Professional Documents

Culture Documents

SC 401 Lecture 02-2 TRANSPORTATION EQUIPMENT

SC 401 Lecture 02-2 TRANSPORTATION EQUIPMENT

Uploaded by

Joseph Baruhiye0 ratings0% found this document useful (0 votes)

11 views6 pages1. Various types of equipment are used to transport materials and personnel around construction sites and between sites, including trucks, dumpers, fork lift trucks, hoists, cranes, and more.

2. Hoists transport materials and passengers vertically and come in static and mobile varieties. Mobile hoists have a maximum height of 24m and do not need tying to structures unless extension pieces are added.

3. Cranes include mobile cranes like self-propelled, lorry-mounted, truck-mounted, and mast cranes, as well as static cranes like guyed derrick and scotch derrick cranes. The appropriate crane is chosen based on capabilities, site conditions, and

Original Description:

Original Title

sc 401 lecture 02-2 TRANSPORTATION EQUIPMENT

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. Various types of equipment are used to transport materials and personnel around construction sites and between sites, including trucks, dumpers, fork lift trucks, hoists, cranes, and more.

2. Hoists transport materials and passengers vertically and come in static and mobile varieties. Mobile hoists have a maximum height of 24m and do not need tying to structures unless extension pieces are added.

3. Cranes include mobile cranes like self-propelled, lorry-mounted, truck-mounted, and mast cranes, as well as static cranes like guyed derrick and scotch derrick cranes. The appropriate crane is chosen based on capabilities, site conditions, and

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

11 views6 pagesSC 401 Lecture 02-2 TRANSPORTATION EQUIPMENT

SC 401 Lecture 02-2 TRANSPORTATION EQUIPMENT

Uploaded by

Joseph Baruhiye1. Various types of equipment are used to transport materials and personnel around construction sites and between sites, including trucks, dumpers, fork lift trucks, hoists, cranes, and more.

2. Hoists transport materials and passengers vertically and come in static and mobile varieties. Mobile hoists have a maximum height of 24m and do not need tying to structures unless extension pieces are added.

3. Cranes include mobile cranes like self-propelled, lorry-mounted, truck-mounted, and mast cranes, as well as static cranes like guyed derrick and scotch derrick cranes. The appropriate crane is chosen based on capabilities, site conditions, and

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 6

SC401:CONSTRUCTION

TECHNIQUES AND SITE

ORGANISATION

CONSTRUCTION EQUIPMENTS

LECTURER: Eng. HAPPYNESS PAUL

Friday November 18th 2022 – 08:00hrs – 10hrs

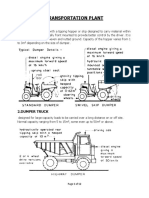

TRANSPORTING PLANTS

Movement of materials and /or personnel around and between sites can be very time consuming

and non-productive. Therefore wherever economically possible contractors will use some form of

mechanical transportation.

The movement required can be horizontal, vertical or a combination of both.

• Lorries and trucks

These are used for transportation of men and materials around the site and between sites. Vast

ranges of lorries are available for construction works with refinements such as tipping , tail host and

self-loading facilities using hydraulic lifting gears. Some trucks , like concrete mixer trucks are

designed for specific types of materials.

• Dumpers

Dumpers have often been rightly described as the “maids-of-all-work” on construction sites because

they can be used for many on site transportation duties. They are available in different capacities.

• Folk lift trucks

Folk lift trucks are used for handling mainly paleted materials quickly and efficiently around

construction sites over the rough terrain normally encountered. Designs available offer the choice of

front- or rear wheel drive and four wheels with various mast heights and lifting capacities.

TRANSPOTING PLANTS

• Hoists

Are a means of transporting materials or passengers vertically by means of a moving level platform.

Some designs permit combined materials and passenger movement. Under no circumstances should

passengers be transported on hoists designed specifically for lifting materials only.

Static and mobile

Two types are available, static and mobile. The static version consists of a mast or tower with the lift

platform either cantilevered from the small section mast of centrally suspended with guides on either

sides within an enclosing tower.

Both forms need to be plumb and tied to the structure or scaffold at the intervals recommended by the

manufacturer ensure stability.

Mobile hoists usually have a maximum height of 24 m and do not need tying to structure unless

extension pieces are fitted when they are then treated as cantilever hoist. All mobile hoists should be

positioned on a firm level base and jacked to ensure stability.

• Cranes

A crane may be defined as a device or machine for lifting loads by means of a rope. The use of cranes

has greatly increased in construction industry due mainly to the need to raise the large and heavy

prefabricated components often used in modern structures.

