Professional Documents

Culture Documents

DM Plant

DM Plant

Uploaded by

Awaiz Khan0 ratings0% found this document useful (0 votes)

63 views16 pagesThe document describes a visit to a de-mineralization water plant. It discusses how the plant removes impurities from raw water through various ion exchange processes to produce purified water. Major equipment in the plant includes filters, cation exchange units, anion exchange units, and storage tanks. The ion exchange process works by trapping cations on resin in cation units and anions on resin in anion units. Calculations are shown for ionic load and throughput of one of the cation units.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes a visit to a de-mineralization water plant. It discusses how the plant removes impurities from raw water through various ion exchange processes to produce purified water. Major equipment in the plant includes filters, cation exchange units, anion exchange units, and storage tanks. The ion exchange process works by trapping cations on resin in cation units and anions on resin in anion units. Calculations are shown for ionic load and throughput of one of the cation units.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

63 views16 pagesDM Plant

DM Plant

Uploaded by

Awaiz KhanThe document describes a visit to a de-mineralization water plant. It discusses how the plant removes impurities from raw water through various ion exchange processes to produce purified water. Major equipment in the plant includes filters, cation exchange units, anion exchange units, and storage tanks. The ion exchange process works by trapping cations on resin in cation units and anions on resin in anion units. Calculations are shown for ionic load and throughput of one of the cation units.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 16

INDUSTRIAL VISIT/

TRAINING

(CHC-4910)

Study of De-Mineralization

Water Plant

Presented by – Arohi Shandilya

B.Tech. 4th year Chemical Engineering

Faculty No. – 19CHB081

Enrollment No. – GK1255

Serial No. - 02

CONTENTS:

• Introduction

• De-Mineralization Water Plant (DM Plant)

• Purpose of DM Plant

• Major Equipments

• Process of DM Plant

• Ion-Exchange Mechanism

• Calculations of Ionic load and Throughput

INTRODUCTION

There are ten divisions under Offsite and

Utilities – 7. Effluent Treatment Plant

1.Fire and Safety

8. Ammonia Storage

2.Captive Power Steam Generation Plant

9. Main Flare Stack

3.De-Mineralisation Plant

10. Distributed Control System

4.Cooling Water System

5.Instrument Air Plant

6.Inert Gas Generation Plant

DE-MINERALIZATION WATER PLANT

• The Fresh Water contains various impurities such as

• SUSPENDED SOLIDS: Debris, Dust & Dirt, Organic matter, Turbidity.

• DISSOLVED SOLIDS: Cations, Anions, Colloids.

• GASES: CO2, O2, NH3, H2S.

• These impurities results in corrosive and scaling nature of water, which is harmful for

any process equipment in plant.

• DM Water Plant ensure removal of total suspended solids, total dissolved solids, gases

and other materials (as oil and organic matters) from water and produces pure water

(polished water) through ion exchange process.

DM Plant

PURPOSE OF DM PLANT

• To Produce Polished Water For The Entire Complex @ 500 M³/hr, used as Boiler

Feed Water for Steam Generation as well as for Quenching and Process Flushing.

• DM water is supplied to steam generating units and process plants. The boiler feed

water’s total dissolved solids must be less than 0.02ppm.

• Low pH or dissolved oxygen in the water attacks the steel. This causes pitting or

lowering the thickness of the steel tubes, leading to rupture of the boiler tubes.

• Impurities carried over in the steam, causing deposits on turbine blades leading to

reduced turbine efficiency, high vibrations, and blade failure.

MAJOR EQUIPMENTS

• Two Pressure Sand Filters ( 2 X 150 m^3/Hr)

• Three Cation Units ( 3 X 150 m^3 /Hr)

• Four Anion Units ( 4 X 150 m^3 /Hr)

• Four Condensate Cation Units ( 4 X 120 m^3 /Hr)

• Five Mixed Bed Units ( 5 X 200 m^3 /Hr)

• Two Degassed Towers

MAJOR EQUIPMENTS

Intermediate Storage Tanks :

• FWST Filter water storage tank

• SWST Service water storage tank

• DGST Degassed water storage tank

• PCST Process condensate water storage tank

• DMST Demineralized water storage tank

• PWST Polish water storage tank

PROCESS OF DM PLANT

PROCESS OF DM PLANT

• Raw water, from raw water ring header, passes through the pressure sand filters

where total suspended solids (as debris, dust & dirt, silt, sand, mud) get removed.

