Professional Documents

Culture Documents

Structural Sections Presentation Slides PPTSTSEN21

Structural Sections Presentation Slides PPTSTSEN21

Uploaded by

kumarmohit0203Copyright:

Available Formats

You might also like

- Activity 2.1.2 Beam Deflection: Preliminary Lab Calculations To Determine Beam Modulus of ElasticityDocument8 pagesActivity 2.1.2 Beam Deflection: Preliminary Lab Calculations To Determine Beam Modulus of ElasticityJulius PaganNo ratings yet

- Moment of Inertia of Cracked SectionDocument33 pagesMoment of Inertia of Cracked SectionAtta Muhammad95% (20)

- Building Construction ScheduleDocument8 pagesBuilding Construction Scheduleengrfarhansiddiqui75% (4)

- Design of Single Storey RCC Framed BuildingDocument86 pagesDesign of Single Storey RCC Framed BuildingBaba Maisam Shabir89% (97)

- Isotensoid FormulationDocument12 pagesIsotensoid Formulationnhung_33No ratings yet

- CE323-18 MODULE 2 MTN v01Document9 pagesCE323-18 MODULE 2 MTN v01ira garciaNo ratings yet

- Oct10 - Steelwise - Web - Oh YesDocument2 pagesOct10 - Steelwise - Web - Oh YesJohnny ChungNo ratings yet

- Stress and Deflection Analysis of Belleville Spring PDFDocument6 pagesStress and Deflection Analysis of Belleville Spring PDFDeepak BhopeNo ratings yet

- Unit - Ii One Dimensional Problems Part - ADocument29 pagesUnit - Ii One Dimensional Problems Part - ADHARMADURAI.P MEC-AP/AERONo ratings yet

- Nonlinear ElementsDocument12 pagesNonlinear ElementsnagarajuNo ratings yet

- Interaction Diagram For Concrete ColumnsDocument14 pagesInteraction Diagram For Concrete Columnsgeogohigh100% (1)

- 2nd Btech MECH 2021-22 MOS Ses-K4 PDFDocument8 pages2nd Btech MECH 2021-22 MOS Ses-K4 PDFGopi TNo ratings yet

- Column Design Aci Code PDFDocument15 pagesColumn Design Aci Code PDFPhil MarceloNo ratings yet

- CEN 202 Mechanics of Materials: Beam DeflectionsDocument13 pagesCEN 202 Mechanics of Materials: Beam DeflectionsMuhammad Shaqeem RosdiNo ratings yet

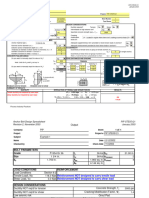

- Ste05121spreadsheet Anchor Bolt Design PDF FreeDocument10 pagesSte05121spreadsheet Anchor Bolt Design PDF Freeveeran08No ratings yet

- Adv Struc Lec 02Document9 pagesAdv Struc Lec 02BABAN GUHANo ratings yet

- Open Hole Plate PP TDocument33 pagesOpen Hole Plate PP TThomas RaffestinNo ratings yet

- Stress Concentration Due To A Circular HoleDocument3 pagesStress Concentration Due To A Circular HolePranav VikirtanNo ratings yet

- Modeling of Discrete Intersecting Discontinuities in Rock Mass Using XFEM Level Set ApproachDocument8 pagesModeling of Discrete Intersecting Discontinuities in Rock Mass Using XFEM Level Set ApproachMARCOSNo ratings yet

- النوتة الحسابيةDocument26 pagesالنوتة الحسابيةاحمد عبد العزيزNo ratings yet

- LN 8 Bult-Up SectionDocument18 pagesLN 8 Bult-Up SectionThevinduNo ratings yet

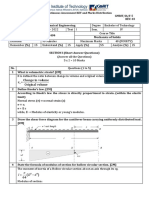

- Hyderabad Campus FIRST SEMESTER 2015-2016: (12 Marks)Document1 pageHyderabad Campus FIRST SEMESTER 2015-2016: (12 Marks)aayushi doshiNo ratings yet

- 1443purl ME ESE-II 1995-1999Document155 pages1443purl ME ESE-II 1995-1999TirunamalaPhanimohanNo ratings yet

