Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

1 viewsBoundy8e PPT Ch02

Boundy8e PPT Ch02

Uploaded by

AndrewCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You might also like

- Technical Drawing With Engineering Graphics 16Th Edition Frederick E Giesecke Full ChapterDocument67 pagesTechnical Drawing With Engineering Graphics 16Th Edition Frederick E Giesecke Full Chapterdarlene.baker133100% (9)

- Revit Standards Manual V2Document91 pagesRevit Standards Manual V2Nhu Huynh100% (1)

- Geometric Dimensioning and TolerancingDocument3 pagesGeometric Dimensioning and Tolerancingdesign12No ratings yet

- Heat Integration AssignmentDocument8 pagesHeat Integration AssignmentMian Kamran AliNo ratings yet

- BPT Targha Instalation ManualDocument12 pagesBPT Targha Instalation ManualFernando Manon100% (1)

- Basics of Geometrical Dimensioning & ToleranceDocument25 pagesBasics of Geometrical Dimensioning & ToleranceGarry GillNo ratings yet

- Boundy8e PPT Ch01Document19 pagesBoundy8e PPT Ch01AndrewNo ratings yet

- Boundy8e PPT Ch03Document29 pagesBoundy8e PPT Ch03AndrewNo ratings yet

- A Textbook of Drawing by S.lesaDocument30 pagesA Textbook of Drawing by S.lesadavid.padsonNo ratings yet

- Gambar Teknik 1 PDFDocument22 pagesGambar Teknik 1 PDFIndah HaninditaNo ratings yet

- Unit Interpretation: StructureDocument8 pagesUnit Interpretation: StructureIghfigufifiNo ratings yet

- JGB20203 (P) WW1 Projection ViewsDocument46 pagesJGB20203 (P) WW1 Projection ViewsMuhammad IzzuanNo ratings yet

- Understanding Y14 5 Dimension Ing and TolerancingDocument114 pagesUnderstanding Y14 5 Dimension Ing and Tolerancingfunnyface9No ratings yet

- Drawing StandardsDocument12 pagesDrawing StandardsAgung Bayu100% (1)

- GD&TDocument11 pagesGD&TrakshithmpNo ratings yet

- Designing With Parametric Sketches: What Is Parametric SketchingDocument8 pagesDesigning With Parametric Sketches: What Is Parametric Sketchingrizviabbas2010No ratings yet

- Lecture 1 - Fundamentals of Engineering DrawingDocument31 pagesLecture 1 - Fundamentals of Engineering Drawingengidadereje100% (1)

- DSMDocument5 pagesDSMmanuel medinaNo ratings yet

- 978 1 58503 459 8 2Document88 pages978 1 58503 459 8 2marcelo_adcampNo ratings yet

- Unit 10 Working DrawingsDocument17 pagesUnit 10 Working Drawingsomoak2015No ratings yet

- CFD ProjectDocument4 pagesCFD ProjectkrukshNo ratings yet

- Interpretation and Use of Technical Drawings: U1-Chapter 1Document37 pagesInterpretation and Use of Technical Drawings: U1-Chapter 1hamidhardNo ratings yet

- 3D Detailing of Reinforced Concrete and Steel Connections With AutoCAD Revit Structure2Document16 pages3D Detailing of Reinforced Concrete and Steel Connections With AutoCAD Revit Structure2tmssorinNo ratings yet

- HTTP WWW - Welding.com Weld - Symbols - Welding - SymbolsDocument21 pagesHTTP WWW - Welding.com Weld - Symbols - Welding - Symbolsvmuthu76No ratings yet

- Imensionin: Automatic Understanding of Engineering DrawingsDocument12 pagesImensionin: Automatic Understanding of Engineering DrawingsSrinath SaiNo ratings yet

- DrawstandDocument7 pagesDrawstandMacedo S OliveiraNo ratings yet

- CHAPTER 10 Working Drawings and AssembliesDocument12 pagesCHAPTER 10 Working Drawings and AssembliesKishore BhatNo ratings yet

