Professional Documents

Culture Documents

Weekly Toolbox Talk - WK 1

Weekly Toolbox Talk - WK 1

Uploaded by

ahmkassas5Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weekly Toolbox Talk - WK 1

Weekly Toolbox Talk - WK 1

Uploaded by

ahmkassas5Copyright:

Available Formats

Weekly Meeting Package

1 © 2014 Weatherford. All rights reserved.

Weekly Topic – Planning and Risk Management

The key step to performing any task successfully is to plan the task successfully.

In order to plan the task successfully you need to:

1. Have the right tools to facilitate planning the task.

2. Have the competence to use the tools.

WDI has many tools for planning our tasks including:

• Daily Rig Operations Meetings

• TRA

• SOPs

• JHAs

• Pre-task Toolbox meetings/Take 5s

2 © 2014 Weatherford. All rights reserved.

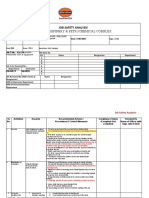

Weekly Topic – Job Hazard Analysis

What is a JHA?

A JHA is a risk assessment/planning tool.

When should a JHA be used?

Prior to starting the job.

Who should be present for a JHA?

All personnel who will be involved in the

job.

3 © 2014 Weatherford. All rights reserved.

Weekly Topic – Job Hazard Analysis

Step 1 – Outline the steps in the job. An existing TRA or SOP can help define these.

Lets look at a JHA for a Sandblasting job:

1. Hold pre-task safety meeting with all men

involved in the task and review the JHA

2. Cover all parts with masking tape which are not

to be sand blasted & isolate & lock out equipment.

3. Check all parts of blaster machine &

function test same.

4. Fill up sand in hopper of the machine

using screen.

5. Barricade the working area & place sign

board.

6. Don the required PPE.

7. Painter to start sand blasting the

equipment.

4 © 2014 Weatherford. All rights reserved.

Weekly Topic – Job Hazard Analysis

Step 2 – Identify the hazard at each step of the task.

*The hazard(s) is for that specific step.

1. Hold pre-task safety meeting with all men Missed step in analysis.

involved in the task and review the JHA

2. Cover all parts with masking tape which are not Damaged to sensitive

to be sand blasted & isolate & lock out equipment. equipment.

3. Check all parts of blaster machine & Hose under pressure hit

function test same. someone & injured.

4. Fill up sand in hopper of the machine Sand inhaled or getting

using screen. into eyes.

5. Barricade the working area & place sign Hand cut by sign board.

board.

6. Don the required PPE. Wrong PPE for the job.

7. Painter to start sand blasting the Loss of balance while

equipment. sandblasting.

5 © 2014 Weatherford. All rights reserved.

Weekly Topic – Job Hazard Analysis

Step 3 – Identify what control need to be in place to control the hazard(s) for that step.

1. Hold pre-task safety meeting with all men Missed step in analysis. Use proper JHA format

involved in the task and review the JHA and review SOP steps.

2. Cover all parts with masking tape which are not Damaged to sensitive

to be sand blasted & isolate & lock out equipment. equipment. Follow LOTO procedure.

3. Check all parts of blaster machine & Hose under pressure hit Wear PPE while testing

function test same. someone & injured. and secure hose.

4. Fill up sand in hopper of the machine Sand inhaled or getting

using screen. into eyes. Wear mask and goggles.

5. Barricade the working area & place sign Hand cut by sign board. Wear gloves while placing

board. sign.

6. Don the required PPE. Supervisor to verify PPE

Wrong PPE for the job.

is correct for job.

7. Painter to start sand blasting the Loss of balance while Ground to be clear of

equipment. sandblasting. obstacles. Levelled as

needed.

6 © 2014 Weatherford. All rights reserved.

Weekly Topic – Job Hazard Analysis

Step 4 – Identify who is responsible for that step and for ensuring the controls are in place

to mitigate the hazards for that step.

