Professional Documents

Culture Documents

SNF Draft

SNF Draft

Uploaded by

firmanlaksono43Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SNF Draft

SNF Draft

Uploaded by

firmanlaksono43Copyright:

Available Formats

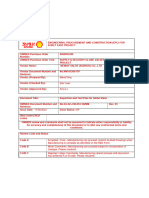

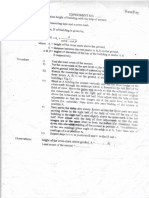

QUALITY INSPECTION SKILL

RULES :

1. Disediakan 1 Set leaf spring dan coil spring

2. Tim mengambil undian untuk mendapatkan item

inspeksi apa pada IRS yang akan diukur (1 tim

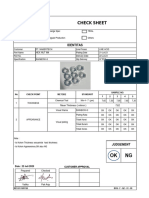

Form : ISP-3002 Assy

Rev : 0 INSPECTION RECORD SHEET

5 item inspeksi) -> Terdapat 2 IRS (Leaf

Spring & Coil Spring)

Date : 20.12.2018

Proses : ASSEMBLING LINE Kondisi Alat ukur

Roll Meter OK / NG

Type Prod. : _____________________ Qty OK : Acuan Kerja : Caliper OK / NG

Part No. : _____________________ Lot No. : _______ Qty NG : Drawing Rev : Gauge OK / NG

3. Tim melakukan 5 item inspeksi (Based on undian)

INSTRUMENT & SAMPLE

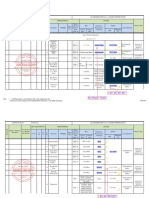

No ITEM PENGECEKAN STANDARD JUDGEMENT

KONDISI ALAT UKUR V1 V2 V3

A PENATAAN (SET UP)

1 Jumlah Leaf ( * ) Visual Pcs. OK NG

dengan alat ukur/ alat bantu yang sudah

Box Gauge / P. ± OK NG

2 Dimensi Center Grinding OK / NG

Width Gauge L. ± OK NG

Drawing

: OK NG

3 Bentuk dan Dimensi Silencer Caliper OK / NG

: OK NG

disediakan, dan ditulis pada IRS Leaf Spring &

: OK NG

Dimensi & Jenis Caliper & : OK NG

4 OK / NG

Interleaf / Shimcaster / Spacer Visual : OK NG

: OK NG

Coil Spring dengan acuan standart pada drawing

: OK NG

Caliper &

5 Bentuk dan Dimensi Klip OK / NG : OK NG

Visual

: OK NG

Klip Main : mm OK NG

6 Jarak Klip ke Ujung Leaf ( * ) Linier Scale OK / NG

4. Waktu pengecekan selama 5 menit

Klip Helper : mm OK NG

7 Jarak Silencer / Grove Ke Ujung Leaf ( * ) Linier Scale OK / NG mm OK NG

8 Dimensi Center Bolt Caliper OK / NG OK NG

9 Dimensi dan Arah Braket Caliper & Visual OK / NG OK NG

10 Kerataan Cat Dasar Visual Rata

11 Urutan Penataan Leaf & Arah Potong Visual Urut & Lengkap OK NG

B ASSY LEAF

1 Gap Wrapper ( * ) Linier Scale OK / NG mm OK NG

2 Squarness ( * ) Squarness Gauge OK / NG Max. mm OK NG

3 Gap Antar Leaf / Gap Ujung Taper Gauge OK / NG / mm OK NG

4 Free Camber Main / Helper Before SLT ( * ) Straight & Linier Scale OK / NG / mm OK NG

5 Arah Center Bolt Visual C T OK NG

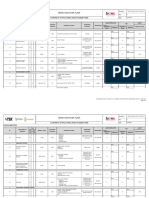

C SETTING - TESTING

1

2

3

Setting Load ( * )

Total Thickness ( * )

Free Camber Main / Helper After SLT ( * )

