Professional Documents

Culture Documents

Smaw NC I Cot 1 2023

Smaw NC I Cot 1 2023

Uploaded by

Words Wero Niar Mascarinas0 ratings0% found this document useful (0 votes)

48 views22 pagesThis document discusses fillet welding. It defines fillet welding as the process of joining two pieces of metal together whether perpendicular or at an angle. There are two types of joints in fillet welding: tee joints, which are two pieces of metal perpendicular to each other, and lap joints, which are two pieces of metal that overlap and are welded at the edges. The document outlines the parts of a fillet weld and provides instructions for students to practice fillet welding in different positions. It also includes review questions to assess student understanding.

Original Description:

Original Title

Smaw Nc i Cot 1 2023

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses fillet welding. It defines fillet welding as the process of joining two pieces of metal together whether perpendicular or at an angle. There are two types of joints in fillet welding: tee joints, which are two pieces of metal perpendicular to each other, and lap joints, which are two pieces of metal that overlap and are welded at the edges. The document outlines the parts of a fillet weld and provides instructions for students to practice fillet welding in different positions. It also includes review questions to assess student understanding.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

48 views22 pagesSmaw NC I Cot 1 2023

Smaw NC I Cot 1 2023

Uploaded by

Words Wero Niar MascarinasThis document discusses fillet welding. It defines fillet welding as the process of joining two pieces of metal together whether perpendicular or at an angle. There are two types of joints in fillet welding: tee joints, which are two pieces of metal perpendicular to each other, and lap joints, which are two pieces of metal that overlap and are welded at the edges. The document outlines the parts of a fillet weld and provides instructions for students to practice fillet welding in different positions. It also includes review questions to assess student understanding.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 22

SMAW NC I

SHIELDED METAL ARC WELDING

R K P

W O

H O

REVIEW

What are the different welding positions?

Can you establish full weld and penetration even

in a horizontal position? How?

Observe uniformity of bead ripples in accordance with welding standards

OBJECTIVES

Define Fillet Welding.

Perform lap joint flat position in accordance with

welding standards.

Observe uniformity of bead ripples in accordance

with welding standards

LETS PLAY

MOTIVATION

DIFFERENT TYPES OF ANGLES

QUESTIONS

What are the different types of

angles?

How do angles help the structure

strong?

ACTIVITY 1

Finding the area and angle of the triangles

GROUP ACTIVITY:

Lets group the class into 3 groups

Assign a leader and assistant leader

Students will meet with their group

Each group will receive an activity sheet.

You have only 3 minutes to accomplish the

activity

Each group will present the activity.

GROUP 1

Find the area of the triangle.

To find a triangle's area, use

the formula area = 1/2 * base *

height. Choose a side to use for

the base, and find the height of

the triangle from that base. Then,

plug in the measurements you

have for the base and height into

the formula.

GROUP 2

Find the missing angle of the

triangle.

To find a missing angle in a

triangle, subtract the two known

angles from 180°. We have a

triangle with 60°, 100°, and one

missing angle. The three angles

will add up to 180° in total. We

subtract this from 180° to find the

missing angle.

GROUP 3

Measure the angles of the triangle using a protractor.

1. Steps in measuring an angle with a protractor.

2. Place the midpoint of the protractor on the VERTEX of the angle.

3. Line up one side of the angle with the zero line of the protractor

(where you see the number 0).

4. Read the degrees where the other side crosses the number scale.

Fillet Welding

Perform Fillet weld on Carbon Steel Plates (FC)

Lesson

Fillet Welding

The process of joining two

pieces of metal together whether

they be perpendicular or at an

angle. These welds are

commonly referred to as Tee

joints which are two pieces of

metal perpendicular to each

other or Lap joints which are

two pieces of metal that overlap

and are welded at the edges Tee Joint Lap Joint

There are 5 parts of fillet weld

1. The root of the weld is part of the deepest

penetration which is the opposite angle of

the hypotenuse.

2. The toes of the weld are essentially the

edges or the points of the hypotenuse.

3. The face of the weld is the outer visual or

hypotenuse that you see when looking at a

fillet weld.

