Professional Documents

Culture Documents

Mix Design

Mix Design

Uploaded by

HISHAM0 ratings0% found this document useful (0 votes)

4 views20 pagesThis document discusses mix design procedures for asphalt concrete, including aggregate gradation, blending, and Marshall testing. It provides tables showing the gradation of coarse, fine, and filler aggregates. It describes trial and error, analytical, and graphical methods for blending aggregates to achieve the desired gradation. Finally, it outlines the Marshall mix design process, including procedures for compacting specimens and determining volumetric properties and stability from compression testing.

Original Description:

Original Title

03. Mix Design (3)

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses mix design procedures for asphalt concrete, including aggregate gradation, blending, and Marshall testing. It provides tables showing the gradation of coarse, fine, and filler aggregates. It describes trial and error, analytical, and graphical methods for blending aggregates to achieve the desired gradation. Finally, it outlines the Marshall mix design process, including procedures for compacting specimens and determining volumetric properties and stability from compression testing.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

4 views20 pagesMix Design

Mix Design

Uploaded by

HISHAMThis document discusses mix design procedures for asphalt concrete, including aggregate gradation, blending, and Marshall testing. It provides tables showing the gradation of coarse, fine, and filler aggregates. It describes trial and error, analytical, and graphical methods for blending aggregates to achieve the desired gradation. Finally, it outlines the Marshall mix design process, including procedures for compacting specimens and determining volumetric properties and stability from compression testing.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 20

Mix Design

Highway Engineering (VEB3013)

© 2017 U N I V E R S I T I T E K N O L O G I P E T R O N A S

All rights reserved. No part of this document may be reproduced, stored in a retrieval system or transmitted in any form or by any

means (electronic, mechanical, photocopying, recording or otherwise) without the permission of the copyright owner.

Aggregate Gradation

Aggregate Gradation (Coarse)

BS Sieve Size Cum.

Retained (g) Passing (g) Passing (%)

(mm) Retained (%)

28.0 0 1000 0 100

20.0 0 1000 0 100

14.0 100 900 10 90

10.0 500 500 50 50

5.0 900 100 100 10

3.35 950 50 100 5

1.18 1000 0 100 0

0.425 1000 0 100 0

0.150 1000 0 100 0

0.075 1000 0 100 0

PAN 1000 0 100 0

Aggregate Gradation (Fine)

BS Sieve Size Cum.

Retained (g) Passing (g) Passing (%)

(mm) Retained (%)

28.0 0 500 0 100

20.0 0 500 0 100

14.0 0 500 0 100

10.0 0 500 0 100

5.0 75 425 15 85

3.35 200 300 40 60

1.18 350 150 70 30

0.425 400 100 80 20

0.150 450 50 90 10

0.075 470 30 94 6

PAN 500 0 100 0

Aggregate Gradation (Filler)

BS Sieve Size Cum.

Retained (g) Passing (g) Passing (%)

(mm) Retained (%)

28.0 0 100 0 100

20.0 0 100 0 100

14.0 0 100 0 100

10.0 0 100 0 100

5.0 0 100 0 100

3.35 0 100 0 100

1.18 0 100 0 100

0.425 0 100 0 100

0.150 0 100 0 100

0.075 20 80 20 80

PAN 80 0 100 0

Aggregate Blending

• Trial Error

• Analytical

• Graphical

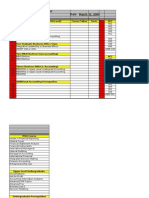

Aggregate Gradation (Trial Error)

BS Sieve Course Course Agg. Fine Agg. Filler Total

Fine Agg. Filler JKR (Passing)

Size (mm) Agg. (35%) (63%) (2%) (Passing)

28.0 100 100 100 100 100 100 100 100

20.0 100 100 100 35 63 2 100 100

14.0 90 100 100 31.5 63 2 96.5 90 - 100

10.0 50 100 100 17.5 63 2 82.5 76 – 86

5.0 10 85 100 3.5 53.55 2 59.05 50 – 62

3.35 5 60 100 1.75 37.8 2 41.55 40 – 54

1.18 - 30 100 0 18.9 2 20.9 18 – 34

0.425 - 20 100 0 12.6 2 14.6 12 - 24

0.150 - 10 100 0 6.3 2 8.3 6 - 14

0.075 - 6 80 0 3.78 1.6 5.38 4-8

Aggregate Gradation (Analytical)

Aggregate Gradation (Graphical)

Aggregate Gradation (Blended)

Marshall Mix Design

Marshall Mix Design

Marshall Mix Design

Marshall Mix Design

Marshall Mix Design

Volume, of Specimen Approximate Thickness of Correction.

