Professional Documents

Culture Documents

20me53i Week6 Day3 Session1

20me53i Week6 Day3 Session1

Uploaded by

raju0 ratings0% found this document useful (0 votes)

21 views7 pagesThe document outlines the 8 stages of the generic additive manufacturing (AM) process:

1) Design, 2) Slicing, 3) Parameter Selection, 4) Build Preparation, 5) Build, 6) Removal, 7) Post Processing, and 8) Application. It provides details on each stage, such as assigning part parameters during the build stage, removing finished parts using cutting tools, and additional treatments sometimes required before parts are ready for use.

Original Description:

Original Title

20ME53I_WEEK6_DAY3_SESSION1

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines the 8 stages of the generic additive manufacturing (AM) process:

1) Design, 2) Slicing, 3) Parameter Selection, 4) Build Preparation, 5) Build, 6) Removal, 7) Post Processing, and 8) Application. It provides details on each stage, such as assigning part parameters during the build stage, removing finished parts using cutting tools, and additional treatments sometimes required before parts are ready for use.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

21 views7 pages20me53i Week6 Day3 Session1

20me53i Week6 Day3 Session1

Uploaded by

rajuThe document outlines the 8 stages of the generic additive manufacturing (AM) process:

1) Design, 2) Slicing, 3) Parameter Selection, 4) Build Preparation, 5) Build, 6) Removal, 7) Post Processing, and 8) Application. It provides details on each stage, such as assigning part parameters during the build stage, removing finished parts using cutting tools, and additional treatments sometimes required before parts are ready for use.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 7

Department of Collegiate and Technical Education

STEPS IN GENERIC AM PROCESS

ADVANCED MANUFACTURING( V Semester)

Mechanical Engineering

Prepared by

SHREEDHAR.S. BANDE

GPT VIJAYAPUR

Advanced Manufacturing– 20ME53I

Steps in Generic AM process

Advanced Manufacturing– 20ME53I

Stage 5: Build

• Part parameters are assigned to each and every component/part

to be build. Multiple sets of part parameters can be used in the

same build on different parts.

• These parameters are taken into account in the slicing process

that takes place in the previous step of the process chain. As a

result, the parameters chosen in the slicer have to correspond to

the actual parameters selected on the AM system.

• Once part parameters are selected the building process, the build

process starts and is controlled and monitored by the AM system

itself.

• Building the part is mainly an automated process and the

machine can largely carry on without supervision. Only

superficial monitoring of the machine needs to take place at this

time to ensure no errors have taken place like running out of

material, power or software glitches, etc.

Advanced Manufacturing– 20ME53I

Stage 6: Removal

• Once the RP machine has completed the build, the parts must be

removed. This may require interaction with the machine, which

may have safety interlocks to ensure for example that the

operating temperatures are sufficiently low or that there are no

actively moving parts.

• Removal of finished part from the build plate typically involves

the use of cutting tools such as band saws, or wire EDM for

higher fidelity and flexibility.

Stage 7: Post processing

• Once removed from the machine, parts may require an amount

of additional cleaning up before they are ready for use. Parts

may be weak at this stage or they may have supporting features

that must be removed. This therefore often requires time and

careful, experienced manual manipulation.

Advanced Manufacturing– 20ME53I

Stage 8: Application

• Parts may now be ready to be used. However, they may also

require additional treatment before they are acceptable for use.

For example, they may require priming and painting to give an

acceptable surface texture and finish. Treatments may be

laborious and lengthy if the finishing requirements are very

demanding

.