4. The legs are the other two sides of the

triangular fillet weld.

The leg length is usually designated as the

size of the weld.

5. The throat of the weld is the distance from

the center of the face to the root of the

weld.

Let’s Watch the video on the process of fillet weld.

Why do we need to apply 45 degrees working angle on the fillet weld

flat position?

What is the part of fillet welding? Can you name it?

GENERALIZATION

1. What is fillet welding?

2. What are the two types of joints in fillet

welding?

PERFORMANCE

Direction:

Using plates and electrodes create a

fillet welding using a gap 3/32.

Each student will do two trials of

correct weld puddling of fillet lap joint

horizontal position.

This is an individual activity and must

be accomplished chronologically.

Material:

o Mild Steel Plate 3/16” or thicker

o 1/8” Fleet weld 37 (E6013)

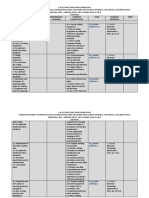

ASSESSMENT

DIRECTION: Choose the letter of the correct answer.

1. What do call the process of joining two pieces of metal together whether they be

perpendicular or at an angle?

a. Lap Joint b. Fillet Welding c. Groove Welding d. Tee Joint

2. Which Joint design refers to two pieces of metal welded perpendicular?

a. Lap Joint b. Fillet Welding c. Groove Welding d. Tee Joint

3. Which Joint design refers to a two pieces of metal that overlap?

a. Lap Joint b. Fillet Welding c. Groove Welding d. Tee Joint

4. What part of fillet welding refers to the outer visual or hypotenuse that you see when

looking at a fillet weld.?

a. Face b. Actual throat c. Leg d. Toe

5. What part of fillet welding refers to the distance from the face’s center to the weld’s root?

a. Face b. Actual throat c. Leg d. Toe

ASSIGNMENT

Bring your personal protective equipment and welding materials for the

continuation of the welding activity.

1. Mask with Filter lens

2. Leather Gloves

3. 3 inchers flat bars

4. Welding Electrode

You might also like

- Taste of Paradise Chapter 2Document16 pagesTaste of Paradise Chapter 2Gisele Ferreira33% (6)

- LS Magazine Ls Models Ls Land Issue Video LSM lsm09 08 02 Mega PDFDocument4 pagesLS Magazine Ls Models Ls Land Issue Video LSM lsm09 08 02 Mega PDFPaul25% (4)

- DLP August 22, 2022 SmawDocument3 pagesDLP August 22, 2022 SmawTeacher Ronel SDO Navotas100% (1)

- Chemrite Grout NSDocument2 pagesChemrite Grout NSghazanfar0% (1)

- RRLfor Gasoline StationDocument6 pagesRRLfor Gasoline StationWellan Joy Dela Fuerta100% (1)

- TVL Smaw11 Q1 M 11Document8 pagesTVL Smaw11 Q1 M 11Earl Christian BonaobraNo ratings yet

- PDF Q1 Mod 4 SMAW12 EnhancedDocument32 pagesPDF Q1 Mod 4 SMAW12 Enhancedrey ebasanNo ratings yet

- Smaw 12 Module 1 Grade 12Document39 pagesSmaw 12 Module 1 Grade 12HERNAN JAY BUYOK100% (1)

- Smaw 9 Q3 W1Document6 pagesSmaw 9 Q3 W1Words Wero MascarinasNo ratings yet

- GRADE 12 SMAW MODULE 4A 1st QuarterDocument20 pagesGRADE 12 SMAW MODULE 4A 1st QuarterClare GarcesNo ratings yet

- Different Weaving Motion (4F) : Mini LessonDocument4 pagesDifferent Weaving Motion (4F) : Mini LessonSweni De GraciaNo ratings yet

- TVL Smaw11 Q1 M 10Document10 pagesTVL Smaw11 Q1 M 10Earl Christian BonaobraNo ratings yet

- Mastery Test Lesson 2 Metal Works 2Document6 pagesMastery Test Lesson 2 Metal Works 2Jessie MirandaNo ratings yet

- Module 1 Essentials of WeldingDocument22 pagesModule 1 Essentials of WeldingMARCOE ALONZO ACAIN100% (2)