(cm3) Specimen (cm) Coefficient

200-213 2.54 5.56

214-225 2.70 5.00

226-237 2.86 4.55

238-250 3.02 4.17

251-264 3.18 3.85

265-276 3.34 3.57

277-289 3.49 3.33

290-301 3.65 3.03

302-316 3.81 2.78

317-328 3.97 2.50

329-340 4.13 2.27

Correction 341-353 4.29 2.08

Coefficient 354-367

368-379

4.45

4.60

1.92

1.79

for Stability 380-392 4.76 1.67

393-405 4.92 1.56

406-420 5.08 1.47

421-431 5.24 1.39

432-443 5.40 1.32

444-456 5.56 1.25

457-470 5.72 1.19

471-482 5.88 1.14

483-495 6.03 1.09

496-508 6.19 1.04

509-522 6.35 1.00

523-535 6.51 0.96

536-546 6.67 0.93

547-559 6.83 0.89

560-573 6.99 0.86

574-585 7.14 0.83

Marshall Mix Design

Marshall Mix Design

Marshall Mix Design

Marshall Mix Design

Thank You

© 2017 INSTITUTE OF TECHNOLOGY PETRONAS SDN BHD

All rights reserved. No part of this document may be reproduced, stored in a retrieval system or transmitted in any form or by any means (electronic,

mechanical, photocopying, recording or otherwise) without the permission of the copyright owner.

You might also like

- 11 Loading Gauge, Kinematic Envelope & Minimum Structure GaugeDocument22 pages11 Loading Gauge, Kinematic Envelope & Minimum Structure GaugeHISHAM100% (1)

- Das - Foundation Engineering - 8e - SI - Chapter10Document65 pagesDas - Foundation Engineering - 8e - SI - Chapter10HISHAMNo ratings yet

- Informatica TutorialsDocument2 pagesInformatica Tutorialsj_jeevan_jNo ratings yet

- Filter Media 15.1.2015Document17 pagesFilter Media 15.1.2015Prashant SinghNo ratings yet

- Sieve Analysis ReportDocument1 pageSieve Analysis ReportBaluku BennetNo ratings yet

- 1-Particale Size Distribution Updated For All TestsDocument18 pages1-Particale Size Distribution Updated For All TestsAmmar AliNo ratings yet

- 680 615 525 390 280 80 20 0 Jumlah 715 100: Analisa SaringanDocument7 pages680 615 525 390 280 80 20 0 Jumlah 715 100: Analisa SaringanRivaldi YaldiNo ratings yet

- Etrhb 2Document2 pagesEtrhb 2Karim IderNo ratings yet

- Fuller: Etrhb Dosage 400KgDocument2 pagesFuller: Etrhb Dosage 400KgKarim IderNo ratings yet

- Revision 1 (VEB3013)Document6 pagesRevision 1 (VEB3013)Muhd SyahidNo ratings yet

- Anissa Puspa N - 201121003 - PENGGABUNGAN AGREGATDocument10 pagesAnissa Puspa N - 201121003 - PENGGABUNGAN AGREGATanissa pspNo ratings yet

- Graphs For Seive AnalysisDocument4 pagesGraphs For Seive AnalysisVivek SettipalliNo ratings yet

- Gradasi GabunganDocument6 pagesGradasi GabunganAnggi SktS'corpharattionNo ratings yet

- Tromp Curve Calculations and ResultsDocument3 pagesTromp Curve Calculations and Resultsrecai100% (3)

- Theoretical Blending: Bituminous Concrete Grade-IDocument3 pagesTheoretical Blending: Bituminous Concrete Grade-IDeepakNo ratings yet

- Coarse: Aggregate Test ResultsDocument24 pagesCoarse: Aggregate Test ResultsMahendar ErramNo ratings yet

- Unit-I-Aggregate GradingDocument22 pagesUnit-I-Aggregate GradingashoknrNo ratings yet

- fullerBetonprojeteGICO 1711 1Document4 pagesfullerBetonprojeteGICO 1711 1Karim IderNo ratings yet

- CIVN3004 LAB REPORT (Group 9)Document6 pagesCIVN3004 LAB REPORT (Group 9)Kavish DayaNo ratings yet

