Professional Documents

Culture Documents

36x48-Template-V5 (Autosaved)

36x48-Template-V5 (Autosaved)

Uploaded by

ramakrishnaraocvsCopyright:

Available Formats

You might also like

- SAP2000 Base Isolation PDFDocument34 pagesSAP2000 Base Isolation PDFoscavier100% (2)

- Coatings and InksDocument50 pagesCoatings and InksAndrew KellyNo ratings yet

- ACI Code 315-14Document22 pagesACI Code 315-14murad_ce0% (3)

- Smart Memory Alloys: Asim RahimatpureDocument3 pagesSmart Memory Alloys: Asim RahimatpureKarneshwar SannamaniNo ratings yet

- IiscDocument21 pagesIiscGautham AnsuNo ratings yet

- Final PresentationDocument19 pagesFinal PresentationK HARSHITHANo ratings yet

- Magnets in Maxillofacial Prosthodontics ManuscriptDocument14 pagesMagnets in Maxillofacial Prosthodontics ManuscriptShankar arumugamNo ratings yet

- Shape Memory Alloys: A State of Art Review: IOP Conference Series: Materials Science and EngineeringDocument14 pagesShape Memory Alloys: A State of Art Review: IOP Conference Series: Materials Science and EngineeringSAMUEL ALBERTO ZAMBRANA MALDONADONo ratings yet

- Module 1: Fundamentals of Mse 1.: The Materials Selection ProcessDocument2 pagesModule 1: Fundamentals of Mse 1.: The Materials Selection ProcesstumambingaleahNo ratings yet

- 65 Days ScheduleDocument20 pages65 Days SchedulearaedapponNo ratings yet

- Eriez WetDrumSeparators BrochureDocument8 pagesEriez WetDrumSeparators Brochureranjeevkumar100% (1)

- Kimia Material Kelompok 1 - Imperfection in SolidsDocument21 pagesKimia Material Kelompok 1 - Imperfection in SolidsTitah Aldila BudiastantiNo ratings yet

- MOR Outline: - Need For Model Reduction - Steady-State Case (Linear and Nonlinear) - Dynamic Linear CaseDocument11 pagesMOR Outline: - Need For Model Reduction - Steady-State Case (Linear and Nonlinear) - Dynamic Linear CasesorzomNo ratings yet

- A Modular Torsioanl Actuator Using Shape Memory Alloy WiresDocument8 pagesA Modular Torsioanl Actuator Using Shape Memory Alloy WiresYoungshik KimNo ratings yet

- Lecture 1.3Document6 pagesLecture 1.3wemata7962No ratings yet

- Shape Memory AlloysDocument6 pagesShape Memory AlloysKali DasNo ratings yet

- Balasubramanian 2021 J. Phys. Conf. Ser. 2054 012078Document11 pagesBalasubramanian 2021 J. Phys. Conf. Ser. 2054 012078Kanchan JoshiNo ratings yet

- An Overview of Vibration and Seismic Applications of Niti Shape Memory AlloyDocument13 pagesAn Overview of Vibration and Seismic Applications of Niti Shape Memory Alloyhamed nozariNo ratings yet

- Applications of Shape Memory Alloys in C PDFDocument9 pagesApplications of Shape Memory Alloys in C PDFOdai Khaled Abdullah Abdu MoslehNo ratings yet

- Diluted Magnetic Semiconductor NanowiresDocument19 pagesDiluted Magnetic Semiconductor NanowiresVinicius PimentaNo ratings yet

- SimaDocument16 pagesSimaDeepakNo ratings yet

- Chapter 4-Polymer Structures Chapter 4 - Polymer Structures: Polymer Microstructure Polymer MicrostructureDocument13 pagesChapter 4-Polymer Structures Chapter 4 - Polymer Structures: Polymer Microstructure Polymer MicrostructuregoldflackNo ratings yet

- 03 Mech 438 538 Material Environment Safety 012621Document7 pages03 Mech 438 538 Material Environment Safety 012621hdjhdzjzNo ratings yet

- Datta 2018Document9 pagesDatta 2018Sullivam PrestesNo ratings yet

- Structural MaterialsDocument24 pagesStructural MaterialsSameer DhruwNo ratings yet

- Advancedmaterial 141214033536 Conversion Gate01Document20 pagesAdvancedmaterial 141214033536 Conversion Gate01Ethan HuntNo ratings yet

- Thermal Procedure (Heating/cooling) Are Called Memory MetalsDocument10 pagesThermal Procedure (Heating/cooling) Are Called Memory Metalsgobinath216No ratings yet

- Chapter 13: Applications and Processing of Ceramics Taxonomy of CeramicsDocument3 pagesChapter 13: Applications and Processing of Ceramics Taxonomy of CeramicsAjyant SuryaNo ratings yet