1. Hold pre-task safety meeting with all men Missed step in analysis. Use proper JHA format

and review SOP steps. Senior Tool pusher.

involved in the task and review the JHA

2. Cover all parts with masking tape which are not Damaged to sensitive Senior Mechanic/

Follow LOTO procedure.

to be sand blasted & isolate & lock out equipment. equipment. Electrician.

3. Check all parts of blaster machine & Hose under pressure hit Wear PPE while testing

function test same. someone & injured. and secure hose. Senior Mechanic.

4. Fill up sand in hopper of the machine Sand inhaled or getting Wear mask and goggles.

using screen. into eyes. Assistant Driller.

5. Barricade the working area & place sign Hand cut by sign board. Wear gloves while placing

board. sign. Assistant Driller.

6. Don the required PPE. Supervisor to verify PPE

Wrong PPE for the job. Assistant Driller.

is correct for job.

7. Painter to start sand blasting the Loss of balance while Ground to be clear of

equipment. sandblasting. obstacles. Levelled as Assistant Driller.

needed.

7 © 2014 Weatherford. All rights reserved.

Weekly Topic – Job Hazard Analysis

Step 5 – Check that the required control are in place before commencing the job.

1. Hold pre-task safety meeting with all men Missed step in analysis. Use proper JHA format Senior Toolpusher.

involved in the task and review the JHA and review SOP steps.

2. Cover all parts with masking tape which are not Damaged to sensitive Senior

Follow LOTO procedure.

to be sand blasted & isolate & lock out equipment. equipment. Mechanic/Electician.

3. Check all parts of blaster machine & Hose under pressure hit Wear PPE while testing

Senior Mechanic.

function test same. someone & injured. and secure hose.

4. Fill up sand in hopper of the machine Sand inhaled or getting Wear mask and goggles. Assistant Driller.

using screen. into eyes.

5. Barricade the working area & place sign Hand cut by sign board. Wear gloves while placing Assistant Driller.

board. sign.

6. Don the required PPE. Supervisor to verify PPE

Wrong PPE for the job. Assistant Driller.

is correct for job.

7. Painter to start sand blasting the Loss of balance while Ground to be clear of

Assistant Driller.

equipment. sandblasting. obstacles. Levelled as

needed.

8 © 2014 Weatherford. All rights reserved.

You might also like

- Qdoc - Tips Visionplus Interview QuestionsDocument3 pagesQdoc - Tips Visionplus Interview QuestionsHari Prasad SL Reddy100% (1)

- 644K Service Manual MPTS ™Document456 pages644K Service Manual MPTS ™F Labio Alex100% (4)

- JOB HAZARD ANALYSIS - Cable PullingDocument7 pagesJOB HAZARD ANALYSIS - Cable PullingJayson Escamillan100% (2)

- Method Statement For ExcavationDocument5 pagesMethod Statement For ExcavationNikhil RathiNo ratings yet

- Valid For Chassis Numbers A591628-610058, B381169-411900, D126230-127623, E707830-716714, 849582Document202 pagesValid For Chassis Numbers A591628-610058, B381169-411900, D126230-127623, E707830-716714, 849582ANDREY100% (3)

- Job Safety Analysis (JSA) - Rebar Installation/steel Fixing DateDocument1 pageJob Safety Analysis (JSA) - Rebar Installation/steel Fixing DatenabeelNo ratings yet

- JHA Sample PDFDocument2 pagesJHA Sample PDFT.DAVID DHASNo ratings yet

- 000 SAP - SD MM FI QM WM PP TablesDocument12 pages000 SAP - SD MM FI QM WM PP TablessilmarapgNo ratings yet

- Manual GA 55 VSD Atlas CompresorDocument114 pagesManual GA 55 VSD Atlas Compresormondaxa_mme50% (4)

- Waterjets Vs PropellersDocument1 pageWaterjets Vs Propellersaeromexpower2009No ratings yet