• . Filtered raw water get stored in Filtered Raw Water Storage Tank & Service Water

Storage Tank. Service Water Storage Tank supplies water as drinking water in plant

& as plant cleaning water i.e., service water.

• Filtered Water Storage Tank supplies water to Cation units (WAC and SAC) where

Calcium ions, Magnesium ions, Sodium ions, Potassium ions & other cation traces

are removed from water.

• The outlet water, then passes through Degassed Tower where carbon dioxide gets

removed from water and processed water gets stored in Degassed Water Storage

Tank.

• Degassed Water Storage Tank supplies water to Anion units (WBA and SBA), where

Sulphate ions, Chloride ions, Nitrate ions, Bi-carbonate ions, reactive silica ions are

removed. The outlet water gets stored in De-Mineralised Storage Tank.

PROCESS OF DM PLANT

• In Demineralised storage tank, turbine condensate from process plants also

gets stored. De-Mineralised Storage tank supplies water to Mixed Bed for

further purifying and Mixed Bed’s outlet water gets stored in Polished Water

Storage Tank as polished water.

• Process condensate water and Steam condensate water get stored in Process

Condensate Storage Tank and this water after passing through Activated

carbon filters & Process Condensate Cation Units gets stored in Degassed

Water Storage Tank

ION-EXCHANGE MECHANISM

• As water passes through Weak Acid Cation unit, Ca, Mg and Fe ions are trapped in the

resin bed and H ions are released. The reaction is given below:

Ca&Mg(HCO3)2 + 2RH R2Ca&Mg + 2H2O + 2CO2

• In Strong Acid Cation unit, Na and K ions are trapped in resin bed along with bivalent

cations (Ca, Mg etc.) and H ions are released. The reactions are as follows:

NaCl + RH RNa + HCl

Na2SO4 + 2RH 2RNa + H2SO4

ION-EXCHANGE MECHANISM

• In Weak Base Anion Unit, SO4, Cl and NO3 ions replace the resin’s OH functional group. The

reactions are follows:

H2SO4 + 2ROH R2SO4 + 2H2O

HCl + ROH RCl + H2O

HNO3 + ROH RNO3 + H2O

• In Strong Base Anion Unit, HCO3 and HSiO3 ions are caught in resin bed along with other

anions. The reactions are given below:

H2CO3 + ROH RHCO3 + H2O

H2SiO3 + ROH RHSiO3 + H2O

• The reactions involved in Process Condensate Cation unit are as follows:

KOH + RH RK + H2O

(NH4)OH + RH RNH4 + H2O

CALCULATIONS

For Weak Acid Cation Unit (WAC) :

Raw water analysis gives the following result:

Calcium hardness as CaCO3 = 105 ppm

Magnesium hardness as CaCO3 = 95 ppm

Sodium hardness as Na = 155 ppm

Potassium as K = 6 ppm

Total iron as Fe = 0.15 ppm

Now, all parameters are calculated in ppm as CaCO3.

Sodium as CaCO3 = ppm of Na*equivalent weight of CaCO3/ Eq. wt. of Na

= 155*50/ 23

= 336.96 ppm

CALCULATIONS

Similarly, Potassium as CaCO3 = 6*50/39 = 7.69 ppm

Iron as CaCO3 = 0.15*50/28 = 0.268 ppm

Ionic load on WAC = Ca + Mg + Fe

= 105 + 95 + 0.268 ppm

= 200.268 ppm as CaCO3

Resin volume in WAC = 8 m3

Exchange Capacity of resin = 200 kg as CaCO3/ m3 of resin volume

Regeneration Efficiency = 70%

CALCULATIONS

Throughput of WAC = Resin volume*Exchange Capacity* Reg. eff.* 1000

Total ionic load (ppm as CaCO3)

= 8*200*0.7*1000

200.268

= 5592.5 m3

You might also like

- FelicityPlansky Hydrite Chemical Co Membrane Forum 2016Document42 pagesFelicityPlansky Hydrite Chemical Co Membrane Forum 2016camadire1584No ratings yet

- 20 Elements of Periodic Table (20EPT)Document6 pages20 Elements of Periodic Table (20EPT)Daksh DevanshNo ratings yet

