Professional Documents

Culture Documents

5-1-ABC Classification

5-1-ABC Classification

Uploaded by

Ferney DeviaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5-1-ABC Classification

5-1-ABC Classification

Uploaded by

Ferney DeviaCopyright:

Available Formats

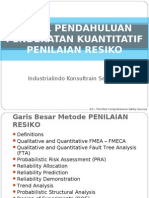

ASSET MANAGEMENT PILLAR CREATION

In practice, we have

defined:

1st –the indicator to work

2nd –how to control the established indicators

3rd –on what machine to start working

4th –how to reduce the breakdowns

ASSET MANAGEMENT MEETING

EFFECTIVE MAINTENANCE PILLAR CREATION

3rd – On what machine we started working

We used the ABC criterion to establish priority and policies of

Maintenance.

ASSET MANAGEMENT MEETING

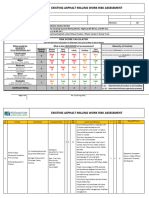

MACHINE ABC CLASSIFICATION

FLUXOGRAM TO CLASSIFY THE MACHINE

S

Ojo RULES TO CLASSIFY THE MACHINE

Q CLASS

E

Risk potential of

W S accidents due to an

equipment

High accident risk Low accident risk Despicable accident

risk

breakdown

Losses potential,

D Q claims and reworks High potential in Low potential in Despicable potential

( Source: quality causing losses, causing losses, in causing losses,

deployment) claims or reworks claims or reworks

D

claims or reworks

Time the equipment is

F W

available for

production

( Manned Hours)

24 hs / day 8 - 24 hs / day 8 hs / day

F Impact caused in

the production line The machine failure The machine failure The machine failure

M D (Lead Time) due to

an equipment

interrupts the following

productive process

doesn’t interrupt the

following productive

process,

doesn’t interrupt the

following productive

process

breakdown although it generates

losses

M Equipment 1 breakdown / 2

F breakdown F > 1 breakdown / months to 1 F < 1 breakdown /

frequency 2months breakdown / 6 6 months

months

A B C

Medium time to

M repair the

equipment

MTTR >= 2 hs 0,5 < MTTR > 2 hs MTTR < 0,5 hs

PM

ASSET MANAGEMENT MEETING

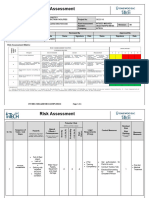

Ojo MACHINE ABC CLASSIFICATION

S

Risk potential of occurring

Q

S physical and environmental

accidents due to equipment

bad conditions

W

Safety and

D

D

Environmenta

F l

F High Accident

M Risk

M

A B C

PM Low Accident Risk

Despicable

Accident Risk

ASSET MANAGEMENT MEETING

MACHINE ABC CLASSIFICATION

S Ojo Losses, claims and

Q

Q reworks potential

( Source: quality

W deployment)

D

D

Qualit High potential in

F

causing losses,

F y

claims or reworks

M

A B C

Low potential in

PM causing losses,

claims or reworks

Despicable

potential in causing

losses, claims or

reworks

ASSET MANAGEMENT MEETING

MACHINE ABC CLASSIFICATION

S

Time the equipment

Q

W

W is available for

production

( Manned Hours)

D

D

F

24 hs /

Working

F

M

day

M Time

A B C

PM

8 - 24 hs /

day

8 hs /

day

ASSET MANAGEMENT MEETING

MACHINE ABC CLASSIFICATION

S

Impact caused in the line

Q

D production (Lead Time)