- Mechanical Actuators: Dr. Bruce K. Gale Fundamentals of MicromachiningDocument8 pagesMechanical Actuators: Dr. Bruce K. Gale Fundamentals of MicromachiningChidananda BasavannaNo ratings yet

- TS WLims IO-enDocument5 pagesTS WLims IO-enErich ThomasNo ratings yet

- Engineering Materials and Their Properties: Bda 20402engineeringmaterials Selection Semester 2 Session 2019/2020Document16 pagesEngineering Materials and Their Properties: Bda 20402engineeringmaterials Selection Semester 2 Session 2019/2020Praven KumarNo ratings yet

- Simulia Abaqus Standard DatasheetDocument3 pagesSimulia Abaqus Standard Datasheetuser923019231831No ratings yet

- Scheme of PresentationDocument31 pagesScheme of Presentation1DA19ME073 Nawraj PandeyNo ratings yet

- OverviewDocument3 pagesOverviewyasindeepNo ratings yet

- Brochure Abaqus Explicit PDFDocument2 pagesBrochure Abaqus Explicit PDFOmar FrancoNo ratings yet

- Shape Memory Alloy AnkitDocument13 pagesShape Memory Alloy AnkitankitNo ratings yet

- Seismic Assessment of Concentrically Braced Steel Frames With Shape Memory Alloy BracesDocument9 pagesSeismic Assessment of Concentrically Braced Steel Frames With Shape Memory Alloy BracesabdulghafrNo ratings yet

- Introduction To Material ScienceDocument17 pagesIntroduction To Material ScienceThanmay B MNo ratings yet

- Study of Optical Fibers Strain-Temperature Sensitivities Using Hybrid Brillouin-Rayleigh SystemDocument11 pagesStudy of Optical Fibers Strain-Temperature Sensitivities Using Hybrid Brillouin-Rayleigh SystemFelipe Santos de AlmeidaNo ratings yet

- Shape Memory Alloys Unlocking The ExtraordinaryDocument10 pagesShape Memory Alloys Unlocking The ExtraordinarySoundous TayssirNo ratings yet

- 1.) Module (Introduction To Strength of Materials)Document14 pages1.) Module (Introduction To Strength of Materials)Jeffrey ManansalaNo ratings yet

- Magnet Selection Constantinides Gorham 2003 PSN Hi ResDocument22 pagesMagnet Selection Constantinides Gorham 2003 PSN Hi Reshuuphuc2909No ratings yet

- Smart MaterialsDocument17 pagesSmart MaterialsABDUL SHAFI MNo ratings yet

- National Institute of Technology RourkelaDocument1 pageNational Institute of Technology Rourkelasivaji naikNo ratings yet

- Shape Memory AlloysDocument21 pagesShape Memory AlloysMrinal Raj SinghNo ratings yet

- Abaqus/Explicit 2017 Data Sheet: Analysis Types Material DefinitionsDocument2 pagesAbaqus/Explicit 2017 Data Sheet: Analysis Types Material DefinitionsMatias GentileNo ratings yet

- Corrosion and Wear Properties of Aluminium Aa6061/Snail Shell+Chitosan CompositesDocument14 pagesCorrosion and Wear Properties of Aluminium Aa6061/Snail Shell+Chitosan CompositesBinwa-ari NumbereNo ratings yet

- Machining, Drawing & SolidworksDocument9 pagesMachining, Drawing & Solidworksmadi100% (1)

- 3 - CEM - Testing of Mechanical Properties PDFDocument11 pages3 - CEM - Testing of Mechanical Properties PDFSmit GandhiNo ratings yet

- Boatti PHD PresDocument41 pagesBoatti PHD PresygfrostNo ratings yet

- SeismicInterpretation Theory2020 Part3Document6 pagesSeismicInterpretation Theory2020 Part3DanielArielYobelNo ratings yet

- COMSOL Workshop PDFDocument23 pagesCOMSOL Workshop PDFحيدر ممتاز حسين الشاميNo ratings yet

- Lecture - 9 Laser Beam MachiningDocument18 pagesLecture - 9 Laser Beam MachiningAbdulrahman goudaNo ratings yet

- Load Cells-Cas Displacement/Position Sensors I-Target: PotentiometricDocument2 pagesLoad Cells-Cas Displacement/Position Sensors I-Target: PotentiometricYadi Elsa NDNo ratings yet

- Dasar Teori KPDocument14 pagesDasar Teori KPheruNo ratings yet

- 4 Steel - SMRF - BehaviorDocument67 pages4 Steel - SMRF - Behavioreduardox11No ratings yet

- Diana10 1 Dams Brochure Dec 2016 Print VersionDocument4 pagesDiana10 1 Dams Brochure Dec 2016 Print VersionMirza FadlulahNo ratings yet