- Pumpable Concrete Proposed Combined Aggregates Grading LimitsDocument4 pagesPumpable Concrete Proposed Combined Aggregates Grading LimitsAndrew MwambaNo ratings yet

- Seive AnalysisDocument1 pageSeive Analysisrit0pathaniaNo ratings yet

- 5 To 10 MM AGGREGATE SIEVEDocument1 page5 To 10 MM AGGREGATE SIEVENajma BatoolNo ratings yet

- Gradasi Timbunan YulongkashiDocument4 pagesGradasi Timbunan YulongkashiBagusNo ratings yet

- Grain SizeDocument3 pagesGrain SizeNurul Mudhillah AliNo ratings yet

- Seive 2Document6 pagesSeive 2Abbas tahmasebi poorNo ratings yet

- Fullerbetonprojete 0812 1Document1 pageFullerbetonprojete 0812 1Karim IderNo ratings yet

- COMBINE of Sieve Analysis FGHFDocument3 pagesCOMBINE of Sieve Analysis FGHFASHOKKUMARNo ratings yet

- Jorge Alejandro Escallón Burgos - Taller 2Document3 pagesJorge Alejandro Escallón Burgos - Taller 2Jorge Alejandro Escallon BurgosNo ratings yet

- BMMix Design Grade 2Document24 pagesBMMix Design Grade 2abdisalamNo ratings yet

- C4M Sieve AnalysisDocument10 pagesC4M Sieve Analysissamar varshneyNo ratings yet

- DBM Grade 2 Blending Jmf-Bin OnlyDocument4 pagesDBM Grade 2 Blending Jmf-Bin OnlySooraj Matter LabNo ratings yet

- Dynamic Cone Penetrometer Test (D C P)Document5 pagesDynamic Cone Penetrometer Test (D C P)eko bari wNo ratings yet

- PipeDocument9 pagesPipeNghiaNo ratings yet

- Calculo d50 ProyectoDocument4 pagesCalculo d50 ProyectoCatalina PedrazaNo ratings yet

- All in AggregateDocument12 pagesAll in AggregateGaurav SharmaNo ratings yet

- Tebal Perkerasan Subgrade 6%Document1 pageTebal Perkerasan Subgrade 6%jhonsonNo ratings yet

- TotalDocument3 pagesTotalayuNo ratings yet

- Marshall Stability Test PDFDocument8 pagesMarshall Stability Test PDFAnonymous FO4sHLLONo ratings yet

- Eng - Formulation B - 40: Melange - 1 CPJ 42,5 AccDocument3 pagesEng - Formulation B - 40: Melange - 1 CPJ 42,5 AccKarim IderNo ratings yet

- Grading Evelopes For GC Material - 28.5mm NomDocument2 pagesGrading Evelopes For GC Material - 28.5mm NomAndrew MwambaNo ratings yet

- Soil Mechanics - Sample Calculations For A Sieve Analysis - University of TwenteDocument3 pagesSoil Mechanics - Sample Calculations For A Sieve Analysis - University of TwenteMaria Elena RiusNo ratings yet

- Mecanica de Suelos I Informe IIDocument4 pagesMecanica de Suelos I Informe IIjean paulNo ratings yet

- Sieve Analysis GraphDocument9 pagesSieve Analysis GraphRoa Mae JulatonNo ratings yet

- Tugas 6 BaprogDocument12 pagesTugas 6 BaprogAndy FadhilaNo ratings yet

- Estudio de Molienda 1Document19 pagesEstudio de Molienda 1Frank CaritasNo ratings yet

- Gradiva ProgramDocument7 pagesGradiva Programapi-3841190No ratings yet

- Analisis Saringan: Agregat Kasar 2000 GRDocument22 pagesAnalisis Saringan: Agregat Kasar 2000 GR12O21OO82-Natasya eka PutriRBNo ratings yet

- Tabel Material Bu Rocha PolbanDocument1 pageTabel Material Bu Rocha Polbankodok wodoNo ratings yet

- Gates-Gaudin-Schumann Plot: Cumulative Percent PassingDocument1 pageGates-Gaudin-Schumann Plot: Cumulative Percent PassingAgen KolarNo ratings yet