due to equipment

W breakdown

D

D The machine failure

F interrupts the

F following productive

M process

M Deliver

y The machine failure

A B C

doesn’t interrupt the

PM following productive

process, although it

generates losses

The machine failure

doesn’t interrupt the

following productive

process or there is

another spare machine

ASSET MANAGEMENT MEETING

MACHINE ABC CLASSIFICATION

S

Equipment failure

Q

W

F frequency

D

D

F

F F > 1 failure / 2

M months

M

Frequency

A B C

1 failure / 2 months

PM

to

1 failure / 6 months

F < 1 failure / 6

months

ASSET MANAGEMENT MEETING

MACHINE ABC CLASSIFICATION

S

Medium Time to

Q

W

M Repair the

Equipment

D

D

F

F MTTR >= 2

M

hs

M

A B C

PM

0,5 < MTTR > 2

Maintainability hs

MTTR < 0,5

h

ASSET MANAGEMENT MEETING

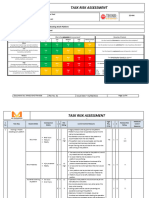

MACHINE ABC CLASSIFICATION

S

Q

Summary

W Potential Assessment

Machine Clas

S Q W D F M s

D VTV 13( VTV A

D

LaminatorI ) 21

( Laminator A

F

Steven I) A

F

s

VTV 14( VTV B

M

Side II ) B

M Sealer

Schiav B

iLaminator 24 ( Laminator B

A B C Slitter II ) B

PM s

Palletizing System Gantry B

Robot

Palletizing System B

Shrink

Palletizing System B

Conveyors

Transformer C

s

Palletizing System X C

Dryer

Doctor C

s

Compressed X C

air

Cold X C

water

Air C

conditioning

Polyethylene X C

Silos Monte Mor

Example

ASSET MANAGEMENT MEETING

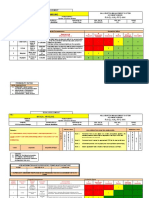

Maintenance Policy

Applied Maintenance by

Classification •Predictive Maintenance

•Preventive Maintenance

•All breakdowns analysis and Autonomous Maintenance support

Machine A by the Systemic Improvement Team

•Breakdown Reduction Team (Focused)

•RCM Analysis (Reliability Centered Maintenance)

•Predictive Maintenance

•Preventive Maintenance

Machine B •Breakdown Reduction Team ( Focused )

•All breakdowns analysis by the area maintenance team.

•Corrective Maintenance

•Predictive and Preventive Maintenance in utility equipment

Machine C •Breakdowns Monitoring by the area maintenance team in order not

to become repetitive

New Equipment •Corrective Maintenance

•Preventive Maintenance according to Manufacturer specifications

in the packages • Breakdowns Analysis

production •ABC Classification after one year use

ASSET MANAGEMENT MEETING

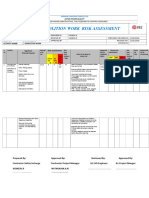

Realizar la matriz de clasificación de acuerdo con la

norma ISO 55001

1. Realice el levantamiento de sus activos.

2. Realice la matriz de criticidad

estableciendo referencias cuantitativas

para cada criterio y

3. Evalué la ponderación.

4. Realice la grafica de ponderación e inicie

el proceso de desarrollo de confiabilidad.

ASSET MANAGEMENT MEETING

You might also like

- General Power of Attorney Format For NRIDocument2 pagesGeneral Power of Attorney Format For NRIreal estate jaipur71% (35)

- Risk Assessment For Curtain Wall & Glazing InstallationDocument4 pagesRisk Assessment For Curtain Wall & Glazing InstallationChristos Loutrakis75% (4)

- Risk Assessment For BridgeDocument31 pagesRisk Assessment For BridgeMariam Mousa100% (2)

- Building Character in This Age of DegeneracyDocument41 pagesBuilding Character in This Age of DegeneracyShawn ValentinoNo ratings yet

- ABC ClassificationDocument11 pagesABC ClassificationJUan Banquez GarciaNo ratings yet

- In Practice, We Have Defined:: 1 - The Indicator To Work 2 - How To Control The Established IndicatorsDocument11 pagesIn Practice, We Have Defined:: 1 - The Indicator To Work 2 - How To Control The Established IndicatorsJUan Banquez GarciaNo ratings yet

- TRA - Scaffold Erection & ModificationDocument16 pagesTRA - Scaffold Erection & ModificationibrahimNo ratings yet

- Scaffold Erection & Dismantling Rev: 00: Task Risk AssessmentDocument9 pagesScaffold Erection & Dismantling Rev: 00: Task Risk Assessmentibrahim100% (1)

- RA Existing Asphalt Milling WorksDocument8 pagesRA Existing Asphalt Milling WorksSolimanNo ratings yet

- An Example: W.R.T Thermal Power PlantDocument3 pagesAn Example: W.R.T Thermal Power PlantArunNo ratings yet