- Material Science Topic 1Document9 pagesMaterial Science Topic 1Ahmad Afham AhmadNo ratings yet

- Static Equipment Material SelectionDocument58 pagesStatic Equipment Material SelectionLorenzoNo ratings yet

- SMA-Based Muscle-Like Actuation in Biologically Inspired Robots: A State of The Art ReviewDocument30 pagesSMA-Based Muscle-Like Actuation in Biologically Inspired Robots: A State of The Art ReviewWilliam H. CoralNo ratings yet

- 2 Examination of Ultrafine Grained NickelDocument9 pages2 Examination of Ultrafine Grained NickelramakrishnaraocvsNo ratings yet

- 3 Experimental and Numerical Investigation On Pure Aluminum by ECAPDocument9 pages3 Experimental and Numerical Investigation On Pure Aluminum by ECAPramakrishnaraocvsNo ratings yet

- Vacancy Loop AlDocument4 pagesVacancy Loop AlramakrishnaraocvsNo ratings yet

- Data Analytics NewDocument11 pagesData Analytics NewramakrishnaraocvsNo ratings yet

- Data AnalyticsDocument11 pagesData AnalyticsramakrishnaraocvsNo ratings yet

- Wear of RailsDocument13 pagesWear of RailsMusanif Ahmed FarooqiNo ratings yet

- Aieee 2003Document43 pagesAieee 2003NCERT SolutionsNo ratings yet

- 4.project ReportDocument38 pages4.project ReportJagadeeshan SivanNo ratings yet

- ABB Valve Series 14Document8 pagesABB Valve Series 14HafziNo ratings yet

- Kegiatan Kalibrasi Tahun: 2022: Puskesmas GUNUNG KALERDocument2 pagesKegiatan Kalibrasi Tahun: 2022: Puskesmas GUNUNG KALERNova ArdiantoNo ratings yet

- 2425 FormulasDocument2 pages2425 FormulassonuNo ratings yet

- GE Lighting Systems Decashield Series Spec Sheet 2-83Document4 pagesGE Lighting Systems Decashield Series Spec Sheet 2-83Alan MastersNo ratings yet

- First Periodical Examination For GRADE 7 SCIENCEDocument2 pagesFirst Periodical Examination For GRADE 7 SCIENCEMyrson MalayanNo ratings yet

- Carlo Rovelli UNBELIEVABLE Similarities Between Rovelli's Works (2007-2021) and My Works (2002-2007)Document51 pagesCarlo Rovelli UNBELIEVABLE Similarities Between Rovelli's Works (2007-2021) and My Works (2002-2007)Gabriel VacariuNo ratings yet

- XI - A - Differential & Integration-1Document2 pagesXI - A - Differential & Integration-1mishrasplparthNo ratings yet

- Majorana Fermions in Condensed Matter Physics: The 1D Nanowire CaseDocument6 pagesMajorana Fermions in Condensed Matter Physics: The 1D Nanowire CaseOscar BohórquezNo ratings yet

- Shayma Chem II Lab Manual.... Petrochemical Engineering DepartmentDocument55 pagesShayma Chem II Lab Manual.... Petrochemical Engineering DepartmentMUHAMMAD AKRAM100% (1)

- Butterfly Valve and FlowDocument5 pagesButterfly Valve and FlowMurugan RangarajanNo ratings yet

- Parcheta Szwindowska Et Al 2023 Fabrication and Characterization of Green Polyurethane Foams With Enhanced VibrationDocument10 pagesParcheta Szwindowska Et Al 2023 Fabrication and Characterization of Green Polyurethane Foams With Enhanced Vibrationsyamsutajri100% (1)

- Tutorial 5&6 Mechanics of Machine (Q)Document1 pageTutorial 5&6 Mechanics of Machine (Q)Raiham EffendyNo ratings yet

- Unit 3 Natural ResourcesDocument23 pagesUnit 3 Natural Resourcesankit kaleNo ratings yet

- Double Shear Single ShearDocument3 pagesDouble Shear Single ShearJoyce ChepkiruiNo ratings yet

- I87 GhinvrrDocument8 pagesI87 GhinvrrFact LoopNo ratings yet

- DOP Plixxopol SF 8721W enDocument2 pagesDOP Plixxopol SF 8721W enCristina AndronescuNo ratings yet

- MAINTENANCE ENGINEERING SyllabusDocument2 pagesMAINTENANCE ENGINEERING Syllabus132 Arindam DattaNo ratings yet

- Manual Bomba CPXDocument36 pagesManual Bomba CPXRolando Felipe Tapia Moyano100% (1)

- بروشور وزارت دفاع PDFDocument100 pagesبروشور وزارت دفاع PDFXen XenNo ratings yet