- CHAPTER 10 Working Drawings and AssembliesDocument12 pagesCHAPTER 10 Working Drawings and Assembliesprasannaa2020No ratings yet

- ED7111Document117 pagesED7111palaniappan_pandianNo ratings yet

- Engineering Graphics! Detailing - Page 2Document10 pagesEngineering Graphics! Detailing - Page 2perryNo ratings yet

- Basic Gear Terminology and CalculationDocument10 pagesBasic Gear Terminology and CalculationTesseract spyderNo ratings yet

- FALLSEM2020-21 MEE3501 ETH VL2020210100431 Reference Material I 16-Jul-2020 Introduction To Freehand Sketches Layouts SymbolsDocument38 pagesFALLSEM2020-21 MEE3501 ETH VL2020210100431 Reference Material I 16-Jul-2020 Introduction To Freehand Sketches Layouts SymbolsJawa freakNo ratings yet

- DRAW10W - Geometric Dimensioning and TolerancesDocument8 pagesDRAW10W - Geometric Dimensioning and TolerancesPaolo GochingcoNo ratings yet

- Boundy8e PPT Ch08Document19 pagesBoundy8e PPT Ch08sonchemenNo ratings yet

- Types of ConstraintsDocument17 pagesTypes of ConstraintstomveuskensNo ratings yet

- Engineering Drawings - GD&TDocument45 pagesEngineering Drawings - GD&TMichael Wood100% (1)

- Aircraft Drawing - Chap 2 PDFDocument24 pagesAircraft Drawing - Chap 2 PDFnotonectal100% (1)

- Design Through Engineering Integration of Connecting ROD: AbstractDocument4 pagesDesign Through Engineering Integration of Connecting ROD: Abstractketthegr8No ratings yet

- Lecture 3Document15 pagesLecture 3saadbutt43215No ratings yet

- Cec 209 - Civil Engineering Drawing IDocument44 pagesCec 209 - Civil Engineering Drawing IVietHungCao89% (9)

- Tolerancias Pza FundicionDocument3 pagesTolerancias Pza FundicionGuero TeoNo ratings yet

- Detailed Weldment DrawingDocument2 pagesDetailed Weldment Drawingvpandya1981No ratings yet

- Fundamentals 07.04.03Document22 pagesFundamentals 07.04.03maddy_scribdNo ratings yet

- Engineering Drawing: Unlocking Visual Perception in Engineering DrawingFrom EverandEngineering Drawing: Unlocking Visual Perception in Engineering DrawingNo ratings yet

- ENGINEERING DROWING Chapter 2Document22 pagesENGINEERING DROWING Chapter 2DT artNo ratings yet

- Paper727 32Document6 pagesPaper727 32Azeb TeklemariamNo ratings yet

- Lipman - MBE Rep For AM Paper V5aDocument17 pagesLipman - MBE Rep For AM Paper V5aUmer AfzalNo ratings yet

- Spur Gear - 2Document30 pagesSpur Gear - 2Vaibhav VaibsNo ratings yet

- Basic GD&T DesmukhDocument236 pagesBasic GD&T DesmukhDineshCaddNo ratings yet

- Modelling of GD&TDocument6 pagesModelling of GD&TKarthik KarunanidhiNo ratings yet

- Autocad ManualDocument11 pagesAutocad ManualNaga KiranNo ratings yet

- Me 8381 Lab ManualDocument36 pagesMe 8381 Lab ManualMohanraj SubramaniNo ratings yet

- Geometrical and Mechanical Drawing: Paper 2Document8 pagesGeometrical and Mechanical Drawing: Paper 2jayaseelan39No ratings yet

- EDG Lab Manual-1-6Document6 pagesEDG Lab Manual-1-6Tor kokonoeNo ratings yet

- Basic Gear Terminology and Calculation - KHK GearsDocument8 pagesBasic Gear Terminology and Calculation - KHK GearsSuyandi SinagaNo ratings yet

- 1 58503 283 2 2Document65 pages1 58503 283 2 2marcelo_adcampNo ratings yet

- 04 - Branch ConnectionsDocument24 pages04 - Branch Connectionsdario84100% (2)

