Professional Documents

Culture Documents

Section 13 BASIC PUMP SIZING FOR ESP

Section 13 BASIC PUMP SIZING FOR ESP

Uploaded by

Yassin MuhssenOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 13 BASIC PUMP SIZING FOR ESP

Section 13 BASIC PUMP SIZING FOR ESP

Uploaded by

Yassin MuhssenCopyright:

Available Formats

ESP Application Engineering

Section 13

Basic Equipment Sizing

Section 5b Haward Technology Middle East 1

ESP Application Engineering

Pump Sizing

Now that we know how to understand TDH (System)

Curves and how they relate to Pump Performance curves

we shall review some of the parameters relating to the

Oil well that need to be considered when sizing ESP’s

We will later review the effect of changing downhole

conditions and changing operating speed on the way the

pump is expected to perform.

Section 5b Haward Technology Middle East 2

ESP Application Engineering

Information Required to Size Pump & Why

Casing & liner depths, size & weight :

• To find casing ID, to ensure equipment selected will

fit in the well.

Production tubing size, weight & length :

• To calculate friction loss from pump to surface,

• To ensure enough room available for ESP cable

Section 5b Haward Technology Middle East 3

ESP Application Engineering

Information Required to Size Pump & Why

Well profile : deviated / vertical; if deviated: deviation survey :

• To ensure pump can be run to its intended set depth and not

landed in deviated section.

• For proper calculation of net vertical lift

• For selecting the proper protector configuration

Is there any downhole size restriction (Y-tool, casing patch, sand

screen, … ? ):

• To ensure pump can be run to its intended set depth

• To ensure equipment selected will fit in the well.

Section 5b Haward Technology Middle East 4

ESP Application Engineering

Information Required to Size Pump & Why

Produced Fluid & gas properties :

• Water, Oil and Gas SG, Water Cut -> to calculate produced fluid SG

• GOR, Bubble point/Solution GOR -> to see if gas separator/gas

handling device might be required

• Gas impurities (CO2, H2S, N2) -> to see if Redalloy equipment might

be required

• PVT lab Data & Viscosity calibration (if available) -> same as above

• Emulsions, abrasives (any sand production, type of sand) -> to see if

we need to use ARZ pump

Section 5b Haward Technology Middle East 5

ESP Application Engineering

Information Required to Size Pump & Why

Productivity data :

• SBHP and PI or FBHP and test flow rate (second is preferable) -> to

calculate well productivity

General well data :

• Perforated intervals and depths.

• PBTD, TD

• Planned completion schematic

• Bottomhole temperature

• Required/planned wellhead pressure

Section 5b Haward Technology Middle East 6

ESP Application Engineering

Information Required to Size Pump & Why

How’s the reservoir expected to change in the future:

• Pressure decline, pressure maintenance plan

• Water cut increase

• Effect of other artificial lift schemes in the area

• Gas breakthrough

• -> for better pump selection to anticipate future

well condition

Section 5b Haward Technology Middle East 7

ESP Application Engineering

Information Required to Size Pump & Why

General surface related information:

• Power supply available (voltage, frequency)

• Power supply stability, quality (harmonics, regular

trips)

• Surface facility arrangement

• Wellhead type

• -> to properly select motor, cable and surface

equipment

Section 5b Haward Technology Middle East 8

ESP Application Engineering

Pump Sizing Example

Well A has 7”, 23 lb/ft casing from surface to TD;

perforation top at 2500 ft; vertical well.

We want to produce 2,000 bpd with 60%WC; oil gravity

30o API, water gravity 1.07.

Completion : just ESP and 2-7/8” tubing up to surface.

Pump is to be set at 2200 ft. Fluid level is @ 839 ft.

Required WHP : 200 psi, BHT: 215oF; supply voltage

frequency: 60 Hz

Section 5b Haward Technology Middle East 9

ESP Application Engineering

Pump Sizing Exercise - Answer

Wellhead Pressure (in feet):

141.5

Oil SG = ____________ = 0.876

131.5 + 30

Fluid SG = (fw x w) + (fo x o).

= (0.60 x 1.07) + (0.40 x 0.876) = 0.992

Wellhead Pressure *2.31

Wellhead "Feet" = ______________

sp.gr.

= (200 * 2.31)/0.992 = 466 ft

Section 5b Haward Technology Middle East 10

ESP Application Engineering

Pump Sizing Exercise - Answer

Net vertical lift = Pump set depth – fluid level

= 2200 – 839 = 1361 ft

Tubing friction loss = 26 ft (refer to tubing friction loss

chart)

TDH = Wellhead Pressure(ft) + Net vertical lift +

Friction

= 466 + 1361 + 23 = 1850 ft

We need a pump that would deliver 1850 ft head @2000

bpd flow rate.