Advanced Manufacturing– 20ME53I

REFERENCES

Additive manufacturing of metals by Li yang-Keng Hsu, Donald

Godfrey

Additive manufacturing technology by Ian Gibson, David Rosen

Various sources of internet

Advanced Manufacturing– 20ME53I

Thank you

Advanced Manufacturing– 20ME53I

You might also like

- Safety Standard For Platform Lifts and Stairway Chairlifts: ASME A18.1-2020Document81 pagesSafety Standard For Platform Lifts and Stairway Chairlifts: ASME A18.1-2020Raphael Elvis Lino Calderon100% (1)

- PC40MR-1 Sebm016808Document947 pagesPC40MR-1 Sebm016808George Jhonson89% (28)

- s830 CatalogoDocument7 pagess830 Catalogojuan apazaNo ratings yet

- 20me53i Week6 Day3 Session1Document6 pages20me53i Week6 Day3 Session1rajuNo ratings yet

- Additive Manufacturing and Future of Automated FactoryDocument30 pagesAdditive Manufacturing and Future of Automated FactoryBhramith KNo ratings yet

- AM Need and IntroductionDocument13 pagesAM Need and IntroductionNishant MayekarNo ratings yet

- Additive ManufacturingDocument13 pagesAdditive ManufacturingPrajwal ChatraNo ratings yet

- Explanation On AM StepsDocument3 pagesExplanation On AM StepsSofwan JuewekNo ratings yet

- Group TechnologyDocument26 pagesGroup TechnologyMohitNo ratings yet

- Excel: InstrumentsDocument14 pagesExcel: Instrumentsdarsuboy161No ratings yet

- AM Process ChainDocument21 pagesAM Process ChainShubhamNo ratings yet

- Lecture 7 - Machining Process and Machining Tools (Part 1)Document24 pagesLecture 7 - Machining Process and Machining Tools (Part 1)sharifah atiqahNo ratings yet

- 0085-Design For AssemblyDocument41 pages0085-Design For AssemblyAmolPagdalNo ratings yet

- Kalaignar Karunanidhi Institute of Technology Coimbatore - 641 402 Department of Mechanical EngineeringDocument95 pagesKalaignar Karunanidhi Institute of Technology Coimbatore - 641 402 Department of Mechanical EngineeringThiru MoorthyNo ratings yet

- Dfmae Unit 1Document28 pagesDfmae Unit 1Hariprasad100% (1)

- Additive Manufacturing: Presented by Nazma AmrinDocument23 pagesAdditive Manufacturing: Presented by Nazma AmrinSai SrinivasNo ratings yet

- Ime 4Document21 pagesIme 4pavan06mceNo ratings yet

- Manufacturing Event GuidelinesDocument3 pagesManufacturing Event GuidelinesTinu MawaleNo ratings yet

- PM - Chapter 5 - R1 Systems Development Cycle Middle & Later Stages 200413Document20 pagesPM - Chapter 5 - R1 Systems Development Cycle Middle & Later Stages 200413Himanshu Rajesh PatnekarNo ratings yet

- Cellular Manufacturing & Group TechnologyDocument25 pagesCellular Manufacturing & Group TechnologySapari VelNo ratings yet

- 6 CNC Theory - GeneralDocument20 pages6 CNC Theory - GeneralManojAnandNo ratings yet

- AutomationDocument5 pagesAutomationashfaq_ahmed_7No ratings yet

- Job Analysis Sheet: 2. Principal AccountabilitiesDocument2 pagesJob Analysis Sheet: 2. Principal AccountabilitiesAvneet MaanNo ratings yet

- Mti 80002347 110723074315Document132 pagesMti 80002347 110723074315domino BgsadNo ratings yet

- Process Selection and Facility Layout: Teaching NotesDocument25 pagesProcess Selection and Facility Layout: Teaching Notesyasin arafatNo ratings yet

- Edm Shahrul DKM4B 07DKM22F1011Document8 pagesEdm Shahrul DKM4B 07DKM22F1011Young RussleNo ratings yet

- Chapter - 1 Total Productive MaintenanceDocument47 pagesChapter - 1 Total Productive MaintenancePrwesh Singh Dikhit RajputNo ratings yet

- Unit IDocument6 pagesUnit IDhaneshNo ratings yet

- AM FinalDocument59 pagesAM Finaldummy vNo ratings yet

- Computer Integrated Manufacturing 15ME62TDocument15 pagesComputer Integrated Manufacturing 15ME62TRaghuraj DanadamNo ratings yet

