Professional Documents

Culture Documents

Section 14a ESP PUMP SIZING EXAMPLE No2

Section 14a ESP PUMP SIZING EXAMPLE No2

Uploaded by

Yassin Muhssen0 ratings0% found this document useful (0 votes)

42 views21 pagesThe document provides a 10 step procedure for sizing an ESP pump for a high water cut well. It then works through an example application, collecting well data, determining production capacity, calculating total dynamic head, selecting pump components, motor, protector, cable, and surface equipment. Specifically, it sizes an ESP for a well producing 6000 BPD of oil and water, selecting a 177 stage pump, 350 HP motor, and other components to match the calculated requirements.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides a 10 step procedure for sizing an ESP pump for a high water cut well. It then works through an example application, collecting well data, determining production capacity, calculating total dynamic head, selecting pump components, motor, protector, cable, and surface equipment. Specifically, it sizes an ESP for a well producing 6000 BPD of oil and water, selecting a 177 stage pump, 350 HP motor, and other components to match the calculated requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

0 ratings0% found this document useful (0 votes)

42 views21 pagesSection 14a ESP PUMP SIZING EXAMPLE No2

Section 14a ESP PUMP SIZING EXAMPLE No2

Uploaded by

Yassin MuhssenThe document provides a 10 step procedure for sizing an ESP pump for a high water cut well. It then works through an example application, collecting well data, determining production capacity, calculating total dynamic head, selecting pump components, motor, protector, cable, and surface equipment. Specifically, it sizes an ESP for a well producing 6000 BPD of oil and water, selecting a 177 stage pump, 350 HP motor, and other components to match the calculated requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 21

ESP Application Engineering

Section 14a

Pump Sizing

Example 2

Section 5d Haward Technology Middle East 1

ESP Application Engineering

Pump Sizing Procedure

(High Water cut well)

1. Collect data (well, production, fluid, electrical)

2. Determine the production capacity of the well

3. Calculate Total Dynamic Head (TDH) and determine

tubing size

4. Select pump stage type

5. Calculate the number of pump stages required

6. Check pump shaft loading and pump housing pressure.

Section 5d Haward Technology Middle East 2

ESP Application Engineering

Pump Sizing Procedure

(High Water cut well)

7. Calculate motor horsepower requirements and select

a suitable motor

8. Calculate the protector thrust bearing load and select

a suitable protector

9. Determine the correct cable size and select a suitable

cable type.

10. Calculate the surface voltage and KVA requirements

and select a suitable switchboard and transformer

Section 5d Haward Technology Middle East 3

ESP Application Engineering

1. Collect Data

Casing size

Perforation depth

S.G. of produced fluid

Tubing sizes available

Pump setting depth

Static Fluid Level

Productivity Index

Bottom Hole Temperature

Wellhead Pressure required

Desired Flowrate

Section 5d Haward Technology Middle East 4

ESP Application Engineering

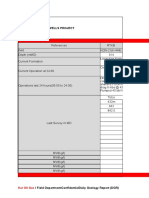

1. Collect Data

Casing size 7.0 inch

Perforation depth 5000 ft.

S.G. of produced fluid 1.05

Tubing sizes available 3.5 inch OD UVE, 9.3 LB.

Pump setting depth ? ft

Static Fluid Level 1820 ft

Static Bottom Hole Pressure 2000 psi

Water Cut 30 %

Water S.G. 1.05

Oil API Gravity 30

Section 5d Haward Technology Middle East 5

ESP Application Engineering

1. Collect Data

Productivity Index 0.9 BPD/psi

Bottom Hole Temperature 250 deg F

Wellhead Pressure reqd. 50 psi

Desired Flowrate 6000 BPD

Section 5d Haward Technology Middle East 6

ESP Application Engineering

We have an Oil and Water Mixture

In this example we have a mixture of oil and water

Therefore we need to calculate an average SG for the

fluid mixture.