- JSA Rebar Cutting & BendingDocument2 pagesJSA Rebar Cutting & BendingGunjan Sinha AdityaNo ratings yet

- 712-Lubrcation Pipe Checking and Changing of CSR#2Document5 pages712-Lubrcation Pipe Checking and Changing of CSR#2Buddy HartNo ratings yet

- Asphalt Paving JsaDocument2 pagesAsphalt Paving Jsanabeel100% (1)

- Job Safety Analysis (JSA) - Painting DateDocument2 pagesJob Safety Analysis (JSA) - Painting DatenabeelNo ratings yet

- RA - Backfilling (Draft)Document2 pagesRA - Backfilling (Draft)Nick KrugerNo ratings yet

- Job Safety Analysis (JSA) - Carpentry Works DateDocument1 pageJob Safety Analysis (JSA) - Carpentry Works DatenabeelNo ratings yet

- SOP-12-Installation and Disconnection of Live Head of Drilliing LineDocument6 pagesSOP-12-Installation and Disconnection of Live Head of Drilliing LineDQE040 HSSENo ratings yet

- Toaz - Info 5 Jsa Rebar Cutting Amp Bending PRDocument2 pagesToaz - Info 5 Jsa Rebar Cutting Amp Bending PRthennarasuNo ratings yet

- 18 - Maintenance of Skip HoistDocument5 pages18 - Maintenance of Skip Hoistgiet11aei010No ratings yet

- Hydro TestDocument8 pagesHydro Testmozzammil saqibNo ratings yet

- Job Safety Analysis - Doc With Penumatic TestingDocument5 pagesJob Safety Analysis - Doc With Penumatic TestingDeshbandhu Aman Pandey100% (1)

- Job Safety AnalysisOverhauling Dismantling and Fitting of BA OTP AWP SWP VDP FASP BASPDocument2 pagesJob Safety AnalysisOverhauling Dismantling and Fitting of BA OTP AWP SWP VDP FASP BASPDevkanta MondalNo ratings yet

- Using The Man RaidingDocument2 pagesUsing The Man RaidingkhurramNo ratings yet

- Jsa For Excavation and BackfillingDocument5 pagesJsa For Excavation and Backfillingshaibaz chafekarNo ratings yet

- JSA HydrotestingDocument1 pageJSA Hydrotestingdinesh kumarNo ratings yet

- Job Hazard Analysis - TubingsDocument9 pagesJob Hazard Analysis - TubingsJayson Escamillan100% (1)

- PGAT2 MOS CSA 001 - MOS of Plastering WorkDocument4 pagesPGAT2 MOS CSA 001 - MOS of Plastering WorkViisshnu SilvarajooNo ratings yet

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocument1 pageJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseNo ratings yet

- Tile WorkDocument1 pageTile WorknabeelNo ratings yet

- JSA For Hydrotesting of 24 Production HeaderDocument4 pagesJSA For Hydrotesting of 24 Production HeaderjavithNo ratings yet

- PGAT2-MOS-CSA-001 - MOS of Moisture Board Installation at AHU RoomDocument3 pagesPGAT2-MOS-CSA-001 - MOS of Moisture Board Installation at AHU RoomViisshnu SilvarajooNo ratings yet

- SOP BORED PILE Work ActivityDocument6 pagesSOP BORED PILE Work ActivityliawNo ratings yet

- Risk Assessment Shuttering Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument3 pagesRisk Assessment Shuttering Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadavNo ratings yet

- JOB HAZARD ANALYSIS - ConduitDocument9 pagesJOB HAZARD ANALYSIS - ConduitJayson Escamillan100% (2)

- Jsa Ep Horizon Industrial Park.Document4 pagesJsa Ep Horizon Industrial Park.venkatNo ratings yet

- JOB HAZARD ANALYSIS - Cable TrayDocument10 pagesJOB HAZARD ANALYSIS - Cable TrayJayson Escamillan100% (2)