- SRS (Sulphate Removal System) - Brine Electrolysis - ThyssenKrupp Uhde Chlorine Engineers (Japan) LTDDocument2 pagesSRS (Sulphate Removal System) - Brine Electrolysis - ThyssenKrupp Uhde Chlorine Engineers (Japan) LTDpetros222No ratings yet

- Nouryon. mTA Salt. Electrolysis Salt PDFDocument3 pagesNouryon. mTA Salt. Electrolysis Salt PDFAbigail HernandezNo ratings yet

- Silica Scaling in Water TreatmentDocument5 pagesSilica Scaling in Water TreatmentRais Nur FuadiNo ratings yet

- Water Treatment ChemicalsDocument9 pagesWater Treatment Chemicalsjidi125737No ratings yet

- Thermal Power Plant Water ChemistryDocument33 pagesThermal Power Plant Water ChemistryNAITIK100% (7)

- Water TreatmentDocument27 pagesWater TreatmentEzhil Vendhan Palanisamy100% (1)

- Water Treatment Plant Chemical Safety Presentation Complete Final 1Document21 pagesWater Treatment Plant Chemical Safety Presentation Complete Final 1api-339319779100% (1)

- Process Description DM - 100610 R1Document7 pagesProcess Description DM - 100610 R1balajikrishnanNo ratings yet

- .Water Treatment - O.r.ureteDocument57 pages.Water Treatment - O.r.ureteyogesh100% (2)

- Example For Corporate Presentation Veolia PresentationDocument41 pagesExample For Corporate Presentation Veolia PresentationswordprakashNo ratings yet

- MSDS of Poly Aluminum ChlorideDocument5 pagesMSDS of Poly Aluminum ChlorideGautamNo ratings yet

- Electrochemistry ChloralkaliDocument10 pagesElectrochemistry ChloralkaliAnonymous y7dpcKfKxMNo ratings yet

- Material Safety Data Sheet Material Safety Data SheetDocument3 pagesMaterial Safety Data Sheet Material Safety Data SheetKarthik0% (2)

- Production of Vinyl Chloride Process SelectionDocument58 pagesProduction of Vinyl Chloride Process SelectionAngela Clariz DulaNo ratings yet

- Water TreatmentDocument10 pagesWater TreatmentchristopherNo ratings yet

- SOP For Ammonical NitrogenDocument2 pagesSOP For Ammonical Nitrogendjsp5009No ratings yet

- STP Comparision of ProcessDocument11 pagesSTP Comparision of Processwd100% (1)

- Lecture On Water Treatment Plant: M/S Jindal Power Limited (4X250 MW) Opjstpp, Tamnar, RaigarhDocument41 pagesLecture On Water Treatment Plant: M/S Jindal Power Limited (4X250 MW) Opjstpp, Tamnar, RaigarhPrudhvi RajNo ratings yet

- Sistem SelcopermDocument39 pagesSistem SelcopermGROIIM100% (1)

- Advances in Sidestream Ammonia Removal StrategiesDocument60 pagesAdvances in Sidestream Ammonia Removal Strategiesagagne9503No ratings yet

- Caustic Soda 1Document21 pagesCaustic Soda 1arpit garg100% (1)

- Ammonium SulfateDocument3 pagesAmmonium SulfateXiwen Huang100% (1)

- Need of Boiler Feed Water Treatment - Boiler Water Treatment ProcessDocument14 pagesNeed of Boiler Feed Water Treatment - Boiler Water Treatment ProcessjagjitNo ratings yet

- DomestosDocument6 pagesDomestosJason SmithNo ratings yet

- Applications of Weak Acid Cation Resin in Waste TreatmentDocument9 pagesApplications of Weak Acid Cation Resin in Waste TreatmentSandeep MishraNo ratings yet

- AGC AGC-CHEMICALS - Effect of Impurities On Membrane Performance & Recovery of Performance-Flemion Seminar 2012 PDFDocument59 pagesAGC AGC-CHEMICALS - Effect of Impurities On Membrane Performance & Recovery of Performance-Flemion Seminar 2012 PDFTahir KhalidNo ratings yet

- WWT DisinfectionDocument49 pagesWWT DisinfectionMwemeziNo ratings yet

- Scale Control OverviewDocument22 pagesScale Control OverviewReda Abdel AzimNo ratings yet

- Anaerobic Treatment IBC PDFDocument61 pagesAnaerobic Treatment IBC PDFCarolina Alejandra Sanhueza SandovalNo ratings yet