Ave S.G. = ((0.7 x 1.05) + (0.3 x 0.876))

= 0.735 + 0.263 = 0.998

Fluid Gradient = 0.433

Section 5d Haward Technology Middle East 7

ESP Application Engineering

We also have to Calculate the Static Fluid

Level

What do we know to help us

1. Fluid Gradient = 0.433 as we have just calculated

2. SBHP — which has been given at the depth of 5000

ft.

Section 5d Haward Technology Middle East 8

ESP Application Engineering

Calculating the Static Fluid Level

Section 5d Haward Technology Middle East 9

ESP Application Engineering

2. Determine the Production Capacity of

the Well

Flowing fluid level = Static fluid level + Drawdown

Max Drawdown possible = 5000 ft — 381= 4619 ft.

Max Drawdown (psi) = 4619 x 0.433 psi/ft = 2000 psi

(Gradient = 0.433x S.G.)

Maximum possible flow (drawing fluid right down to

the perforations = 2000 psi x 3.5 BPD/psi = 7000 BPD

Section 5d Haward Technology Middle East 10

ESP Application Engineering

3. Calculate TDH @ 1300 BPD

Flowing Fluid Level @ 6000 BPD = SFL + DD

Draw Down (psi) = 6000 BPD/ 3.5 BPD/psi = 1714 psi

Draw Down (feet) = 1714 psi/ .433 psi/ft = 3958 ft.

Flowing Fluid Level = 381 ft + 3958 ft = 4339 ft

Friction Loss = 100 ft per 1 k ft x 4841 ft = 484 ft

Section 5d Haward Technology Middle East 11

ESP Application Engineering

3. Calculate TDH @ 1300 BPD

WHP = 50 psi /0.433 psi/ft = 115 ft.

Total Dynamic Head = Static Lift + WHP + Friction

TDH = 4339 + 115 + 484 = 4938 Ft

Section 5d Haward Technology Middle East 12

ESP Application Engineering

4. Select Pumps Stage type

Select a pump suitable for installation in 7.00 inch

casing and also capable of producing 6000 BPD

SELECT a GN 5200

Section 5d Haward Technology Middle East 13

ESP Application Engineering

5. Calculate the Number of Stages Required

At 6000BPD the GN 5600 generates 28 ft per stage

(please review the GN 5600 curve in the catalog)

Number of stages required = 4938 ft/ 28 ft per stage

= 176 stages

Utilizing the next standard Housing sizes

Select 2 x 68 housings and 1 x 41 = 177 stages

Section 5d Haward Technology Middle East 14

ESP Application Engineering

6. Check Shaft Loading and Housing Pressure

Limitations

Pump Hp = 1.8 HP/stage x 177 x 1.0 (SG) = 318.6 HP

Maximum shaft HP rating = 375 HP (see curve)

Therefore the standard shaft is O.K.

Maximum head in operating range = 34 X 177 = 6018 ft.

Maximum pressure in range = 6018 ft x .433 = 2605 psi

Housing pressure rating = 5000 psi (see curve)

Therefore the housing is O.K.

Section 5d Haward Technology Middle East 15

ESP Application Engineering

7. Select Motor

Motor HP required = pump HP = 318.6 HP

Select a motor suitable for installation in 7.0 inch well

Therefore select a 540 series motor (5.43 inch O.D.)

Select a 540 series 350 HP, 4400 volt, 48 amp

(Tandem motor made up of 1 x UT motor and 1 x CT

motor — each 2220 volt, 48 amp sections. A UMB is

required.

Section 5d Haward Technology Middle East 16

ESP Application Engineering

8. Calculate Protector thrust Bearing Load

and Choose Protector Type

Maximum pressure in operating range = 2605 psi

Cross sectional area of Pump shaft = 0.785 sq. in.

TB load for floater pumps = 2605 psi x 0.785 sq. in

=2033 lbs

Select standard Bronze bearing rated at 4000 lbs @

250 deg F (information in protector section of catalog)

(Note Standard bearing not recommended @ > 250 deg

F)

Section 5d Haward Technology Middle East 17

ESP Application Engineering

9. Determine Cable Size

Motor is rated 350 HP, 60 HZ., 48 Amp

Pump Load is 318.6 HP

Motor operating current = 318.6/350 x 50 = 43.7amp.