Section 5b Haward Technology Middle East 11

ESP Application Engineering

2000 bpd Pump Sizing

The first thing to do is to look in the catalog to see

what pumps are available which will produce 2000

bpd.

For 60 Hz power, we will use the 3500 RPM curves.

Note: If the power were 50 Hz, we would use the 2917

RPM curves.

Section 5b Haward Technology Middle East 12

ESP Application Engineering

2000 bpd Pump Sizing

Pump Monel Shaft Shaft Recommended Capacity @ 60Hz

Series – O.D Type Max BHP Size (BPD) (M3/D))

Section 5b Haward Technology Middle East 13

ESP Application Engineering

2000 bpd Pump Sizing

The two vertical green lines represent the

recommended operating range

Section 5b Haward Technology Middle East 14

ESP Application Engineering

2000 bpd Pump Sizing

A "D" series pump is 4.00 inches in diameter

Section 5b Haward Technology Middle East 15

ESP Application Engineering

2000 bpd Pump Sizing

"G" series pump is 5.13 inches in diameter

Section 5b Haward Technology Middle East 16

ESP Application Engineering

2000 bpd Pump Sizing

Notice that G pumps put out more head than D pumps

Section 5b Haward Technology Middle East 17

ESP Application Engineering

2000 bpd Pump Sizing

Section 5b Haward Technology Middle East 18

ESP Application Engineering

General Sizing Tips:

What do we do with that many choices?

We could size all and compare them but that might take

more time than we have. Consider ways to cull them

before going too far.

Section 5b Haward Technology Middle East 19

ESP Application Engineering

Bigger Diameter is almost always better:

Advantages: Disadvantages:

Usually More Efficient Lower Maximum Pressure

Usually Less Expensive Can Interfere w/ Y-Tool

Better in Gas & Viscosity More Downthrust

Handles Higher HP

Section 5b Haward Technology Middle East 20

ESP Application Engineering

General Sizing Tips:

Based on this, let's eliminate the "D" series pumps since

they are smaller diameter.

Now compare the GN1600, GN2100 and GN2500.

Section 5b Haward Technology Middle East 21

ESP Application Engineering

2000 bpd Pump Sizing

Section 5b Haward Technology Middle East 22

ESP Application Engineering

2000 bpd Pump Sizing

Note that the GN1600 only supplies about 35 feet per

stage while the GN2100 supplies 45 feet per stage and

the GN2500 supplies 46.1 feet per stage. This means

that the GN2100 and GN2500 will take fewer stages to

do the job.

Note also that the GN2100 would be operating closer to

the middle of the recommended range which means

that this pump will be more efficient.

Section 5b Haward Technology Middle East 23

ESP Application Engineering

2000 bpd Pump Sizing

The fewer stages and better efficiency will most likely

mean that the GN2100 will be less expensive to

purchase as well as to operate so let's use it.

Section 5b Haward Technology Middle East 24

ESP Application Engineering

2000 bpd Pump Sizing

Note the head per stage is about 45 feet.

Section 5b Haward Technology Middle East 25

ESP Application Engineering

2000 bpd Pump Sizing

For our example, we have calculated that we need a

pump that will produce 1850 feet of Total Dynamic

head.

We now know the GN2100 we have chosen will provide 45

feet per stage.

1850 feet

-------------- = 41 stages

45 ft/stage

This means we will need a 41 stage GN2100 to do the job.

Section 5b Haward Technology Middle East 26

ESP Application Engineering

2000 bpd Pump Sizing

Now that the Pump sizing part of equipment selection

is over, let’s look at the other important curve for the

GN2100 which is the Brake Horsepower (BHP) curve.

Section 5b Haward Technology Middle East 27

ESP Application Engineering

2000 bpd Pump Sizing

Note that the BHP/stage @ 2000 BPD is about 1.05

Section 5b Haward Technology Middle East 28

ESP Application Engineering

2000 bpd Pump Sizing

1.05 BHP/stage * 41 stages = 43 Horsepower

This means that the pump will require 43 horsepower to

do the job.

Section 5b Haward Technology Middle East 29

ESP Application Engineering

2000 bpd Pump Sizing

In Summary:

We needed to design a pump to produce 1850 feet of

head at 2000 BPD.

We looked at five possible pumps and, using some simple

guidelines, we eliminated four of them.

Section 5b Haward Technology Middle East 30

ESP Application Engineering

2000 bpd Pump Sizing

We ended up with a 41 stage GN2100 which will draw 43

horsepower.

That's all there is to sizing a pump.

By the way, what is the efficiency?