Data SLT

Caliper

Straight & Linier Scale

OK / NG

OK / NG

OK / NG /

Kgf

mm

mm

OK

OK

OK

NG

NG

NG

TOOLS :

• KALIPER

4 Overall Length at Free Camber ( * ) Linier Scale / Roll Meter OK / NG mm OK NG

D PRESS CLIP

1 Assy Width Box Gauge OK / NG Max. mm OK NG

• JIG/ GAUGE

mm OK NG

2 Dimensi Baut Klip + Pipa Caliper OK / NG

mm OK NG

3 Arah Baut Klip (Viewed from A Side) Visual L R OK NG

4 Torsi Center Bolt ( * ) Torque Wrench OK / NG Kgf.m(N.m) OK NG

5

6

7

Caulking Center Bolt

Gap antara Klip dengan Leaf ( * )

Gap Flatness (Length of Flatness/200) ( * )

Visual

Taper Gauge / Fuller

Straight & Taper Gauge

OK / NG

OK / NG

Max.

Max.

mm

mm

OK

OK

OK

NG

NG

NG

• 1 SET PRODUK LEAF

• 1 PRODUK COIL

E FINISH PAINT

1 Jenis Cat Finish SOP / Drawing Check Di Awal shift & ketika OK NG

ada perubahan komposisi (Cat

2 Viscositas Cat Finish ( * ) Iwata Cup & Stop Watch OK / NG Detik / Thinner) OK NG

• DRAWING LEAF & COIL

3 Ketebalan & Kerataan Cat Finish ( * ) Delta Scope & Visual OK / NG Min. 35 µm & Rata OK NG

F PART NUMBER

1 Part Number Visual OK NG

2 Posisi Marking, Ranking & Part. No Visual OK NG

• IRS LEAF & COIL

Inside Diameter EF / Bushing ( A ) Ø ± OK NG

3 Plug Gauge OK / NG

Inside Diameter EF / Bushing ( B ) Ø ± OK NG

Eye Width EF / Height Of Bushing ( A ) mm OK NG

4 Caliper / Width Gauge OK / NG

Eye Width EF / Height Of Bushing ( B ) mm OK NG

D ip erik s a D ib u a t

: ITEM CHECK FIT FUNCTION

IRS

Keterangan :

* Beri Tanda ( 0 ) Bila hasil pemeriksaan dinyatakan Sesuai dengan standart

* Beri Tanda ( x ) Bila hasil pemeriksaan dinyatakan Tidak Sesuai dengan standart

* Untuk item pemeriksaaan yang bertanda ( * ) cantumkan hasil pengukuran pada kolom S ta ff Q C QC P ro d u k si

* PASTIKAN ARAH SHIM CASTER TIDAK TERBALIK D a te : S h ift : I / II / III

You might also like

- Chapter 1 - Triangulation and TrilaterationDocument21 pagesChapter 1 - Triangulation and TrilaterationABAMELANo ratings yet

- Itp-Inspection & Test Plan: Containment InstallationDocument1 pageItp-Inspection & Test Plan: Containment InstallationwagwahkiabatheNo ratings yet

- ATPL Nav PlottingDocument6 pagesATPL Nav PlottingScipio100% (1)

- Revalidation FormatDocument2 pagesRevalidation FormatVipin KumarNo ratings yet

- Phiếu OQC KGDK02-07.06.2021Document2 pagesPhiếu OQC KGDK02-07.06.2021long nguyễn vănNo ratings yet

- Inspection Report: KG-AH13 Rev. Drawing ADocument2 pagesInspection Report: KG-AH13 Rev. Drawing Along nguyễn vănNo ratings yet

- Galva: Galva Deco Parts Pvt. LTDDocument2 pagesGalva: Galva Deco Parts Pvt. LTDSanjeev Kumar YadavNo ratings yet

- Bot 1L IBMO (Lot 3)Document2 pagesBot 1L IBMO (Lot 3)Thảo Ngọc VũNo ratings yet

