2 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Part 1 - Materials and Manufacturing ElementsDocument101 pagesPart 1 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Multiple Choice Quiz For Groover BookDocument36 pagesMultiple Choice Quiz For Groover BooktitanfallkillofweekNo ratings yet

- ASME IIC SFA5.16 - TiDocument10 pagesASME IIC SFA5.16 - TitragaldabasNo ratings yet

- 004aisi4140 - 105KDocument4 pages004aisi4140 - 105Ksundaramoorthy kamanNo ratings yet

- ASTM A789A789M - pdqv6897Document4 pagesASTM A789A789M - pdqv6897Nayth Andres GalazNo ratings yet

- Wagner, Karl Edward - Gothic TouchDocument14 pagesWagner, Karl Edward - Gothic TouchmartynekNo ratings yet

- C Purlin Data SheetDocument6 pagesC Purlin Data SheetAkhil VNNo ratings yet

- Process Planning AssimentDocument9 pagesProcess Planning Assimentዮሐንስ ታደሰNo ratings yet

- Introduction To Stainless SteelDocument19 pagesIntroduction To Stainless Steelkrishna chiruNo ratings yet

- Wires For Submerged Arc Welding of Creep Resistant Steels: Copper Coated Low Alloy Steel Solid WiresDocument6 pagesWires For Submerged Arc Welding of Creep Resistant Steels: Copper Coated Low Alloy Steel Solid WiresDeepak BhatiNo ratings yet

- Valve Standards ANSI BS APIDocument6 pagesValve Standards ANSI BS APIBenysetiyawanNo ratings yet

- Krishna Engineering College Department of Mechanical EngineeringDocument4 pagesKrishna Engineering College Department of Mechanical EngineeringVivek BajpaiNo ratings yet

- Asme Section Ii A-2 Sa-995Document4 pagesAsme Section Ii A-2 Sa-995Anonymous GhPzn1xNo ratings yet

- MQ SP P 5024Document16 pagesMQ SP P 5024jaseel kNo ratings yet

- Hardness Examination StandardDocument3 pagesHardness Examination StandardMohd Akmal Shafie100% (1)

- 2 Catalouge-1 PDFDocument43 pages2 Catalouge-1 PDFArif TandraNo ratings yet

- Astm e 2016 WireDocument29 pagesAstm e 2016 WireDavid KlinkenbergNo ratings yet

- Soporte Silleta Con Abrazadera UDocument1 pageSoporte Silleta Con Abrazadera UPaola LopezNo ratings yet

- Conductivity and Resistivity Values For Iron & AlloysDocument6 pagesConductivity and Resistivity Values For Iron & AlloysrexNo ratings yet

- Lecture 1 - Types of Materials and Its ClassificationDocument32 pagesLecture 1 - Types of Materials and Its ClassificationShakeel AhmadNo ratings yet

- Hec Project ReportDocument30 pagesHec Project ReportSudhanshu KumarNo ratings yet

- Presentation - JOINERY HARDWAREDocument159 pagesPresentation - JOINERY HARDWAREKeya JainNo ratings yet

- RM01 - 23 Case Study Friction Stir WeldingDocument49 pagesRM01 - 23 Case Study Friction Stir WeldingAnonymous cgcKzFtXNo ratings yet

- PHSS-ES-5096 Valve SpecificationDocument268 pagesPHSS-ES-5096 Valve SpecificationAfif FadhliNo ratings yet

- List of IndustryDocument14 pagesList of Industrybokul1No ratings yet

- Solid and Flux Cored Welding WiresDocument29 pagesSolid and Flux Cored Welding WiresAli TalebiNo ratings yet

- Astm A681 08 2022Document7 pagesAstm A681 08 2022sridevi72.puppalaNo ratings yet

- Soldering, Brazing and Braze Welding: Ag Metals I Welding Principles & ApplicationsDocument51 pagesSoldering, Brazing and Braze Welding: Ag Metals I Welding Principles & ApplicationsAd Man GeTigNo ratings yet

- Rolling MillsDocument11 pagesRolling MillsSudhir KumarNo ratings yet

- In General, The MIG/MAG Mode of Transfer Best Suited For Welding Thick Sheet Is Spray TransferDocument4 pagesIn General, The MIG/MAG Mode of Transfer Best Suited For Welding Thick Sheet Is Spray TransferLe TuanNo ratings yet