- Appendix C Tensor Indicial Notation in The Approximation of Elasticity Problems 2013 The Finite Element Method Its Basis and Fundamentals Seventh EditDocument10 pagesAppendix C Tensor Indicial Notation in The Approximation of Elasticity Problems 2013 The Finite Element Method Its Basis and Fundamentals Seventh EditLeo Salazar EsquivelNo ratings yet

- ME563 Machine Design II Spring 2002: MD2 - Exam 1 - Solution Spring 2002 NameDocument10 pagesME563 Machine Design II Spring 2002: MD2 - Exam 1 - Solution Spring 2002 NameUdhamNo ratings yet

- TOS 22402 Winter 19th I SCHEME Paper Model Answer PaperDocument25 pagesTOS 22402 Winter 19th I SCHEME Paper Model Answer Paperirshadmirza753No ratings yet

- Sai Phan Huu HanDocument7 pagesSai Phan Huu HanNguyễn Sơn LâmNo ratings yet

- Working Design of Single AnglesDocument2 pagesWorking Design of Single AnglesAnonymous 1BdR0EQgbu100% (1)

- S19 I Scheme PaperbackDocument14 pagesS19 I Scheme Paperbackirshadmirza753No ratings yet

- Fem Unit IDocument34 pagesFem Unit ISAIKUMAR ANo ratings yet

- Sistemas de Protección Sísmica: Resumen: (Máximo 200 Palabras)Document5 pagesSistemas de Protección Sísmica: Resumen: (Máximo 200 Palabras)Luz Acosta De La CruzNo ratings yet

- 12 # Quiz (Eng) - GODocument5 pages12 # Quiz (Eng) - GOshakeelahmadrelibNo ratings yet

- Flexural Members Layered ApproachDocument23 pagesFlexural Members Layered ApproachMohamed mohy el deenNo ratings yet

- STE05121 Spreadsheet REV1 JUL03Document11 pagesSTE05121 Spreadsheet REV1 JUL03arcelitasNo ratings yet

- Design in Timber To Ms 544 Part2: Week 5Document40 pagesDesign in Timber To Ms 544 Part2: Week 5Muhd FaridNo ratings yet

- Period 17 Flexure With Composite BeamsDocument9 pagesPeriod 17 Flexure With Composite BeamsVinod KumarNo ratings yet

- Bicol University College of Engineering Civil Engineering DepartmentDocument3 pagesBicol University College of Engineering Civil Engineering DepartmentMa Ella Mae LogronioNo ratings yet

- Etabs Modelling (Jan2015)Document13 pagesEtabs Modelling (Jan2015)HannaFouadNo ratings yet

- E Tabs Presentation FinalDocument31 pagesE Tabs Presentation FinalSawyu NandarNo ratings yet

- Important Instructions To Examiners:: Definitio n1M Types 1MDocument17 pagesImportant Instructions To Examiners:: Definitio n1M Types 1MPatil pooja100% (1)

- Chapter HandoutDocument5 pagesChapter HandoutAbhichet JeemsantiaNo ratings yet

- ADAPT TN293 RC Ie Deflection 10Document7 pagesADAPT TN293 RC Ie Deflection 10CarsonBaker100% (1)

- Finite Element Analysis of Tie Beams Under The EffDocument12 pagesFinite Element Analysis of Tie Beams Under The EffZainal AbidhynNo ratings yet

- Mec 201 04 Aug 20Document18 pagesMec 201 04 Aug 20hemanth singhNo ratings yet

- MathFor802 PDFDocument21 pagesMathFor802 PDFanon_995042985No ratings yet

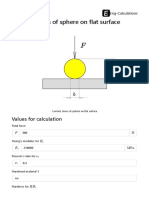

- Contact Stress of Sphere On Flat SurfaceDocument3 pagesContact Stress of Sphere On Flat SurfaceEng-CalculationsNo ratings yet

- SteelDesign Composite Fu NewDocument6 pagesSteelDesign Composite Fu NewEng.Hesham AL-HelaleeNo ratings yet