- Gearless Transmission ReportDocument32 pagesGearless Transmission ReportHarish Kumar73% (22)

- Chemical Bonding and Periodic Trends Part 1Document9 pagesChemical Bonding and Periodic Trends Part 1danielmahsaNo ratings yet

- P. J. Forrester and B. Jancovici - Generalized Plasmas and The Anomalous Quantum Hall EffectDocument7 pagesP. J. Forrester and B. Jancovici - Generalized Plasmas and The Anomalous Quantum Hall EffectGreamxxNo ratings yet

- TDA-V-Series Direct Drive Vane Axial FanDocument2 pagesTDA-V-Series Direct Drive Vane Axial FanKristopher PerinNo ratings yet

- Reflector AntennasDocument20 pagesReflector AntennaslvsaruNo ratings yet

- NACE Review of Recommended PracticesDocument16 pagesNACE Review of Recommended PracticesismaelarchilacastilloNo ratings yet

36x48-Template-V5 (Autosaved)

36x48-Template-V5 (Autosaved)

Uploaded by

ramakrishnaraocvsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

36x48-Template-V5 (Autosaved)

36x48-Template-V5 (Autosaved)

Uploaded by

ramakrishnaraocvsCopyright:

Available Formats

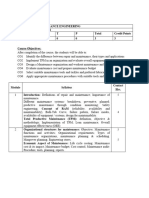

SHAPE MEMORY ALLOYS (SMA’s)

V. Ramesh K Naik

Department of Metallurgical and Materials Engineering

Rajiv Gandhi University of Knowledge Technologies, Nuzvid, AP, India – 521202

Abstract Classification of SMA’s Properties of SMA’s Applications of SMA’s

Shape Memory Alloys (SMA's) are novel materials which SMA’s have gone mainly three important properties. Those are During the last few years, a wide variety of applications of SMA’s

They are classified into two types

have the ability to regain its predetermined shape when have emerged both in form of products and concepts.

1. One-Way SMA’s: 1.Shape Memory Effect

1. Industrial Applications 2. Medical Applications

heated. SMA’s are a type of smart materials which have • To know about SMA’s, certainly we have to know about the

These are exhibiting the • Cryofit hydraulic tube coupling

unique feature diffusion less solid-to-solid phase shape memory effect. • Tumor

transformation from martensite to austenite and vice characteristic of “regaining its • Suppose take a SMA for example NiTi (Nitinol) • Temperature control system

• Eye glasses

versa. Composite structures embedded with SMA’s have original state only on heating alone”. • Force actuators • Bone plates

many benefits like actuation, vibration control and • Heat engines • Surgical anchor,

damping, sensing and self-healing. However, substantial • Lifting devices • Catheters

2. Two-Way SMA’s: • Blood clot filters

research in this area, a comparable adoption of SMA • Sensors

These are exhibiting the • Toys

•

composites by industry has not yet been realized. Because

characteristic of “regaining its • Aeronautics and Robotics

of the material complexity that includes strong

thermomechanical coupling, large inelastic deformations, original state by both heating and

and variable thermoplastic properties. SMA’s are cooling”.

becoming increasingly accepted in engineering Examples:

applications. SMA’s are used in a variety of fields, such as Most common class of SMA’s is

medical and aeronautical. Many fields have been Nitinol (Ni-Ti alloys). Other alloys

researching on these materials, attracted by their capacity

Showing this effect include CuZn, Advantages Disadvantages

to dissipate energy through high-strain hysteretic cycles 2. Pseudoelasticity

without significant residual strains. NiAl, NiMn, CuZnAl, CuZnSi, CuZnGa, NiMnAl,

Bio-compatibility • Expensive

NiMnCr, NiMnTi, NiTiFe, MnFeSi, AuCd .etc..

Diverse field of applications • Poor fatigue life

Introduction Detwinned Martensite

(stressed)

Good mechanical properties

Memory of Memory alloys: Transformations in SMA’s: Corrosion resistance

The earliest recorded observation of the shape Based on temperature it will undergoes into two forms

Conclusion

STRESS

memory effect was by Avne Olander in 1932. He observed 2. Martensite transformation There are many possible applications for SMAs. The many

the pseudoelastic behavior in Au-Cd alloy. In1967, at • When the material is subjected at low temperature then uses and applications of shape memory alloys ensure a bright

Naval Ordance Laboratory, Beuhler discovers shape it will exhibit a martensite phase Mf Ms As Af

future for these metals. Research is currently carried out at many

memory effect in nickel titanium alloy (Nitinol) which robotics departments and materials science departments. With the