Section 5b Haward Technology Middle East 31

ESP Application Engineering

2000 bpd Pump Sizing

In Summary:

Remember that

Flow * Head *

= ________________

BHP * 135,771

Where: Flow = BPD

Head = Feet

BHP = BHP

For this pump, h = 63.4%

Section 5b Haward Technology Middle East 32

ESP Application Engineering

2000 bpd Pump Sizing

Now that we have mastered sizing pumps, let's go

back and size the GN1600 and GN2500 for comparison.

In order to do this we will need to:

1. Read the head per stage

2. Calculate the number of stages required

3. Read the BHP per stage

4. Calculate the total horsepower required

5. Calculate the efficiency

Section 5b Haward Technology Middle East 33

ESP Application Engineering

GN1600 & GN2500 Sizing:

The head per stage is about 35.5 feet and 46.1 feet.

Section 5b Haward Technology Middle East 34

ESP Application Engineering

GN1600 & GN2500 Sizing:

1850 feet

___________ = 52 stages GN1600

35.5 ft/stage

This means we will need a 52 stage GN1600, or

1850 feet

___________ = 40 stages GN2500

46.1 ft/stage

This means we will need a 40 stage GN2500 to do the job

Section 5b Haward Technology Middle East 35

ESP Application Engineering

GN1600 Sizing:

The GN1600 requires about 0.93 BHP at 2000 BPD

0.93 BHP/stage * 52 stages = 48.5 Horsepower

This means that the pump will require 48.5 Hp to do the

job.

Section 5b Haward Technology Middle East 36

ESP Application Engineering

GN2500 Sizing:

The GN2500 requires about 1.14 BHP at 2000 BPD

1.14 BHP/stage * 40 stages = 45.6 Horsepower

This means that the pump will require 45.6 Hp to do the

job.

Section 5b Haward Technology Middle East 37

ESP Application Engineering

GN1600 & GN2500 Sizing:

Calculating Efficiency:

Flow * Head *

= ---------------------

BHP * 135,771

Since the only thing in the equation which has changed is

the BHP and we are now dividing by larger numbers than

before, the efficiency should go down.

Section 5b Haward Technology Middle East 38

ESP Application Engineering

GN1600 & GN2500 Sizing:

= 56.2% with the GN1600, and

= 59.8% with the GN2500,

compared to 63.4% for the GN2100

Section 5b Haward Technology Middle East 39

ESP Application Engineering

Sizing Comparison:

The GN1600 is 56.2% efficient and requires 48.5 Hp

The GN2500 is 59.8% efficient and requires 45.6 Hp

The GN2100 is 63.4% efficient and requires 43 Hp

In three cases we have calculated the horsepower

necessary to "run" the pump. How much energy

(horsepower) is each pump actually supplying to the

fluid?

Section 5b Haward Technology Middle East 40

ESP Application Engineering

Energy usage Considerations

Let’s look at Efficiency in another way

Work out of Pump

() =

Work in to Pump

Section 5b Haward Technology Middle East 41

ESP Application Engineering

Energy usage Considerations

= work out/work in

For the GN1600:

56.2% = work out / 48.5 Hp Work Out = 27.3 Hp

For the GN2500:

59.8% = work out / 45.6 Hp Work Out = 27.3 Hp

For the GN2100:

63.4% = work out / 43 Hp Work Out = 27.3 Hp

As you can see, regardless of what type of pump we use, the

energy required to pump the fluid is constant, but the energy

required to operate the Pump varies

Section 5b Haward Technology Middle East 42

ESP Application Engineering

Sizing Comparison: Energy usage

For the GN1600:

48.5 Hp - 27.3 Hp = 21.2 Hp missing

For the GN2500:

45.6 Hp - 27.3 Hp = 18.3 Hp missing

For the GN2100:

43 Hp - 27.3 Hp = 15.7 Hp missing

Where did it go?

Section 5b Haward Technology Middle East 43

ESP Application Engineering

Sizing Comparison: Energy usage

We can see that, as predicted, the GN1600 and GN2500

are less efficient so they will require a larger motor to be

purchased as well as more electricity to run them.

Additionally the GN1600 pump took more stages (52

compared to 41) so will probably be a more expensive

pump.

The GN2100 is a better sizing.

Section 5b Haward Technology Middle East 44

ESP Application Engineering

Sizing Comparison: Summary

With all these choices, which motor should we use for

a given application?

The process to select the best motor for the

application will depend on the economic compromises

of the user, but in general, after defining the

customers objectives and the pump horsepower load

for the application, we can resume the process of

selection of the motor as an iterative process which

includes:

Section 5b Haward Technology Middle East 45

ESP Application Engineering

Steps in Selection

I. Motor Series

II. Motor Type

III. Motor configuration, Voltage and Amperage

IV. Actual motor performance & Operating

Temperature and compare against max. temperature

V. Re-select motor if necessary

Section 5b Haward Technology Middle East 46

ESP Application Engineering

Motor Series

In general, just as in pumps, the bigger the better.