- Technical Drawing: Unlocking Computer Vision Through Technical DrawingFrom EverandTechnical Drawing: Unlocking Computer Vision Through Technical DrawingNo ratings yet

- Structural Drafting - A Practical Presentation of Drafting and Detailed Methods used in Drawing up Specifications for Structural Steel WorkFrom EverandStructural Drafting - A Practical Presentation of Drafting and Detailed Methods used in Drawing up Specifications for Structural Steel WorkRating: 3 out of 5 stars3/5 (1)

- Geometric Modeling: Exploring Geometric Modeling in Computer VisionFrom EverandGeometric Modeling: Exploring Geometric Modeling in Computer VisionNo ratings yet

- ENGLISHDocument4 pagesENGLISHALLISONNo ratings yet

- Soils OBJ Solved - 070021Document17 pagesSoils OBJ Solved - 070021Antoinette Wiafe100% (1)

- Pollution ProjectDocument17 pagesPollution Projectdenis becheruNo ratings yet

- Module 11Document64 pagesModule 11Andrew Dela CruzNo ratings yet

- Pavement Design1Document57 pagesPavement Design1Mobin AhmadNo ratings yet

- Adina ModelisationDocument240 pagesAdina ModelisationSafia SoufiNo ratings yet

- Mohammad Faisal Haroon - Envr506 - Week7Document4 pagesMohammad Faisal Haroon - Envr506 - Week7Hasan AnsariNo ratings yet

- 1.a Form Heavy ElementsDocument6 pages1.a Form Heavy ElementsJoshua BermoyNo ratings yet

- Gis PortefolioDocument12 pagesGis PortefolioruimauricioferreiraNo ratings yet

- TZL1D L96 6000LM FST Mvolt 50K 80cri WHDocument6 pagesTZL1D L96 6000LM FST Mvolt 50K 80cri WHSolidNo ratings yet

- Motion in 1 D Jee Main LevelDocument7 pagesMotion in 1 D Jee Main LevelShashwat KhuranaNo ratings yet

- 2011 07 PDFDocument334 pages2011 07 PDFmasimaha1379No ratings yet

- Successful BreastfeedingDocument22 pagesSuccessful BreastfeedingAnonymous QBm9WoHspNo ratings yet

- Rps School System: Final Term (2018)Document7 pagesRps School System: Final Term (2018)Zahra AhmedNo ratings yet

- Asian33 112009Document40 pagesAsian33 112009irmuhidinNo ratings yet

- Guida Busplan 2003Document31 pagesGuida Busplan 2003cajun28No ratings yet

- Additional Charges of Daos in Agt 2019Document17 pagesAdditional Charges of Daos in Agt 2019heraldNo ratings yet

- M.H. Saboo Siddik College of Engineering: CertificateDocument55 pagesM.H. Saboo Siddik College of Engineering: Certificatebhanu jammu100% (1)

- Module 13 Panelboards and SwitchboardsDocument32 pagesModule 13 Panelboards and SwitchboardsCamilla AlbaNo ratings yet

- Subject Name: Biology 9Document22 pagesSubject Name: Biology 9Naveed Ahmed ButtNo ratings yet

- PT Indah Jaya II + III: 2 X JMS 620 GS-N.L J C345Document369 pagesPT Indah Jaya II + III: 2 X JMS 620 GS-N.L J C345SaasiNo ratings yet

- Reverse Unloader Valve Rev0Document1 pageReverse Unloader Valve Rev0JasonNo ratings yet

- Q& A Operation Management CaseDocument4 pagesQ& A Operation Management CaseAbdullah Al MunirNo ratings yet

- Lenovo Ideapad Y700-14ISK: User GuideDocument32 pagesLenovo Ideapad Y700-14ISK: User GuideRudi B. RosidiNo ratings yet

- Inteligent Street LightingDocument14 pagesInteligent Street LightingMariana PereiraNo ratings yet

- Beverage Purchasing ControlDocument51 pagesBeverage Purchasing ControlMoses Mwah Muraya100% (2)