- Reverse Osmosis in Wastewater ApplicationsDocument24 pagesReverse Osmosis in Wastewater ApplicationsfarooqkhanerNo ratings yet

- Cyanide Treatment TechnologiesDocument3 pagesCyanide Treatment Technologiesdei_sandeep7994No ratings yet

- Sugar IndustryDocument27 pagesSugar IndustryChali HaineNo ratings yet

- Effluent Reuse in Power PlantsDocument29 pagesEffluent Reuse in Power Plantsபிரசன்னகுமார் ஆனந்தன்100% (1)

- Cleaning Procedure-GeneralDocument2 pagesCleaning Procedure-Generalmunawar786100% (1)

- ETP UpgradationDocument7 pagesETP UpgradationYogesh DhekaleNo ratings yet

- Prensentation Slides For Industry BriefingDocument40 pagesPrensentation Slides For Industry BriefingkunalkhubaniNo ratings yet

- Gas Chlorine StationsDocument46 pagesGas Chlorine StationsakramhomriNo ratings yet

- Unit 4-Water TreatmentDocument11 pagesUnit 4-Water Treatmentgopi nath sahuNo ratings yet

- Siemens Water TechnologiesDocument33 pagesSiemens Water TechnologiesmaheshvbendreNo ratings yet

- MSDS - Nitric AcidDocument5 pagesMSDS - Nitric AcidFkr JabarNo ratings yet

- Alum From Scrap AluminiumDocument10 pagesAlum From Scrap AluminiumAnonymous D5g37JjpGBNo ratings yet

- 225 Na Engg DataDocument8 pages225 Na Engg DatadeyprasenNo ratings yet

- Nalco 72215 (GHS)Document8 pagesNalco 72215 (GHS)Waseem SyedNo ratings yet

- Preparation of Bleaching PowderDocument2 pagesPreparation of Bleaching PowderStanleyEzeNo ratings yet

- Test Method For ResinsDocument10 pagesTest Method For ResinsAvoid Be PoorNo ratings yet

- Calculation WWTDocument18 pagesCalculation WWTRafaelNo ratings yet

- Sewage Treatment PlantDocument11 pagesSewage Treatment Plantsewage treatmentplantNo ratings yet

- Where, The Temperature Ratio, Capacity Ratio, R A Value of 0.8 Is Generally Not AcceptedDocument43 pagesWhere, The Temperature Ratio, Capacity Ratio, R A Value of 0.8 Is Generally Not AcceptedAditya DeokarNo ratings yet

- Internship Report NishatDocument30 pagesInternship Report NishatdfdgdgdgNo ratings yet

- MSDS - ACUTHERM 3221 Boiler AntiscalantDocument4 pagesMSDS - ACUTHERM 3221 Boiler AntiscalantBopanna BolliandaNo ratings yet

- 2010 SMR ClarifierDocument60 pages2010 SMR ClarifierRohan Kakde100% (1)

- Product Bulletin - PC-33Document4 pagesProduct Bulletin - PC-33Aymen HentatiNo ratings yet

- OxyChem Caustic Soda HandbookDocument52 pagesOxyChem Caustic Soda HandbookJohn BarryNo ratings yet

- Tannin BasedDocument5 pagesTannin BasedVinod SindhavNo ratings yet

- 19 I Lewatit FO 36 Presentation For Customers ShortDocument31 pages19 I Lewatit FO 36 Presentation For Customers ShortAlfonso José García LagunaNo ratings yet

- GVT-ODIS-SWRO For PBMC PDFDocument35 pagesGVT-ODIS-SWRO For PBMC PDFSwati BhattacharyyaNo ratings yet

- DM PlantDocument35 pagesDM PlantSaurav Shankar100% (3)

- Docslide - Us - Thermal Power Plant Water ChemistryDocument33 pagesDocslide - Us - Thermal Power Plant Water ChemistryHumayun Rashid Khan100% (1)

- Steam Generation in Power PlantsDocument13 pagesSteam Generation in Power PlantsAurenio RibeiroNo ratings yet

- Leather Manufacturing ProcessDocument26 pagesLeather Manufacturing ProcessAwaiz KhanNo ratings yet