• Material will be very soft Austenite

proved to be a major breakthrough in the field of shape innovative ideas for applications of SMA’s and the number of

memory alloys. He is one who discover this class of • This can be in two forms Temperature products on the market using SMA’s continually growing,

SMA’s. In 1980, it was used by NASA in an Earth orbiting Twinned and Detwinned martensite advances in the field of shape memory alloys for use in many

3. Hysteresis different fields of study seem very promising.

space station. 1970-1980 – First reports of nickel-titanium 2. Austenite transformation • The transformation or temperature changes even though they are

implants being used in medical applications. Mid-1990s, • When the material is subjected at high temperature then happening in a wide range, there is no overlapping of References

Memory metals start to become widespread in medicine it shows austenite phase. transformation happening here • Y. H. Teh 2003. A Control System for Achieving Rapid Controlled Motions From Shape

Memory Alloy (SMA) Actuator Wires. B.Eng. Honours Thesis, Dept. Engineering, The

and soon move to other applications. Within the last ten • Material is having a stronger bond Australian National University.

• R. Featherstone & Y. H. Teh 2004. Improving the Speed of Shape Memory Alloy Actuators by

years, a number of commercial products have appeared in

By heating and cooling we can change these phases, Faster Electrical Heating. Int. Symp. Experimental Robotics.

the market and the understanding of the phenomenon has • Y. H. Teh & R. Featherstone 2004. A New Control System for Fast Motion Control of SMA

that is the extraordinary unique property the SMA’s Actuator Wires. Shape Memory And Related Technologies.

very much increased. • L.G. Machado, M.A. Savi, Medical applications of shape memory alloys, Brazilian Journal of

have got. Medical and Biologial Research Vol. 36 (2003), pp. 683-691

• J. Van Humbeeck, Non-medical applications of shape memory alloys, Materials Science and

A phase transformation which occurs between these Engineering A273-275 (1999), pp. 134-148

• K. Otsuka, C. M. Wayman, Shape memory materials, Cambridge university press, 1st ed. 1999

What is Shape Memory Alloys (SMA’s)? two phases upon heating/cooling is the basis for the • J-M. Philippe, Art and Shape-Memory Alloys, Leonardo, Vol. 22 (1989), pp. 117-120

• Abeyaratne, R. and Kim S. (1997). Cyclic effects in shape-memory alloys: A one-dimensional

A shape-memory alloys (SMA, smart metal, unique properties of the SMA’s continuum model, Int. Jl. of Sol. Struct. 34(25), pp. 3273–3289.

• Auricchio, F. and Taylor, R. L. (1997). Shape-memory alloys modeling and numerical

memory metal, memory alloy, muscle wire, smart The important part of SMA’s are which we have to look simulations of the finite strain superelastic behavior, Comput. Meth. Appl. Mech. Engg. 143, pp.

alloy) are metal alloys that can be deformed at one into their characteristics or properties.

175-194.

• Birman, V. (1997). Review of mechanics of shape memory alloy structures, Appl. Mech.

temperature but when heated and cooled, return to their Reviews 50, pp. 629-645.

• Wu MH, Schetky LM. Industrial applications for shape memory alloys. In: International

“original” Shape. conference on shape memory and superelastic technologies. Pacific Grove, California, USA;

2000. p. 171–82.

Shape memory alloys (SMA) have been known for • Funakubo H, Kennedy JB. Shape memory alloys. In: Gordon and breach, xii+ 275, 15 22 cm,

illustrated; 1987.

over five decades and modeling of their response has

attracted much attention over the last two decades. Recent

increase in the range of applications of these materials has Ramesh K Naik. V

Department of Metallurgical and Materials Engineering

lead to an increased focus on modeling their • Low temperature High temperature Rajiv Gandhi University of Knowledge Technologies, Nuzvid, AP, India – 521202

thermomechanical response. austenite Email id:- rameshrguktn@gmail.com

Cell No:- +91 7995126206

martensite (twinned) cubic structure

RESEARCH POSTER PRESENTATION DESIGN © 2015

www.PosterPresentations.com

You might also like

- SAP2000 Base Isolation PDFDocument34 pagesSAP2000 Base Isolation PDFoscavier100% (2)

- Coatings and InksDocument50 pagesCoatings and InksAndrew KellyNo ratings yet

- ACI Code 315-14Document22 pagesACI Code 315-14murad_ce0% (3)

- Smart Memory Alloys: Asim RahimatpureDocument3 pagesSmart Memory Alloys: Asim RahimatpureKarneshwar SannamaniNo ratings yet

- IiscDocument21 pagesIiscGautham AnsuNo ratings yet

- Final PresentationDocument19 pagesFinal PresentationK HARSHITHANo ratings yet

- Magnets in Maxillofacial Prosthodontics ManuscriptDocument14 pagesMagnets in Maxillofacial Prosthodontics ManuscriptShankar arumugamNo ratings yet