- Symmetry: Multinode M2150 Intelligent ControllerDocument6 pagesSymmetry: Multinode M2150 Intelligent Controlleradela sampayoNo ratings yet

- SOLUTION VECTOR ANALYSIS BY S M YUSUF PDF - Are You Looking For Solution VectorDocument6 pagesSOLUTION VECTOR ANALYSIS BY S M YUSUF PDF - Are You Looking For Solution VectorZara Malik67% (3)

Boundy8e PPT Ch02

Boundy8e PPT Ch02

Uploaded by

Andrew0 ratings0% found this document useful (0 votes)

1 views22 pagesOriginal Title

Boundy8e_PPT_Ch02

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

0 ratings0% found this document useful (0 votes)

1 views22 pagesBoundy8e PPT Ch02

Boundy8e PPT Ch02

Uploaded by

AndrewCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 22

Chapter Two

Dimensioning Drawings:

Symbols, Methods, Common

Features and Screw Threads

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-1

Purpose

This chapter provides an overview of how to:

apply linear and angular dimensions to engineering

drawings

use a range of symbols representing common

features

represent screw threads according to standard

practice

indicate standard procedures when applying

dimensions.

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-2

Apply linear and angular dimensions

to engineering drawings

Dimensions are characteristics such as length or

angle who’s magnitude is identified using an

appropriate unit of measurement.

Standard dimension symbols are utilised to

represent geometrical features and these are

proportional to the height of characters (text) used

on a particular drawing.

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-3

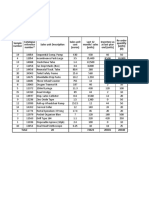

Table 2.1

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-4

Table 2.1 (cont)

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-5

Apply linear and angular dimensions

to engineering drawings

Dimension lines are thin, continuous lines that

indicate the extent of a measurement.

Projection lines are thin continuous lines that

transfer detail from one view to another or allow

dimensions to be inserted (indicate the limit of

measurement).

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-6

Apply linear and angular dimensions

to engineering drawings

Linear dimensions normally expressed in

millimetres without the ‘mm’ symbol.

Angular dimensions can be expressed either as

degrees, minutes and seconds or decimal degrees.

Dimensions can be ‘unidirectional’ (drawn parallel

to bottom of drawing) or ‘aligned’ (drawn parallel

to dimension line) as shown in Figure 2.3, p.23

(Boundy, 2012).

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-7

Apply linear and angular dimensions

to engineering drawings

If a number of parallel dimensions are grouped

together they should be ‘staggered’ to enable ease

of reading.

‘Functional’ dimensions are inserted on detail

drawings to show the proper working relationship

of mating parts and are necessary for the

operation of the product.

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-8

Apply linear and angular dimensions

to engineering drawings

For ease of reading, ‘overall’ dimensions are

provided on the outside of a group of linear

measurement; however, one or more of the

dimensions that make up the overall length is

omitted to allow variations of size (see Figure 2.5,

p.24).

‘Auxiliary’ dimensions (indicated by enclosing the

dimension in brackets) are overall dimensions

which are added while still including all dimensions

that add up to the overall value.

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-9

Apply linear and angular dimensions

to engineering drawings

A dimension underlined with a thick continuous

line is not drawn to scale.

When a dimension is too large to fit on a drawing

the free end is terminated in a double arrow head.

No more dimensions than necessary are included

on a drawing.

Dimensioning should lead readers to a clear

understanding of the relationship of parts and their

real magnitude.

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-10

Use a range of symbols representing

common features

This symbol Ø represents diameter and is placed

preceding the dimension indicating a hole or

cylinder.

A radius dimension is preceded by the letter R.

Methods of dimensioning diameters and radii are

illustrated in Figures 2.7 and 2.8, p.25 (Boundy,

2012).

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-11

Use a range of symbols representing

common features

Spherical dimensions are preceded by the letter S

and either Ø or R depending on the dimension.

The □ symbol indicates the feature is a square and

is followed by its ‘across the flats’ dimension;

however, if the symbol is included in a hole

dimension then it indicates the Envelope Principle

(described on pages 96 and 98) has been applied.