- Tib FinalDocument21 pagesTib FinalAwaiz KhanNo ratings yet

- ONGC OverviewDocument15 pagesONGC OverviewAwaiz KhanNo ratings yet

- Fuel CellsDocument18 pagesFuel CellsAwaiz KhanNo ratings yet

- Chemistry MRSM 2008Document73 pagesChemistry MRSM 2008kenwoo1978No ratings yet

- 9 Tausends GoldDocument14 pages9 Tausends GoldGeorge O AmadoNo ratings yet

- GOC AllenDocument27 pagesGOC AllenAshish RanjanNo ratings yet

- Oliveira Pinto Culture of Marine Shrimp (Litopenaeus Vannamei) in Biofloc Technology System Using Artificially Salinized Freshwater ZootechnicalDocument6 pagesOliveira Pinto Culture of Marine Shrimp (Litopenaeus Vannamei) in Biofloc Technology System Using Artificially Salinized Freshwater ZootechnicalAngeloNo ratings yet

- Recycling of Mine Tailings For The Geopolymers P 2022 Case Studies in ConstrDocument22 pagesRecycling of Mine Tailings For The Geopolymers P 2022 Case Studies in ConstrShaker Qaidi100% (1)

- PI - TPROT e 6Document1 pagePI - TPROT e 6NawelNo ratings yet

- Tabel Kimia Additiv SementDocument1 pageTabel Kimia Additiv SementAry RachmanNo ratings yet

- Cefpodoxime 200 Tab New 1Document25 pagesCefpodoxime 200 Tab New 1Gurdev SinghNo ratings yet

- Chemistry Class 11 Part 2Document161 pagesChemistry Class 11 Part 2maupravin1230% (1)

- Jurnal Acute Decompensated Heart FailureDocument4 pagesJurnal Acute Decompensated Heart FailureMayang Sri WulandNo ratings yet

- Act B5 HEAT-GI F2022 Lab ReportDocument7 pagesAct B5 HEAT-GI F2022 Lab ReportLiamNo ratings yet

- NIFLECDocument6 pagesNIFLECRonald Ariyanto WiradirnataNo ratings yet

- United States Patent (10) Patent No.: US 9,375,501 B2Document13 pagesUnited States Patent (10) Patent No.: US 9,375,501 B2Choo Wei shengNo ratings yet

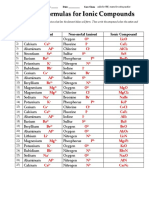

- Core UNIT 4 - Assignment 2 - Writing Formulas For Ionic CompoundsDocument3 pagesCore UNIT 4 - Assignment 2 - Writing Formulas For Ionic CompoundsCrystal R.MNo ratings yet

- Class 11 CH 10 S Block ElementsDocument7 pagesClass 11 CH 10 S Block Elementsإدريس أل أذهري100% (1)

- BioDocument61 pagesBiojustin LimnardyNo ratings yet

- Chemistry Igcse 1 PDFDocument35 pagesChemistry Igcse 1 PDFRohit MITTALNo ratings yet

- Customer letter-PL 2022-Siemens-THCDocument21 pagesCustomer letter-PL 2022-Siemens-THCOlla FitriNo ratings yet

- CEM1008F Test 1 2018Document9 pagesCEM1008F Test 1 2018HopeNo ratings yet

- ALS Malaysia Recommended Holding Times and PreservationsDocument2 pagesALS Malaysia Recommended Holding Times and Preservations'aoe'Lia RahmawatiNo ratings yet

- TitretteDocument8 pagesTitrettejulianNo ratings yet

- Valency: Combining Power of AtomsDocument56 pagesValency: Combining Power of AtomsDaniel PalmerNo ratings yet

- PDS PURELYTHE 103 Na - DW - CPUDocument1 pagePDS PURELYTHE 103 Na - DW - CPUOnie Hammamz OylNo ratings yet

- Atomic AnswersDocument10 pagesAtomic AnswersKelumNo ratings yet

- TG Cheese and Yogurt 012710Document37 pagesTG Cheese and Yogurt 012710Rafael de la Huerta0% (1)

- Chemical List 2018Document6 pagesChemical List 2018Jowie Lica CabaccanNo ratings yet

- Aashto PP 65Document58 pagesAashto PP 65Francisco EscuadraNo ratings yet

- Animal NutritionDocument112 pagesAnimal NutritionJames TongNo ratings yet

- Sampling System Procedimento para A Calibracao de Dissolved-Oxygen-Sensor-Rosemount-En-990776Document28 pagesSampling System Procedimento para A Calibracao de Dissolved-Oxygen-Sensor-Rosemount-En-990776Houston MacazeNo ratings yet