TRANSPOTING PLANTS

• Cranes cont’d

The range of cranes available is very wide and therefore actual choice must be made on the basis of

sound reasoning, overall economics, capabilities of cranes under consideration, prevailing site conditions

and the anticipated utilization of the equipment.

• Mobile cranes

Mobile cranes come in a wide variety of designs and capacities, generally with 360 degrees rotation or

slewing circle, a low pivot and luffing jib, the main exception being the mast crane. Mobile cranes can be

classified into self-propelled, lorry-mounted , truck mounted and mast and gantry cranes.

• Self-propelled cranes

These are wheel-mounted mobile cranes that are generally of low lifting capacities of up to 10 tonnes.

They can be distinguished from other mobile cranes by the fact that the driver has only on cab position

for both driving and operating the crane. They are extremely mobile but to be efficient they usually

require a hard level surface from which to work.

• Lorry-mounted cranes

These consist of a crane mounted on a specially designed lorry or truck. The operator drives the vehicle

between sites from a conventional cab but has to operate the crane engine and controls from separate

crane operating position. The capacity ranges from 5 to 20 tonnes in the free-standing position but using

the jack outriggers built into the chassis can increase this.

TRANSPOTING PLANTS

Cranes cont’d

• Truck-mounted cranes

This form of mobile crane is usually based on the standard power unit. Capable of being rigged as an

excavator. These cranes can traverse around most sites without the need of firm level surface and have

capacity ranges similar to the lorry-mounted cranes.

• Mast cranes

These cranes are often confused with mobile tower cranes. The main differences are:

• Mast is mounted on the jib pivots and held in the vertical position by ties;

• Cranes are high pivot machines with a luffing jib;

• Operation is usually from the chassis of the machine.

Mast cranes can either be lorry- or truck-mounted machines.

• Gantry crane

Gantry or portal crane is a rail-mounted crane consisting a horizontal transverse beam which carries a

combined driver’s cab and hook supporting saddle. The beam is supported by rail mounted “A” frames on

powered bogies situated on both sides of the building under construction. This is a particularly safe form of

crane as it requires no ballast, give the driver an excellent all round view and allows the hook three-way

movement of vertical, horizontal and traverse directions.

TRANSPOTING PLANTS

Cranes cont’d

• Static or stationary cranes

These cranes are fixed at their working positions and are used primarily for lifting heavy loads such as

structural steelwork.

• Guyed derrick cranes

Simple and inexpensive form of static crane consisting of a lattice mast with a pedestal bearing stabilized

by five or more enchored-guy ropes. The jib is of low pivot type and is slightly shorter in length than the

mast height so that it can rotate through the whole 360 degrees without fouling the guy ropes if raised in

the near vertical position.

• Scotch derrick cranes

Consists of mast and a luffing jib which is usually longer than the jib used on a similar capacity guyed

derrick crane. Stabilisation is obtained by using lattice members called guys and stays. Two guys are fixed

to the top of the slewing mast at an angle of 45 degrees with the horizontal and at an angle of 90

degrees in plan, the lower ends of the guys are connected to the end of horizontal stays fixed to base of

the mast forming an angle of 90 degrees in plan. A horizontal brace is fixed between the ends of the guys

and stays , forming a complete triangulation of stabilising members together with the mast. These cranes

are only capable of slewing 270 degrees, being restricted in further rotational movement by the sloping

lattice guys. Resistance to overturning can be provided by a kentledge applied to the struts and brace, or

these members can be bolted to temporary concrete bases.

You might also like

- Manual P160Document11 pagesManual P160Jefril SiruNo ratings yet

- Conventional General Cargo Handling Including Cargo GearDocument74 pagesConventional General Cargo Handling Including Cargo GearGlenbert Sabenorio75% (4)

- FINAL PPT-CranesDocument56 pagesFINAL PPT-CranesLeilani ManalaysayNo ratings yet

- Satyavani Projects and Consultants Pvt. LTD.: Presentation By:P. Surya Prakash, MDDocument81 pagesSatyavani Projects and Consultants Pvt. LTD.: Presentation By:P. Surya Prakash, MDurmilayadavNo ratings yet

- CraneDocument11 pagesCranesamuelNo ratings yet

- Week 9 - Materials Handling and MechanisationDocument60 pagesWeek 9 - Materials Handling and Mechanisation2023308591No ratings yet

- Cranes: K N Narasimha Prasad, Assistant Professor, Grade I, Nicmar, GoaDocument29 pagesCranes: K N Narasimha Prasad, Assistant Professor, Grade I, Nicmar, GoaPrakash BaskaranNo ratings yet