Examples of both these are shown in Figures 2.10

and 2.11, p.26 (Boundy, 2012).

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-12

Use a range of symbols representing

common features

Holes, form or shape should be indicated by an

appropriate symbol, e.g. □ or

The depth of the hole (indicated by the symbol )

relates to the full form depth, if the depth is

unspecified they are considered through holes.

Figure 2.12 on the next slide indicates methods of

dimensioning holes using both end and side views.

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-13

Figure 2.12

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-14

Use a range of symbols representing

common features

Hole position may be indicated by specifying pitch

diameter or rectangular coordinates (e.g. Figures

2.13 and 2.14, p.27).

The methods for indicating countersinks ( ),

counterbores ( ) and chamfers is illustrated in

figures 2.16, 2.17 and 2.18, p.28 (Boundy, 2012).

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-15

Use a range of symbols representing

common features

Dimensioning rectangular and square keyways in

shafts and hubs is illustrated in Figure 2.19, p.29,

and tolerance dimensions for keyways (not

considered at this stage) are provided in Tables 2.2

and 2.3, pp.30–31 (Boundy, 2012).

Woodruff keys require an overall linear dimension

and the diameter of the cut (as shown Figure 2.22,

p.32)

Taper ( ) dimensioning is illustrated in Figure

2.23 p.32.

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-16

Represent screw threads according

to standard practice

Screw threads may be represented by:

end view

side view – external threads and sectional internal

threads

side view – internal threads

limit of useful length of threads

the diameter of a metric thread is the nominal size

of the thread; for example, an M12 thread has a

nominal diameter of 12mm.

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-17

Represent screw threads according

to standard practice

When showing a thread in section, the hatching is

continued to the minor diameter of an internal

thread and the outer diameter of an external

thread (Figure 2.24, p.33 Boundy 2012).

When threads are assembled and sectioned

hatching is omitted over the length of common

contact (Figure 2.25 (a) and (b), p.33).

Special threads are often shown as a partial

section illustrating the form of the thread (Figure

2.25 (c), p.33).

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-18

Represent screw threads according

to standard practice

Full threads are dimensioned to the end of true

shape of the thread.

Runout of the thread (where thread gradually

reduces shape) can be measured if required (Figure

2.26, p.34).

The diameter of metric threads is always preceded

by the capital letter M which indicates metric thread.

If the metric thread is not a coarse series thread the

pitch is added to the dimension (fig 2.27b, p.34)

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-19

Represent screw threads according

to standard practice

For through holes, thread length is not required

unless the design requires a thread length to be

added (i.e. thread does not go all the way

through).

In a blind hole it is important to nominate full

thread depth and an allowance for thread/

production runout (Figure 2.27 (c) and (d), p.34).

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-20

Represent screw threads according

to standard practice

The minor diameter of a thread is effectively its

tapping size, which is calculated by ‘outside

diameter – pitch’; the pitch is obtained from charts

(e.g. Table 2.4, p.37).

The depth of thread (the distance between the two

lines representing the thread in a drawing) can be

calculated by:

depth = 0.577 x pitch (internal thread)

depth = 0.604 x pitch (external thread).

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-21

Summary

To facilitate drawing interpretation a standard

approach to dimensioning is required. AS1100.101

provides a structured methodology for indicating

linear and angular dimensions; in addition, to

simplify identification of common features, symbols

may be used.

Furthermore, the common thread form in Australia

is metric and care must be taken to identify its

pitch and thread length to enable accurate

interpretation of manufacturing requirements.