- Survival of The Fittest - The Process Control ImperativeDocument10 pagesSurvival of The Fittest - The Process Control ImperativeEdNo ratings yet

- Types of Production Systems - 01-09-09Document17 pagesTypes of Production Systems - 01-09-09kmoharilNo ratings yet

- 1.introduction - AC MFG RevDocument20 pages1.introduction - AC MFG RevTarmizy MZakiNo ratings yet

- CC 5291 M.E Cad Anna UniversityDocument95 pagesCC 5291 M.E Cad Anna UniversityJsvijay KumarNo ratings yet

- Methods ManufacturingDocument22 pagesMethods Manufacturingchetanpatil24No ratings yet

- Mechanical Engineering Design: IlyasDocument32 pagesMechanical Engineering Design: IlyasAsif RahmanNo ratings yet

- Chapter-5 Need and Importance of TestingDocument6 pagesChapter-5 Need and Importance of TestingArslan AhmadNo ratings yet

- Advanced Manufacturing TechnologyDocument23 pagesAdvanced Manufacturing Technologyusha23021988No ratings yet

- EGF305 Topic 5-Intro To Failure Analysis PDFDocument34 pagesEGF305 Topic 5-Intro To Failure Analysis PDFasdfasdNo ratings yet

- Shape Deposition Manufacturing and Multijet ModelingDocument13 pagesShape Deposition Manufacturing and Multijet ModelingRitam GangulyNo ratings yet

- Manual 1 - Jishu-Hozen PDFDocument14 pagesManual 1 - Jishu-Hozen PDFvignesh88in2332No ratings yet

- Design For Manufacturability and TestabilityDocument14 pagesDesign For Manufacturability and Testabilityjagadees21No ratings yet

- 17PME328E: Process Planning and Cost EstimationDocument48 pages17PME328E: Process Planning and Cost EstimationDeepak MisraNo ratings yet

- Automotive Interior Parts Production Equipment CatalogDocument24 pagesAutomotive Interior Parts Production Equipment CatalogLuckyLokeShNo ratings yet

- Lean Systems: Principles of TPS/LeanDocument13 pagesLean Systems: Principles of TPS/LeanKathiravan RajendranNo ratings yet

- Module 1Document12 pagesModule 1swaroop kenganalNo ratings yet

- Intoduction To Additive Manufacturing (17ME82) DR - Lakshmidevamma.M.M Department of Mechanical Engineering, Gec, KushalnagarDocument14 pagesIntoduction To Additive Manufacturing (17ME82) DR - Lakshmidevamma.M.M Department of Mechanical Engineering, Gec, KushalnagarAKASHNo ratings yet

- Fused Deposition Modeling (FDM)Document3 pagesFused Deposition Modeling (FDM)Ahmed Khalid HussainNo ratings yet

- AM 7th Sem Solution 31.01.21 in CourseDocument9 pagesAM 7th Sem Solution 31.01.21 in CourseRaj PatelNo ratings yet

- Plastic Processing Lab Sheet - 3D PrintingDocument2 pagesPlastic Processing Lab Sheet - 3D PrintingAqil AzadNo ratings yet

- Chapter 4Document58 pagesChapter 4rajmessi2001No ratings yet

- Unit 1Document60 pagesUnit 1Ayush KumarNo ratings yet

- Converting Design To PrototypeDocument4 pagesConverting Design To PrototypeRrdbjdNo ratings yet

- Ind Inp-SahithDocument16 pagesInd Inp-SahithSàñdèép SûññyNo ratings yet

- Manufacturing EngineeringDocument62 pagesManufacturing EngineeringMuhammad IrvanNo ratings yet

- Vishal Gajare Internship ProgramDocument17 pagesVishal Gajare Internship ProgramVishal GajareNo ratings yet

- Tractor Manufactu Ring: Ae 101: Course AuditDocument15 pagesTractor Manufactu Ring: Ae 101: Course AuditArnel SisonNo ratings yet

- Quantity Production Method: Adhesive Bonding. They Form A Joint Between Two Components That Cannot Be EasilyDocument3 pagesQuantity Production Method: Adhesive Bonding. They Form A Joint Between Two Components That Cannot Be EasilyDebaditya DattaNo ratings yet