- CranesDocument34 pagesCranesSaleemAhmadMalikNo ratings yet

- Cranes AssignmentDocument7 pagesCranes Assignmentندى حسينNo ratings yet

- Heavy DutyDocument23 pagesHeavy DutyEmran MuftiNo ratings yet

- Types of Cranes: Presented by Sayantan Das ROLL NO: 1854003Document49 pagesTypes of Cranes: Presented by Sayantan Das ROLL NO: 1854003SacrosanctSayantan100% (1)

- Lifting and Handling EquipmentsDocument54 pagesLifting and Handling Equipmentsalvin100% (1)

- Building Materials and Construction: Presentation On CranesDocument10 pagesBuilding Materials and Construction: Presentation On Cranesamit jainNo ratings yet

- Construction Technology-Static CranesDocument14 pagesConstruction Technology-Static CranesPrarthana roy RNo ratings yet

- Cranes: Excavating EquipmentsDocument17 pagesCranes: Excavating EquipmentszarkimaNo ratings yet

- Cranes, Construction MachinesDocument34 pagesCranes, Construction Machinesmansoor azam100% (2)

- Lecture 1A Listing and HoistingDocument29 pagesLecture 1A Listing and Hoistingmoyo josephNo ratings yet

- CT Equipment'sDocument48 pagesCT Equipment'sMohamed MoinuNo ratings yet

- Construction Technology: Unit-Iii Cranes and Other Lifting DevicesDocument27 pagesConstruction Technology: Unit-Iii Cranes and Other Lifting DevicesMageshwarNo ratings yet

- ConveyorDocument74 pagesConveyorSamuel MergaNo ratings yet

- Cranes (Abhishek & Praveen)Document17 pagesCranes (Abhishek & Praveen)Praveen KrNo ratings yet

- Southern Luzon State UniversityDocument6 pagesSouthern Luzon State UniversityJulius Mark CerrudoNo ratings yet

- Topic 5 - Temporary Works and Services - BSR552Document59 pagesTopic 5 - Temporary Works and Services - BSR552NURULFARHANA DAUDNo ratings yet

- Material Handling DeviceDocument21 pagesMaterial Handling Devicegbsone01No ratings yet

- Gantry CraneDocument19 pagesGantry CraneENVERNo ratings yet

- Skid Steer LoaderDocument82 pagesSkid Steer LoaderSimma VishnuNo ratings yet

- Topic 6 - Construction Machinery - Crane SafetyDocument107 pagesTopic 6 - Construction Machinery - Crane Safetypangcheat pubgNo ratings yet

- CraneDocument14 pagesCraneMañas Godwin M.No ratings yet

- Design and Fabrication of Portable Gib CraneDocument36 pagesDesign and Fabrication of Portable Gib CraneAbdul Rasheed100% (7)

- Crane TypesDocument5 pagesCrane TypesSAFIQUL ISLAMNo ratings yet

- Plant BiDocument44 pagesPlant BiRetro PunkNo ratings yet

- Guided By:-Presented By: - Prof. P.M. Nemade Amit Maurya (B.E.) CivilDocument30 pagesGuided By:-Presented By: - Prof. P.M. Nemade Amit Maurya (B.E.) CivilAr Aayush GoelNo ratings yet

- Importance of LiftDocument10 pagesImportance of LiftmansiNo ratings yet

- Hoisting EquipmentDocument101 pagesHoisting EquipmentmichaelNo ratings yet

- Types of CraneDocument7 pagesTypes of CraneAltayeb YassinNo ratings yet

- Week 8 - Crane CraneDocument11 pagesWeek 8 - Crane CranefarrahfarinaNo ratings yet

- FPD Unit-2 Material HandlingDocument58 pagesFPD Unit-2 Material HandlingVinay KorekarNo ratings yet

- Franco, Reinier M. Me 503 - Me51S1 - Industrial ProcessesDocument11 pagesFranco, Reinier M. Me 503 - Me51S1 - Industrial ProcessesReinier FrancoNo ratings yet

- UntitledDocument25 pagesUntitledRoshan MaindanNo ratings yet

- Mobile: Truck-Mounted CraneDocument10 pagesMobile: Truck-Mounted CraneYoga RajNo ratings yet

- Industrial Process Module No. 2Document17 pagesIndustrial Process Module No. 2Ismaeli KielNo ratings yet

- Conveyorspt-170911094349Document48 pagesConveyorspt-170911094349reshma jahaanNo ratings yet

- MH CH-2Document12 pagesMH CH-2Nebiyou KorraNo ratings yet

- Tower Crane TBGDocument48 pagesTower Crane TBGChristianNo ratings yet

- TELEHANDLERSDocument6 pagesTELEHANDLERSMark MorwaniNo ratings yet

- Conveyorspt 170911094349 PDFDocument49 pagesConveyorspt 170911094349 PDFGowthaman MaruthamuthuNo ratings yet