Copyright 2012 McGraw-Hill Australia Pty Ltd

PPTs t/a Engineering Drawing 8e by Boundy 2-22

You might also like

- Technical Drawing With Engineering Graphics 16Th Edition Frederick E Giesecke Full ChapterDocument67 pagesTechnical Drawing With Engineering Graphics 16Th Edition Frederick E Giesecke Full Chapterdarlene.baker133100% (9)

- Revit Standards Manual V2Document91 pagesRevit Standards Manual V2Nhu Huynh100% (1)

- Geometric Dimensioning and TolerancingDocument3 pagesGeometric Dimensioning and Tolerancingdesign12No ratings yet

- Heat Integration AssignmentDocument8 pagesHeat Integration AssignmentMian Kamran AliNo ratings yet

- BPT Targha Instalation ManualDocument12 pagesBPT Targha Instalation ManualFernando Manon100% (1)

- Basics of Geometrical Dimensioning & ToleranceDocument25 pagesBasics of Geometrical Dimensioning & ToleranceGarry GillNo ratings yet

- Boundy8e PPT Ch01Document19 pagesBoundy8e PPT Ch01AndrewNo ratings yet

- Boundy8e PPT Ch03Document29 pagesBoundy8e PPT Ch03AndrewNo ratings yet

- A Textbook of Drawing by S.lesaDocument30 pagesA Textbook of Drawing by S.lesadavid.padsonNo ratings yet

- Gambar Teknik 1 PDFDocument22 pagesGambar Teknik 1 PDFIndah HaninditaNo ratings yet

- Unit Interpretation: StructureDocument8 pagesUnit Interpretation: StructureIghfigufifiNo ratings yet

- JGB20203 (P) WW1 Projection ViewsDocument46 pagesJGB20203 (P) WW1 Projection ViewsMuhammad IzzuanNo ratings yet

- Understanding Y14 5 Dimension Ing and TolerancingDocument114 pagesUnderstanding Y14 5 Dimension Ing and Tolerancingfunnyface9No ratings yet

- Drawing StandardsDocument12 pagesDrawing StandardsAgung Bayu100% (1)

- GD&TDocument11 pagesGD&TrakshithmpNo ratings yet

- Designing With Parametric Sketches: What Is Parametric SketchingDocument8 pagesDesigning With Parametric Sketches: What Is Parametric Sketchingrizviabbas2010No ratings yet

- Lecture 1 - Fundamentals of Engineering DrawingDocument31 pagesLecture 1 - Fundamentals of Engineering Drawingengidadereje100% (1)

- DSMDocument5 pagesDSMmanuel medinaNo ratings yet

- 978 1 58503 459 8 2Document88 pages978 1 58503 459 8 2marcelo_adcampNo ratings yet

- Unit 10 Working DrawingsDocument17 pagesUnit 10 Working Drawingsomoak2015No ratings yet

- CFD ProjectDocument4 pagesCFD ProjectkrukshNo ratings yet

- Interpretation and Use of Technical Drawings: U1-Chapter 1Document37 pagesInterpretation and Use of Technical Drawings: U1-Chapter 1hamidhardNo ratings yet

- 3D Detailing of Reinforced Concrete and Steel Connections With AutoCAD Revit Structure2Document16 pages3D Detailing of Reinforced Concrete and Steel Connections With AutoCAD Revit Structure2tmssorinNo ratings yet

- HTTP WWW - Welding.com Weld - Symbols - Welding - SymbolsDocument21 pagesHTTP WWW - Welding.com Weld - Symbols - Welding - Symbolsvmuthu76No ratings yet

- Imensionin: Automatic Understanding of Engineering DrawingsDocument12 pagesImensionin: Automatic Understanding of Engineering DrawingsSrinath SaiNo ratings yet

- DrawstandDocument7 pagesDrawstandMacedo S OliveiraNo ratings yet

- CHAPTER 10 Working Drawings and AssembliesDocument12 pagesCHAPTER 10 Working Drawings and AssembliesKishore BhatNo ratings yet

- CHAPTER 10 Working Drawings and AssembliesDocument12 pagesCHAPTER 10 Working Drawings and Assembliesprasannaa2020No ratings yet

- ED7111Document117 pagesED7111palaniappan_pandianNo ratings yet

- Engineering Graphics! Detailing - Page 2Document10 pagesEngineering Graphics! Detailing - Page 2perryNo ratings yet

- Basic Gear Terminology and CalculationDocument10 pagesBasic Gear Terminology and CalculationTesseract spyderNo ratings yet