- Capacity of Axially Loaded RC Columns With ArbitraDocument13 pagesCapacity of Axially Loaded RC Columns With ArbitraMilutin ZizicNo ratings yet

- EME4403 Finite ElementDocument28 pagesEME4403 Finite ElementAmmar muhammadNo ratings yet

- Mater. Sci. Eng-1Document6 pagesMater. Sci. Eng-1gopierode4No ratings yet

- Introduction To Solid Mechanics ME C85/CE C30 Final Exam Fall, 2013Document8 pagesIntroduction To Solid Mechanics ME C85/CE C30 Final Exam Fall, 2013Rodger PangNo ratings yet

- P Ch-21 Wave+OpticsDocument5 pagesP Ch-21 Wave+Opticsmysoftinfo.incNo ratings yet

- Ijce V3i12p102Document10 pagesIjce V3i12p102William PolNo ratings yet

- The Finite Element Analysis On Reinforced Concrete Short Pier Shear Wall StructuresDocument9 pagesThe Finite Element Analysis On Reinforced Concrete Short Pier Shear Wall StructuresAg PatriaNo ratings yet

- Civil Engineering Materials - Cive 2319: Lec 2 Material Performance and Its MeasurementDocument31 pagesCivil Engineering Materials - Cive 2319: Lec 2 Material Performance and Its MeasurementSiti AsmahaniNo ratings yet

- KNE216/KNE716 Civil Engineering 1: First and Only Paper Ordinary ExaminationDocument8 pagesKNE216/KNE716 Civil Engineering 1: First and Only Paper Ordinary ExaminationSebin GeorgeNo ratings yet

- Design of Random Rubble Masonry Retaining WallDocument26 pagesDesign of Random Rubble Masonry Retaining WallMackNo ratings yet

- FMDS0121 Fire Resistance of Building AssembliesDocument50 pagesFMDS0121 Fire Resistance of Building Assembliespamela552fq4859100% (1)

- 4.0 DiscussionDocument10 pages4.0 Discussionikhmal siddiqNo ratings yet

- Is.12778.2004 0 PDFDocument20 pagesIs.12778.2004 0 PDFPhanindra AttadaNo ratings yet

- 16 - Chapter 6 PDFDocument39 pages16 - Chapter 6 PDFDipankar NathNo ratings yet

- DOUBLE TEES - Technical Data: Span-Load Tables Design Criteria Tolerances Strand LocationsDocument42 pagesDOUBLE TEES - Technical Data: Span-Load Tables Design Criteria Tolerances Strand LocationsRebaz A. OthmanNo ratings yet

- Did You Know That Underpinning of Foundations Is Notifiable Work Under The Building RegulationsDocument7 pagesDid You Know That Underpinning of Foundations Is Notifiable Work Under The Building RegulationsNur Hidayah100% (1)

- Kambiz Janamian, José Aguiar - Concrete Materials and Technology - A Practical Guide-CRC Press (2023)Document397 pagesKambiz Janamian, José Aguiar - Concrete Materials and Technology - A Practical Guide-CRC Press (2023)LucasManoeldaSilva100% (1)

- Mechanics of Structures 2A: Revision Example Sheet - Beam Analysis: Bending Moments and Shear ForcesDocument3 pagesMechanics of Structures 2A: Revision Example Sheet - Beam Analysis: Bending Moments and Shear ForcesPrafulla PiseNo ratings yet

- TTTTDocument4 pagesTTTTIshwar ChauhanNo ratings yet

- Environmental Engineering Concrete Structures: Reported by ACI Committee 350Document24 pagesEnvironmental Engineering Concrete Structures: Reported by ACI Committee 350Jishad NalakathNo ratings yet

- Truss Design GuidDocument3 pagesTruss Design GuidRafi HasanNo ratings yet

- Design Loads and CombinationsDocument4 pagesDesign Loads and CombinationsMihai CalinNo ratings yet

- Experimental Investigation of Chemical and Physical Properties of Cements Manufactured in PakistanDocument15 pagesExperimental Investigation of Chemical and Physical Properties of Cements Manufactured in PakistanAyesha AyubNo ratings yet