Larger diameter motors are less expensive to purchase

(per HP).

They can also go to higher horsepower without the

need for tandem connections which will enhance

reliability-simpler systems are better.

The only exception in this is the 738 motor.

The 738 motor is often more expensive than the 540

due to the lower usage and higher cost of inventory.

Section 5b Haward Technology Middle East 47

ESP Application Engineering

Motor Type - Rating

The motor type is designed with two letters:

The first letter is a code which provides information regarding to

the MOTOR RATING:

• S = Standard (250°F BHT - fixed horsepower),

• M = Intermediate (300°F BHT - conservative fixed HP)

• H = Hotline (450°F Motor Winding Temperature – fixed HP)

• P = High Performance (250°F BHT - conservative fixed HP)

• R = Optimum (400 °F Internal Temperature - variable HP)

Section 5b Haward Technology Middle East 48

ESP Application Engineering

Motor Type - Insulation

The second letter is a code which provides information

about the insulation type:

• K = Conventional winding and varnish

• X = New patented winding material, without varnish

Section 5b Haward Technology Middle East 49

ESP Application Engineering

Old Nomenclature

The designations corresponding to the old designations

for motor types are:

• OLD NEW

• 90-0 SK/SX

• 91 PK/PX

• 90-0 Int. MK/PX

• 92 RK/RX

• HOTLINE HX

Section 5b Haward Technology Middle East 50

ESP Application Engineering

Application of Motors

All motor Hp ratings are based on 1 ft per second

minimum flow past the motor of water.

Lower flow rates or fluids such as oil can lower the

effective Hp rating.

Section 5b Haward Technology Middle East 51

ESP Application Engineering

Bearings

A special note about bearings here:

• The standard bearing is "bi-directional" -- that is the

motor can be run in either direction with no loss in

bearing capacity.

• The Hi-Ex bearing is uni-directional and can only be

operated in one direction. Reverse operation may

lead to bearing failure.

Section 5b Haward Technology Middle East 52

ESP Application Engineering

Configuration, Voltage & Amperage

After choosing the Motor Series and Type, we will know

if it will be necessary for a single or tandem motor to

match the HP requirement of the pump.

Now we should look at Volts and Amps.

Section 5b Haward Technology Middle East 53

ESP Application Engineering

Application of Motors

For any given Hp there will be several voltages and amperages available.

For any given Hp there will be several voltages and amperages available.

Section 5b Haward Technology Middle East 54

ESP Application Engineering

Application of Motors

III. MOTOR CONFIGURATION, VOLTAGE & AMPERAGE,

For example, in a particular Hp if we have a 1000V,

50A motor a 2000V motor would be 25 amps and a 500V

motor would be 100 amps.

In other words KVA is constant.

High voltage motors (single motors) are no more or less

efficient than low voltage motors.

So why have more than one voltage?

Section 5b Haward Technology Middle East 55

ESP Application Engineering

Application of Motors

III. MOTOR CONFIGURATION, VOLTAGE & AMPERAGE,

The answer is not in the motor but in the power cable.

Lower voltage means higher current and this results in

higher voltage lost in the power cable.

So even though the motor efficiency does not change,

the overall system efficiency will decrease with higher

amperage.

If the amperage is too high, the motor may not even be

able to start

Section 5b Haward Technology Middle East 56

ESP Application Engineering

Application of Motors

III. MOTOR CONFIGURATION, VOLTAGE & AMPERAGE,

This explains why the various voltages -- but why such

odd voltages?

Surface motors, for example, are rated at 460V, 4160V,

2300V, etc.

These motors are made to "standard voltages".

Section 5b Haward Technology Middle East 57

ESP Application Engineering

Application of Motors

III. MOTOR CONFIGURATION, VOLTAGE & AMPERAGE,

In a way we have already answered this. The problem

is the voltage drop in the cable. SPS motors have to

contend with a very long length of power cable which

surface motors do not.

If we have a 460V surface supply, we would probably

only want about 430V downhole (for a low Hp motor)

to give us the necessary 460V at the surface including

the cable loss.

Section 5b Haward Technology Middle East 58

ESP Application Engineering

Application of Motors

III. MOTOR CONFIGURATION, VOLTAGE & AMPERAGE,

So in determining motor voltages we are really limited

by surface equipment.

Motor control panels come in certain voltage ranges

such as 600V, 1000V, 1500V, 2400V, etc.

Motor voltages are selected assuming a length of cable

such that the total voltage (motor plus cable loss) will

fall just below one of the panel ratings.

Section 5b Haward Technology Middle East 59

ESP Application Engineering

Application of Motors

III. MOTOR CONFIGURATION, VOLTAGE & AMPERAGE,

Remember the higher voltage the better, but it cannot

be so high that we exceed the control panel rating.