- FALLSEM2020-21 MEE3501 ETH VL2020210100431 Reference Material I 16-Jul-2020 Introduction To Freehand Sketches Layouts SymbolsDocument38 pagesFALLSEM2020-21 MEE3501 ETH VL2020210100431 Reference Material I 16-Jul-2020 Introduction To Freehand Sketches Layouts SymbolsJawa freakNo ratings yet

- DRAW10W - Geometric Dimensioning and TolerancesDocument8 pagesDRAW10W - Geometric Dimensioning and TolerancesPaolo GochingcoNo ratings yet

- Boundy8e PPT Ch08Document19 pagesBoundy8e PPT Ch08sonchemenNo ratings yet

- Types of ConstraintsDocument17 pagesTypes of ConstraintstomveuskensNo ratings yet

- Engineering Drawings - GD&TDocument45 pagesEngineering Drawings - GD&TMichael Wood100% (1)

- Aircraft Drawing - Chap 2 PDFDocument24 pagesAircraft Drawing - Chap 2 PDFnotonectal100% (1)

- Design Through Engineering Integration of Connecting ROD: AbstractDocument4 pagesDesign Through Engineering Integration of Connecting ROD: Abstractketthegr8No ratings yet

- Lecture 3Document15 pagesLecture 3saadbutt43215No ratings yet

- Cec 209 - Civil Engineering Drawing IDocument44 pagesCec 209 - Civil Engineering Drawing IVietHungCao89% (9)

- Tolerancias Pza FundicionDocument3 pagesTolerancias Pza FundicionGuero TeoNo ratings yet

- Detailed Weldment DrawingDocument2 pagesDetailed Weldment Drawingvpandya1981No ratings yet

- Fundamentals 07.04.03Document22 pagesFundamentals 07.04.03maddy_scribdNo ratings yet

- Engineering Drawing: Unlocking Visual Perception in Engineering DrawingFrom EverandEngineering Drawing: Unlocking Visual Perception in Engineering DrawingNo ratings yet

- ENGINEERING DROWING Chapter 2Document22 pagesENGINEERING DROWING Chapter 2DT artNo ratings yet

- Paper727 32Document6 pagesPaper727 32Azeb TeklemariamNo ratings yet

- Lipman - MBE Rep For AM Paper V5aDocument17 pagesLipman - MBE Rep For AM Paper V5aUmer AfzalNo ratings yet

- Spur Gear - 2Document30 pagesSpur Gear - 2Vaibhav VaibsNo ratings yet

- Basic GD&T DesmukhDocument236 pagesBasic GD&T DesmukhDineshCaddNo ratings yet

- Modelling of GD&TDocument6 pagesModelling of GD&TKarthik KarunanidhiNo ratings yet

- Autocad ManualDocument11 pagesAutocad ManualNaga KiranNo ratings yet

- Me 8381 Lab ManualDocument36 pagesMe 8381 Lab ManualMohanraj SubramaniNo ratings yet

- Geometrical and Mechanical Drawing: Paper 2Document8 pagesGeometrical and Mechanical Drawing: Paper 2jayaseelan39No ratings yet

- EDG Lab Manual-1-6Document6 pagesEDG Lab Manual-1-6Tor kokonoeNo ratings yet

- Basic Gear Terminology and Calculation - KHK GearsDocument8 pagesBasic Gear Terminology and Calculation - KHK GearsSuyandi SinagaNo ratings yet

- 1 58503 283 2 2Document65 pages1 58503 283 2 2marcelo_adcampNo ratings yet

- 04 - Branch ConnectionsDocument24 pages04 - Branch Connectionsdario84100% (2)

- Technical Drawing: Unlocking Computer Vision Through Technical DrawingFrom EverandTechnical Drawing: Unlocking Computer Vision Through Technical DrawingNo ratings yet

- Structural Drafting - A Practical Presentation of Drafting and Detailed Methods used in Drawing up Specifications for Structural Steel WorkFrom EverandStructural Drafting - A Practical Presentation of Drafting and Detailed Methods used in Drawing up Specifications for Structural Steel WorkRating: 3 out of 5 stars3/5 (1)