- Activity Hazard Analysis: Well DiggingDocument1 pageActivity Hazard Analysis: Well DiggingarjunkoiralaNo ratings yet

- SOP609 - ESP by Pass Launder Knife Gate Valve FixingDocument12 pagesSOP609 - ESP by Pass Launder Knife Gate Valve FixingSunil KumarNo ratings yet

- SOP-17-Installation and Disassembly of CatwalkDocument7 pagesSOP-17-Installation and Disassembly of CatwalkDQE040 HSSENo ratings yet

- ## PublicDocument1 page## PublicarjunkoiralaNo ratings yet

- Anggik Prasetyo-2002411030 - SOP ChamferDocument5 pagesAnggik Prasetyo-2002411030 - SOP ChamferAnggi PrasetyoNo ratings yet

- Job Safety Analysis (JSA) - Night Work DateDocument2 pagesJob Safety Analysis (JSA) - Night Work Datenabeel100% (2)

- AHA - Retrofitting WorkDocument1 pageAHA - Retrofitting WorkarjunkoiralaNo ratings yet

- 01 Job Hazard Analysis For Piling Works (JHA)Document3 pages01 Job Hazard Analysis For Piling Works (JHA)AmanNo ratings yet

- Job Hazard Analysis (Jha) : Equipment Daily Check Sheet To Be Filled Up Prior To DeploymentDocument13 pagesJob Hazard Analysis (Jha) : Equipment Daily Check Sheet To Be Filled Up Prior To DeploymentPuja SawNo ratings yet

- Risk Assessment Reinforcement Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument3 pagesRisk Assessment Reinforcement Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadavNo ratings yet

- Removal and Replacement of Corroded Mixer Tank Platform Risk AssessmentDocument5 pagesRemoval and Replacement of Corroded Mixer Tank Platform Risk AssessmentPaul ChandaNo ratings yet

- Day 3 Job Hazard Analysis (Handout)Document6 pagesDay 3 Job Hazard Analysis (Handout)mike camsNo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisDeshbandhu Aman PandeyNo ratings yet

- (SWMS) Shaft Work Duct ErectionDocument4 pages(SWMS) Shaft Work Duct Erectionsyed khaja misbhuddinNo ratings yet

- WSWP For Hamisa Installation of Lift FramesDocument6 pagesWSWP For Hamisa Installation of Lift FramesVictor Thembinkosi MakhubeleNo ratings yet

- 630-Lubrication of CSR#3Document7 pages630-Lubrication of CSR#3Buddy HartNo ratings yet

- SOP-15-Installation and Disassembly of BOP Hydraulic Control LineDocument6 pagesSOP-15-Installation and Disassembly of BOP Hydraulic Control LineDQE040 HSSENo ratings yet

- Bat (Rams)Document10 pagesBat (Rams)sodiqismail11No ratings yet

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- JOB HAZARD ANALYSIS - Electrical WorksDocument9 pagesJOB HAZARD ANALYSIS - Electrical WorksJayson Escamillan100% (1)

- Page 25Document1 pagePage 25Theodor PocovnicuNo ratings yet

- JSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTDocument6 pagesJSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTshaibaz chafekar100% (1)

- Sop for Grinding-02Document4 pagesSop for Grinding-02Subhra RanjanNo ratings yet

- JSA Hot Work Indospace RajpuraDocument2 pagesJSA Hot Work Indospace RajpuraGuri PreetNo ratings yet

- Job Safety Analysis: Gujarat RefineryDocument11 pagesJob Safety Analysis: Gujarat RefineryMICHAEL Rose100% (2)

- JSA - Field Instruments InstallationDocument4 pagesJSA - Field Instruments InstallationSagar PadhiyarNo ratings yet

- Job Hazard AnalysisDocument3 pagesJob Hazard AnalysisBrain Dee Tech LtdNo ratings yet