Higher voltage motors require smaller gauge wire and

very low Hp motors simply cannot be wound at very

high voltages because the wire would be too small to

work with.

Section 5b Haward Technology Middle East 60

ESP Application Engineering

Application of Motors

III. MOTOR CONFIGURATION, VOLTAGE & AMPERAGE,

In reality, there are dozens of potential winding

configurations for any particular motor Hp but the

number is intentionally limited to three or four to try

to cover the majority of applications with the minimum

amount of inventory.

Occasionally an application requires a special winding

and engineering should be consulted to see if it is

possible -- not every voltage can be hit exactly.

Section 5b Haward Technology Middle East 61

ESP Application Engineering

Application of Motors

III. MOTOR CONFIGURATION, VOLTAGE & AMPERAGE,

Motors come in single sections (head and base intrinsic)

as well as tandem configurations.

The tandems can include the UT (upper tandem – head

but no base), the CT (center tandem - no head or base)

or the LT (lower tandem - base but no head).

Section 5b Haward Technology Middle East 62

ESP Application Engineering

Application of Motors

III. MOTOR CONFIGURATION, VOLTAGE & AMPERAGE,

An upper tandem motor can be used as a single section

if it is completed on the bottom with either a Universal

Motor Base (UMB) or a Pressure Sensing Instrument

(PSI).

If additional horsepower is required over what can be

achieved in one piece, a CT or LT motor can be added.

Section 5b Haward Technology Middle East 63

ESP Application Engineering

Application of Motors

III. MOTOR CONFIGURATION, VOLTAGE & AMPERAGE,

When putting more than one motor together in tandem

combinations, always keep the sections the same Hp

and voltage. For example a 300 Hp 540 motor should

be made of two 150 Hp motors rather than something

like a 200 Hp and a 100 Hp.

Section 5b Haward Technology Middle East 64

ESP Application Engineering

Application of Motors

III. MOTOR CONFIGURATION, VOLTAGE & AMPERAGE,

So what happens when we put two motors together?

Section 5b Haward Technology Middle East 65

ESP Application Engineering

Application of Motors

III. MOTOR CONFIGURATION, VOLTAGE & AMPERAGE,

With two motors we double the Hp (add the two Hp's

together). We also double the voltage but the

amperage remains the same.

With three motors we triple the Hp and voltage but the

amperage still does not change.

For example, a 140 Hp, 1299V, 69.5A UT motor coupled

to a 140 Hp, 1299V, 69.5 CT motor would give us a 280

Hp, 2598V, 69.5A motor.

Section 5b Haward Technology Middle East 66

ESP Application Engineering

Application of Motors

III. MOTOR CONFIGURATION, VOLTAGE & AMPERAGE,

Always take care when adding motors together so that

the total voltage does not exceed the system limits --

i.e. do not try to put 3500 volts on a 3 kV cable.

Surface controllers, transformers, wellhead feedthru

mandrels, etc. will all have voltage limits we need to

be concerned with.

Section 5b Haward Technology Middle East 67

ESP Application Engineering

Application of Motors

IV. MOTOR PERFORMANCE & OPERATING TEMPERATURE.

Once the motor has been selected, using the software

like SubPUMP we can get the actual motor performance,

velocity and mainly the motor operating temperature, so

we can compare with the limits and check see if any

motor operating parameters have been exceeded.

Section 5b Haward Technology Middle East 68

ESP Application Engineering

End of this

Section

Section 5b Haward Technology Middle East 69

You might also like

- Cat 3304 3306 Industrial Marine Service ManualDocument827 pagesCat 3304 3306 Industrial Marine Service Manualruss mathis100% (35)

- Drilling Rig Operations & A To Z Rotary Drilling Rig ComponentsDocument130 pagesDrilling Rig Operations & A To Z Rotary Drilling Rig ComponentsAhmad93% (28)

- GasLiftValveDesign SI UnitsDocument15 pagesGasLiftValveDesign SI UnitsnvnvNo ratings yet

- Mud Pump NOV 8-P80Document1 pageMud Pump NOV 8-P80jonhyto14100% (1)

- SPE-177990-MS Electric Submersible Pump Installation and Commissioning - Challenges and Lesson Learned From Field DevelopmentDocument17 pagesSPE-177990-MS Electric Submersible Pump Installation and Commissioning - Challenges and Lesson Learned From Field Developmentmahmoud korieshNo ratings yet

- PCE-PRC-1-Primary and Remedial Cementing CoreDocument107 pagesPCE-PRC-1-Primary and Remedial Cementing CoreSergio SanjurjoNo ratings yet

- Case 1. Gas Lift System DesignDocument10 pagesCase 1. Gas Lift System DesignDaniel ChiriacNo ratings yet