Choose a cable size with a volts drop, 30v/1000 ft

Choose No 4 AWG cable

Section 5d Haward Technology Middle East 18

ESP Application Engineering

Calculate Surface Voltage and Size

Switchboard and Transformer

Voltage drop at 43.6mamps = 18.6 volts/1000 ft

We have 4941 ft of cable allowing for 100 ft at surface

Voltage drop = 4.94 x 18.6 = 71.8 volts

Surface Voltage required = 4400 (motor) +72 = 4472 v.

Section 5d Haward Technology Middle East 19

ESP Application Engineering

Calculate Surface Voltage and Size

Switchboard and Transformer

Surface Voltage required = 4400 (motor) +72 = 4472 v.

Therefore use a Non Standard volt rated Switchboard as

the 1512 is 3900 volts max.

Surface KVA = 4472 (volts) x 43.6 (amps) x 1.73 = 337 KVA

1000

Therefore use a 400 KVA 3 phase dual wound transformer –

with multi tapped secondary

Section 5d Haward Technology Middle East 20

ESP Application Engineering

End of this

Section

Section 5d Haward Technology Middle East 21

You might also like

- GasLiftValveDesign SI UnitsDocument15 pagesGasLiftValveDesign SI UnitsnvnvNo ratings yet

- Well ArchitectDocument1 pageWell ArchitectSandesh ChavanNo ratings yet

- Chapter - 09 ESP Design ExamplesDocument16 pagesChapter - 09 ESP Design Examplesdewidar1234100% (11)

- Section 14 ESP PUMP SIZING EXAMPLE No1Document17 pagesSection 14 ESP PUMP SIZING EXAMPLE No1Yassin MuhssenNo ratings yet

- NODAL ANALYSIS SalinanDocument6 pagesNODAL ANALYSIS SalinanZul Fauzi ilhamNo ratings yet

- AL3 ESP 2 ESP SizingDocument30 pagesAL3 ESP 2 ESP Sizingbnomer3No ratings yet

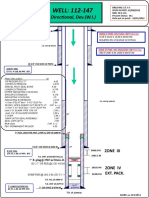

- WELL: 112-147: Directional, Dev. (W.I.)Document15 pagesWELL: 112-147: Directional, Dev. (W.I.)Mostafa KorttamNo ratings yet

- Schlumberger: PIPESIM Open Link - Gas Lift Design & DiagnosticsDocument16 pagesSchlumberger: PIPESIM Open Link - Gas Lift Design & DiagnosticsnvnvNo ratings yet

- Konvensional Test: QSC, MMSCFDDocument7 pagesKonvensional Test: QSC, MMSCFDQisrah Putra HasbiNo ratings yet

- Pumping and Mixing Solution - BRCH - PRINTDocument16 pagesPumping and Mixing Solution - BRCH - PRINTZed WangNo ratings yet

- Gaitas-1 Workover Program - RevFinal - LGRDocument37 pagesGaitas-1 Workover Program - RevFinal - LGRIvan Dario Benavides BonillaNo ratings yet

- TugasNodal 101318031 Muhammad Faqih IndradjiDocument2 pagesTugasNodal 101318031 Muhammad Faqih IndradjilaodiantoniusNo ratings yet

- Bottomhole Pressure 0504083Document6 pagesBottomhole Pressure 0504083Daniel DadzieNo ratings yet

- Api Casing Design: Design Parameters Loads at A DepthDocument2 pagesApi Casing Design: Design Parameters Loads at A DepthrenatoNo ratings yet

- Iwcf Certification Test Surface Bop Kill Sheet: Sicp SidppDocument15 pagesIwcf Certification Test Surface Bop Kill Sheet: Sicp SidppPAOLA ALEJANDRA CHINCHERO QUISPENo ratings yet

- Serie Age Formation Top OH M DJHN-3 0 Continental IntercalaireDocument12 pagesSerie Age Formation Top OH M DJHN-3 0 Continental IntercalaireAlexander KlmNo ratings yet