- RA-GL-HAL-PPS-445 (Working at Height)Document5 pagesRA-GL-HAL-PPS-445 (Working at Height)BalasubramanianNo ratings yet

- 030 - Moving Machineries in Site PremisesDocument6 pages030 - Moving Machineries in Site PremisesPrem ChristianNo ratings yet

- Finance Risk Assessment of CCSU ProjectDocument10 pagesFinance Risk Assessment of CCSU ProjectNavya RaturiNo ratings yet

- Eepsp Ra Swro 003 - 00aDocument9 pagesEepsp Ra Swro 003 - 00afayaz5233No ratings yet

- TRA - Rotary Equipment ErectionDocument29 pagesTRA - Rotary Equipment ErectionBenasher IbrahimNo ratings yet

- Fmea GuideDocument11 pagesFmea GuideSASIKUMARNo ratings yet

- RA GL HAL PPS 404 (Dewatering)Document6 pagesRA GL HAL PPS 404 (Dewatering)BalasubramanianNo ratings yet

- Inherent Risk Assessment - Ammonia Plant - 12032020Document6 pagesInherent Risk Assessment - Ammonia Plant - 12032020Anonymous gWKgdUBNo ratings yet

- Беденко ВладиславDocument6 pagesБеденко Владиславperhik.ruNo ratings yet

- Gas Cylinders Risk AssessmentDocument3 pagesGas Cylinders Risk AssessmentMAB AliNo ratings yet

- 005-JSA X-Ray & Gamma Ray RadiographyDocument7 pages005-JSA X-Ray & Gamma Ray RadiographyMoaatazz NouisriNo ratings yet

- JHA-scaffolding & Hot Work For TrizacDocument12 pagesJHA-scaffolding & Hot Work For Trizacsaud salemNo ratings yet

- Workshop On Hazard Detection in The WorkplaceDocument10 pagesWorkshop On Hazard Detection in The WorkplaceScribdTranslationsNo ratings yet

- 010 - Scaffolding (Erection & Dismantling)Document6 pages010 - Scaffolding (Erection & Dismantling)Prem ChristianNo ratings yet

- SKC S Aerosol Safety Data Sheet EnglishDocument5 pagesSKC S Aerosol Safety Data Sheet EnglishkhairurNo ratings yet

- Lifting - CraneDocument9 pagesLifting - CraneR Sahadeo ReddyNo ratings yet

- Biis-Sf-03-Risk Assessment Form-GeneratorDocument3 pagesBiis-Sf-03-Risk Assessment Form-GeneratorBIIS QAQC Babu SivaNo ratings yet

- 209 Using of Angle GrinderDocument9 pages209 Using of Angle GrindergrantNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDPa imanNo ratings yet

- RA For Power Cable - EEPSP RA SWRO 008 - 00A SignedDocument9 pagesRA For Power Cable - EEPSP RA SWRO 008 - 00A Signedfayaz fayazhotmail.comNo ratings yet

- 038 - Working On Mobile Elevating Work PlatformDocument4 pages038 - Working On Mobile Elevating Work PlatformPrem ChristianNo ratings yet

- Compilation of Assessment Method For Criticality Equipment Rating Rev 2Document13 pagesCompilation of Assessment Method For Criticality Equipment Rating Rev 2Juristiawan FitriansyahNo ratings yet

- OIL FILTERATION - TRA - RevDocument21 pagesOIL FILTERATION - TRA - RevBenasher IbrahimNo ratings yet

- Ref.1.10-RL-Risk LogDocument2 pagesRef.1.10-RL-Risk Logمدريدي الى الابدNo ratings yet

- 06-She-ra-06-Bulk Earthworks Ra Rev01Document12 pages06-She-ra-06-Bulk Earthworks Ra Rev01Mlungisi MadlalaNo ratings yet

- Tra-Derrick Module Assembly Below 30 MetersDocument37 pagesTra-Derrick Module Assembly Below 30 MetersBenasher IbrahimNo ratings yet

- Equipment Risk AssessmentDocument7 pagesEquipment Risk Assessmentgullipalli srinivasa raoNo ratings yet