- Basic Nodal Analysis and Impact of Commingled CompletionDocument5 pagesBasic Nodal Analysis and Impact of Commingled CompletionMod Hah GhasdcNo ratings yet

- A0032-P.2.l01.0 - 20197 - A - A - PPT - 03 - Pumps - 96sDocument84 pagesA0032-P.2.l01.0 - 20197 - A - A - PPT - 03 - Pumps - 96sOlumuyiwa FasehunNo ratings yet

- Section 04 PUMP ROR CURVEDocument46 pagesSection 04 PUMP ROR CURVEYassin MuhssenNo ratings yet

- Amer Hassan Elsayed: Work ExperienceDocument3 pagesAmer Hassan Elsayed: Work ExperienceElsayed AmerNo ratings yet

- 9 20234 A A PPT 01 Well TestingDocument9 pages9 20234 A A PPT 01 Well TestingkienlvNo ratings yet

- Ipr VLPDocument27 pagesIpr VLPMira MirzabaevaNo ratings yet

- Production Logging Interpretation Logging Interpretation Production Logging FundamentalsDocument37 pagesProduction Logging Interpretation Logging Interpretation Production Logging FundamentalsShereef ElsawyNo ratings yet

- PRJ RMC 1 PDFDocument59 pagesPRJ RMC 1 PDFJose Manuel MatossNo ratings yet

- Drilling Fluids and Solids Control Core: Learning ObjectivesDocument50 pagesDrilling Fluids and Solids Control Core: Learning ObjectivesRuben MejiaNo ratings yet

- RES IOR 2 - VirtualDocument66 pagesRES IOR 2 - VirtualKelly ColmenaresNo ratings yet

- Petroskills Course Schedule 2017Document7 pagesPetroskills Course Schedule 2017markfoyNo ratings yet

- Model HSEQ Structures: OMV-EP GuidelineDocument5 pagesModel HSEQ Structures: OMV-EP GuidelineMoaatazz NouisriNo ratings yet

- Toolstring ComponentsDocument11 pagesToolstring ComponentsHedi ChhidiNo ratings yet

- 1 Reservoir DeliverabilityDocument76 pages1 Reservoir DeliverabilityEric FamacyNo ratings yet

- Schlumberger: PIPESIM Open Link - Gas Lift Design & DiagnosticsDocument16 pagesSchlumberger: PIPESIM Open Link - Gas Lift Design & DiagnosticsnvnvNo ratings yet

- Mec CCC 1 PDFDocument51 pagesMec CCC 1 PDFJose Manuel MatossNo ratings yet

- PIPESIM Fundamentals: Workflow/Solutions TrainingDocument206 pagesPIPESIM Fundamentals: Workflow/Solutions TrainingFco Ignacio CamineroNo ratings yet

- 4c AL ESP Vision 2010 PDFDocument22 pages4c AL ESP Vision 2010 PDFDanteNo ratings yet

- ESP Design For WellFlo SoftwareDocument17 pagesESP Design For WellFlo SoftwareAngel NgoNo ratings yet

- Pipesim Modelado AvancadoDocument62 pagesPipesim Modelado Avancadoluis alberto godinez villaNo ratings yet

- Techniques of Artificial Lift For Viscous Oil ENI PDFDocument30 pagesTechniques of Artificial Lift For Viscous Oil ENI PDFRichard More LeonNo ratings yet

- Automate Gas Field Hydrates and Erosion Prediction Using PIPESIM OpenLink and Excel 6124063 01Document13 pagesAutomate Gas Field Hydrates and Erosion Prediction Using PIPESIM OpenLink and Excel 6124063 01ToufikNechNo ratings yet

- 14 - FH & SwivelDocument18 pages14 - FH & SwivelAmin AminNo ratings yet

- Oil Gas Conversion Chart FINAL 1Document2 pagesOil Gas Conversion Chart FINAL 1Arief Budiman HermaniNo ratings yet

- Att#20 - 7077T-000-PP-0000-108 - 00 List of Codes and StandardsDocument62 pagesAtt#20 - 7077T-000-PP-0000-108 - 00 List of Codes and Standardsabdelmalek boudjemaaNo ratings yet

- Lag Time ChartDocument4 pagesLag Time Charthafizi07No ratings yet

- SPE 152975 Using Dynamic Simulations To Optimize The Start-Up Procedure of A Lazy Horizontal Oil WellDocument11 pagesSPE 152975 Using Dynamic Simulations To Optimize The Start-Up Procedure of A Lazy Horizontal Oil Wellmatheus_moreira0990No ratings yet

- Day 6 ESP DIFA Procedure and ReportDocument59 pagesDay 6 ESP DIFA Procedure and ReportomerkhalidhameedNo ratings yet

- Drilling EngineeringDocument77 pagesDrilling EngineeringLok Bahadur RanaNo ratings yet