- Shape Memory Alloys: A State of Art Review: IOP Conference Series: Materials Science and EngineeringDocument14 pagesShape Memory Alloys: A State of Art Review: IOP Conference Series: Materials Science and EngineeringSAMUEL ALBERTO ZAMBRANA MALDONADONo ratings yet

- Module 1: Fundamentals of Mse 1.: The Materials Selection ProcessDocument2 pagesModule 1: Fundamentals of Mse 1.: The Materials Selection ProcesstumambingaleahNo ratings yet

- 65 Days ScheduleDocument20 pages65 Days SchedulearaedapponNo ratings yet

- Eriez WetDrumSeparators BrochureDocument8 pagesEriez WetDrumSeparators Brochureranjeevkumar100% (1)

- Kimia Material Kelompok 1 - Imperfection in SolidsDocument21 pagesKimia Material Kelompok 1 - Imperfection in SolidsTitah Aldila BudiastantiNo ratings yet

- MOR Outline: - Need For Model Reduction - Steady-State Case (Linear and Nonlinear) - Dynamic Linear CaseDocument11 pagesMOR Outline: - Need For Model Reduction - Steady-State Case (Linear and Nonlinear) - Dynamic Linear CasesorzomNo ratings yet

- A Modular Torsioanl Actuator Using Shape Memory Alloy WiresDocument8 pagesA Modular Torsioanl Actuator Using Shape Memory Alloy WiresYoungshik KimNo ratings yet

- Lecture 1.3Document6 pagesLecture 1.3wemata7962No ratings yet

- Shape Memory AlloysDocument6 pagesShape Memory AlloysKali DasNo ratings yet

- Balasubramanian 2021 J. Phys. Conf. Ser. 2054 012078Document11 pagesBalasubramanian 2021 J. Phys. Conf. Ser. 2054 012078Kanchan JoshiNo ratings yet

- An Overview of Vibration and Seismic Applications of Niti Shape Memory AlloyDocument13 pagesAn Overview of Vibration and Seismic Applications of Niti Shape Memory Alloyhamed nozariNo ratings yet

- Applications of Shape Memory Alloys in C PDFDocument9 pagesApplications of Shape Memory Alloys in C PDFOdai Khaled Abdullah Abdu MoslehNo ratings yet

- Diluted Magnetic Semiconductor NanowiresDocument19 pagesDiluted Magnetic Semiconductor NanowiresVinicius PimentaNo ratings yet

- SimaDocument16 pagesSimaDeepakNo ratings yet

- Chapter 4-Polymer Structures Chapter 4 - Polymer Structures: Polymer Microstructure Polymer MicrostructureDocument13 pagesChapter 4-Polymer Structures Chapter 4 - Polymer Structures: Polymer Microstructure Polymer MicrostructuregoldflackNo ratings yet

- 03 Mech 438 538 Material Environment Safety 012621Document7 pages03 Mech 438 538 Material Environment Safety 012621hdjhdzjzNo ratings yet

- Datta 2018Document9 pagesDatta 2018Sullivam PrestesNo ratings yet

- Structural MaterialsDocument24 pagesStructural MaterialsSameer DhruwNo ratings yet

- Advancedmaterial 141214033536 Conversion Gate01Document20 pagesAdvancedmaterial 141214033536 Conversion Gate01Ethan HuntNo ratings yet

- Thermal Procedure (Heating/cooling) Are Called Memory MetalsDocument10 pagesThermal Procedure (Heating/cooling) Are Called Memory Metalsgobinath216No ratings yet

- Chapter 13: Applications and Processing of Ceramics Taxonomy of CeramicsDocument3 pagesChapter 13: Applications and Processing of Ceramics Taxonomy of CeramicsAjyant SuryaNo ratings yet

- Mechanical Actuators: Dr. Bruce K. Gale Fundamentals of MicromachiningDocument8 pagesMechanical Actuators: Dr. Bruce K. Gale Fundamentals of MicromachiningChidananda BasavannaNo ratings yet

- TS WLims IO-enDocument5 pagesTS WLims IO-enErich ThomasNo ratings yet

- Engineering Materials and Their Properties: Bda 20402engineeringmaterials Selection Semester 2 Session 2019/2020Document16 pagesEngineering Materials and Their Properties: Bda 20402engineeringmaterials Selection Semester 2 Session 2019/2020Praven KumarNo ratings yet

- Simulia Abaqus Standard DatasheetDocument3 pagesSimulia Abaqus Standard Datasheetuser923019231831No ratings yet

- Scheme of PresentationDocument31 pagesScheme of Presentation1DA19ME073 Nawraj PandeyNo ratings yet