- 10 SandDocument5 pages10 SandSAFE SERVICES LHRNo ratings yet

- Experiment 3Document7 pagesExperiment 3ShahreyaarNo ratings yet

- DATOS GRANULOMETRIA POR TAMIZADO (Autoguardado)Document3 pagesDATOS GRANULOMETRIA POR TAMIZADO (Autoguardado)BRAYAN HARLEY CORTES TOBARNo ratings yet

- BLENDING Quarry Dust & Sand KJCLDocument6 pagesBLENDING Quarry Dust & Sand KJCLAbu FalasiNo ratings yet

- Mass of Soil Retained (G) Cumulative Mass Retained Above Each SIEVE (G)Document19 pagesMass of Soil Retained (G) Cumulative Mass Retained Above Each SIEVE (G)jomari galiasNo ratings yet

- Analisa Saringan Bahan: Asal: No. Saringan Berat B. Saringan Berat Kode MM Saringan Sampel TertahanDocument12 pagesAnalisa Saringan Bahan: Asal: No. Saringan Berat B. Saringan Berat Kode MM Saringan Sampel TertahanMaksi MilianusNo ratings yet

- KCC PQC Mix BlendingDocument2 pagesKCC PQC Mix BlendingQuality JamNo ratings yet

- CH 1Document7 pagesCH 1Clark Jallen RamosNo ratings yet

- Ejemplo Distancia Media de TransporteDocument9 pagesEjemplo Distancia Media de TransporteJhon Rengifo GanozaNo ratings yet

- Fullerbetonprojete 0612Document6 pagesFullerbetonprojete 0612Karim IderNo ratings yet

- Fullerbetonprojete 0612Document6 pagesFullerbetonprojete 0612Karim IderNo ratings yet

- Size Analysis TutorialDocument11 pagesSize Analysis TutorialratNo ratings yet

- Pipe Friction Loss CalculationDocument9 pagesPipe Friction Loss CalculationEjaz Ahmed RanaNo ratings yet

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesFrom EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesRating: 5 out of 5 stars5/5 (3)

- Road Administration and PlanningDocument66 pagesRoad Administration and PlanningHISHAMNo ratings yet

- 9-Geometric DesignDocument69 pages9-Geometric DesignHISHAMNo ratings yet

- 3 M Original Ground Level: Figure Q1Document14 pages3 M Original Ground Level: Figure Q1HISHAMNo ratings yet

- EXAMPLEDocument17 pagesEXAMPLEHISHAMNo ratings yet

- Pavement Structure MaterialsDocument39 pagesPavement Structure MaterialsHISHAMNo ratings yet

- Utp InternshipDocument13 pagesUtp InternshipHISHAMNo ratings yet

- 10 Classification of Line & Their Track StandardDocument20 pages10 Classification of Line & Their Track StandardHISHAMNo ratings yet

- Course Outline VDB4012Document3 pagesCourse Outline VDB4012HISHAMNo ratings yet

- Course-Planning - VDB4012 - Design of Earth Retaining Structures - May 2020Document7 pagesCourse-Planning - VDB4012 - Design of Earth Retaining Structures - May 2020HISHAMNo ratings yet

- VEB2113 CourseOutlineDocument2 pagesVEB2113 CourseOutlineHISHAMNo ratings yet

- Design of Foundation: Project WorkDocument9 pagesDesign of Foundation: Project WorkHISHAMNo ratings yet

- 8 Ballast, Sub Ballast, Quarry Material & GeotextileDocument12 pages8 Ballast, Sub Ballast, Quarry Material & GeotextileHISHAMNo ratings yet

- GUIDANCE DOCUMENT EIA Registration SchemeDocument72 pagesGUIDANCE DOCUMENT EIA Registration SchemeHISHAMNo ratings yet

- Design and Installation of Concrete Cylinder Piles: Contemporary Issues in Deep FoundationsDocument14 pagesDesign and Installation of Concrete Cylinder Piles: Contemporary Issues in Deep FoundationsHISHAMNo ratings yet

- Distributed Fiber Optic Sensing of Axially Loaded Bored PilesDocument16 pagesDistributed Fiber Optic Sensing of Axially Loaded Bored PilesHISHAMNo ratings yet

- 5 SleepersDocument22 pages5 SleepersHISHAM100% (2)

- Reviewer'sComment Pre Chap3Document198 pagesReviewer'sComment Pre Chap3HISHAMNo ratings yet

- EN Secutex Geotextile Introduction 191203 WebDocument4 pagesEN Secutex Geotextile Introduction 191203 WebHISHAMNo ratings yet