- PCP AE1 - DAY 1.1 Introduction To PCP System and ComponentsDocument66 pagesPCP AE1 - DAY 1.1 Introduction To PCP System and ComponentsCristhian LópezNo ratings yet

- Pipesim HistoryDocument22 pagesPipesim Historydndudc100% (1)

- API Example No. 1 100 100 1000 0.465 78 130 178 0.650 4000 544 7000 1030 8000 12 0.094 25.0 EDocument3 pagesAPI Example No. 1 100 100 1000 0.465 78 130 178 0.650 4000 544 7000 1030 8000 12 0.094 25.0 EashrafsaberNo ratings yet

- Production Technology Wellflo ProjectDocument20 pagesProduction Technology Wellflo ProjectLoh Chun LiangNo ratings yet

- 2nd Stage Separator: For Production Conditions / The Process Can Be AchievedDocument5 pages2nd Stage Separator: For Production Conditions / The Process Can Be AchievedihsansepalmaNo ratings yet

- SPE-196392-MS Gas Lift Robbing Prevention in Dual String Completion Using Production Pressure Operating ValveDocument15 pagesSPE-196392-MS Gas Lift Robbing Prevention in Dual String Completion Using Production Pressure Operating ValveM.No ratings yet

- Total Dynamic Head - TDHDocument37 pagesTotal Dynamic Head - TDHs pNo ratings yet

- Agl TempDocument3 pagesAgl TempArun KumarNo ratings yet

- PoseidonDocument2 pagesPoseidonAlan CordobaNo ratings yet

- ESP Design ScriptDocument5 pagesESP Design ScriptAmmar HrzNo ratings yet

- Artificial Lift Design: Experiment No: Date: - / - /2015Document19 pagesArtificial Lift Design: Experiment No: Date: - / - /2015Chaithanya Kumar DanduNo ratings yet

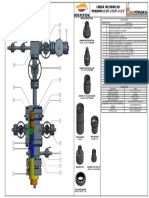

- Cabezal Multibowl Bes PROGRAMA 13 3/8" X 9 5/8" X 4 1/2": Instalations ToolsDocument1 pageCabezal Multibowl Bes PROGRAMA 13 3/8" X 9 5/8" X 4 1/2": Instalations ToolsJonathan AguirreNo ratings yet

- Universiti Teknologi Mara: Name: Student IDDocument6 pagesUniversiti Teknologi Mara: Name: Student IDTun Teja FarlinashNo ratings yet

- NExT Oil and Gas Training Field Development Program 2020 PDFDocument6 pagesNExT Oil and Gas Training Field Development Program 2020 PDFVivarodNo ratings yet

- Well TestingDocument8 pagesWell TestingCar Wooly WyclefNo ratings yet

- Kadanwari Well Integrity Test ProgramDocument28 pagesKadanwari Well Integrity Test ProgramsalmanNo ratings yet

- Subsea Exercise No. 8: Complete The Following Questions Based On The Data GivenDocument3 pagesSubsea Exercise No. 8: Complete The Following Questions Based On The Data GivenOgbodu Ejiro DesmondNo ratings yet

- 2006 International Sucker Rod Pumping WorkshopDocument33 pages2006 International Sucker Rod Pumping WorkshopRodrigo DacolNo ratings yet

- Camille Ri 2017Document36 pagesCamille Ri 2017Александр ШамковNo ratings yet

- OLGA 2014 New Functionalities For Well and DrillingDocument26 pagesOLGA 2014 New Functionalities For Well and DrillingAkin MuhammadNo ratings yet

- Data Header & Choke ManifoldDocument50 pagesData Header & Choke ManifoldRizwan FaridNo ratings yet

- Electrical Submersiblepumps PDFDocument51 pagesElectrical Submersiblepumps PDFRadu Chibzui100% (1)

- Section 14a ESP PUMP SIZING EXAMPLE No2Document21 pagesSection 14a ESP PUMP SIZING EXAMPLE No2Yassin MuhssenNo ratings yet

- ESP - Artificial LiftDocument46 pagesESP - Artificial LiftAYUNo ratings yet

- Section 14 ESP PUMP SIZING EXAMPLE No1Document17 pagesSection 14 ESP PUMP SIZING EXAMPLE No1Yassin MuhssenNo ratings yet

- B0001 Procedure For Pump Selection and Efficiency 20210908Document8 pagesB0001 Procedure For Pump Selection and Efficiency 20210908Luan Pham NgocNo ratings yet

- Production Logging Fundamentals 1667457005Document53 pagesProduction Logging Fundamentals 1667457005macNo ratings yet

- Section 07 MOTORSDocument35 pagesSection 07 MOTORSYassin MuhssenNo ratings yet

- Section 06 PROTECTORSDocument67 pagesSection 06 PROTECTORSYassin MuhssenNo ratings yet