- Check Sheet Pengiriman Dunage Head Cylinder TerbaruDocument1 pageCheck Sheet Pengiriman Dunage Head Cylinder TerbaruPia PitriantoNo ratings yet

- E23-30536-01-03 20240124 CertDocument1 pageE23-30536-01-03 20240124 CertAZLAN AIYUBNo ratings yet

- Format Baru 2019 Appearance Visual Checkbracket Xe-Cs2-5Document1 pageFormat Baru 2019 Appearance Visual Checkbracket Xe-Cs2-5heri yantaNo ratings yet

- Set-Up Approval Report-ABZA-XDocument1 pageSet-Up Approval Report-ABZA-Xswaran autoqaNo ratings yet

- Set-Up Approval Report-Separator UpperDocument1 pageSet-Up Approval Report-Separator Upperswaran autoqaNo ratings yet

- Set-Up Approval Report-XYZDocument1 pageSet-Up Approval Report-XYZswaran autoqaNo ratings yet

- Elbow 3 S80 180D SRDocument1 pageElbow 3 S80 180D SRJovianto PrisilaNo ratings yet

- Set-Up Approval Report-Brkt - HC CollectorDocument2 pagesSet-Up Approval Report-Brkt - HC Collectorswaran autoqaNo ratings yet

- Inspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportDocument3 pagesInspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportPrakash kumarTripathiNo ratings yet

- Set-Up Approval Report-Separator Fuel TankDocument2 pagesSet-Up Approval Report-Separator Fuel Tankswaran autoqaNo ratings yet

- Set-Up Approval Report-Bar PillionDocument1 pageSet-Up Approval Report-Bar Pillionswaran autoqaNo ratings yet

- FJP14313Document5 pagesFJP14313Arun .vNo ratings yet

- FJP14213Document5 pagesFJP14213Arun .vNo ratings yet

- 2305-0-17142-Po 14520706Document4 pages2305-0-17142-Po 14520706Alfonso LopezNo ratings yet

- Elbow 3 s80 90d LR - OkDocument1 pageElbow 3 s80 90d LR - OkJovianto PrisilaNo ratings yet

- 12A. QA-NPD-12 Sani Molds Switch Base ACE-023-01 21-06-2019Document8 pages12A. QA-NPD-12 Sani Molds Switch Base ACE-023-01 21-06-2019delightplasticsNo ratings yet

- Inspection Task Report No. - 5Document2 pagesInspection Task Report No. - 5hilalNo ratings yet

- 156734 - مخطط تدقيق QMS- F -10 -64Document3 pages156734 - مخطط تدقيق QMS- F -10 -64AlQasemNo ratings yet

- Part Re-Validation Report: Dighvijay Plastics & Allied Products PVT LTDDocument5 pagesPart Re-Validation Report: Dighvijay Plastics & Allied Products PVT LTDArun .vNo ratings yet

- PDV-22007C - MARTA FlooringDocument1 pagePDV-22007C - MARTA FlooringFERCHICHI NawelNo ratings yet

- Standard Operation ProcedureDocument3 pagesStandard Operation ProcedureAnand KesarkarNo ratings yet

- LG (67) - G3-1007 Fan (Propeller) G v.2Document10 pagesLG (67) - G3-1007 Fan (Propeller) G v.2Anonymous Lta32Ta9No ratings yet

- E23-30536-03-01 20240124 CertDocument1 pageE23-30536-03-01 20240124 CertAZLAN AIYUBNo ratings yet

- Form-HSE-TMR-005 Welding InspectionDocument1 pageForm-HSE-TMR-005 Welding Inspectionkenia info100% (1)

- M313243-4-1 20240124 CertDocument1 pageM313243-4-1 20240124 CertAZLAN AIYUBNo ratings yet

- Inspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportDocument5 pagesInspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportPrakash kumarTripathiNo ratings yet