- ACE ACADEMY ESE - 2020 (Prelims) - Offline Test Series 01 SolutionDocument13 pagesACE ACADEMY ESE - 2020 (Prelims) - Offline Test Series 01 SolutionAbhilasha CIVILNo ratings yet

- Steel WiseDocument3 pagesSteel WiseJuan Gutier CcNo ratings yet

- Concrete Mix Design As Per IS10262-2009Document24 pagesConcrete Mix Design As Per IS10262-2009Prakash Singh RawalNo ratings yet

- Ameerpet Roof Document Rev A PDFDocument360 pagesAmeerpet Roof Document Rev A PDFrajusk24No ratings yet

- Dokaflex 30 Tec PDFDocument52 pagesDokaflex 30 Tec PDFDiego CruzNo ratings yet

- Pushover CE&CRDocument9 pagesPushover CE&CRAnonymous nwByj9LNo ratings yet

- Beam DesignDocument8 pagesBeam DesignFaraaz FaisalNo ratings yet

- SFD OlderCodesDocument105 pagesSFD OlderCodessalgatranNo ratings yet

- Mapungubwe Interpretation CentreDocument6 pagesMapungubwe Interpretation CentreEdwin AsieduNo ratings yet

- CDOT Bridge Design Manual - 20180101Document431 pagesCDOT Bridge Design Manual - 20180101amraja2001100% (2)

- Research Paper On BearingsDocument9 pagesResearch Paper On BearingsmahakNo ratings yet

- Ce8502 Structural Analysis I MCQDocument26 pagesCe8502 Structural Analysis I MCQRohan GadaveNo ratings yet

- 045-Ibsbi - 2014 - The Design of A Network Arch Bridge Crossing Over Arachos River in Arta GreeceDocument8 pages045-Ibsbi - 2014 - The Design of A Network Arch Bridge Crossing Over Arachos River in Arta GreeceLengendary PhubrNo ratings yet

- Prestressing DocumentDocument59 pagesPrestressing DocumentAmoula Ahmed100% (1)

Structural Sections Presentation Slides PPTSTSEN21

Structural Sections Presentation Slides PPTSTSEN21

Uploaded by

kumarmohit0203Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structural Sections Presentation Slides PPTSTSEN21

Structural Sections Presentation Slides PPTSTSEN21

Uploaded by

kumarmohit0203Copyright:

Available Formats

Quarterly Case Study Session

Presented September 2019

Industrial Case Study:

Material Properties and Structural

Sections-Architecture meets Engineering

Claes Fredriksson, David Mercier, Harriet Parnell

Ansys Materials Education Division

©2021 ANSYS, Inc.

Agenda

Introduction

Structural Section Case Study

Architecture meets Engineering

The Structural Sections Data-table

Shape Factors and Load

Revised Performance Index

Selector Engineering Solver

Finite Element Simulations

Q&A

Community Update

Claes Fredriksson, David Mercier and Harriet

Parnell from the Ansys Materials Education Team

©2021 ANSYS, Inc.

Architecture meets Engineering

The Stata Center, MIT (Cambridge MA), Concrete Structure (before) and Façade (after).

©2021 ANSYS, Inc.

The Structural Sections Data-Table

©2021 ANSYS, Inc.

Structural Sections Loaded in Bending

Beams in bending is a universal use-case

I reflects the cross-section shape

𝐼=∫ 𝑦 𝑏 ( 𝑦 ) 𝑑𝑦

2

Some useful definitions

A = cross-section area E = Young’s modulus

F = point force I = second moment of area

δ = deflection C = constant (here, 3)

S = stiffness (F/δ) This beam: δ = FL3/CEI= 12FL3/CEA

©2021 ANSYS, Inc.

Materials and Shape

Charts of structural sections depend both on

material properties and shape!

©2021 ANSYS, Inc.

Overview of steel structure properties

Properties of all steel structural sections

Sections can be screened as usual

Wood rectangular sections (planks) have surprisingly attractive properties

©2021 ANSYS, Inc.

Bending stiffness per shape (all steel)

Re-define the X-axis:

©2021 ANSYS, Inc.