- Section 15 ESP ITEMS TO CONSIDERDocument18 pagesSection 15 ESP ITEMS TO CONSIDERYassin MuhssenNo ratings yet

- Section 16 ESP FIELD OPERATIONSDocument14 pagesSection 16 ESP FIELD OPERATIONSYassin MuhssenNo ratings yet

- Section 14a ESP PUMP SIZING EXAMPLE No2Document21 pagesSection 14a ESP PUMP SIZING EXAMPLE No2Yassin MuhssenNo ratings yet

- Section 14 ESP PUMP SIZING EXAMPLE No1Document17 pagesSection 14 ESP PUMP SIZING EXAMPLE No1Yassin MuhssenNo ratings yet

- Section 04 PUMP ROR CURVEDocument46 pagesSection 04 PUMP ROR CURVEYassin MuhssenNo ratings yet

- Section 11 ESP CABLEDocument50 pagesSection 11 ESP CABLEYassin MuhssenNo ratings yet

- System For Optimising Pump Station Control - Part II: World Pumps July 2004Document4 pagesSystem For Optimising Pump Station Control - Part II: World Pumps July 2004Rahmi ArslanNo ratings yet

- SIHImulti MSHDocument20 pagesSIHImulti MSHVictor Flores ResendizNo ratings yet

- Curso Cat d6r III STMGDocument73 pagesCurso Cat d6r III STMGSilas F Pimenta90% (20)

- Caprari HMU1 Centrifugal PumpDocument1 pageCaprari HMU1 Centrifugal PumpGiorgiana RosuNo ratings yet

- Williams PumpDocument2 pagesWilliams PumpanantamaNo ratings yet

- ATWOOD Advantage BrochureDocument2 pagesATWOOD Advantage Brochurespong1ertzNo ratings yet

- Overhaul of Generator EngineDocument51 pagesOverhaul of Generator EngineSayem kaifNo ratings yet

- Oil and Chemical Plant Layout and Spacing PDFDocument13 pagesOil and Chemical Plant Layout and Spacing PDFtiffanyyy00No ratings yet

- 655D-EN FinalDocument2 pages655D-EN Finalipunk07mech50% (2)

- 68rfe IntroductionDocument71 pages68rfe IntroductionThePokeOne86% (7)

- Pompa HCP 2Document8 pagesPompa HCP 2Amarizal UMSNo ratings yet

- Best Practices For Cementing Job SoftwareDocument11 pagesBest Practices For Cementing Job SoftwarePegasus Vertex, Inc.No ratings yet

- M.P. Projects STP Master Drawing List Sl. No. Drg. No - Drg. TitleDocument7 pagesM.P. Projects STP Master Drawing List Sl. No. Drg. No - Drg. TitleShubhankar SharmaNo ratings yet

- C4.4 58ekw 60Hz Spec Sheet KCDocument4 pagesC4.4 58ekw 60Hz Spec Sheet KCAnnabelle AnnaNo ratings yet

- Bsa 1409 - d5 Data Sheet enDocument1 pageBsa 1409 - d5 Data Sheet enKvncGmz DzrNo ratings yet

- C13 Service Manual - 1Document180 pagesC13 Service Manual - 1mes100% (1)

- Bap 01 T B PDFDocument4 pagesBap 01 T B PDFyoberNo ratings yet

- FM25 ManualDocument67 pagesFM25 ManualMarcelo MalagoNo ratings yet

- Wintech - Company ProfileDocument4 pagesWintech - Company ProfileFebilaNo ratings yet

- 1007 Disq 0 G Ae 30033 Rev 5 Equipment ListDocument22 pages1007 Disq 0 G Ae 30033 Rev 5 Equipment Listeng20072007100% (1)

- SSP453 For The T5 2010Document64 pagesSSP453 For The T5 2010mamuko100% (1)

- Manual: Servicing Manual Centralized Lubrication System For LIEBHERR Hydraulic Excavator R 9250Document141 pagesManual: Servicing Manual Centralized Lubrication System For LIEBHERR Hydraulic Excavator R 9250Augusto Oliveira100% (2)

- QDK220 Spec Sheet-2Document24 pagesQDK220 Spec Sheet-2AbdelrahmanNo ratings yet

- 5230 Hydraulic ShovelDocument20 pages5230 Hydraulic ShovelOscarNo ratings yet

- Turbine Vol 1Document863 pagesTurbine Vol 1Sakthi Murugan100% (2)

- Cable Schedule SampleDocument9 pagesCable Schedule SampleAmin Hasan AminNo ratings yet

- GT 12 Separator ManualDocument214 pagesGT 12 Separator ManualRaghunath MajeeNo ratings yet