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

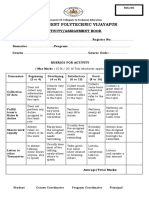

- ACTIVITY BOOK Format - AUG-22Document1 pageACTIVITY BOOK Format - AUG-22rajuNo ratings yet

- 20me53i Week6 Day3 Session1Document6 pages20me53i Week6 Day3 Session1rajuNo ratings yet

- 20me53i Week6 Day3 Session1Document9 pages20me53i Week6 Day3 Session1rajuNo ratings yet

- 20me53i Week6 Day3 Session1Document6 pages20me53i Week6 Day3 Session1rajuNo ratings yet

- W7S1Document16 pagesW7S1rajuNo ratings yet

- 1.STL Files Contains - .: Advanced Manufacturing and Technology and Code 20ME53I 2022-23Document2 pages1.STL Files Contains - .: Advanced Manufacturing and Technology and Code 20ME53I 2022-23rajuNo ratings yet

- JioMart Invoice 16592485700077599ADocument3 pagesJioMart Invoice 16592485700077599ArajuNo ratings yet

- PH.D Notification 08172022105536Document2 pagesPH.D Notification 08172022105536rajuNo ratings yet

- Syllabus ETR 2019 20 Part BDocument62 pagesSyllabus ETR 2019 20 Part BrajuNo ratings yet

- Coursera XWQU3SNPPuuiDocument1 pageCoursera XWQU3SNPPuuirajuNo ratings yet

- LIC's Jeevan Lakshya (T-933) : Benefit IllustrationDocument3 pagesLIC's Jeevan Lakshya (T-933) : Benefit IllustrationrajuNo ratings yet

- In A Pneumatic System An and Gate Is Known As - 5f55b1705714cdf66f75588dDocument3 pagesIn A Pneumatic System An and Gate Is Known As - 5f55b1705714cdf66f75588drajuNo ratings yet

- ME606 - Engineering Costing & EstimatingDocument3 pagesME606 - Engineering Costing & EstimatingrajuNo ratings yet

- Instructions / Checklist For Filling KYC FormDocument19 pagesInstructions / Checklist For Filling KYC FormrajuNo ratings yet

- Tax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Document1 pageTax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)rajuNo ratings yet

- File 1614263265 Brochure FileDocument1 pageFile 1614263265 Brochure FilerajuNo ratings yet

- Exercise 1Document34 pagesExercise 1rajuNo ratings yet

- Client ID LQ2729 Ledger For EQ From 2020-12-21 To 2020-12-28Document2 pagesClient ID LQ2729 Ledger For EQ From 2020-12-21 To 2020-12-28rajuNo ratings yet

- 06 PlateTheory 01 PlateTheory PDFDocument5 pages06 PlateTheory 01 PlateTheory PDFrajuNo ratings yet

- Design Considerations For Connecting Rod: B. Sriharsha, P. Sudhakar RaoDocument6 pagesDesign Considerations For Connecting Rod: B. Sriharsha, P. Sudhakar RaorajuNo ratings yet

- FD07 Mu Ba Ni 2020Document1 pageFD07 Mu Ba Ni 2020rajuNo ratings yet

- Report Name: District Wise CM Janatha Darshan Complains Date and Time: Saturday, August 22, 2020 9:10:58 AM +05:30 User IdDocument2 pagesReport Name: District Wise CM Janatha Darshan Complains Date and Time: Saturday, August 22, 2020 9:10:58 AM +05:30 User IdrajuNo ratings yet

- Materials Selection For Hip Prosthesis by The Method of Weighted PropertiesDocument13 pagesMaterials Selection For Hip Prosthesis by The Method of Weighted PropertiesrajuNo ratings yet

- Corrigendum STA RecttDocument1 pageCorrigendum STA RecttrajuNo ratings yet

- 635C PeçasDocument566 pages635C PeçasGabriely MuriloNo ratings yet

- Lathe, Milling Machine, Computer Numerical Control (CNC) and RobotsDocument25 pagesLathe, Milling Machine, Computer Numerical Control (CNC) and RobotsLAKSH RAMASWAMYNo ratings yet