What does the shape factor mean

𝑏 4 𝐴2

𝐼 𝑜= = 𝑆 𝐸𝐼 𝐼

12 12 𝜑𝑒 = = =12 2

𝑆𝑜 𝐸 𝐼 𝑜 𝐴

Shape

e=1

factor:

I-sections,

e 10

Circular tubes,

e 10

©2021 ANSYS, Inc.

The range of shape factors

e 100 e 1

12 I e

e log ( I ) 2 log ( A ) log

A2 12

©2021 ANSYS, Inc.

Performance Index that includes shape

Function Beam (shaped section).

Constraint Bending stiffness < S*

CEI

S

L3

I is the second moment of area: I

1/ 2 m = mass

I 12 I A = area

e 12 A

A2

e L = length

S = stiffness

A I = second moment of area

Objective Minimize mass, m, where: E = Youngs Modulus

m AL

1/ 2

12 S L5

m Chose materials with smallest

C E

1 / 2 E

1 / 2

e e

©2021 ANSYS, Inc.

Material Selection Including Shape

©2021 ANSYS, Inc.

Shape Factors for Optimal Selection

Material (from Ashby) Steels Aluminum alloys GFRP and CFRP Unreinforced polymers Wood

Max e ( in CES) 65 44 39 12 5

Max f 13 10 9 5 3

©2021 ANSYS, Inc.

Finite Element Simulations

• Can estimate the deflection caused by certain load

• Map the stress within the geometry caused by this load

Provided the necessary material properties are given

Simulation of stress in beams (same area) for fixed material choice Ansys

Discovery Live

Opportunity: Using Granta EduPack to screen and select top material

candidates in combination with Finite Element simulation to optimize

geometry, engineers and designers can reduce the number of material

candidates to consider in structural design.

©2021 ANSYS, Inc.

Material Selection and Simulation

For the design engineer, screening based on material properties, ranking by material-shape

performance index and FE simulations to fix dimensions are complementary:

Performance Index Selection FE simulation of stress and deflection

Top candidates

after screening

Optimized

geometries

• Trade off curves for compromises • Free design parameters

• Equal performance candidates • Von Mises stress maps

• Cost, Eco-properties, Durability, ... • Deflection estimates

©2021 ANSYS, Inc.

Conclusions

The Structural Sections data-table in Level 3 and Level 2 Architecture

Shape factors and Revised Performance Index

The systematic material selection methodology generates significant synergy with structural simulations

©2021 ANSYS, Inc.

© 2021 ANSYS, Inc. All rights reserved.

Use and Reproduction

The content used in this resource may only be used or reproduced for teaching purposes; and any commercial use is strictly prohibited.

Document Information

This case study is part of a set of teaching resources to help introduce students to materials, processes and rational selections.

Ansys Education Resources

To access more undergraduate education resources, including lecture presentations with notes, exercises with worked solutions, microprojects, real

life examples and more, visit www.ansys.com/education-resources.

17 ©2021 ANSYS, Inc.

You might also like

- Activity 2.1.2 Beam Deflection: Preliminary Lab Calculations To Determine Beam Modulus of ElasticityDocument8 pagesActivity 2.1.2 Beam Deflection: Preliminary Lab Calculations To Determine Beam Modulus of ElasticityJulius PaganNo ratings yet

- Moment of Inertia of Cracked SectionDocument33 pagesMoment of Inertia of Cracked SectionAtta Muhammad95% (20)

- Building Construction ScheduleDocument8 pagesBuilding Construction Scheduleengrfarhansiddiqui75% (4)

- Design of Single Storey RCC Framed BuildingDocument86 pagesDesign of Single Storey RCC Framed BuildingBaba Maisam Shabir89% (97)

- Isotensoid FormulationDocument12 pagesIsotensoid Formulationnhung_33No ratings yet

- CE323-18 MODULE 2 MTN v01Document9 pagesCE323-18 MODULE 2 MTN v01ira garciaNo ratings yet

- Oct10 - Steelwise - Web - Oh YesDocument2 pagesOct10 - Steelwise - Web - Oh YesJohnny ChungNo ratings yet

- Stress and Deflection Analysis of Belleville Spring PDFDocument6 pagesStress and Deflection Analysis of Belleville Spring PDFDeepak BhopeNo ratings yet