- December 5, 2022 SmawDocument6 pagesDecember 5, 2022 SmawTeacher Ronel SDO NavotasNo ratings yet

- Module 1 SMAW 11 12 Q2 1Document13 pagesModule 1 SMAW 11 12 Q2 1Marc CadalinNo ratings yet

- MODULE 8 SMAW 11 12 Q2 X 1Document29 pagesMODULE 8 SMAW 11 12 Q2 X 1Marc Cadalin100% (1)

- SHS - SLK - Inudstrial Arts Smaw Marking or Locating Weld DefectsDocument20 pagesSHS - SLK - Inudstrial Arts Smaw Marking or Locating Weld Defectsiammhon100% (1)

- 3RD Quarter Exam Smaw 12 NoteDocument2 pages3RD Quarter Exam Smaw 12 NoteBryan Borje100% (2)

- TVL-SMAW 12 - Week 6 - Lesson 2 - Welding Techniques and ProcedureDocument10 pagesTVL-SMAW 12 - Week 6 - Lesson 2 - Welding Techniques and ProcedureNelPalalonNo ratings yet

- Grades 11 Lesson Plan I. Objectives: Basic JointsDocument3 pagesGrades 11 Lesson Plan I. Objectives: Basic JointsCrisTopher L CablaidaNo ratings yet

- Cot Power PointDocument21 pagesCot Power PointMichael Angelo LumanogNo ratings yet

- Cot Smaw March 7 2021 Isagani AbrilDocument4 pagesCot Smaw March 7 2021 Isagani Abrilisagani abrilNo ratings yet

- SMAW NC I Set C - 50 ItemsDocument9 pagesSMAW NC I Set C - 50 Itemslouie gerasmiaNo ratings yet

- TVL - SM 11 - w4Document4 pagesTVL - SM 11 - w4CrisTopher L CablaidaNo ratings yet

- 11 SMAW Q4 Module 4Document13 pages11 SMAW Q4 Module 4Mark Johnson VillaronNo ratings yet

- TVL - SM 11 - w8Document4 pagesTVL - SM 11 - w8CrisTopher L CablaidaNo ratings yet

- TLE - SM 11 - w2Document4 pagesTLE - SM 11 - w2CrisTopher L CablaidaNo ratings yet

- Smaw-Dlp Lo6 6 1 04 17 23Document5 pagesSmaw-Dlp Lo6 6 1 04 17 23Cacho Jane RoselleNo ratings yet

- Diagnostic-Test G11 SmawDocument7 pagesDiagnostic-Test G11 SmawTeacher Ronel SDO NavotasNo ratings yet

- SMAW 10 Week 3-4Document4 pagesSMAW 10 Week 3-4Jessel Mejia Onza100% (2)

- SMAW NC I Set B - 50 ItemsDocument9 pagesSMAW NC I Set B - 50 Itemslouie gerasmia100% (1)

- SHS - SLK - Industrial Arts Smaw Basic Set Up Fo Smaw MachineDocument20 pagesSHS - SLK - Industrial Arts Smaw Basic Set Up Fo Smaw Machineiammhon100% (1)

- TVL-SMAW 12 - Week 5 - Lesson 2 - Acceptable Criteria For Completed WeldsDocument10 pagesTVL-SMAW 12 - Week 5 - Lesson 2 - Acceptable Criteria For Completed WeldsNelPalalonNo ratings yet

- FINAL SMAW-12-Quarter-3-module 4 PDFDocument20 pagesFINAL SMAW-12-Quarter-3-module 4 PDFRandy Sacatani100% (1)

- TVL - SM 11 - w6Document4 pagesTVL - SM 11 - w6CrisTopher L CablaidaNo ratings yet

- Sir Silva Cot (Final)Document2 pagesSir Silva Cot (Final)Jay Mark BibosoNo ratings yet

- Technical Vocational Livelihood: Shielded Metal Arc WeldingDocument7 pagesTechnical Vocational Livelihood: Shielded Metal Arc Weldingtibo bursioNo ratings yet