- Mechanical Principles: Ishikawajima Rio de JaneiroDocument14 pagesMechanical Principles: Ishikawajima Rio de JaneirokartheepNo ratings yet

- Cranes and Industrial Trucks - GesmundoDocument12 pagesCranes and Industrial Trucks - GesmundoShenlhee GesmundoNo ratings yet

- What Is The Difference Between A Gantry Crane or Jib Crane?Document2 pagesWhat Is The Difference Between A Gantry Crane or Jib Crane?Andrew SebastianNo ratings yet

- ConveyorsDocument45 pagesConveyorsloriel maliglig100% (1)

- Lifting Device Used in ConstructionDocument18 pagesLifting Device Used in ConstructionAr Deyvanai Kannan100% (1)

- MH CH-3Document11 pagesMH CH-3Nebiyou KorraNo ratings yet

- 1.rigging & LiftingDocument48 pages1.rigging & LiftingWaelNo ratings yet

- Transportation PlantDocument12 pagesTransportation Plantpaul machariaNo ratings yet

- What Are The Different Types of Gantry CranesDocument2 pagesWhat Are The Different Types of Gantry Craneshigh2No ratings yet

- Construction MachineryDocument54 pagesConstruction MachineryAlbert PizarroNo ratings yet

- Quiz No. 5 5.0 Tower Crane: 5.2.2.1 Mono TowersDocument14 pagesQuiz No. 5 5.0 Tower Crane: 5.2.2.1 Mono TowersHardik Panchal100% (1)

- Fig 1: On Site Picture of CraneDocument10 pagesFig 1: On Site Picture of Craneansh kushNo ratings yet

- Fig 1: On Site Picture of CraneDocument10 pagesFig 1: On Site Picture of Craneansh kushNo ratings yet

- INDUSTRIAL VECHICLES PRESENTATIONDocument29 pagesINDUSTRIAL VECHICLES PRESENTATIONakampuriraamon14No ratings yet

- Week 2 Highway Design Standards 2014 FINALDocument43 pagesWeek 2 Highway Design Standards 2014 FINALJoseph BaruhiyeNo ratings yet

- Lecture5 - Slope StabilityDocument51 pagesLecture5 - Slope StabilityJoseph Baruhiye100% (1)

- Tutorial 2 FoundationDocument10 pagesTutorial 2 FoundationJoseph BaruhiyeNo ratings yet

- Lecture 6 Raster AnalysisDocument33 pagesLecture 6 Raster AnalysisJoseph BaruhiyeNo ratings yet

- Ground Improvement TechniquesDocument26 pagesGround Improvement TechniquesJoseph BaruhiyeNo ratings yet

- Lecture2 - Vertical StressDocument123 pagesLecture2 - Vertical StressJoseph BaruhiyeNo ratings yet

- Lecture 4.water Seepage Through Soils SlidesDocument37 pagesLecture 4.water Seepage Through Soils SlidesJoseph BaruhiyeNo ratings yet

- TR335 Foundation Engineering II - Deep FoundationsDocument40 pagesTR335 Foundation Engineering II - Deep FoundationsJoseph BaruhiyeNo ratings yet

- SC 401 Lecture 03-1 CONSTRUCTION SITE LAYOUTDocument20 pagesSC 401 Lecture 03-1 CONSTRUCTION SITE LAYOUTJoseph BaruhiyeNo ratings yet

- SC 401 Lecture 01Document17 pagesSC 401 Lecture 01Joseph BaruhiyeNo ratings yet

- SC431 Lecture No. 4 Economic Comparisons (Continued)Document51 pagesSC431 Lecture No. 4 Economic Comparisons (Continued)Joseph BaruhiyeNo ratings yet

- SC 401 Lecture 02-3 (Survey Equipment and Equipment Management)Document30 pagesSC 401 Lecture 02-3 (Survey Equipment and Equipment Management)Joseph BaruhiyeNo ratings yet

- SC431 Lecture No. 5Document58 pagesSC431 Lecture No. 5Joseph BaruhiyeNo ratings yet

- TR232 Chapter 4 Compaction Properties of SoilsDocument31 pagesTR232 Chapter 4 Compaction Properties of SoilsJoseph BaruhiyeNo ratings yet

- Lecture 5 - Emprical Pavement Design - TrafficDocument21 pagesLecture 5 - Emprical Pavement Design - TrafficJoseph BaruhiyeNo ratings yet