- Job HazardDocument5 pagesJob HazardLUIMING RUINo ratings yet

- JSA For Cleaning and Hydro Test of Test SeparatorDocument7 pagesJSA For Cleaning and Hydro Test of Test SeparatorNishantMittal100% (2)

- Introduction To Geology - MCQsDocument2 pagesIntroduction To Geology - MCQsmohan kumar100% (1)

- Code Vision AVRDocument3 pagesCode Vision AVRMohammed AsharNo ratings yet

- Copper OxideDocument2,227 pagesCopper OxideArshad ShaikhNo ratings yet

- Front Panel Board Cable: Replacement InstructionsDocument11 pagesFront Panel Board Cable: Replacement InstructionsRarojuNo ratings yet

- 24WC01 PDFDocument10 pages24WC01 PDFneko1212121515123001No ratings yet

- Manual SPECFEM2DDocument60 pagesManual SPECFEM2DAmorntep JirasakjamroonsriNo ratings yet

- DTN TutorialDocument11 pagesDTN Tutorialكمال ايت حموNo ratings yet

- Law of Friction: Surface Between Two Bodies Oppose Relative MotionDocument11 pagesLaw of Friction: Surface Between Two Bodies Oppose Relative Motionpradeep kumarNo ratings yet

- Sanray Laboratories Private Limited: Tax InvoiceDocument1 pageSanray Laboratories Private Limited: Tax InvoiceSainath AmudaNo ratings yet

- Allen Bradley 1771-IFE AI Card PDFDocument63 pagesAllen Bradley 1771-IFE AI Card PDFnesNo ratings yet

- LAB MANUAL Rebound HammerDocument4 pagesLAB MANUAL Rebound HammerSheikh BajunaidNo ratings yet

- Configuration - TrailersDocument2 pagesConfiguration - TrailersJohan ConradieNo ratings yet

- Scanning Colour Negatives: by Ian LyonsDocument6 pagesScanning Colour Negatives: by Ian LyonsPrimaristianti PutriNo ratings yet

- Liebherr LN 252-1 Zinco AltoDocument6 pagesLiebherr LN 252-1 Zinco AltowiroNo ratings yet

- Static Pressure and Pressure Head in FluidsDocument8 pagesStatic Pressure and Pressure Head in Fluidsyarzar17No ratings yet

- ASI4518R11Document2 pagesASI4518R11Marco Casarano100% (1)

- Factors Affecting The Relative RatesDocument11 pagesFactors Affecting The Relative RatesRalph EvidenteNo ratings yet

- NASA Space Shuttle Orbiter Thermal Protection System Flight ExperienceDocument22 pagesNASA Space Shuttle Orbiter Thermal Protection System Flight ExperienceNguyen Duc BinhNo ratings yet

- Introduction To Dosage Forms - Anshul The PharmacistDocument5 pagesIntroduction To Dosage Forms - Anshul The PharmacistSachin KushareNo ratings yet

- Datasheet - EDS-405A 408A SeriesDocument2 pagesDatasheet - EDS-405A 408A Seriesdenilson.rodr1357No ratings yet

- Productbrochure SD70D-SD70F VOE22B1004051 2009-05Document4 pagesProductbrochure SD70D-SD70F VOE22B1004051 2009-05t1meNo ratings yet

- Question Bank H 1Document3 pagesQuestion Bank H 1Trupti bagalNo ratings yet

- Evaluation of Natural Zeolite As Warm Mix Asphalt Additive and Its Comparison With Other Warm Mix AdditivesDocument11 pagesEvaluation of Natural Zeolite As Warm Mix Asphalt Additive and Its Comparison With Other Warm Mix Additivesalberto1234567No ratings yet

- Arrow Electronics Case Study: Submitted By: Group 3Document24 pagesArrow Electronics Case Study: Submitted By: Group 3Kevval BorichaNo ratings yet