- Unit - Ii One Dimensional Problems Part - ADocument29 pagesUnit - Ii One Dimensional Problems Part - ADHARMADURAI.P MEC-AP/AERONo ratings yet

- Nonlinear ElementsDocument12 pagesNonlinear ElementsnagarajuNo ratings yet

- Interaction Diagram For Concrete ColumnsDocument14 pagesInteraction Diagram For Concrete Columnsgeogohigh100% (1)

- 2nd Btech MECH 2021-22 MOS Ses-K4 PDFDocument8 pages2nd Btech MECH 2021-22 MOS Ses-K4 PDFGopi TNo ratings yet

- Column Design Aci Code PDFDocument15 pagesColumn Design Aci Code PDFPhil MarceloNo ratings yet

- CEN 202 Mechanics of Materials: Beam DeflectionsDocument13 pagesCEN 202 Mechanics of Materials: Beam DeflectionsMuhammad Shaqeem RosdiNo ratings yet

- Ste05121spreadsheet Anchor Bolt Design PDF FreeDocument10 pagesSte05121spreadsheet Anchor Bolt Design PDF Freeveeran08No ratings yet

- Adv Struc Lec 02Document9 pagesAdv Struc Lec 02BABAN GUHANo ratings yet

- Open Hole Plate PP TDocument33 pagesOpen Hole Plate PP TThomas RaffestinNo ratings yet

- Stress Concentration Due To A Circular HoleDocument3 pagesStress Concentration Due To A Circular HolePranav VikirtanNo ratings yet

- Modeling of Discrete Intersecting Discontinuities in Rock Mass Using XFEM Level Set ApproachDocument8 pagesModeling of Discrete Intersecting Discontinuities in Rock Mass Using XFEM Level Set ApproachMARCOSNo ratings yet

- النوتة الحسابيةDocument26 pagesالنوتة الحسابيةاحمد عبد العزيزNo ratings yet

- LN 8 Bult-Up SectionDocument18 pagesLN 8 Bult-Up SectionThevinduNo ratings yet

- Hyderabad Campus FIRST SEMESTER 2015-2016: (12 Marks)Document1 pageHyderabad Campus FIRST SEMESTER 2015-2016: (12 Marks)aayushi doshiNo ratings yet

- 1443purl ME ESE-II 1995-1999Document155 pages1443purl ME ESE-II 1995-1999TirunamalaPhanimohanNo ratings yet

- Appendix C Tensor Indicial Notation in The Approximation of Elasticity Problems 2013 The Finite Element Method Its Basis and Fundamentals Seventh EditDocument10 pagesAppendix C Tensor Indicial Notation in The Approximation of Elasticity Problems 2013 The Finite Element Method Its Basis and Fundamentals Seventh EditLeo Salazar EsquivelNo ratings yet

- ME563 Machine Design II Spring 2002: MD2 - Exam 1 - Solution Spring 2002 NameDocument10 pagesME563 Machine Design II Spring 2002: MD2 - Exam 1 - Solution Spring 2002 NameUdhamNo ratings yet

- TOS 22402 Winter 19th I SCHEME Paper Model Answer PaperDocument25 pagesTOS 22402 Winter 19th I SCHEME Paper Model Answer Paperirshadmirza753No ratings yet

- Sai Phan Huu HanDocument7 pagesSai Phan Huu HanNguyễn Sơn LâmNo ratings yet

- Working Design of Single AnglesDocument2 pagesWorking Design of Single AnglesAnonymous 1BdR0EQgbu100% (1)

- S19 I Scheme PaperbackDocument14 pagesS19 I Scheme Paperbackirshadmirza753No ratings yet

- Fem Unit IDocument34 pagesFem Unit ISAIKUMAR ANo ratings yet

- Sistemas de Protección Sísmica: Resumen: (Máximo 200 Palabras)Document5 pagesSistemas de Protección Sísmica: Resumen: (Máximo 200 Palabras)Luz Acosta De La CruzNo ratings yet

- 12 # Quiz (Eng) - GODocument5 pages12 # Quiz (Eng) - GOshakeelahmadrelibNo ratings yet