- Smaw Nci - Wk4Document4 pagesSmaw Nci - Wk4CrisTopher L CablaidaNo ratings yet

- Grade 11 SMAW - q2 w6Document7 pagesGrade 11 SMAW - q2 w6Jhon Vernie Reponte GambitoNo ratings yet

- TVL - SM 11 - w5Document4 pagesTVL - SM 11 - w5CrisTopher L CablaidaNo ratings yet

- Grade 10 DLP (6th)Document2 pagesGrade 10 DLP (6th)Rico CalamboNo ratings yet

- Grade 11-Platinum Smaw 3RD Quarter ExamDocument3 pagesGrade 11-Platinum Smaw 3RD Quarter Examemmabentonio100% (1)

- Shielded Metal Arc Welding (SMAW) : Worksheet, Week 4Document6 pagesShielded Metal Arc Welding (SMAW) : Worksheet, Week 4Zergie M. Zapanta100% (1)

- 3rd Quarter Exam For SMAWDocument3 pages3rd Quarter Exam For SMAWalvin madahan100% (1)

- Content Content Standard Performance Standard Learning Competencies Code Learning Materials Week Prepare Weld Materials (WM) LO 1. Set-Up Cutting EquipmentDocument9 pagesContent Content Standard Performance Standard Learning Competencies Code Learning Materials Week Prepare Weld Materials (WM) LO 1. Set-Up Cutting Equipmentlip100% (1)

- SMAW Post TestDocument2 pagesSMAW Post TestAdoracion Sales HugoNo ratings yet

- Ia Smaw Nci SHS Q3 Las2 FinalDocument15 pagesIa Smaw Nci SHS Q3 Las2 FinalJoy Buyco100% (1)

- Smaw 11 LP Feb. 21 2019Document2 pagesSmaw 11 LP Feb. 21 2019ronald curayagNo ratings yet

- 12 - SMAW W 3 - Essentials of WeldingDocument10 pages12 - SMAW W 3 - Essentials of WeldingNelPalalon100% (1)

- 1st Periodical Exam Smaw 10-1Document2 pages1st Periodical Exam Smaw 10-1Michael Angelo LumanogNo ratings yet

- DLP - Final-Demo - Weld DefectsDocument11 pagesDLP - Final-Demo - Weld DefectsTrecita BacoNo ratings yet

- TVL Smaw11 Q1 M 18Document9 pagesTVL Smaw11 Q1 M 18Earl Christian BonaobraNo ratings yet

- LESSONPLAN-for-SMAW-12-WEEK-1 RAMON OPSIMARDocument3 pagesLESSONPLAN-for-SMAW-12-WEEK-1 RAMON OPSIMARelizer encarnacion100% (1)

- Shielded Metal Arc Welding: Grade 10Document23 pagesShielded Metal Arc Welding: Grade 10Jessel Mejia OnzaNo ratings yet

- Set-Up Welding Equipment LO1-1.1Document7 pagesSet-Up Welding Equipment LO1-1.1Joy BuycoNo ratings yet

- SMAW TestDocument4 pagesSMAW TestBapunNo ratings yet

- Module - 3identify The Different Weaving Motion - Q2 - SMAW-9-10Document15 pagesModule - 3identify The Different Weaving Motion - Q2 - SMAW-9-10ronel.suan001100% (1)

- DLL - SMAW - 1st Sem - Week 11Document3 pagesDLL - SMAW - 1st Sem - Week 11Mary Antoinette Magallanes100% (1)

- DLP 01-09-23 SmawDocument7 pagesDLP 01-09-23 SmawTeacher Ronel SDO NavotasNo ratings yet

- 1 - Welding Parameters - Current - MST 4,5,6Document4 pages1 - Welding Parameters - Current - MST 4,5,6ryan4munar100% (1)

- Grade 10 Smaw TleDocument6 pagesGrade 10 Smaw TleKim PinedaNo ratings yet

- 2nd Quarter Summative SMAW NC2Document2 pages2nd Quarter Summative SMAW NC2emmabentonioNo ratings yet

- Q3 Ulas Tle10 Smaw Week7 FinalDocument11 pagesQ3 Ulas Tle10 Smaw Week7 FinalFERNANDO COMEDOY JRNo ratings yet