- Kill Sheet: Prerecorded Infromation Pump Strokes RequiredDocument16 pagesKill Sheet: Prerecorded Infromation Pump Strokes RequiredAbdul Hameed OmarNo ratings yet

- Example BHA Tally Directional Drilling 8.5 SectionDocument2 pagesExample BHA Tally Directional Drilling 8.5 Sectionfauzanhaq1602No ratings yet

- Spe 208179-MS - Adipec'21 - PdoDocument12 pagesSpe 208179-MS - Adipec'21 - Pdoamithnair078426No ratings yet

- Hagedorn Brown CorrelationDocument28 pagesHagedorn Brown Correlationberkah haniNo ratings yet

- Volant Specs CRTi4-7.01 PDFDocument5 pagesVolant Specs CRTi4-7.01 PDFRaymond ChuNo ratings yet

- Profile & Cutter Placement: Reference Photo: 17 1/2" FC619Document1 pageProfile & Cutter Placement: Reference Photo: 17 1/2" FC619Hendra SiswantoNo ratings yet

- 9 - 5-8inx7in Retrievable Thermal Liner Hanger Packer and accesories-CCS Well Injector and Producer Steam Flooding MethodDocument6 pages9 - 5-8inx7in Retrievable Thermal Liner Hanger Packer and accesories-CCS Well Injector and Producer Steam Flooding Methodjose gregorio mata cabezaNo ratings yet

- PCP AE1 - DAY 1.1 Introduction To PCP System and ComponentsDocument66 pagesPCP AE1 - DAY 1.1 Introduction To PCP System and ComponentsCristhian LópezNo ratings yet

- Junk Basket DetailsDocument8 pagesJunk Basket DetailsS DasNo ratings yet

- KJDG - Z DwopDocument41 pagesKJDG - Z DwopRANJITH K PNo ratings yet

- Sem-Logo QG-II MAIO 2014 PDFDocument2 pagesSem-Logo QG-II MAIO 2014 PDFPablo Rivas RNo ratings yet

- Blackstar II Dual Telemetry MWD Tool Spec Sheet PDFDocument4 pagesBlackstar II Dual Telemetry MWD Tool Spec Sheet PDFDani HpNo ratings yet

- Petroleum Engineering 325 Petroleum Production Systems: Wellbore Flow Performance I Single-Phase FlowDocument51 pagesPetroleum Engineering 325 Petroleum Production Systems: Wellbore Flow Performance I Single-Phase FlowBruno ReinosoNo ratings yet

- Khurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationDocument9 pagesKhurmala Field Field Department Drilling Deve. Oil Wells Project TU Locationahmed1adnan-10No ratings yet

- TCB-X1005 Proposed Liner Running Tally 5''Document8 pagesTCB-X1005 Proposed Liner Running Tally 5''juan_ba777No ratings yet

- Section 04 PUMP ROR CURVEDocument46 pagesSection 04 PUMP ROR CURVEYassin MuhssenNo ratings yet

- Wo Esp DevelopmentsDocument6 pagesWo Esp DevelopmentsHamed GeramiNo ratings yet

- Hardfacing Workshop Supplies BrochureDocument8 pagesHardfacing Workshop Supplies BrochureAhmad Reza FarokhiNo ratings yet

- ESP PumpDocument57 pagesESP PumpAlind dosky100% (1)

- Daily Drilling Report: Danan Oilfield DevelopmentDocument3 pagesDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNo ratings yet

- ESP Component and Design ItDocument76 pagesESP Component and Design Itomerkhalidhameed100% (1)

- 05 02 18 Saturn Specifications 5.8Document1 page05 02 18 Saturn Specifications 5.8Jose FavaNo ratings yet

- 02 Drill Bit Hydraulics CalculationsDocument61 pages02 Drill Bit Hydraulics CalculationsArkhatTompakovNo ratings yet

- MOCS Application PosterDocument2 pagesMOCS Application PosterChikh YassineNo ratings yet

- Actions and Data Required Before The KillDocument86 pagesActions and Data Required Before The KillGMNo ratings yet