- Flexural Members Layered ApproachDocument23 pagesFlexural Members Layered ApproachMohamed mohy el deenNo ratings yet

- STE05121 Spreadsheet REV1 JUL03Document11 pagesSTE05121 Spreadsheet REV1 JUL03arcelitasNo ratings yet

- Design in Timber To Ms 544 Part2: Week 5Document40 pagesDesign in Timber To Ms 544 Part2: Week 5Muhd FaridNo ratings yet

- Period 17 Flexure With Composite BeamsDocument9 pagesPeriod 17 Flexure With Composite BeamsVinod KumarNo ratings yet

- Bicol University College of Engineering Civil Engineering DepartmentDocument3 pagesBicol University College of Engineering Civil Engineering DepartmentMa Ella Mae LogronioNo ratings yet

- Etabs Modelling (Jan2015)Document13 pagesEtabs Modelling (Jan2015)HannaFouadNo ratings yet

- E Tabs Presentation FinalDocument31 pagesE Tabs Presentation FinalSawyu NandarNo ratings yet

- Important Instructions To Examiners:: Definitio n1M Types 1MDocument17 pagesImportant Instructions To Examiners:: Definitio n1M Types 1MPatil pooja100% (1)

- Chapter HandoutDocument5 pagesChapter HandoutAbhichet JeemsantiaNo ratings yet

- ADAPT TN293 RC Ie Deflection 10Document7 pagesADAPT TN293 RC Ie Deflection 10CarsonBaker100% (1)

- Finite Element Analysis of Tie Beams Under The EffDocument12 pagesFinite Element Analysis of Tie Beams Under The EffZainal AbidhynNo ratings yet

- Mec 201 04 Aug 20Document18 pagesMec 201 04 Aug 20hemanth singhNo ratings yet

- MathFor802 PDFDocument21 pagesMathFor802 PDFanon_995042985No ratings yet

- Contact Stress of Sphere On Flat SurfaceDocument3 pagesContact Stress of Sphere On Flat SurfaceEng-CalculationsNo ratings yet

- SteelDesign Composite Fu NewDocument6 pagesSteelDesign Composite Fu NewEng.Hesham AL-HelaleeNo ratings yet

- Capacity of Axially Loaded RC Columns With ArbitraDocument13 pagesCapacity of Axially Loaded RC Columns With ArbitraMilutin ZizicNo ratings yet

- EME4403 Finite ElementDocument28 pagesEME4403 Finite ElementAmmar muhammadNo ratings yet

- Mater. Sci. Eng-1Document6 pagesMater. Sci. Eng-1gopierode4No ratings yet

- Introduction To Solid Mechanics ME C85/CE C30 Final Exam Fall, 2013Document8 pagesIntroduction To Solid Mechanics ME C85/CE C30 Final Exam Fall, 2013Rodger PangNo ratings yet

- P Ch-21 Wave+OpticsDocument5 pagesP Ch-21 Wave+Opticsmysoftinfo.incNo ratings yet

- Ijce V3i12p102Document10 pagesIjce V3i12p102William PolNo ratings yet

- The Finite Element Analysis On Reinforced Concrete Short Pier Shear Wall StructuresDocument9 pagesThe Finite Element Analysis On Reinforced Concrete Short Pier Shear Wall StructuresAg PatriaNo ratings yet

- Civil Engineering Materials - Cive 2319: Lec 2 Material Performance and Its MeasurementDocument31 pagesCivil Engineering Materials - Cive 2319: Lec 2 Material Performance and Its MeasurementSiti AsmahaniNo ratings yet

- KNE216/KNE716 Civil Engineering 1: First and Only Paper Ordinary ExaminationDocument8 pagesKNE216/KNE716 Civil Engineering 1: First and Only Paper Ordinary ExaminationSebin GeorgeNo ratings yet

- Design of Random Rubble Masonry Retaining WallDocument26 pagesDesign of Random Rubble Masonry Retaining WallMackNo ratings yet

- FMDS0121 Fire Resistance of Building AssembliesDocument50 pagesFMDS0121 Fire Resistance of Building Assembliespamela552fq4859100% (1)