- 22.07.23 Hex Nut M4Document1 page22.07.23 Hex Nut M4Heri IrawanNo ratings yet

- MBA01161Document5 pagesMBA01161Arun .vNo ratings yet

- Check Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportDocument1 pageCheck Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportJovianto PrisilaNo ratings yet

- Msa1.11 For ExerciseDocument2 pagesMsa1.11 For ExerciseRohit TripathiNo ratings yet

- EG.02.J.96.053.102NM 03 1 PublicationDocument6 pagesEG.02.J.96.053.102NM 03 1 Publicationfhairuz.wahidNo ratings yet

- Inspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportDocument2 pagesInspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportPrakash kumarTripathiNo ratings yet

- QA-NPD-12 Sani Molds Switch Base ACE-023-01 25-04-2019Document14 pagesQA-NPD-12 Sani Molds Switch Base ACE-023-01 25-04-2019delightplasticsNo ratings yet

- 447 Final Inspn Edited PDFDocument3 pages447 Final Inspn Edited PDFATHIBAN VNo ratings yet

- 8D Wheel WobblingDocument2 pages8D Wheel Wobblingmunireddy.vNo ratings yet

- Elbow 2 S40 45D LRDocument1 pageElbow 2 S40 45D LRJovianto PrisilaNo ratings yet

- 5W SheetDocument1 page5W Sheetgagandeep isherNo ratings yet

- XZB (36B) Rotating Cups-Installation Technique and Inspection RecordDocument23 pagesXZB (36B) Rotating Cups-Installation Technique and Inspection RecordPercy ChenNo ratings yet

- $RP0EVX9Document4 pages$RP0EVX9hemanth rompilliNo ratings yet

- Supplier Self Part RevalidationDocument2 pagesSupplier Self Part RevalidationChetan PatilNo ratings yet

- LQC STDDocument2 pagesLQC STDAstronNo ratings yet

- Qap - Structural Mechanical FabricationDocument8 pagesQap - Structural Mechanical Fabricationbharathi_pmNo ratings yet

- Set-Up Approval Report-Bar Comp PillionDocument1 pageSet-Up Approval Report-Bar Comp Pillionswaran autoqaNo ratings yet

- Quality Control PlanDocument1 pageQuality Control PlanJoki PenangNo ratings yet

- Weekly Report For Control Valve - REV 0 15 January 2023Document12 pagesWeekly Report For Control Valve - REV 0 15 January 2023Andy ArdianNo ratings yet

- CP ProductionDocument7 pagesCP Productionsandeep.pantNo ratings yet

- Supplier Self Part RevalidationDocument2 pagesSupplier Self Part RevalidationChetan PatilNo ratings yet

- Tsks-001844-00-Csa-Pl-0000-F07-00 - Concrete Structures and Foundations Itp Rev.0 - 10-08-2021Document4 pagesTsks-001844-00-Csa-Pl-0000-F07-00 - Concrete Structures and Foundations Itp Rev.0 - 10-08-2021tiote moussaNo ratings yet

- OIR - Top Hook BracketDocument1 pageOIR - Top Hook BracketHafizi HassanNo ratings yet

- Control PlanDocument4 pagesControl PlanRakesh PandeyNo ratings yet

- Check Sheet Blasting Inspeksi: Tanggal: No. DokumenDocument4 pagesCheck Sheet Blasting Inspeksi: Tanggal: No. DokumenQuality PatriaNo ratings yet

- Weighing Balance Equipment Maintenance RecordDocument1 pageWeighing Balance Equipment Maintenance Recordsree mahendra labsNo ratings yet

- Form Pengukuran GroundingDocument2 pagesForm Pengukuran GroundingghooestiepNo ratings yet

- LDC Lot 11..Document3 pagesLDC Lot 11..kival231No ratings yet

- SB Instrument Quotation RevisedDocument3 pagesSB Instrument Quotation RevisedVikas KunduNo ratings yet

- Surveyor-1styear (VolumeII of II) - TheoryDocument122 pagesSurveyor-1styear (VolumeII of II) - Theorysouravsaha.civil11No ratings yet