- OverviewDocument3 pagesOverviewyasindeepNo ratings yet

- Brochure Abaqus Explicit PDFDocument2 pagesBrochure Abaqus Explicit PDFOmar FrancoNo ratings yet

- Shape Memory Alloy AnkitDocument13 pagesShape Memory Alloy AnkitankitNo ratings yet

- Seismic Assessment of Concentrically Braced Steel Frames With Shape Memory Alloy BracesDocument9 pagesSeismic Assessment of Concentrically Braced Steel Frames With Shape Memory Alloy BracesabdulghafrNo ratings yet

- Introduction To Material ScienceDocument17 pagesIntroduction To Material ScienceThanmay B MNo ratings yet

- Study of Optical Fibers Strain-Temperature Sensitivities Using Hybrid Brillouin-Rayleigh SystemDocument11 pagesStudy of Optical Fibers Strain-Temperature Sensitivities Using Hybrid Brillouin-Rayleigh SystemFelipe Santos de AlmeidaNo ratings yet

- Shape Memory Alloys Unlocking The ExtraordinaryDocument10 pagesShape Memory Alloys Unlocking The ExtraordinarySoundous TayssirNo ratings yet

- 1.) Module (Introduction To Strength of Materials)Document14 pages1.) Module (Introduction To Strength of Materials)Jeffrey ManansalaNo ratings yet

- Magnet Selection Constantinides Gorham 2003 PSN Hi ResDocument22 pagesMagnet Selection Constantinides Gorham 2003 PSN Hi Reshuuphuc2909No ratings yet

- Smart MaterialsDocument17 pagesSmart MaterialsABDUL SHAFI MNo ratings yet

- National Institute of Technology RourkelaDocument1 pageNational Institute of Technology Rourkelasivaji naikNo ratings yet

- Shape Memory AlloysDocument21 pagesShape Memory AlloysMrinal Raj SinghNo ratings yet

- Abaqus/Explicit 2017 Data Sheet: Analysis Types Material DefinitionsDocument2 pagesAbaqus/Explicit 2017 Data Sheet: Analysis Types Material DefinitionsMatias GentileNo ratings yet

- Corrosion and Wear Properties of Aluminium Aa6061/Snail Shell+Chitosan CompositesDocument14 pagesCorrosion and Wear Properties of Aluminium Aa6061/Snail Shell+Chitosan CompositesBinwa-ari NumbereNo ratings yet

- Machining, Drawing & SolidworksDocument9 pagesMachining, Drawing & Solidworksmadi100% (1)

- 3 - CEM - Testing of Mechanical Properties PDFDocument11 pages3 - CEM - Testing of Mechanical Properties PDFSmit GandhiNo ratings yet

- Boatti PHD PresDocument41 pagesBoatti PHD PresygfrostNo ratings yet

- SeismicInterpretation Theory2020 Part3Document6 pagesSeismicInterpretation Theory2020 Part3DanielArielYobelNo ratings yet

- COMSOL Workshop PDFDocument23 pagesCOMSOL Workshop PDFحيدر ممتاز حسين الشاميNo ratings yet

- Lecture - 9 Laser Beam MachiningDocument18 pagesLecture - 9 Laser Beam MachiningAbdulrahman goudaNo ratings yet

- Load Cells-Cas Displacement/Position Sensors I-Target: PotentiometricDocument2 pagesLoad Cells-Cas Displacement/Position Sensors I-Target: PotentiometricYadi Elsa NDNo ratings yet

- Dasar Teori KPDocument14 pagesDasar Teori KPheruNo ratings yet

- 4 Steel - SMRF - BehaviorDocument67 pages4 Steel - SMRF - Behavioreduardox11No ratings yet

- Diana10 1 Dams Brochure Dec 2016 Print VersionDocument4 pagesDiana10 1 Dams Brochure Dec 2016 Print VersionMirza FadlulahNo ratings yet

- Material Science Topic 1Document9 pagesMaterial Science Topic 1Ahmad Afham AhmadNo ratings yet

- Static Equipment Material SelectionDocument58 pagesStatic Equipment Material SelectionLorenzoNo ratings yet

- SMA-Based Muscle-Like Actuation in Biologically Inspired Robots: A State of The Art ReviewDocument30 pagesSMA-Based Muscle-Like Actuation in Biologically Inspired Robots: A State of The Art ReviewWilliam H. CoralNo ratings yet

- 2 Examination of Ultrafine Grained NickelDocument9 pages2 Examination of Ultrafine Grained NickelramakrishnaraocvsNo ratings yet

- 3 Experimental and Numerical Investigation On Pure Aluminum by ECAPDocument9 pages3 Experimental and Numerical Investigation On Pure Aluminum by ECAPramakrishnaraocvsNo ratings yet