- 4.0 DiscussionDocument10 pages4.0 Discussionikhmal siddiqNo ratings yet

- Is.12778.2004 0 PDFDocument20 pagesIs.12778.2004 0 PDFPhanindra AttadaNo ratings yet

- 16 - Chapter 6 PDFDocument39 pages16 - Chapter 6 PDFDipankar NathNo ratings yet

- DOUBLE TEES - Technical Data: Span-Load Tables Design Criteria Tolerances Strand LocationsDocument42 pagesDOUBLE TEES - Technical Data: Span-Load Tables Design Criteria Tolerances Strand LocationsRebaz A. OthmanNo ratings yet

- Did You Know That Underpinning of Foundations Is Notifiable Work Under The Building RegulationsDocument7 pagesDid You Know That Underpinning of Foundations Is Notifiable Work Under The Building RegulationsNur Hidayah100% (1)

- Kambiz Janamian, José Aguiar - Concrete Materials and Technology - A Practical Guide-CRC Press (2023)Document397 pagesKambiz Janamian, José Aguiar - Concrete Materials and Technology - A Practical Guide-CRC Press (2023)LucasManoeldaSilva100% (1)

- Mechanics of Structures 2A: Revision Example Sheet - Beam Analysis: Bending Moments and Shear ForcesDocument3 pagesMechanics of Structures 2A: Revision Example Sheet - Beam Analysis: Bending Moments and Shear ForcesPrafulla PiseNo ratings yet

- TTTTDocument4 pagesTTTTIshwar ChauhanNo ratings yet

- Environmental Engineering Concrete Structures: Reported by ACI Committee 350Document24 pagesEnvironmental Engineering Concrete Structures: Reported by ACI Committee 350Jishad NalakathNo ratings yet

- Truss Design GuidDocument3 pagesTruss Design GuidRafi HasanNo ratings yet

- Design Loads and CombinationsDocument4 pagesDesign Loads and CombinationsMihai CalinNo ratings yet

- Experimental Investigation of Chemical and Physical Properties of Cements Manufactured in PakistanDocument15 pagesExperimental Investigation of Chemical and Physical Properties of Cements Manufactured in PakistanAyesha AyubNo ratings yet

- ACE ACADEMY ESE - 2020 (Prelims) - Offline Test Series 01 SolutionDocument13 pagesACE ACADEMY ESE - 2020 (Prelims) - Offline Test Series 01 SolutionAbhilasha CIVILNo ratings yet

- Steel WiseDocument3 pagesSteel WiseJuan Gutier CcNo ratings yet

- Concrete Mix Design As Per IS10262-2009Document24 pagesConcrete Mix Design As Per IS10262-2009Prakash Singh RawalNo ratings yet

- Ameerpet Roof Document Rev A PDFDocument360 pagesAmeerpet Roof Document Rev A PDFrajusk24No ratings yet

- Dokaflex 30 Tec PDFDocument52 pagesDokaflex 30 Tec PDFDiego CruzNo ratings yet

- Pushover CE&CRDocument9 pagesPushover CE&CRAnonymous nwByj9LNo ratings yet

- Beam DesignDocument8 pagesBeam DesignFaraaz FaisalNo ratings yet

- SFD OlderCodesDocument105 pagesSFD OlderCodessalgatranNo ratings yet

- Mapungubwe Interpretation CentreDocument6 pagesMapungubwe Interpretation CentreEdwin AsieduNo ratings yet

- CDOT Bridge Design Manual - 20180101Document431 pagesCDOT Bridge Design Manual - 20180101amraja2001100% (2)

- Research Paper On BearingsDocument9 pagesResearch Paper On BearingsmahakNo ratings yet

- Ce8502 Structural Analysis I MCQDocument26 pagesCe8502 Structural Analysis I MCQRohan GadaveNo ratings yet

- 045-Ibsbi - 2014 - The Design of A Network Arch Bridge Crossing Over Arachos River in Arta GreeceDocument8 pages045-Ibsbi - 2014 - The Design of A Network Arch Bridge Crossing Over Arachos River in Arta GreeceLengendary PhubrNo ratings yet

- Prestressing DocumentDocument59 pagesPrestressing DocumentAmoula Ahmed100% (1)