- Project Risk LogDocument6 pagesProject Risk LogRaj MoktanNo ratings yet

- QP Guideline For Hazid Review: Doc File No.: GDL-S-040 R1 Page 22 of 27 Custodian Dept: STDocument1 pageQP Guideline For Hazid Review: Doc File No.: GDL-S-040 R1 Page 22 of 27 Custodian Dept: STsanjayNo ratings yet

- RA-GL-HAL-PPS-442 (Air Pigging)Document5 pagesRA-GL-HAL-PPS-442 (Air Pigging)BalasubramanianNo ratings yet

- RA-GL-HAL-PPS-406 (Environment)Document4 pagesRA-GL-HAL-PPS-406 (Environment)BalasubramanianNo ratings yet

- OSHP-CH03 Risk RegisterDocument31 pagesOSHP-CH03 Risk Registerabubakrelsaid90No ratings yet

- RA-GL-HAL-PPS-444 (Manual Handling)Document7 pagesRA-GL-HAL-PPS-444 (Manual Handling)BalasubramanianNo ratings yet

- Baseline Risk Assessment 2014 Construction Regulations (Rev 2)Document26 pagesBaseline Risk Assessment 2014 Construction Regulations (Rev 2)preciousphooko50No ratings yet

- Hirarc of Soil Investigation at Gadang Construction SiteDocument21 pagesHirarc of Soil Investigation at Gadang Construction Sitesyafiq ishakNo ratings yet

- Hira For DemolitionDocument3 pagesHira For DemolitionMokka SamaiyalNo ratings yet

- Pfmea TemplateDocument2 pagesPfmea TemplateAdetunji Babatunde TaiwoNo ratings yet

- 014 - Manual HandlingDocument4 pages014 - Manual HandlingPrem ChristianNo ratings yet

- Evaluation Chart For Ranking Equipment Edge MillingDocument6 pagesEvaluation Chart For Ranking Equipment Edge MillingParesh ValaNo ratings yet

- Hirarc SlideDocument19 pagesHirarc SlideKrishnan Mudaliar Bopalan100% (1)

- Baseline Risk Assessment FSDocument17 pagesBaseline Risk Assessment FSStephenNo ratings yet

- RISK ASSESSMENT - Repairs To in Situ Kerbing - BLaying Paving, Kerb & Paper Chute - CON - RA - 054 - 1 Rev 0Document8 pagesRISK ASSESSMENT - Repairs To in Situ Kerbing - BLaying Paving, Kerb & Paper Chute - CON - RA - 054 - 1 Rev 0Nick KrugerNo ratings yet

- Mechanical RiskDocument19 pagesMechanical RiskScribdTranslationsNo ratings yet

- 5 - Guidelines For Ranking of MachinesDocument1 page5 - Guidelines For Ranking of MachinesRounak AnandNo ratings yet

- Pile Integrity Testing RADocument12 pagesPile Integrity Testing RAmdfahad0047No ratings yet

- Risk Assessment FormDocument4 pagesRisk Assessment Formbeshoy100% (2)

- Fmea Fta ModuleDocument156 pagesFmea Fta ModuleIan Maldonado100% (1)

- Hvac WorksDocument4 pagesHvac WorksSaleem BashaNo ratings yet

- Pump DiagnosticDocument29 pagesPump DiagnosticZahid RashidNo ratings yet

- Risk Assessment For Scaffolding Erection and DismantlingDocument6 pagesRisk Assessment For Scaffolding Erection and Dismantling92qhnqmrhsNo ratings yet

- Triple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsFrom EverandTriple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsNo ratings yet

- Norma P - IDDocument1 pageNorma P - IDFerney DeviaNo ratings yet

- A5E43215508A Sicherheitshinweise SIMOTICS GP SD DP FL en-USDocument10 pagesA5E43215508A Sicherheitshinweise SIMOTICS GP SD DP FL en-USFerney DeviaNo ratings yet

- Un Sistema de Aprendizaje de Insectos A Base de Juego Móvil para Mejorar El AprendizajeDocument9 pagesUn Sistema de Aprendizaje de Insectos A Base de Juego Móvil para Mejorar El AprendizajeFerney DeviaNo ratings yet

- Marine Pollution Bulletin: ArticleinfoDocument11 pagesMarine Pollution Bulletin: ArticleinfoFerney DeviaNo ratings yet