- Vacancy Loop AlDocument4 pagesVacancy Loop AlramakrishnaraocvsNo ratings yet

- Data Analytics NewDocument11 pagesData Analytics NewramakrishnaraocvsNo ratings yet

- Data AnalyticsDocument11 pagesData AnalyticsramakrishnaraocvsNo ratings yet

- Wear of RailsDocument13 pagesWear of RailsMusanif Ahmed FarooqiNo ratings yet

- Aieee 2003Document43 pagesAieee 2003NCERT SolutionsNo ratings yet

- 4.project ReportDocument38 pages4.project ReportJagadeeshan SivanNo ratings yet

- ABB Valve Series 14Document8 pagesABB Valve Series 14HafziNo ratings yet

- Kegiatan Kalibrasi Tahun: 2022: Puskesmas GUNUNG KALERDocument2 pagesKegiatan Kalibrasi Tahun: 2022: Puskesmas GUNUNG KALERNova ArdiantoNo ratings yet

- 2425 FormulasDocument2 pages2425 FormulassonuNo ratings yet

- GE Lighting Systems Decashield Series Spec Sheet 2-83Document4 pagesGE Lighting Systems Decashield Series Spec Sheet 2-83Alan MastersNo ratings yet

- First Periodical Examination For GRADE 7 SCIENCEDocument2 pagesFirst Periodical Examination For GRADE 7 SCIENCEMyrson MalayanNo ratings yet

- Carlo Rovelli UNBELIEVABLE Similarities Between Rovelli's Works (2007-2021) and My Works (2002-2007)Document51 pagesCarlo Rovelli UNBELIEVABLE Similarities Between Rovelli's Works (2007-2021) and My Works (2002-2007)Gabriel VacariuNo ratings yet

- XI - A - Differential & Integration-1Document2 pagesXI - A - Differential & Integration-1mishrasplparthNo ratings yet

- Majorana Fermions in Condensed Matter Physics: The 1D Nanowire CaseDocument6 pagesMajorana Fermions in Condensed Matter Physics: The 1D Nanowire CaseOscar BohórquezNo ratings yet

- Shayma Chem II Lab Manual.... Petrochemical Engineering DepartmentDocument55 pagesShayma Chem II Lab Manual.... Petrochemical Engineering DepartmentMUHAMMAD AKRAM100% (1)

- Butterfly Valve and FlowDocument5 pagesButterfly Valve and FlowMurugan RangarajanNo ratings yet

- Parcheta Szwindowska Et Al 2023 Fabrication and Characterization of Green Polyurethane Foams With Enhanced VibrationDocument10 pagesParcheta Szwindowska Et Al 2023 Fabrication and Characterization of Green Polyurethane Foams With Enhanced Vibrationsyamsutajri100% (1)

- Tutorial 5&6 Mechanics of Machine (Q)Document1 pageTutorial 5&6 Mechanics of Machine (Q)Raiham EffendyNo ratings yet

- Unit 3 Natural ResourcesDocument23 pagesUnit 3 Natural Resourcesankit kaleNo ratings yet

- Double Shear Single ShearDocument3 pagesDouble Shear Single ShearJoyce ChepkiruiNo ratings yet

- I87 GhinvrrDocument8 pagesI87 GhinvrrFact LoopNo ratings yet

- DOP Plixxopol SF 8721W enDocument2 pagesDOP Plixxopol SF 8721W enCristina AndronescuNo ratings yet

- MAINTENANCE ENGINEERING SyllabusDocument2 pagesMAINTENANCE ENGINEERING Syllabus132 Arindam DattaNo ratings yet

- Manual Bomba CPXDocument36 pagesManual Bomba CPXRolando Felipe Tapia Moyano100% (1)

- بروشور وزارت دفاع PDFDocument100 pagesبروشور وزارت دفاع PDFXen XenNo ratings yet

- Gearless Transmission ReportDocument32 pagesGearless Transmission ReportHarish Kumar73% (22)

- Chemical Bonding and Periodic Trends Part 1Document9 pagesChemical Bonding and Periodic Trends Part 1danielmahsaNo ratings yet

- P. J. Forrester and B. Jancovici - Generalized Plasmas and The Anomalous Quantum Hall EffectDocument7 pagesP. J. Forrester and B. Jancovici - Generalized Plasmas and The Anomalous Quantum Hall EffectGreamxxNo ratings yet

- TDA-V-Series Direct Drive Vane Axial FanDocument2 pagesTDA-V-Series Direct Drive Vane Axial FanKristopher PerinNo ratings yet

- Reflector AntennasDocument20 pagesReflector AntennaslvsaruNo ratings yet

- NACE Review of Recommended PracticesDocument16 pagesNACE Review of Recommended PracticesismaelarchilacastilloNo ratings yet