- Pge 307 Week 1Document387 pagesPge 307 Week 1Raed Al-nomanNo ratings yet

- Da13 DDR N1 13991115 142 0Document3 pagesDa13 DDR N1 13991115 142 0Hamed NazariNo ratings yet

- DDR N°1 - Atk29 - TP180 - 08022017Document3 pagesDDR N°1 - Atk29 - TP180 - 08022017Nour MohammedNo ratings yet

- Rotaflex Long Stroke Pumping UnitDocument12 pagesRotaflex Long Stroke Pumping UnitMaxiSanchezNo ratings yet

- For Reference Only: Drill Pipe Performance Characteristics ©Document3 pagesFor Reference Only: Drill Pipe Performance Characteristics ©alekz89100% (1)

- Noble CorporationDocument25 pagesNoble CorporationFahmi Tamimi El MahmudNo ratings yet

- Completion (Natural Flow)Document3 pagesCompletion (Natural Flow)Mohammed Ali YoussefNo ratings yet

- Ipr VLPDocument9 pagesIpr VLPRoger Ronaldo Montero CoronaciónNo ratings yet

- 16.TDI FCR Data 9.625 43.50 PPF P110 BTC Rev.7Document1 page16.TDI FCR Data 9.625 43.50 PPF P110 BTC Rev.7javier monteroNo ratings yet

- Da13 DDR N1 14000104 191 0Document3 pagesDa13 DDR N1 14000104 191 0Hamed NazariNo ratings yet

- Hosan 1 EWOR Final CheckDocument40 pagesHosan 1 EWOR Final CheckvengurionNo ratings yet

- Model A Hydro TripDocument1 pageModel A Hydro TripFernando OlaveoNo ratings yet

- Da13 DDR N1 13991122 149 0Document3 pagesDa13 DDR N1 13991122 149 0Hamed NazariNo ratings yet

- Day 6 ESP DIFA Procedure and ReportDocument59 pagesDay 6 ESP DIFA Procedure and ReportomerkhalidhameedNo ratings yet

- Amal-18 Sta DDR#20 02-03-2020Document30 pagesAmal-18 Sta DDR#20 02-03-2020eng7mohamed7hashimNo ratings yet

- Assortment of Mini ApplicationsDocument1 pageAssortment of Mini ApplicationsAbdul Hameed OmarNo ratings yet

- C - Wellbore Cleaning Technology - H03280-BR PDFDocument26 pagesC - Wellbore Cleaning Technology - H03280-BR PDFAlexandru AndreiNo ratings yet

- Production Engineering - Presentation To The InternsDocument25 pagesProduction Engineering - Presentation To The Internsmweheyo asaphNo ratings yet

- 12 Pump Sizing Example 1 & 2ADocument37 pages12 Pump Sizing Example 1 & 2AMohamed Abd El-MoniemNo ratings yet

- Section 07 MOTORSDocument35 pagesSection 07 MOTORSYassin MuhssenNo ratings yet

- Section 13 BASIC PUMP SIZING FOR ESPDocument69 pagesSection 13 BASIC PUMP SIZING FOR ESPYassin MuhssenNo ratings yet

- Section 06 PROTECTORSDocument67 pagesSection 06 PROTECTORSYassin MuhssenNo ratings yet

- Section 15 ESP ITEMS TO CONSIDERDocument18 pagesSection 15 ESP ITEMS TO CONSIDERYassin MuhssenNo ratings yet

- Section 16 ESP FIELD OPERATIONSDocument14 pagesSection 16 ESP FIELD OPERATIONSYassin MuhssenNo ratings yet

- Section 11 ESP CABLEDocument50 pagesSection 11 ESP CABLEYassin MuhssenNo ratings yet

- Section 14 ESP PUMP SIZING EXAMPLE No1Document17 pagesSection 14 ESP PUMP SIZING EXAMPLE No1Yassin MuhssenNo ratings yet

- Section 04 PUMP ROR CURVEDocument46 pagesSection 04 PUMP ROR CURVEYassin MuhssenNo ratings yet