- J 26 Air-Jet Spinning Machine Brochure 2887-V2 enDocument24 pagesJ 26 Air-Jet Spinning Machine Brochure 2887-V2 enYogesh JoshiNo ratings yet

- The MathWorksDocument9 pagesThe MathWorksEmmanuelNo ratings yet

- Broom Manufacture Machine: StartDocument62 pagesBroom Manufacture Machine: StartHaziq PazliNo ratings yet

- Double Paddle MixerDocument118 pagesDouble Paddle MixerArun Kumar80% (5)

- Design, Control, and Testing of A Thumb Exoskeleton With Series Elastic ActuationDocument21 pagesDesign, Control, and Testing of A Thumb Exoskeleton With Series Elastic ActuationÖmer GürNo ratings yet

- Mixer Cooler KMC 200 - 400 R - Ket - 6.002 (60 KGS)Document5 pagesMixer Cooler KMC 200 - 400 R - Ket - 6.002 (60 KGS)Krishna PrasadNo ratings yet

- PMS 420 Machine Replacement Repairs Guidance InstructionDocument17 pagesPMS 420 Machine Replacement Repairs Guidance InstructionIvo NijenhuisNo ratings yet

- Steam Press Project Rview ReportDocument19 pagesSteam Press Project Rview Reportअंकित चौधरीNo ratings yet

- 0598a17 - GBRDocument65 pages0598a17 - GBRtim kaminskyNo ratings yet

- JIMEX 2012 - JORDAN EXPORTERS OF MACHINERY AND ELECTRICITY Http://jimex2012.weebly - ComDocument40 pagesJIMEX 2012 - JORDAN EXPORTERS OF MACHINERY AND ELECTRICITY Http://jimex2012.weebly - ComThaisCorpNo ratings yet

- R Lineal de Bolas SKFDocument32 pagesR Lineal de Bolas SKFFreddy yimy Quispe de La CruzNo ratings yet

- ProfinetDocument8 pagesProfinetPeter VeermanNo ratings yet

- Đề 4Document5 pagesĐề 4kimlamtranNo ratings yet

- Manual TurbineDocument61 pagesManual TurbineDana SandruNo ratings yet

- Grove YB5500 Series: Product GuideDocument24 pagesGrove YB5500 Series: Product GuideDanilo Mina MunaycoNo ratings yet

- High Speed Transfer - 1hdk400072e D Sue3000 Operating Manual - Hires PDFDocument176 pagesHigh Speed Transfer - 1hdk400072e D Sue3000 Operating Manual - Hires PDFhebert_No ratings yet

- Machine GuardingDocument71 pagesMachine GuardingWouter PlessersNo ratings yet

- LDDM Linear Direct Drive Motors. ULIM SeriesDocument24 pagesLDDM Linear Direct Drive Motors. ULIM SeriesajibNo ratings yet

- Chapter 14 Force, Energy and Simple Machines-1Document4 pagesChapter 14 Force, Energy and Simple Machines-1Manoj KaushalNo ratings yet

- The Mechanical EngineerDocument2 pagesThe Mechanical EngineerLUIS MIGUEL LARICO CAMANo ratings yet

- Manual Lubricator1Document5 pagesManual Lubricator1tambangan 3ANo ratings yet

- Skilled Air For Industry Kice Kice Industries Inc 3 Table of Contents 1 Introduction PDFDocument31 pagesSkilled Air For Industry Kice Kice Industries Inc 3 Table of Contents 1 Introduction PDFturcoinnNo ratings yet

- Gear SystemDocument57 pagesGear SystemWilson LimNo ratings yet

- Flux Motor 2018Document29 pagesFlux Motor 2018caifanesvsjaguaresNo ratings yet

- Ngs 6.2 U2t Questionblank 62 2Document109 pagesNgs 6.2 U2t Questionblank 62 2glorialinNo ratings yet