- Church ArchitectureDocument349 pagesChurch ArchitectureJoseph BaruhiyeNo ratings yet

- TR232 Chapter 1 Flow of Water Through SoilsDocument46 pagesTR232 Chapter 1 Flow of Water Through SoilsJoseph BaruhiyeNo ratings yet

- BearingsDocument51 pagesBearingspatel ketan67% (3)

- Icc-ds-006-R-0 (Amc - Icc Al Madina Project Hse Plan Rev 0)Document107 pagesIcc-ds-006-R-0 (Amc - Icc Al Madina Project Hse Plan Rev 0)anon_388527680No ratings yet

- MTC Flexible Conduit (Anaconda)Document1 pageMTC Flexible Conduit (Anaconda)Aufa Jaya Perkasa LegalityNo ratings yet

- YCIVDocument64 pagesYCIVAvce Cw100% (2)

- Types of Earthing (As Per IEC Standards) - Electrical Engineering CommunityDocument10 pagesTypes of Earthing (As Per IEC Standards) - Electrical Engineering CommunitySantosh Thapa100% (1)

- مركزي كاريير ٢٠١٨ PDFDocument1 pageمركزي كاريير ٢٠١٨ PDFHamada HegabNo ratings yet

- Clash Detection in BIM ModelingDocument63 pagesClash Detection in BIM ModelingSantosh RaiNo ratings yet

- Module Building UtilitiesDocument11 pagesModule Building UtilitiesAlyanna AvorqueNo ratings yet

- Metropolitan Cebu Water District Vs Mactan Rock IndustriesDocument3 pagesMetropolitan Cebu Water District Vs Mactan Rock IndustriesNikkiNo ratings yet

- Retaining WallDocument37 pagesRetaining WallMUTHUKKUMARAMNo ratings yet

- House Demolition PlanDocument1 pageHouse Demolition Planchoclate2012No ratings yet

- Job Description Position: BIM Manager - Pune Metro 3 BackgroundDocument2 pagesJob Description Position: BIM Manager - Pune Metro 3 BackgroundMandar GorheNo ratings yet

- Financial Proposal TALIPAPADocument5 pagesFinancial Proposal TALIPAPAMelody Frac ZapateroNo ratings yet

- MSM - August2017 PDFDocument70 pagesMSM - August2017 PDFVin1803No ratings yet

- Contract Management in Civil Works ProjectsDocument305 pagesContract Management in Civil Works Projectspradeeporchha100% (3)

- Webbing Sling - SWLDocument4 pagesWebbing Sling - SWLChandrasekhar SonarNo ratings yet

- Water QuantityDocument86 pagesWater QuantityMulu TsegayNo ratings yet

- Experimental Investigation On The Flexural Behaviour of Channel SlabsDocument5 pagesExperimental Investigation On The Flexural Behaviour of Channel SlabsDharma banothuNo ratings yet

- 7.rock PropertiesDocument58 pages7.rock PropertiesBoos yousufNo ratings yet

- MS For Expansion JointDocument10 pagesMS For Expansion JointAvirup ChandaNo ratings yet

- 33SV5G150T 101680141: Anglian Pumping ServicesDocument3 pages33SV5G150T 101680141: Anglian Pumping ServicesAlu menzikenNo ratings yet

- To: From: Submitted By: SubjectDocument10 pagesTo: From: Submitted By: SubjectL. A. PatersonNo ratings yet

- Constructing The Roadbed: 7-1 Soil As StructureDocument4 pagesConstructing The Roadbed: 7-1 Soil As StructureMark Darryl Mansay DeloriaNo ratings yet

- Tolerance ManualDocument188 pagesTolerance ManualAhmadNo ratings yet

- Technical - Enclosures - IP55Document1 pageTechnical - Enclosures - IP55ScalperNo ratings yet

- Visvesvaraya Technological University BELAGAVI - 590 018: "Computer Aided Building Planning and Drawing" 15CV54Document25 pagesVisvesvaraya Technological University BELAGAVI - 590 018: "Computer Aided Building Planning and Drawing" 15CV54NIKHIL DNo ratings yet

- Metraflex Fireloop™: Down Have The 180 Return Supported. (See Installation Instructions.)Document1 pageMetraflex Fireloop™: Down Have The 180 Return Supported. (See Installation Instructions.)ANTONIO GUTIERREZ MIRANDANo ratings yet

- Corridor Pressurization Calculation 20170310Document1 pageCorridor Pressurization Calculation 20170310wow proNo ratings yet

- MEPF BOQ - AZURE TargetDocument33 pagesMEPF BOQ - AZURE TargetUpendra ChariNo ratings yet