- 2 - Dilemma and Foundation of MoralityDocument11 pages2 - Dilemma and Foundation of MoralityReyzhel Mae MatienzoNo ratings yet

- Rotaract Songs: Compiled By: Rotr. Afolabi OluwadamilolaDocument24 pagesRotaract Songs: Compiled By: Rotr. Afolabi Oluwadamilolaphysco azNo ratings yet

- Ballesteros National High School: The Impact of Marketing-Sales Relationship To Business PerformanceDocument56 pagesBallesteros National High School: The Impact of Marketing-Sales Relationship To Business PerformanceGlenziel RiveraNo ratings yet

- Types of Lies and LiarsDocument3 pagesTypes of Lies and LiarsCrisfer SantosNo ratings yet

- Claude Is A Fourth Year Engineering University Student Who Has JDocument1 pageClaude Is A Fourth Year Engineering University Student Who Has Jtrilocksp SinghNo ratings yet

- Resignation of Director - 3Document4 pagesResignation of Director - 3EugeneNo ratings yet

- Appointment of Trustees (Jan. 18)Document4 pagesAppointment of Trustees (Jan. 18)Leanna RoperNo ratings yet

- Mansi Deokar PDFDocument2 pagesMansi Deokar PDFMansi DeokarNo ratings yet

- Social and Ethical Impact of MediaDocument4 pagesSocial and Ethical Impact of MediaanamNo ratings yet

- (U) Daily Activity Report: Marshall DistrictDocument6 pages(U) Daily Activity Report: Marshall DistrictFauquier NowNo ratings yet

- FA000 Advantages-And-Disadvantages-Of-Participatory-Planning WIP AIR v001Document3 pagesFA000 Advantages-And-Disadvantages-Of-Participatory-Planning WIP AIR v001baoshi3382100% (1)

- Legal WritingDocument160 pagesLegal WritingRoger JavierNo ratings yet

- PC Tomasi Naulu Appeal LetterDocument2 pagesPC Tomasi Naulu Appeal LetterNetani SeruwaqaNo ratings yet

- Omar Lee Consutling AgreementDocument5 pagesOmar Lee Consutling AgreementAndrewNo ratings yet

- Self Efficacy ScaleDocument2 pagesSelf Efficacy ScaleShruti ShrivastavaNo ratings yet

- Sale of Goods Act (9.6.2022) DiscussionDocument19 pagesSale of Goods Act (9.6.2022) DiscussionDrEi Shwesin HtunNo ratings yet

- Rubric Healthy Body Image and Self-Esteem ProjectDocument4 pagesRubric Healthy Body Image and Self-Esteem Projectapi-482784376No ratings yet

- Students Personal Data With Data Privacy StatementDocument2 pagesStudents Personal Data With Data Privacy StatementMaimaitrazoNo ratings yet

- Effective Communication - MastermindDocument42 pagesEffective Communication - Mastermindgroom saurabh100% (1)

- Bioethics in Surgical PracticeDocument21 pagesBioethics in Surgical PracticeFree ZingNo ratings yet

- Valuing UsDocument1 pageValuing UsSpeech & Language Therapy in PracticeNo ratings yet

- Isokene (Stop My Wife From Smiling) E-Novel by Opeyemi AkintundeDocument97 pagesIsokene (Stop My Wife From Smiling) E-Novel by Opeyemi Akintundevea100% (1)

- Module 5 - Kartilya NG Katipunan (ReviewerDocument2 pagesModule 5 - Kartilya NG Katipunan (ReviewerMj PamintuanNo ratings yet

- Political Science AssignmentDocument3 pagesPolitical Science AssignmentpushkalNo ratings yet

- Ethical Issues in International Marketing PDFDocument2 pagesEthical Issues in International Marketing PDFTaylorNo ratings yet

- Management Ethics and Social ResponsibilityDocument30 pagesManagement Ethics and Social ResponsibilityarchievedaNo ratings yet

- Purser ReviewerDocument3 pagesPurser Reviewerbianca pelayoNo ratings yet

- Neighbors Are The People Who Live Near UsDocument1 pageNeighbors Are The People Who Live Near Usarsamufti91100% (1)