- AP II Assignment 1Document2 pagesAP II Assignment 1manan khndlwlNo ratings yet

- Mosaic TRD2 Tests U7 1Document3 pagesMosaic TRD2 Tests U7 1Patricia Alfaro GarijoNo ratings yet

- SLG Chem2 LG 4.9 BuffersDocument6 pagesSLG Chem2 LG 4.9 BuffersIman SontousidadNo ratings yet

- Project 89 May 2012 UpdateDocument73 pagesProject 89 May 2012 UpdategonflynnNo ratings yet

- Airbus FBW Flight Control Laws: Abbreviated SummaryDocument5 pagesAirbus FBW Flight Control Laws: Abbreviated SummaryPiyushNo ratings yet

- Theology Finals - Grade 11Document7 pagesTheology Finals - Grade 11Sophia BiancaNo ratings yet

- Maintenance Manual: Thermo King Corp., Minneapolis, MN, U.S.ADocument52 pagesMaintenance Manual: Thermo King Corp., Minneapolis, MN, U.S.AING. RUBENSNo ratings yet

- Straight / Angulated Multi-Unit System: © MIS Corporation. All Rights ReservedDocument12 pagesStraight / Angulated Multi-Unit System: © MIS Corporation. All Rights ReservedKrupali JainNo ratings yet

- Advances in Textile Waste Water TreatmentDocument17 pagesAdvances in Textile Waste Water TreatmentYamitakaiNo ratings yet

- Radha BurnierDocument1 pageRadha BurnierarpitaNo ratings yet

- Enhanced DSL AlgorithmsDocument78 pagesEnhanced DSL AlgorithmsDaniel AlejandriNo ratings yet

- CM YSM Air Handling Unit Catalogue Part4Document1 pageCM YSM Air Handling Unit Catalogue Part4JosephRusselVizmanosNo ratings yet

- A Study of How Lighting Can Affect A Guests Dining ExperienceDocument133 pagesA Study of How Lighting Can Affect A Guests Dining ExperiencehattyuuNo ratings yet

- Wind Load Calculation + Design CriteriaDocument7 pagesWind Load Calculation + Design CriteriaAnonymous 2Dz4Kq9M7No ratings yet

- Mock Test 1 (Q.e.)Document3 pagesMock Test 1 (Q.e.)Mehul PatilNo ratings yet

- Signals and Systems: BITS PilaniDocument21 pagesSignals and Systems: BITS Pilanirajeevdutt_1215No ratings yet

- Kong Long Huat Borax Decahydrate, BI GHSDocument14 pagesKong Long Huat Borax Decahydrate, BI GHSOsh 0717No ratings yet

- Mvc2 ManualDocument49 pagesMvc2 ManualMICHELLE ALEXANDRA SOTOMAYOR MONTECINOSNo ratings yet

- Uk Erik Common Rail Nozzle Catalogue 2014 PDFDocument13 pagesUk Erik Common Rail Nozzle Catalogue 2014 PDFjeferson de castro souzaNo ratings yet

- Fitness Center 1 Cs Practical For Class 12Document13 pagesFitness Center 1 Cs Practical For Class 12aeeeelvishbhaiiNo ratings yet

- Machiavelli'S Critique of Christianity: Paul-Erik KorvelaDocument31 pagesMachiavelli'S Critique of Christianity: Paul-Erik KorvelaMichael MungaiNo ratings yet

- Sustainable Development and Its CharacteristicsDocument3 pagesSustainable Development and Its CharacteristicsToxic XitNo ratings yet

- QUINTA DE PACOS PresentationDocument2 pagesQUINTA DE PACOS PresentationBeatrice ŞtefaniaNo ratings yet

- Manual Haier HYC-390 enDocument24 pagesManual Haier HYC-390 enDaniel BuitragoNo ratings yet

- Piano Tuning GuidelinesDocument6 pagesPiano Tuning GuidelinesAleksandraMladenovićNo ratings yet

- Rtaf SVX001C en - 11252015Document106 pagesRtaf SVX001C en - 11252015Thiraviam AyyappanNo ratings yet