- Geometric Modeling: Exploring Geometric Modeling in Computer VisionFrom EverandGeometric Modeling: Exploring Geometric Modeling in Computer VisionNo ratings yet

- ENGLISHDocument4 pagesENGLISHALLISONNo ratings yet

- Soils OBJ Solved - 070021Document17 pagesSoils OBJ Solved - 070021Antoinette Wiafe100% (1)

- Pollution ProjectDocument17 pagesPollution Projectdenis becheruNo ratings yet

- Module 11Document64 pagesModule 11Andrew Dela CruzNo ratings yet

- Pavement Design1Document57 pagesPavement Design1Mobin AhmadNo ratings yet

- Adina ModelisationDocument240 pagesAdina ModelisationSafia SoufiNo ratings yet

- Mohammad Faisal Haroon - Envr506 - Week7Document4 pagesMohammad Faisal Haroon - Envr506 - Week7Hasan AnsariNo ratings yet

- 1.a Form Heavy ElementsDocument6 pages1.a Form Heavy ElementsJoshua BermoyNo ratings yet

- Gis PortefolioDocument12 pagesGis PortefolioruimauricioferreiraNo ratings yet

- TZL1D L96 6000LM FST Mvolt 50K 80cri WHDocument6 pagesTZL1D L96 6000LM FST Mvolt 50K 80cri WHSolidNo ratings yet

- Motion in 1 D Jee Main LevelDocument7 pagesMotion in 1 D Jee Main LevelShashwat KhuranaNo ratings yet

- 2011 07 PDFDocument334 pages2011 07 PDFmasimaha1379No ratings yet

- Successful BreastfeedingDocument22 pagesSuccessful BreastfeedingAnonymous QBm9WoHspNo ratings yet

- Rps School System: Final Term (2018)Document7 pagesRps School System: Final Term (2018)Zahra AhmedNo ratings yet

- Asian33 112009Document40 pagesAsian33 112009irmuhidinNo ratings yet

- Guida Busplan 2003Document31 pagesGuida Busplan 2003cajun28No ratings yet

- Additional Charges of Daos in Agt 2019Document17 pagesAdditional Charges of Daos in Agt 2019heraldNo ratings yet

- M.H. Saboo Siddik College of Engineering: CertificateDocument55 pagesM.H. Saboo Siddik College of Engineering: Certificatebhanu jammu100% (1)

- Module 13 Panelboards and SwitchboardsDocument32 pagesModule 13 Panelboards and SwitchboardsCamilla AlbaNo ratings yet

- Subject Name: Biology 9Document22 pagesSubject Name: Biology 9Naveed Ahmed ButtNo ratings yet

- PT Indah Jaya II + III: 2 X JMS 620 GS-N.L J C345Document369 pagesPT Indah Jaya II + III: 2 X JMS 620 GS-N.L J C345SaasiNo ratings yet

- Reverse Unloader Valve Rev0Document1 pageReverse Unloader Valve Rev0JasonNo ratings yet

- Q& A Operation Management CaseDocument4 pagesQ& A Operation Management CaseAbdullah Al MunirNo ratings yet

- Lenovo Ideapad Y700-14ISK: User GuideDocument32 pagesLenovo Ideapad Y700-14ISK: User GuideRudi B. RosidiNo ratings yet

- Inteligent Street LightingDocument14 pagesInteligent Street LightingMariana PereiraNo ratings yet

- Beverage Purchasing ControlDocument51 pagesBeverage Purchasing ControlMoses Mwah Muraya100% (2)

- Symmetry: Multinode M2150 Intelligent ControllerDocument6 pagesSymmetry: Multinode M2150 Intelligent Controlleradela sampayoNo ratings yet

- SOLUTION VECTOR ANALYSIS BY S M YUSUF PDF - Are You Looking For Solution VectorDocument6 pagesSOLUTION VECTOR ANALYSIS BY S M YUSUF PDF - Are You Looking For Solution VectorZara Malik67% (3)