- NG Stay Head Pipe Lc4a Pt. Kmil (HM)Document3 pagesNG Stay Head Pipe Lc4a Pt. Kmil (HM)syaiful rizkiNo ratings yet

- Registros Lectura de Mediciones Del Vernier: Tuerca LargoDocument6 pagesRegistros Lectura de Mediciones Del Vernier: Tuerca LargojesusNo ratings yet

- Peta ArisDocument1 pagePeta ArisNur Kemas Asyifa AsyifaNo ratings yet

- Group B2Document18 pagesGroup B2MUHAMMAD AZIM BIN MOHD RASHIDNo ratings yet

- The Steps How To Use Theodolite For SurveyingDocument2 pagesThe Steps How To Use Theodolite For Surveyinglong bottomNo ratings yet

- Stage Micrometer S12, 0.1mm Horizontal Line in 0.002mm Divisions, Black Slide/glass Disc RS-MN-35-SG12T0Document2 pagesStage Micrometer S12, 0.1mm Horizontal Line in 0.002mm Divisions, Black Slide/glass Disc RS-MN-35-SG12T0Alina ElenaNo ratings yet

- Navigational CalculationsDocument42 pagesNavigational CalculationsIwan MaspaitellaNo ratings yet

- CE 010 Fundamentals of Surveying (ENSE21S1)Document36 pagesCE 010 Fundamentals of Surveying (ENSE21S1)Bea Merr MazoNo ratings yet

- Checking Aids: SBCT Industries LLPDocument1 pageChecking Aids: SBCT Industries LLPSBCT QCNo ratings yet

- Spso Iac Ils T Cat C D Rwy22Document1 pageSpso Iac Ils T Cat C D Rwy22Jose Carlos ParodiNo ratings yet

- Position Fixing MethodsDocument28 pagesPosition Fixing MethodsFlexi100% (1)

- Classification of SurveyDocument20 pagesClassification of SurveyganeshNo ratings yet

- L6 Methods of Provision of Ground Control PointsDocument15 pagesL6 Methods of Provision of Ground Control PointsKenny BoatNo ratings yet

- Special Publication 65-1 Part 1Document100 pagesSpecial Publication 65-1 Part 1Micole BrodethNo ratings yet

- 10 Kit Rep Caliper Rymeautomotive 2019Document132 pages10 Kit Rep Caliper Rymeautomotive 2019Alberto GonzalezNo ratings yet

- Sextant ManualDocument2 pagesSextant ManualAnanyaNo ratings yet

- Ce2204 LPDocument3 pagesCe2204 LPBalaji DuraiyanNo ratings yet

- Pdf-Crop - 2023-01-19T161057.257Document3 pagesPdf-Crop - 2023-01-19T161057.257Thermo PlastNo ratings yet

- 02pengenalan Kepada Fizik - SoalanDocument11 pages02pengenalan Kepada Fizik - SoalanNick Naz LikeNo ratings yet

- For Use With Cat Mobile Crimper M6: MN) CouplingsDocument3 pagesFor Use With Cat Mobile Crimper M6: MN) CouplingsAli AdelNo ratings yet

- Gauges and InstrumentsDocument14 pagesGauges and InstrumentsRatan Misra100% (1)

- Unit 6 Tacheometer Tacheometry Surveying Classification Stadia Method Distance Elevation Calculation 2021Document51 pagesUnit 6 Tacheometer Tacheometry Surveying Classification Stadia Method Distance Elevation Calculation 2021JUMIOTNo ratings yet

- Longitude by Chronometer PlanetDocument1 pageLongitude by Chronometer PlanetBandar AlmalkiNo ratings yet

- Technical Description: BoundariesDocument4 pagesTechnical Description: BoundariesJohn Rey MontemorNo ratings yet

- Technical Report On TopographicDocument15 pagesTechnical Report On TopographicSAMUELNo ratings yet