- 1 Narra Nickel Mining Vs RedmontDocument2 pages1 Narra Nickel Mining Vs Redmontjimmy100% (1)

- Legal Resources - EFT (Electronic - Funds - Transfer) ExplainedDocument9 pagesLegal Resources - EFT (Electronic - Funds - Transfer) ExplainedBrad100% (5)

- Chapter 25 - Fundamentals of Corporate Finance 9th Edition - Test BankDocument21 pagesChapter 25 - Fundamentals of Corporate Finance 9th Edition - Test BankKellyGibbonsNo ratings yet

- AMADA RANCE Vs NLRCDocument2 pagesAMADA RANCE Vs NLRCAya BaclaoNo ratings yet

- CH 03Document33 pagesCH 03Akshay GoelNo ratings yet

- Partnership LiquidationDocument6 pagesPartnership Liquidationyoj assenavNo ratings yet

- Handbook Om NokiaDocument461 pagesHandbook Om NokiaAndrewNo ratings yet

- Bibliography Books: Research Methods For Graduate Business and Social Science StudentsDocument9 pagesBibliography Books: Research Methods For Graduate Business and Social Science StudentsyezdiarwNo ratings yet

- Definitions of E CommernceDocument7 pagesDefinitions of E CommernceTusiime Wa Kachope SamsonNo ratings yet

- Company Profile Puji Rejeki PDFDocument19 pagesCompany Profile Puji Rejeki PDFR Dimas Tri NugrohoNo ratings yet

- Cibl-Rdpl Apparel Erp Nov09Document21 pagesCibl-Rdpl Apparel Erp Nov09anujbirjuNo ratings yet

- CC 2 Marks Unit 1 - 5Document24 pagesCC 2 Marks Unit 1 - 5arunaradhiNo ratings yet

- Internship Report ON Recruitment & Selection Process of Max: Submitted BY Shubhi Raizada (MB2014038)Document57 pagesInternship Report ON Recruitment & Selection Process of Max: Submitted BY Shubhi Raizada (MB2014038)AshutoshSharma100% (1)

- J2EE BasicsDocument198 pagesJ2EE BasicsAshok Kumar BhanuNo ratings yet

- Entrepreneurial MindDocument6 pagesEntrepreneurial MindAlma Padduyao Cablinan50% (2)

- Peranan Serikat Pekerja Dalam Perlindungan Hukum Terhadap Pencegahan Pelecehan Seksual Untuk Pekerja Perempuan Di Tempat KerjaDocument11 pagesPeranan Serikat Pekerja Dalam Perlindungan Hukum Terhadap Pencegahan Pelecehan Seksual Untuk Pekerja Perempuan Di Tempat KerjaCayaNo ratings yet

- Haryana CST Return Format Form - 1Document2 pagesHaryana CST Return Format Form - 1Virender SainiNo ratings yet

- Epari Sahil Sip ReportDocument34 pagesEpari Sahil Sip ReportK Abinash Prusty0% (1)

- MSA Program Template 2009-10Document2 pagesMSA Program Template 2009-10popp00pNo ratings yet

- Design Buku Kenangan Revised-2Document17 pagesDesign Buku Kenangan Revised-2yuliaNo ratings yet

- VDR TitlesDocument12 pagesVDR TitleszhangjieNo ratings yet

- Crisis ManagementDocument2 pagesCrisis ManagementMars CervantesNo ratings yet

- Types of Production SystemDocument4 pagesTypes of Production SystemDemi DelizoNo ratings yet

- Webinar 7: Standards To Bank On: PFRS and PAS For BanksDocument2 pagesWebinar 7: Standards To Bank On: PFRS and PAS For BanksRoland Vincent JulianNo ratings yet

- Project Report On HR in BATADocument128 pagesProject Report On HR in BATAAman RajNo ratings yet

- Whiz IT Services LLPDocument7 pagesWhiz IT Services LLPWhizIT Services0% (1)

- Urchase Decision of Customers Towards Havells Products"Document77 pagesUrchase Decision of Customers Towards Havells Products"Nishikant PiyooshNo ratings yet

- Ky Can An Attorney Overbill /fradulent Billing?Document64 pagesKy Can An Attorney Overbill /fradulent Billing?api-25948763100% (1)

- 7 Steps To World Class ManufacturingDocument15 pages7 Steps To World Class Manufacturingmuneerpp100% (2)